A reflective asphalt mixture

An asphalt mixture and reflective technology, applied in the field of road building materials, can solve problems such as scratches on broken glass, prone to rutting and cracking, and impact on construction safety, so as to reduce the impact on the ecological environment, alleviate the spalling problem, and reduce The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a kind of reflective asphalt mixture comprising the following raw materials: asphalt, mineral aggregate and an anti-stripping agent in an amount of 0.2% of the asphalt weight, wherein the oil-stone ratio of asphalt to mineral aggregate is 4%, and the mineral aggregate includes at least Crushed stone, mineral powder and porous reflective glass beads.

[0030] In the mineral material of the present embodiment, the mass ratio (powder-to-glue ratio) of the selected mineral powder to asphalt is 1, and in the selected mineral powder, the consumption of slaked lime powder is 1% of the total mineral material.

[0031] In the mineral material of this embodiment, the porous reflective glass beads with a dosage of 5% of the weight of the mineral material are selected. The ratio is 1.8-2.4, replacing part of the gravel aggregates of 2.36-4.75mm in the gradation of raw ore materials.

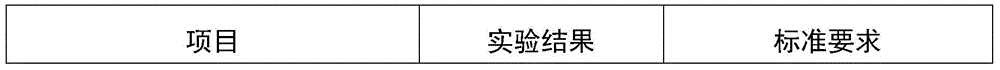

[0032] Specifically, the reflective asphalt mixture of the present embod...

Embodiment 2

[0041] The materials used for the reflective asphalt mixture provided in this embodiment are basically the same as those in Embodiment 1, and the similarities will not be repeated. 2% of the total amount, select the porous reflective glass microspheres whose admixture is 25% of the mineral weight.

[0042] Specifically, the reflective asphalt mixture of the present embodiment includes the following raw materials:

[0043] 100 parts of asphalt;

[0044] 0.2 parts of anti-stripping agent;

[0045] Mineral material 2500 parts;

[0046]The mineral material includes at least mineral powder, gravel and porous reflective glass beads, wherein the amount of porous reflective glass beads is 625 parts; the amount of mineral powder is 100 parts, and the mineral powder includes 50 parts of slaked lime powder.

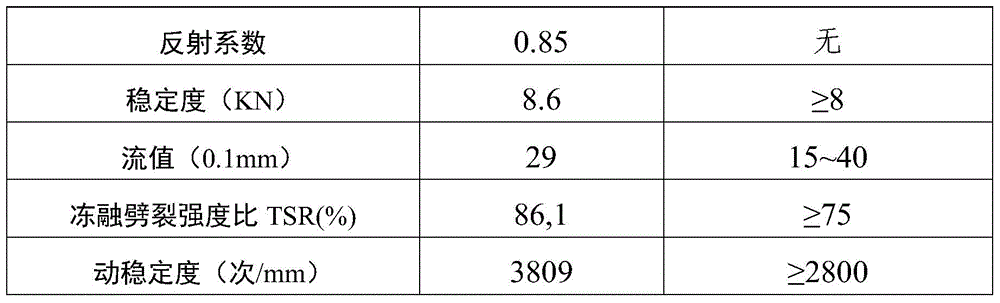

[0047] The performance parameters of the prepared reflective asphalt mixture are shown in Table 2.

[0048] Table 2 Performance parameters of asphalt mixture

[0049] ...

Embodiment 3

[0051] This embodiment provides a kind of reflective asphalt mixture comprising the following raw materials: asphalt, mineral aggregate and an anti-stripping agent with an amount of 0.3% of the asphalt weight, wherein the oil-stone ratio of asphalt to mineral aggregate is 5%, and the mineral aggregate includes at least Crushed stone, mineral powder and porous reflective glass beads.

[0052] In the mineral material of this embodiment, the mass ratio (powder-to-glue ratio) of the selected mineral powder to asphalt is 1.2, and in the selected mineral powder, the consumption of slaked lime powder is 1.5% of the total mineral material.

[0053] Among the mineral materials in this embodiment, the porous reflective glass beads with a dosage of 15% of the weight of the mineral material are selected. The ratio is 1.8-2.4, replacing part of the gravel aggregates of 2.36-4.75mm in the gradation of raw ore materials.

[0054] Specifically, the reflective asphalt mixture of the present e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com