Diamond-like coating piston ring with double transition layers

A technology of diamond coating and transition layer, which is applied in the field of piston rings, can solve the problems of surface coating failure, uneven stress release, and carbon coating layer collapse, so as to improve the bonding effect, relieve peeling, and improve Effect of Hardness Gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of above-mentioned piston ring comprises the steps:

[0055] The first step is to roughen the piston ring base 1 and perform degreasing and hydrocarbon cleaning;

[0056] In the second step, the treated piston ring base 1 is clamped, wiped and then loaded into a furnace;

[0057] The third step is to add the piston ring substrate 1 treated in the second step into the vacuum coating equipment, vacuumize to the set vacuum degree after sealing, perform ion cleaning on the piston ring substrate 1 after preheating, stop heating and let it stand 0.5h to a temperature of 90-100°C;

[0058] The preheating time is 20min, and the preheating temperature is 120°C;

[0059] The fourth step is to prime the chromium target and then the titanium target. The conditions for chromium target shooting are 1~2h, 110~130°C, and the conditions for titanium target shooting are 1.5~3h, 110~130°C, and then proceed Alternate coating of hard carbon coating and soft carbon ...

Embodiment 1

[0062] In a specific embodiment of the present application, the carbon coating 4 includes ten groups of soft carbon coatings and hard carbon coatings combined with each other, wherein the hard carbon coating is along the direction from the inside to the outside of the piston ring. The hardnesses are 1800, 1920, 2040, 2160, 2280, 2400, 2520, 2640, 2760, 2880; the hardness of the soft carbon coating along the piston ring from inside to outside is 1300, 1350, 1400, 1450, 1500, 1550, 1600, 1650, 1700;

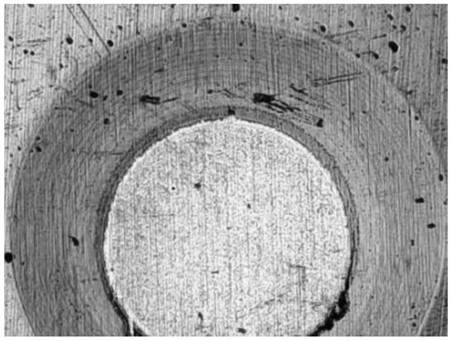

[0063] Carry out ball milling test to the carbon coating of above-mentioned molding, test result sees figure 2 ;

[0064] The conditions of the ball milling test are: grind the coating for 10 minutes with a diamond powder abrasive with a thickness of 1 to 2 microns, and then grind with a diamond powder abrasive with a thickness of 0.25 to 0.5 microns for 20 minutes. The grinding angle: 45° to 60° with the horizontal line .

Embodiment 2

[0066] A double transition layer diamond-like coating piston ring, comprising a piston ring base 1 and a transition layer bonded to the piston ring base 1, and also including a carbon coating 4 bonded to the surface of the transition layer;

[0067] The transition layer includes chromium coating 2 and titanium coating 3 combined with each other, wherein the thickness of chromium coating 2 is 150nm, and the thickness of titanium coating 3 is 350nm;

[0068] The distribution of carbon coating 4 is the same as in Example 1

[0069] Wherein the chromium coating 2 is combined with the piston ring substrate 1, the hard carbon coating in the carbon coating 4 is combined with the titanium coating 3, and the total thickness of the carbon coating 4 is 8 μm;

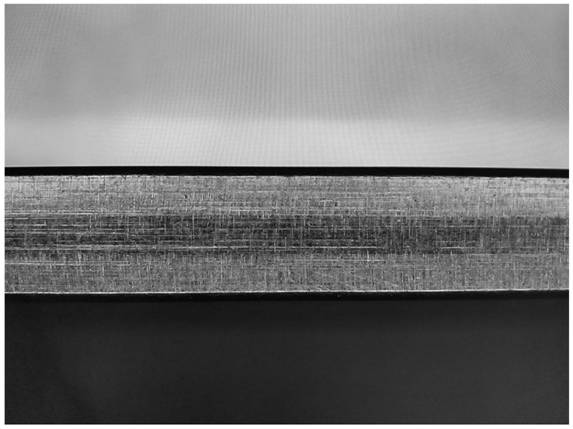

[0070] Test formed piston rings:

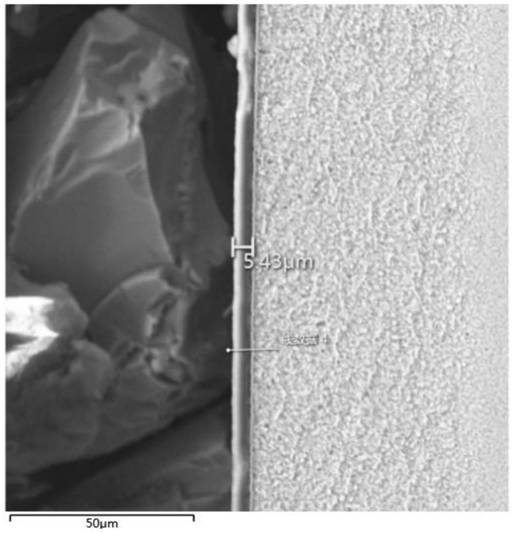

[0071] Electron microscope image of the transition layer and carbon coating 4 of the formed piston ring image 3 shown;

[0072] The SEM structure spectrum of the DLC coating of the formed pist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com