Pipe joint rear cutting ferrule and heat processing method

A heat treatment method and joint card technology, applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, coating, etc., can solve the problems of inability to adapt to pressure and sealing requirements, deterioration of corrosion resistance, poor anti-seizure performance, etc. Achieve the effect of improved mechanical properties, good corrosion resistance and enhanced hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

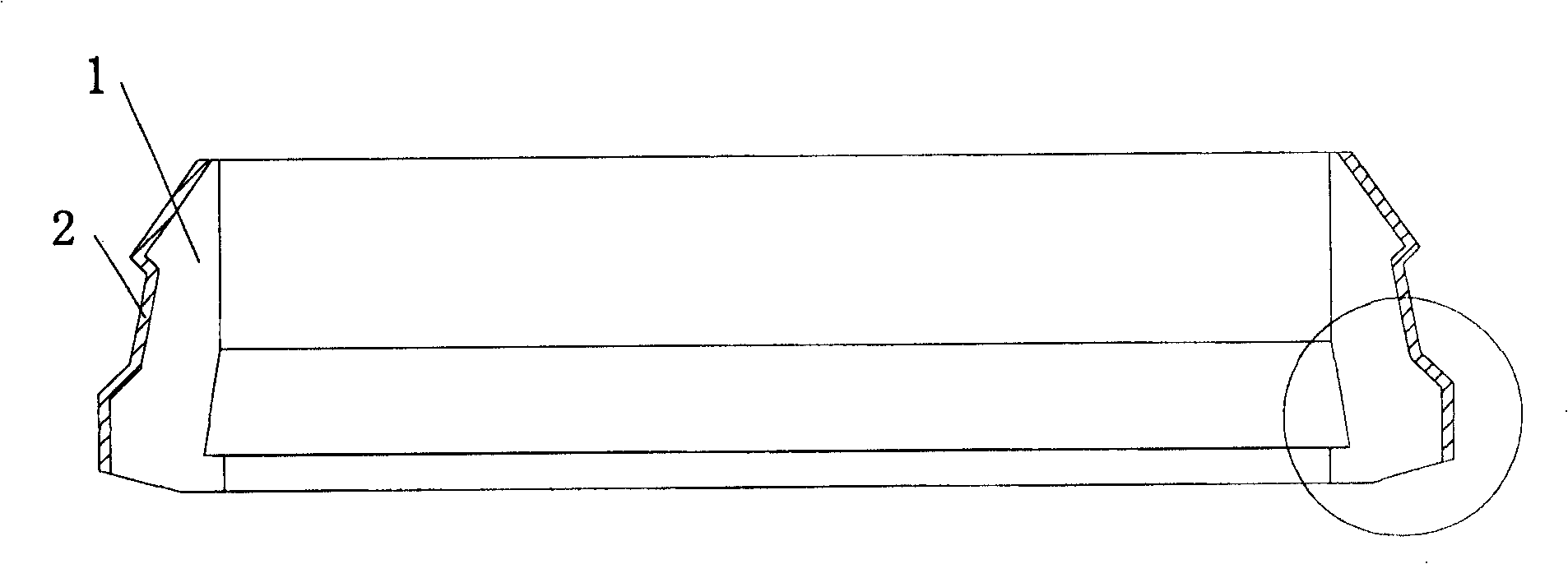

[0019] Below in conjunction with the accompanying drawings, the present invention will be described in detail. The rear card of the present invention is a rear card ferrule with a double clamp structure, such as figure 1 As shown, it includes a rear card body 1 with a tapered front end, and a reinforced solid solution infiltrated layer 2 is compounded on the outer surface of the rear card body 1. The thickness of the reinforced solid solution infiltrated layer 2 is 10-30 μm, and the reinforced solid solution infiltrated layer 2 can be a carburized layer, a nitrided layer or a carbonitrided layer.

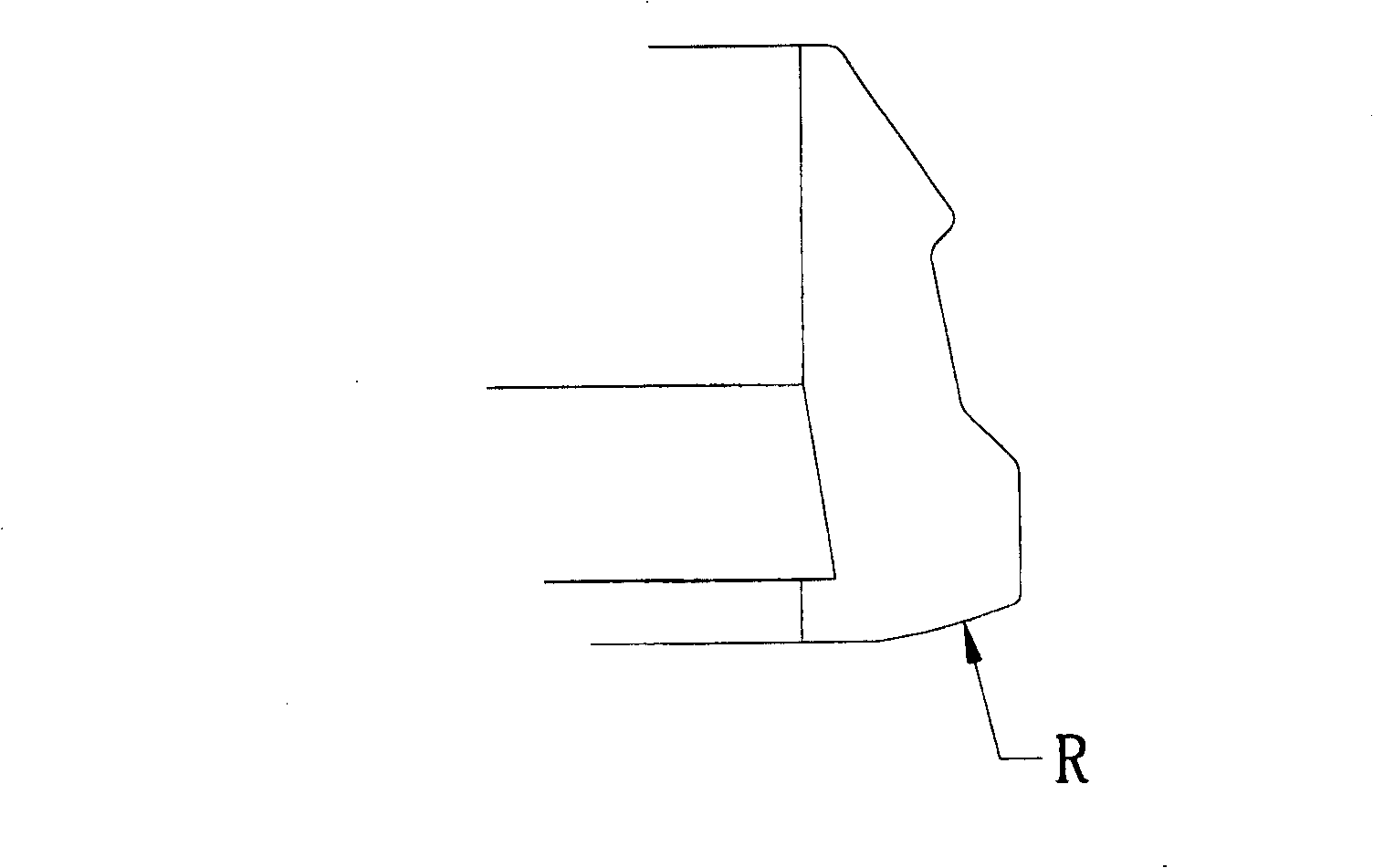

[0020] The taper of the front taper surface of the rear card body is 60-80°, the rear end of the rear card body and the action surface of the joint nut form an arc surface, and the radius of the arc surface is R, see figure 2 .

[0021] Use low-pressure plasma glow discharge technology to carry out nitriding surface strengthening on the austenitic stainless steel back card between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com