Automobile body projection welding workstation based on 2D visual guidance

A visual guidance and automobile body technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of low degree of automation, complex type change, poor solder joint efficiency, etc., and achieve high intelligence, high intelligence, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

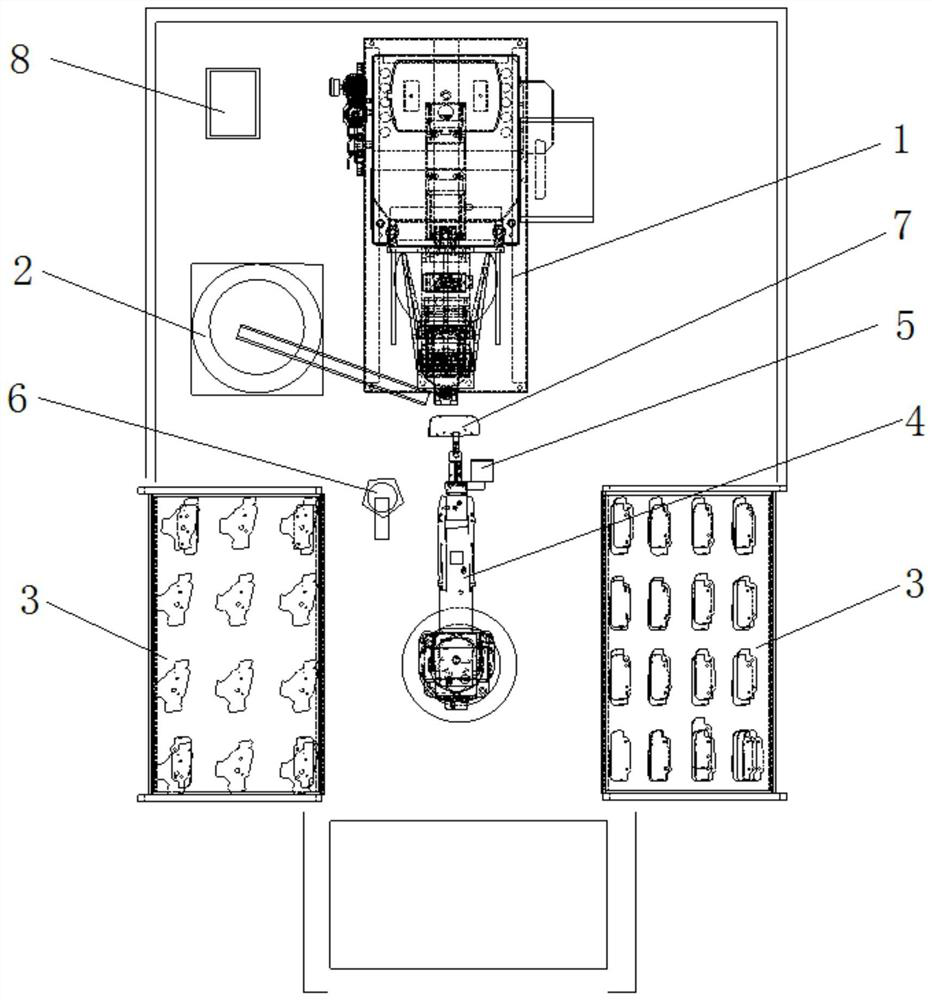

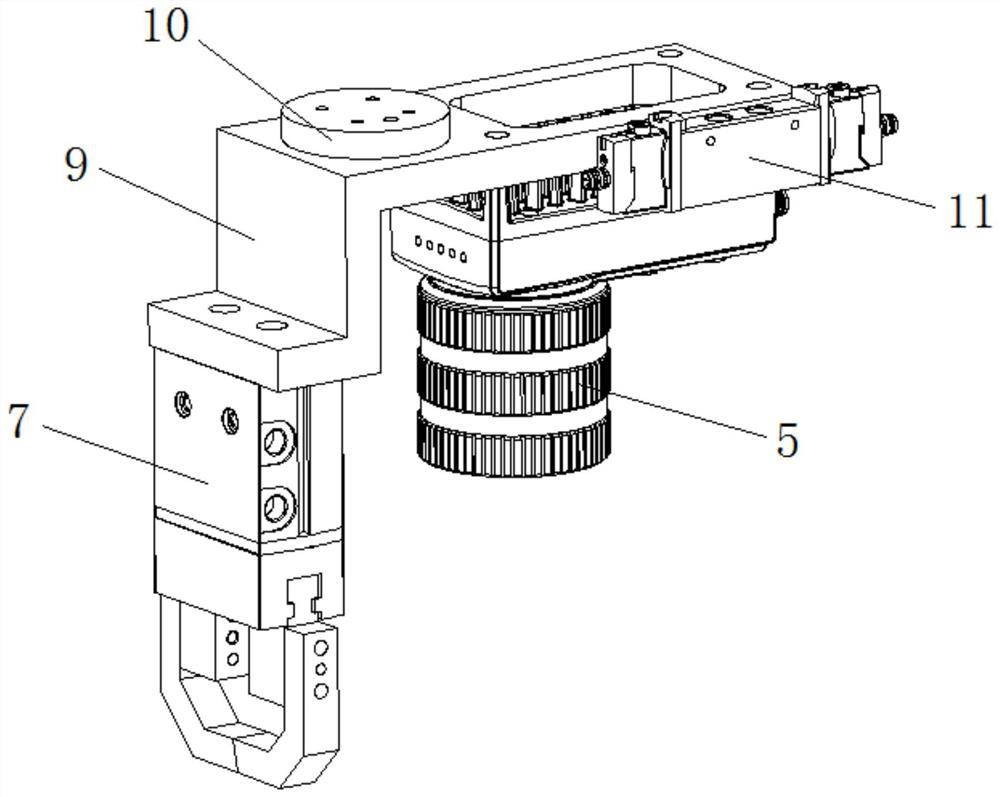

[0023] like figure 1 As shown, an automobile body projection welding workstation based on 2D vision guidance, the workstation includes a projection welding machine 1, a nut conveyor 2, a feeding table 3 and a robot 4, the projection welding machine 1 and the robot 4 are arranged oppositely, and the nut conveyor 2 is set on one side of the projection welding machine 1, and the loading table 3 is set on the side of the robot 4, and the robot 4 is provided with a gripper 7 for grabbing the body parts on the feeding table 3 and for guiding the gripper 7 to grab the body The first 2D vision guide 5 of the parts, the second 2D vision guide 6 for guiding the gripper 7 to send the body parts to the projection welding machine 1 is provided on one side of the robot 4, the gripper 7, the first 2D vision guide 5 and the second 2D vision guide 6 are all connected to the automatic controller, the first 2D vision guide 5 includes a first camera lens, the second 2D vision guide 6 includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com