A Probe Fatigue Impedance Tester

A technology of impedance testing and fatigue, which is applied in the direction of measuring resistance/reactance/impedance, applying repetitive force/pulsation force to test material strength, measuring devices, etc. It can solve the problems of long detection cycle and large waste of finished products, etc., and achieve replacement The effect of short line time, small amount of use, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below with examples, so as to fully understand and implement the implementation process of how the present invention uses technical means to solve technical problems and achieve technical effects.

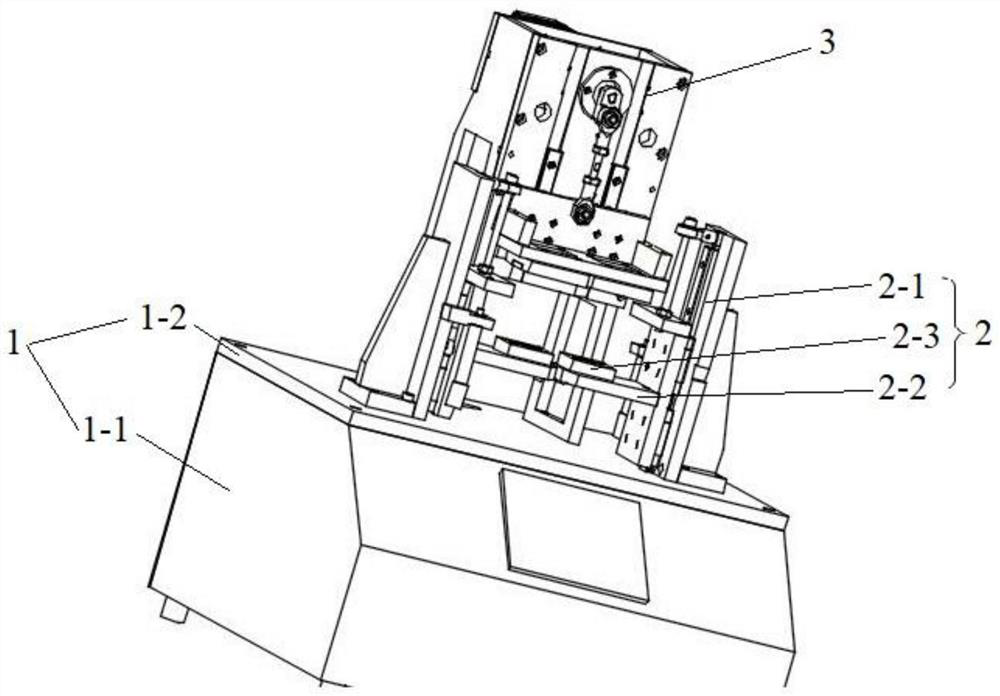

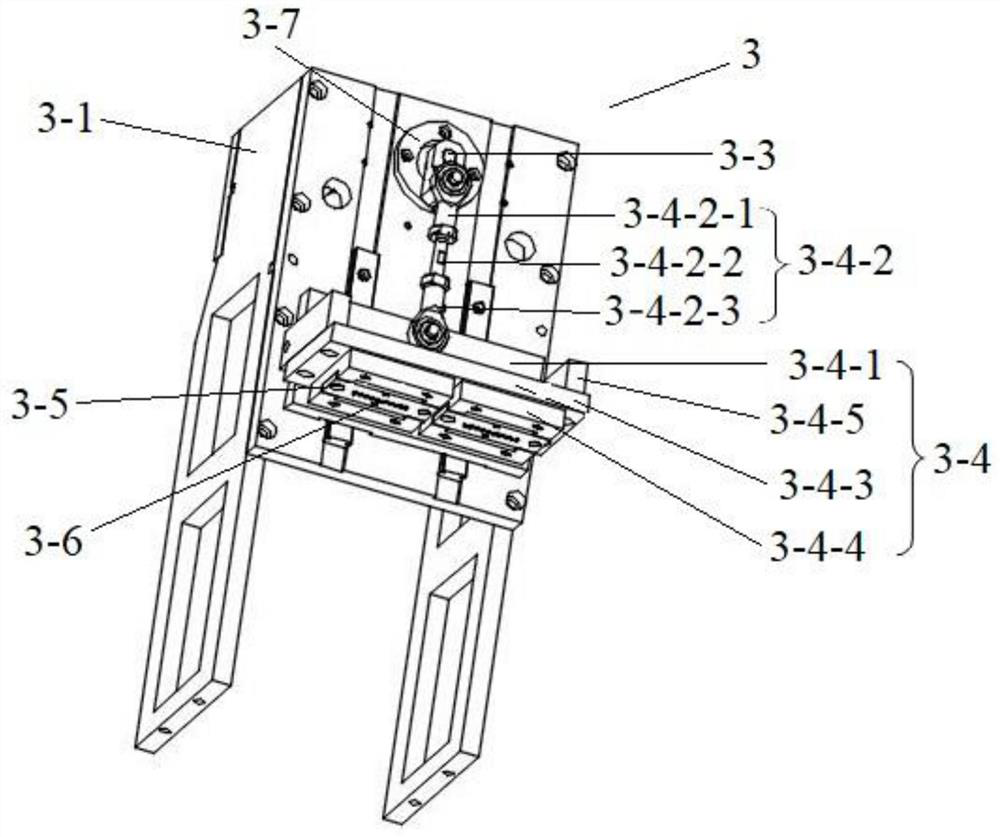

[0030] The invention discloses a probe fatigue impedance testing machine, the structure is as follows: figure 1 shown, including:

[0031] A box mechanism 1, which plays a supporting role, and is used to carry the bearing mechanism 2 and the riveting test mechanism 3;

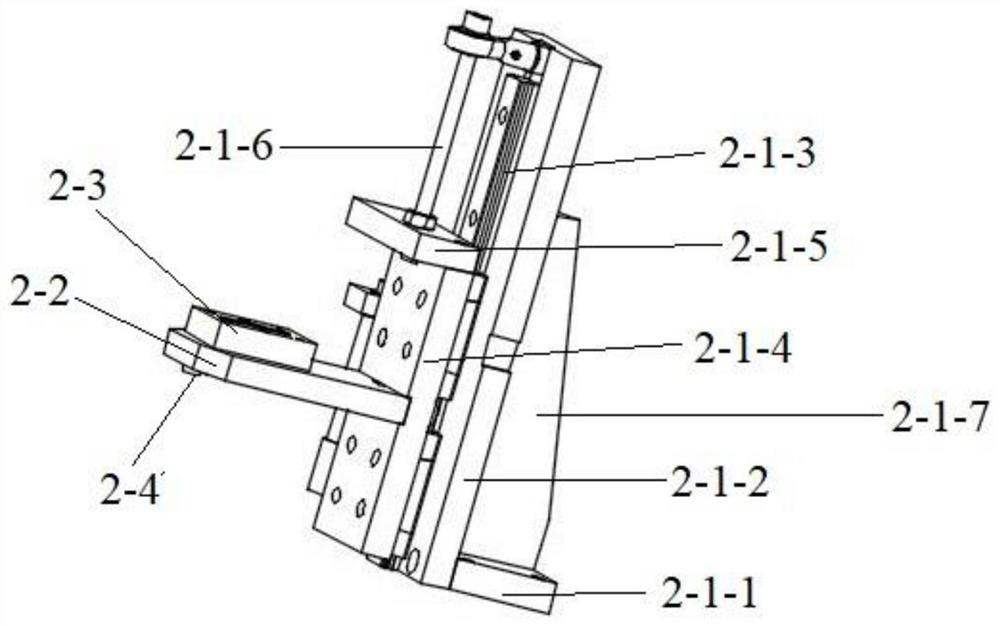

[0032] Two seat mechanism 2, such as figure 2 As shown, two seat mechanisms 2 are arranged as mirror images. The seat mechanism 2 includes a support mechanism 2-1 fixed on the box body mechanism 1. The inner side of the support mechanism 2-1 is horizontally provided with a seat horizontal plate 2-2. A seat 2-3 is arranged on the horizontal plate 2-2 of the seat, and a first test needle 2-4 is arranged under the horizontal plate 2-2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com