A method for replacing movable pulley blocks in bridge cranes

A technology of bridge cranes and movable pulley blocks, which is applied to the direction of traveling bridge cranes, cranes, load blocks, etc., and can solve the problems of short replacement operation time, reduced operation intensity, and high work intensity, and achieves short replacement operation time and reduced The effect of increasing work intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

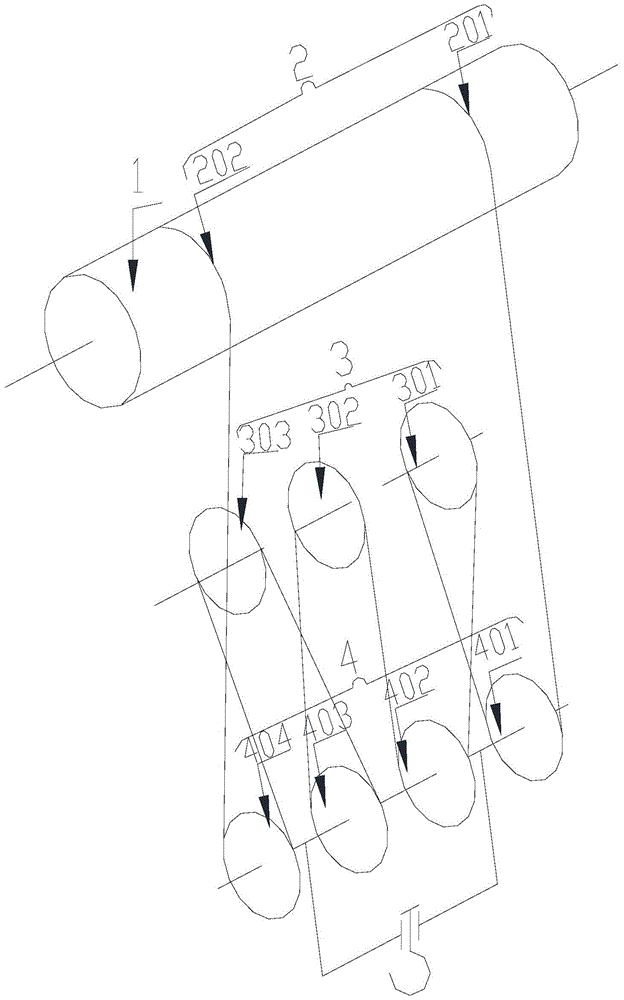

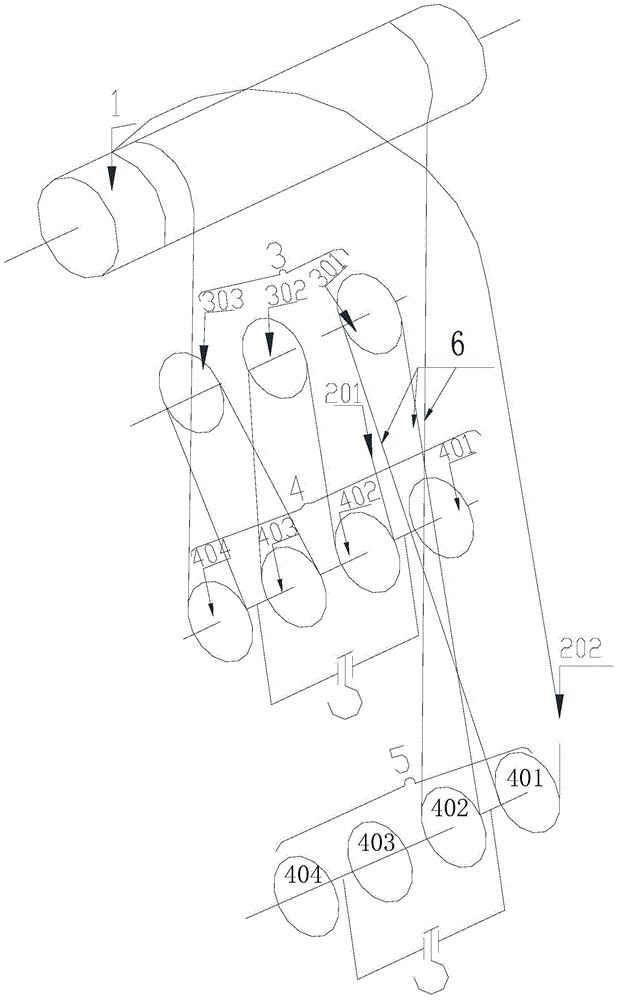

[0040] Such as figure 2 As shown, in this embodiment, using the above-mentioned method for replacing the movable pulley block in the bridge crane, replacing the movable pulley block with four movable pulleys includes the following steps:

[0041] Step 101) Remove the limit switch (not shown) on the reel 1, lower the old movable pulley block 4 wound on the wire rope to the work area, and place the old movable pulley block 4 and the replaced new movable pulley block 5 side by side;

[0042] Step 102) Put down all the wire ropes 2 wound on the reel 1 until the two ends of the wire ropes are pressed by the pressure plate (not shown) and remain on the reel 1, remove the pressure plate at one end of the reel 1, and Strip the exposed first rope end 201 from the reel 1 and place it on the ground;

[0043] Step 103) Rotate the reel 1 in the forward direction, so that the other end of the reel 1 is wound with the steel wire rope 2 and continues to be wound on the reel 1, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com