Wire rod cooling device and wire rod cooling method

A technology of cooling device and cooling method, which is applied in the direction of workpiece cooling device, cooling bed, quenching device, etc., can solve the problems of unfixed ring spacing, irregular overlapping method of wire rods, irregular overlapping method, etc., and eliminate the decline in yield , Reduce the effect of temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

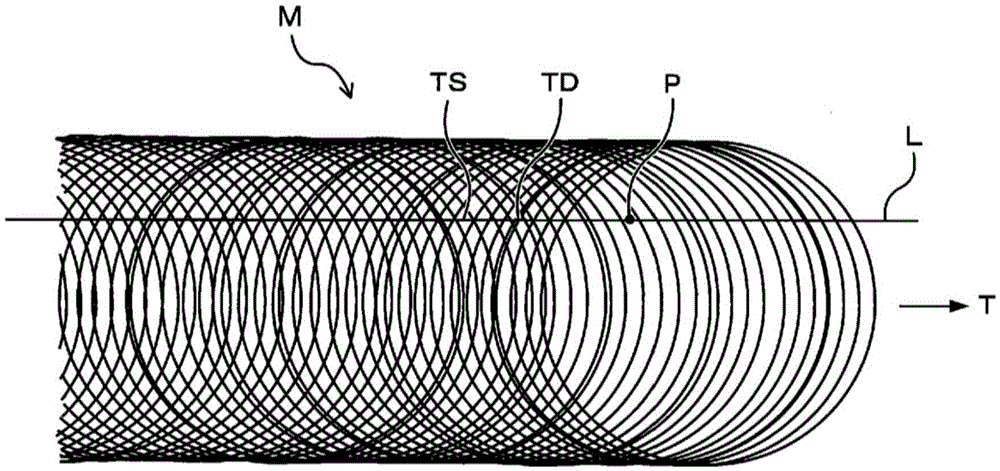

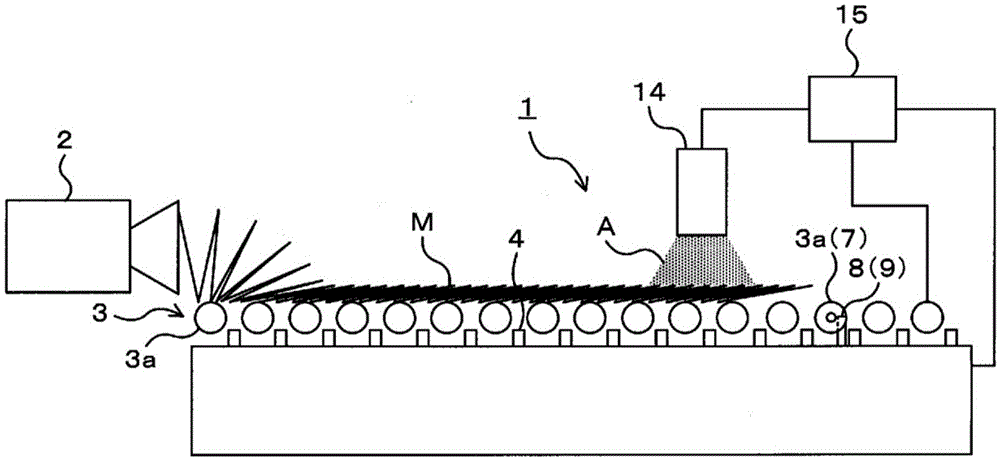

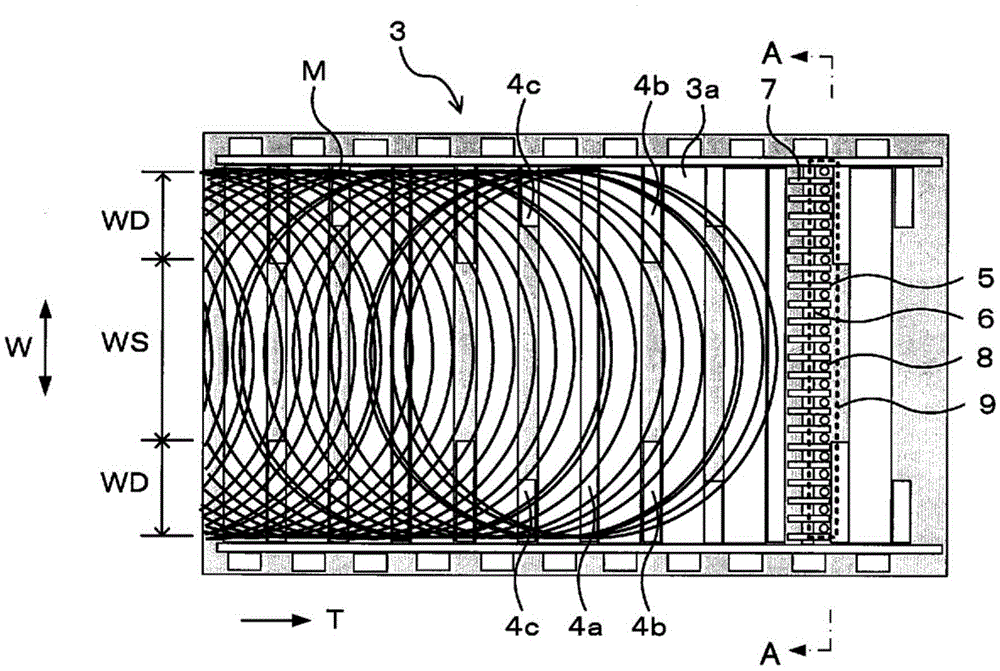

[0052] Next, an embodiment of the present invention will be described based on the wire rod cooling device 1 that cools the non-concentric ring-shaped wire M coiled by the wire laying machine 2 (wire coiler). In addition, in the present embodiment, the conveying speed of the endless wire material M by the roller conveyor 3 provided on the exit side of the wire laying machine 2 is constant. In addition, in the present embodiment, compressed air is used as the refrigerant for cooling the annular wire material M. FIG. As the refrigerant of the conventional Stelmore cooling, air sent by a blower is used. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the element which has substantially the same functional structure, and repeated description is abbreviate|omitted.

[0053] Such as figure 2 , image 3 As shown, in the wire rod cooling device 1 , the slit nozzle 4 is provided between the rollers 3 a of the roller conveyor 3 . Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com