Inkjet recording device

A technology for inkjet recording and recording media, applied in printing devices, printing, etc., can solve problems such as image quality degradation, and achieve the effect of reducing temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings. However, in the embodiments described below, various technically preferable limitations are added in order to implement the present invention, but the scope of the invention is not limited to the following embodiments and illustrated examples.

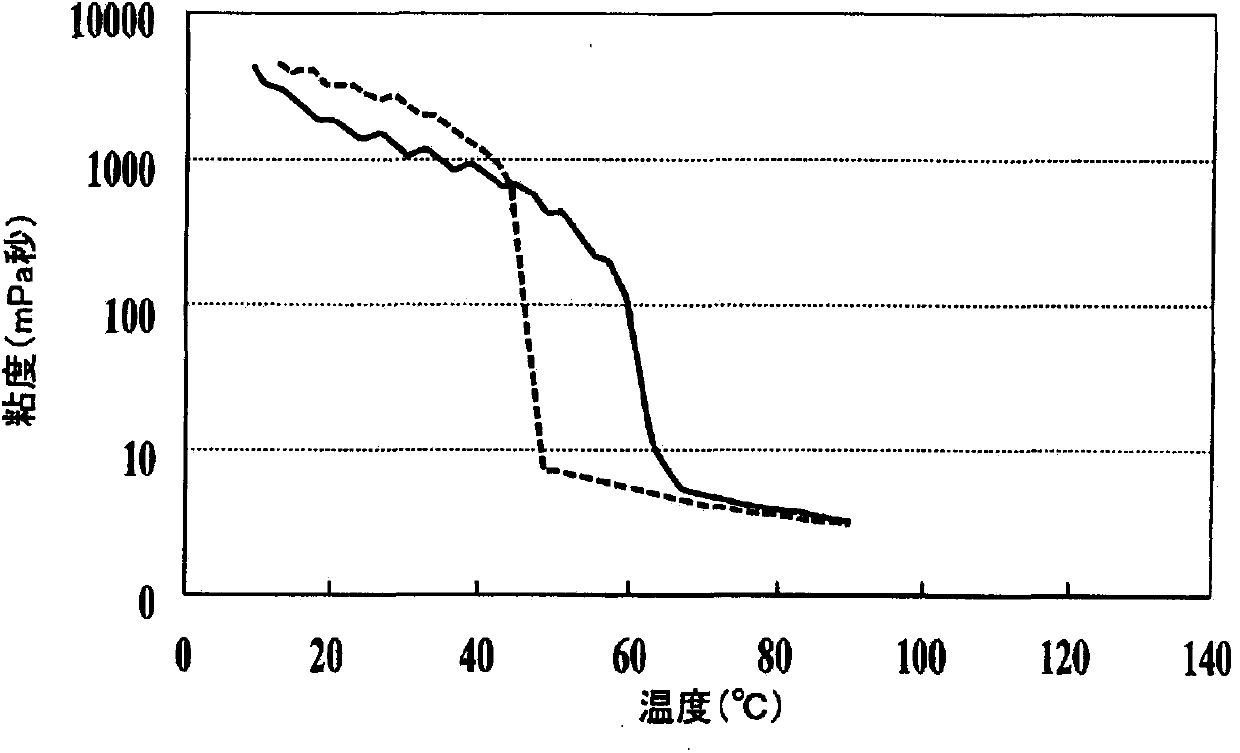

[0057] The inkjet recording device 1 of the present embodiment uses a temperature-sensitive thickening type ink that changes phase into a gel state, a solid state, or a liquid state depending on temperature.

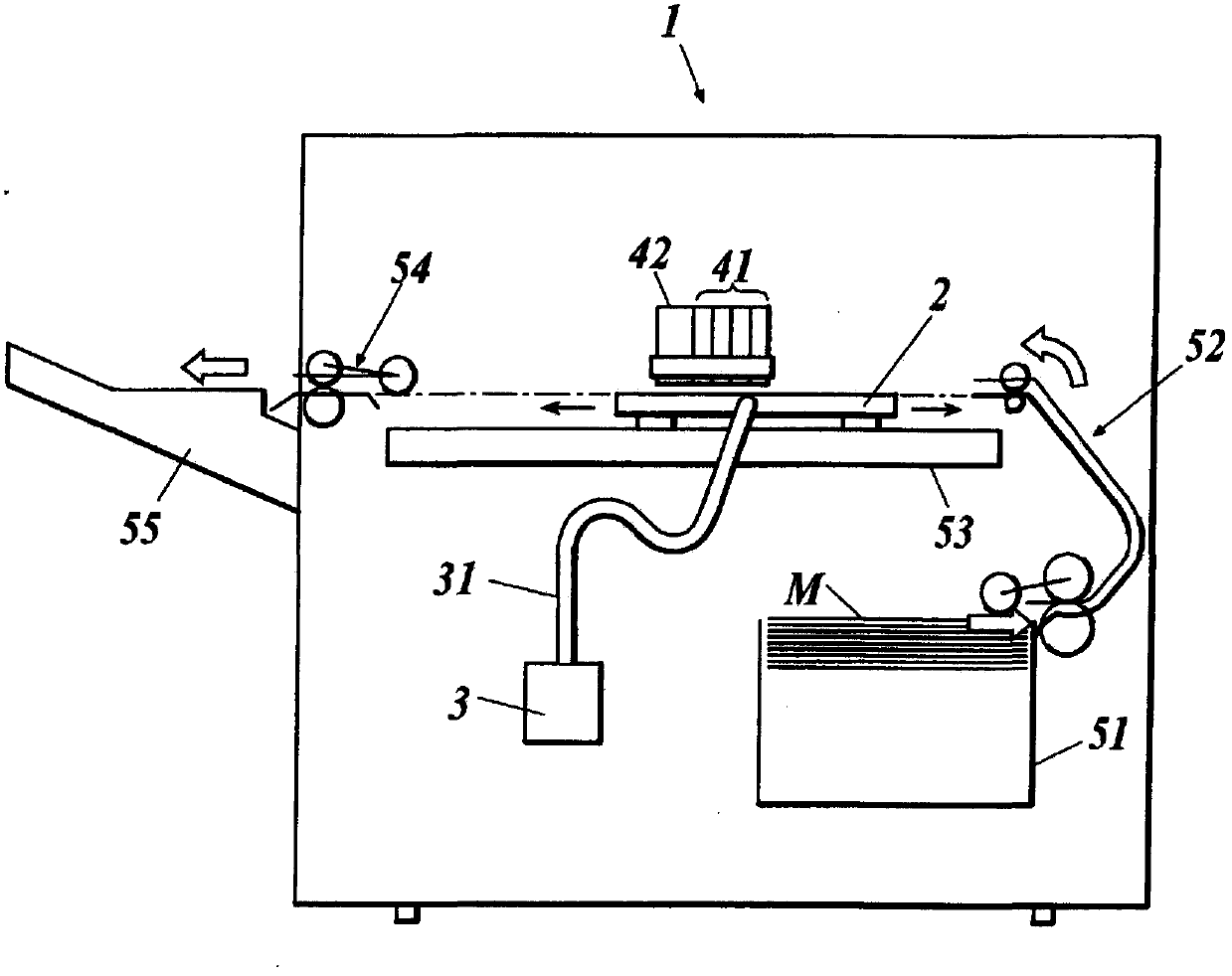

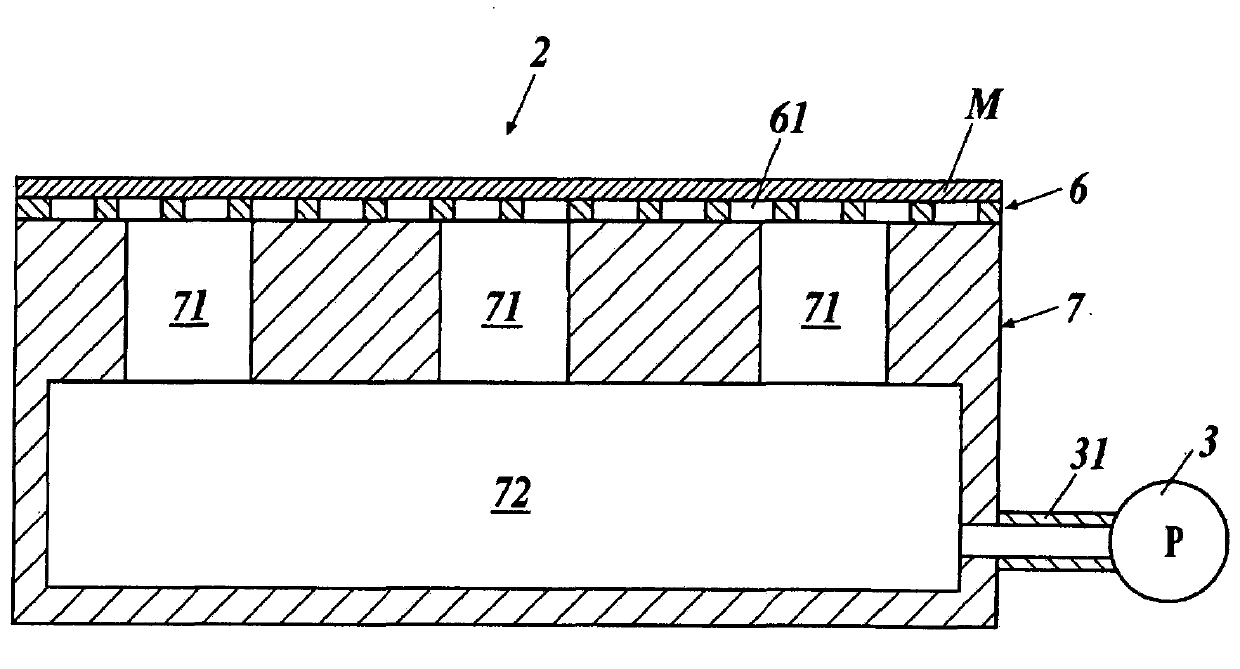

[0058] Such as figure 1 The inkjet recording apparatus 1 of the present embodiment shown in the figure includes the following devices: a recording medium fixing device 2 for sucking and fixing the recording medium M, a suction pump 3 as a negative pressure generating device, an inkjet recording head 41, and a light irradiation device. 42. The paper feeding tray 51 for accommodating the recording medium M, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com