Double-air path bidirectional automatic assembling device for high-temperature Hopkinson pressure bar experiment

A Hopkinson pressure bar and automatic assembly technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large cooling of test pieces, unstable assembly, low success rate, etc., to reduce temperature unevenness, reduce Effect of cold contact time and improvement of assembly success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

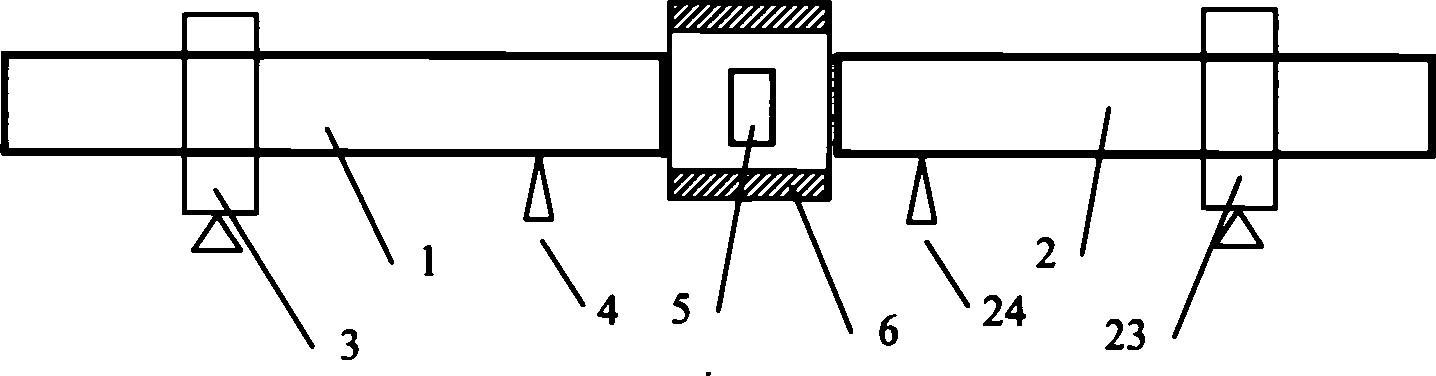

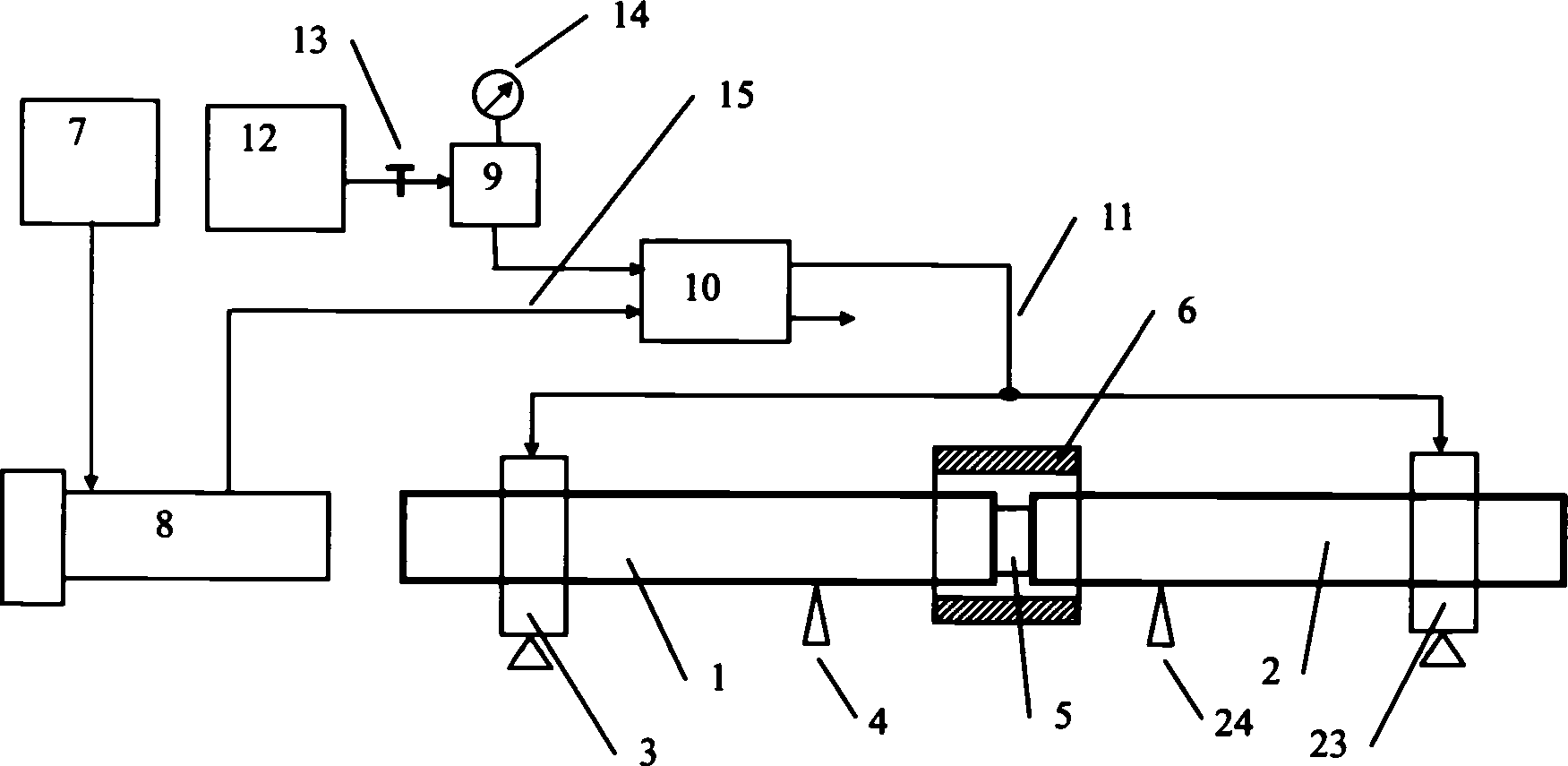

[0022] figure 2 , Figure 4 , Figure 5 In, the two-way dual-air circuit automatic assembly device used for the high-temperature Hopkinson pressure bar experiment includes an incident rod 1, a transmission rod 2, and a pushing support (3, 23) respectively arranged on the incident rod 1 and the transmission rod 2. The heating furnace 6 and the gas circuit; the test piece is set in the center of the heating furnace 6, and the pushing supports (3, 23) are respectively composed of a cylinder and a piston. The air path is set as a dual air path, and the propelling air path 11 of the pushing support and the firing air path 15 of the air cannon are set as independent air source air paths; the dual air path contains a total air source 7, an independent sub air source 12, The firing gas path 15, the small gas tank 9, the main valve 10, and the pushing gas path 11 of the air cannon; the connection relationship of the gas path is: the total gas source 7 is connected to the main valve 10 th...

Embodiment 2

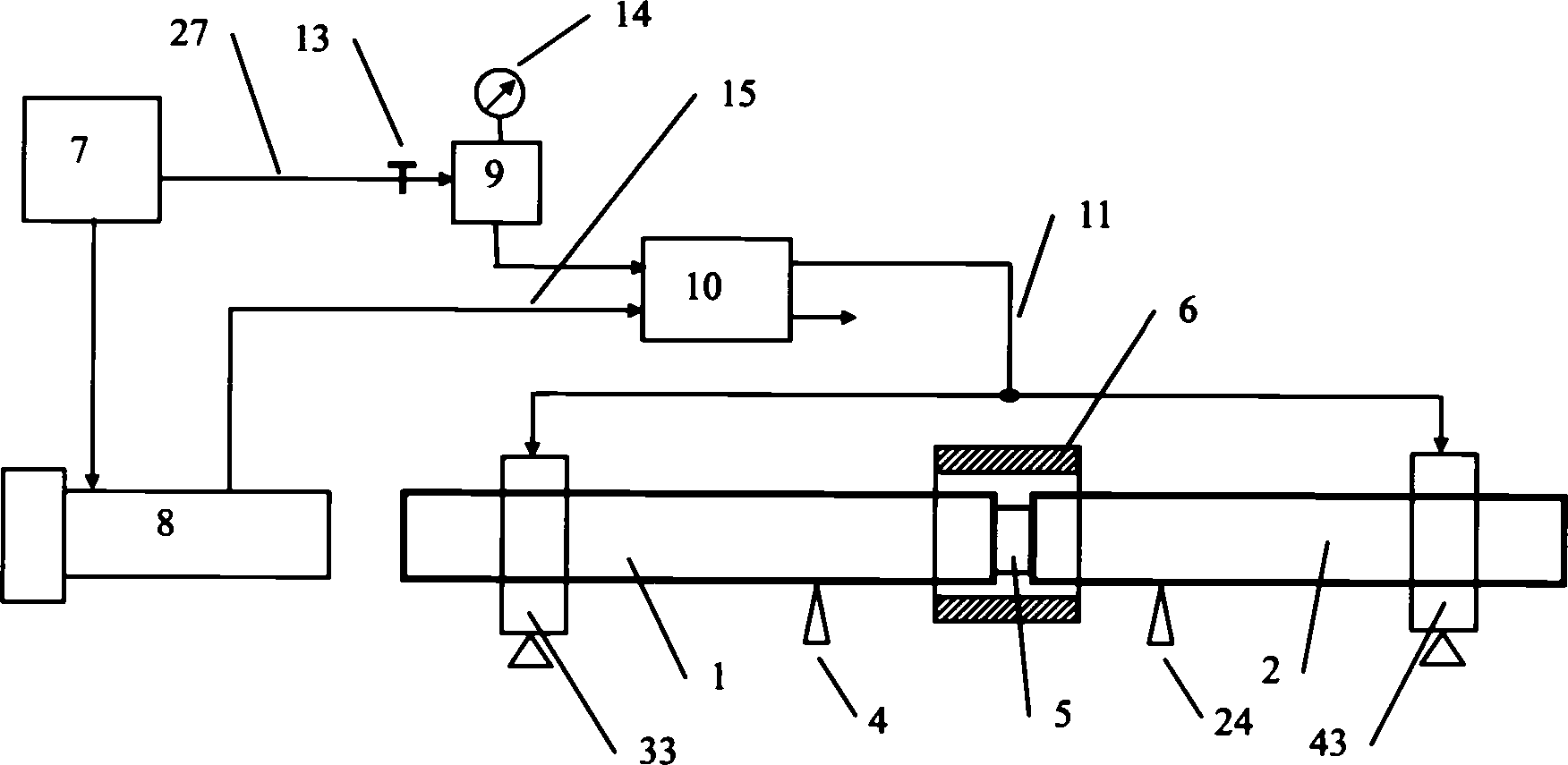

[0029] in image 3 , Figure 4 , Figure 6 In, the two-way dual-air circuit automatic assembly device used for the high-temperature Hopkinson pressure rod experiment includes an incident rod 1, a transmission rod 2, and a push support (33, 43) respectively arranged on the incident rod 1 and the transmission rod 2. The heating furnace (6) and the gas path; the test piece is set in the center of the heating furnace 6, the pushing support 33 is composed of a cylinder 35 and a piston 31, and the pushing support 43 has the same structure as the pushing support 33. The air path is set as a dual air path, and the pushing air path of the push support and the air cannon firing air path are set as separate air source air paths; the dual air path contains the total air source 7 and the divided air drawn from the total air source 7. Source 27, the firing gas path 15, the small air tank 9, the main valve 10, and the push gas path 11 of the air cannon; the connection relationship of the gas path...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com