Supercharger with exhaust gas recirculation

A technology of supercharging and recirculation, applied in exhaust gas recirculation, mechanical equipment, machine/engine, etc., can solve the problems of increasing complexity and cost of the engine, and achieve the effect of high boost pressure ratio and torque characteristics improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

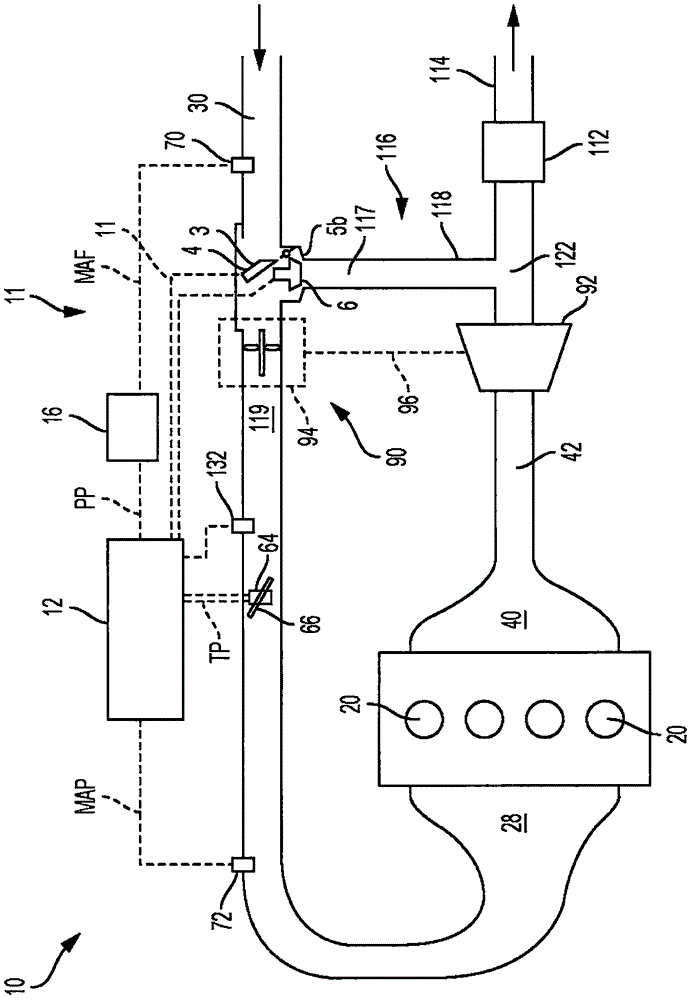

[0058] now go to figure 1 , shows a schematic diagram of an engine, or engine system 10 , that may be included in a propulsion system of an automobile. Engine 10 may be controlled at least partially by a control system including controller 12 and by input from a vehicle operator (eg, driver) via an input device 16 (eg, an accelerator pedal). The pedal may be coupled to a pedal position sensor (not shown) for generating a proportional pedal position signal (PP) or the like.

[0059]Engine 10 may include multiple combustion chambers 20 (ie, cylinders), which may be arranged in an inline 4 configuration, as illustrated. However, it should be understood that engine 10 may include any number of cylinders in any configuration (eg, V-6, I-6, V-12, opposed 4, etc.).

[0060] Although in figure 1 Not shown, each combustion chamber 20 (ie, cylinder) of engine 10 may include combustion chamber walls with a piston positioned therein. The piston may be coupled to the crankshaft such th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com