High-pressure common rail type diesel engine and design method thereof

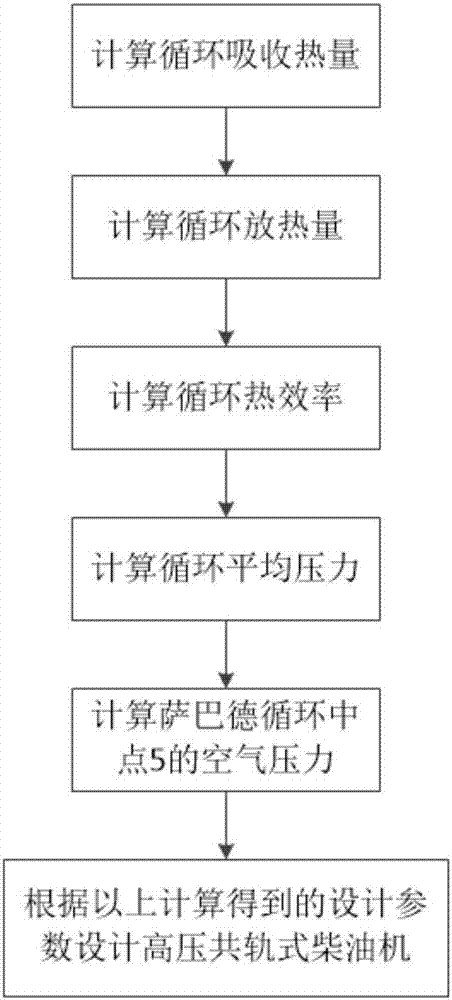

A design method and diesel engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of difficult high-pressure common rail diesel engines, cumbersome average effective pressure values, and low accuracy of results, and achieve good fuel injection Features, comprehensive performance index improvement, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] Embodiment: Taking the vehicle diesel engine of Weichai National V emission standard as an example, the design method of the high-pressure common rail diesel engine of the present invention is illustrated. The relevant technical parameters of the Weichai National V emission standard vehicle diesel engine are shown in Table 1.

[0073] Table 1 Diesel engine related technical parameters

[0074]

[0075] Calculation example of Sabad cycle under four rail pressures, Table 2 shows the maximum pressure of Sabad cycle corresponding to four target rail pressures.

[0076] Table 2 The maximum cycle pressure corresponding to the four target rail pressures

[0077]

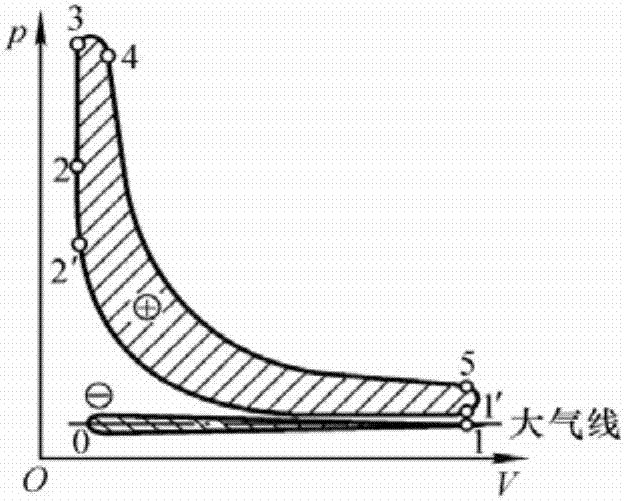

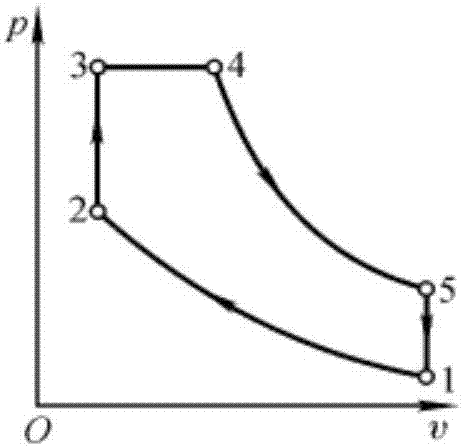

[0078] It should be noted that the maximum temperature and pressure of the diesel engine Sabad cycle under the four rail pressures are different, but the inlet and exhaust temperatures of the ideal gas are the same, that is, Figure 5 and Image 6 The gas states at point 1 and point 5 are the same. Table 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com