Program controlled brushless DC motor

A technology of DC motors and electric motors, applied in the direction of single motor speed/torque control, torque ripple control, electrical components, etc., can solve the problem of low average value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

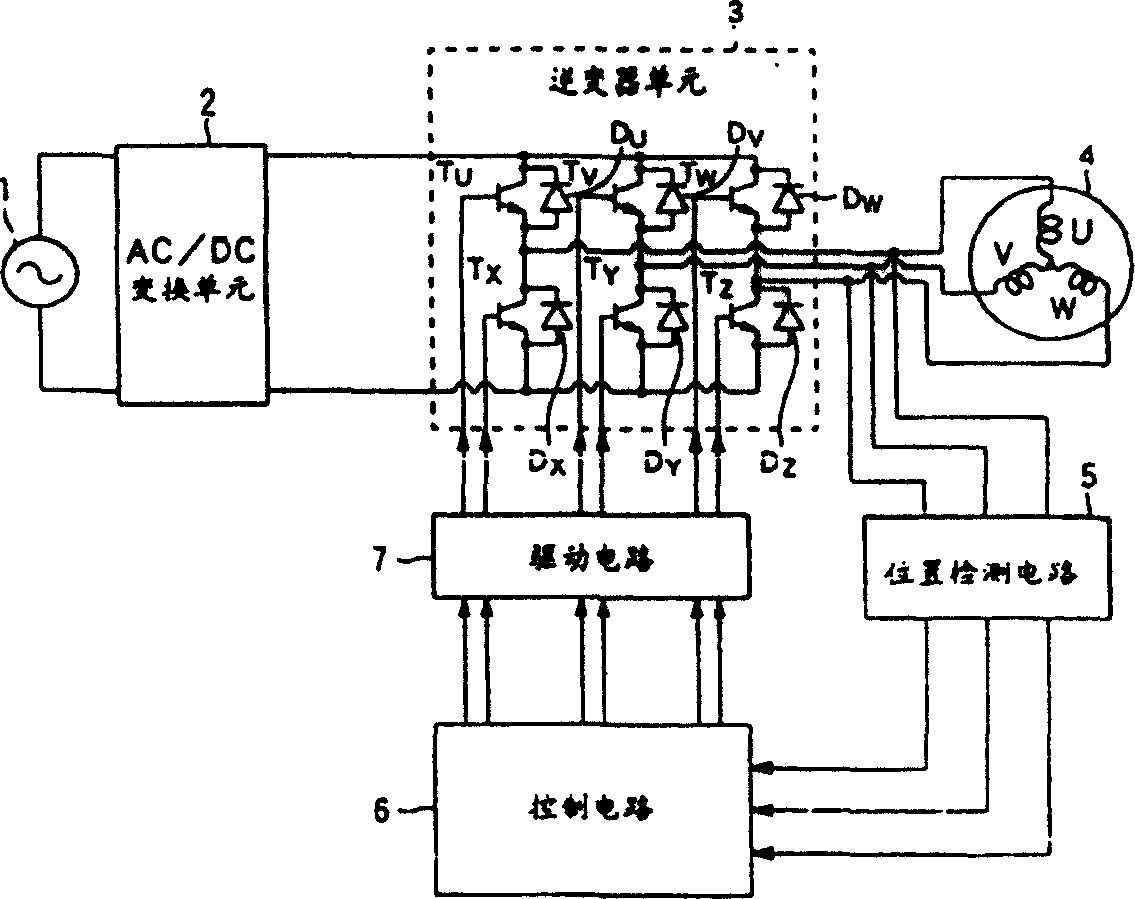

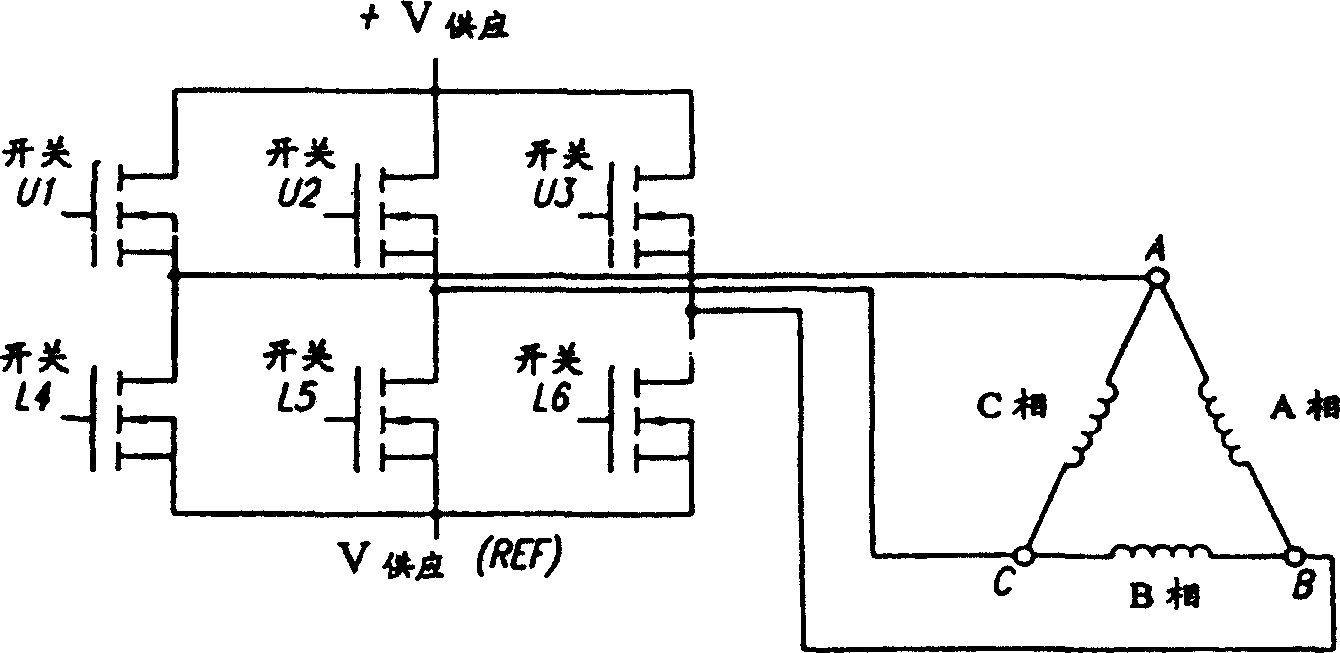

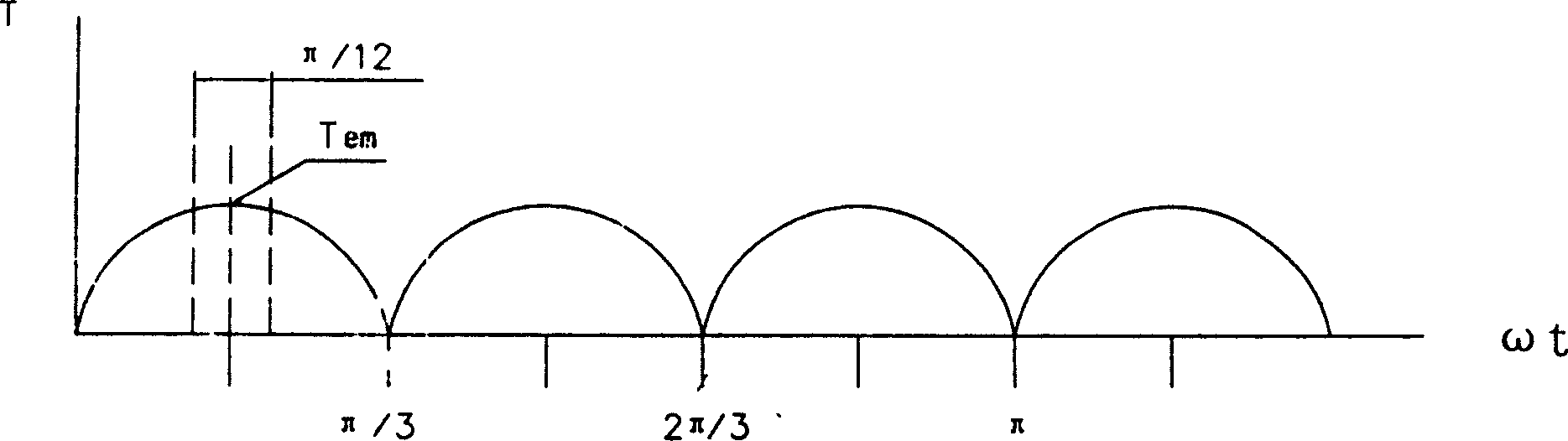

[0025] Embodiments of the present invention will be described below with reference to the drawings. Such as Figure 5a , Figure 5b , Figure 5c As shown, a program-controlled brushless DC motor includes an outer rotor, an inner stator and a motor operating circuit, and is characterized in that NS rotor permanent magnets 2 are evenly distributed on the inner cylindrical surface of the outer shell 1 of the outer rotor, and the outer rotor Trigger permanent magnets 4 are evenly distributed on the circumference of the circular plane in the middle part of the end cover 6; the inner stator is provided with stator electromagnetic coil windings 7, and the stator electromagnetic coil windings are connected in series by every adjacent three groups of coils. The triangular load electromagnetic coils are connected in parallel between the triangular load electromagnetic coils; the opposite inner stator end of the trigger permanent magnet 4 is fixed with a circular Hall sensor mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com