Method for preparing pla-ppc-pu copolymerized gold by utilizing pla reclaimed material and its product and application

A PLA-PPC-PU, PPC-PU technology, applied in the direction of plastic recycling, recycling technology, additive processing, etc., can solve the problems of by-product cyclic carbonate residue, unavoidable PLA degradation, metal catalyst residue, etc. Achieve the effect of solving poor reactivity, high cost and high acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

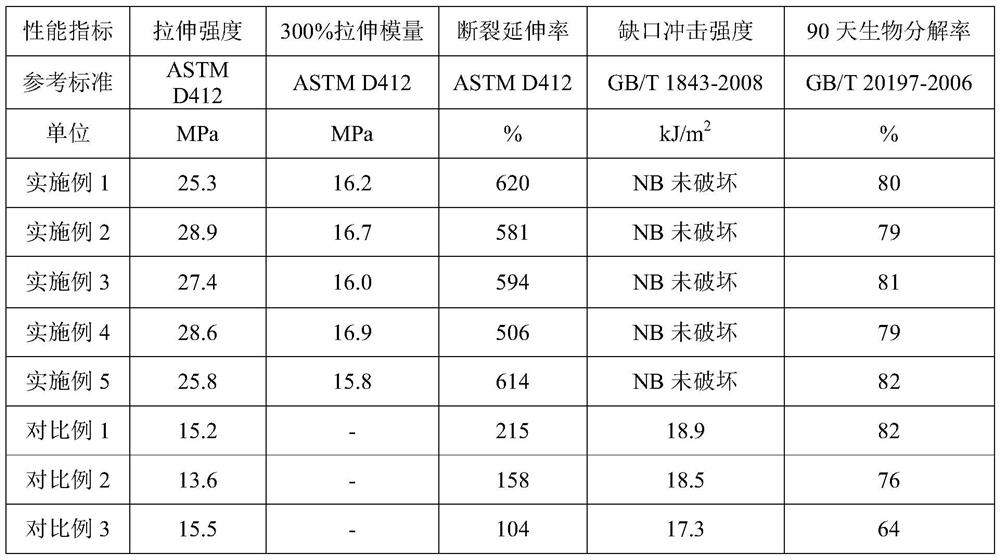

Examples

Embodiment 1

[0041] 1) Using discarded PLA reclaimed material, GPC test molecular weight is 80,000 g / mol, take 100kg and add it to the reaction kettle with chloroform, heat up to 50°C and stir to dissolve, keep the chloroform condensed and refluxed, add 3.59kg 1,2-propanediol and 6.5g of 4-dialkylaminopyridine, alcoholysis reaction for 3.5h, then warmed up to 75°C and vacuumed to -0.09MPa, removed the solvent chloroform and condensed and collected into the storage tank for later use, took samples from the kettle to remove the solvent in a vacuum oven The obtained hydroxyl-terminated low-molecular-weight PLA liquid has a hydroxyl value of 27.91 mgKOH / g, an acid value of 0.38 mgKOH / g, and a molecular weight of 4020 g / mol.

[0042] 2) Add 100kg of propylene carbonate and 2kg of 1,6-hexanediol to the reaction kettle and stir evenly at room temperature, add 10.2g of organic phosphazene catalyst, react for 6h, heat up to 90°C and vacuumize for 2h to remove low boilers, and get The PPC that adopt...

Embodiment 2

[0045] 1) Using discarded PLA reclaimed material, GPC test molecular weight is 100,000 g / mol, take 100kg and add it to the reaction kettle with chloroform, heat up to 50°C and stir to dissolve, keep the chloroform condensed and refluxed, add 1.12kg ethylene glycol and 8.5g 4-Dialkylaminopyridine, alcoholysis for 3 hours, then heated to 75°C and vacuumed to -0.09MPa, removed the solvent chloroform and condensed and collected in a storage tank for later use. Samples were taken from the kettle and tested after removing the solvent in a vacuum oven The hydroxyl value of low molecular weight PLA liquid terminated by hydroxyl group is 11.2 mgKOH / g, the acid value is 0.32 mgKOH / g, and the molecular weight is 10017 g / mol.

[0046] 2) Add 100kg of propylene carbonate and 1.575kg of ethylene glycol into the reaction kettle and stir evenly at room temperature, add 12.5g of organic phosphazene catalyst, react for 7 hours and then raise the temperature to 90°C for 2 hours to remove low boil...

Embodiment 3

[0049] 1) Using discarded PLA reclaimed material, GPC test molecular weight is 115,000 g / mol, take 100kg and add it to the reaction kettle with chloroform, heat up to 50°C and stir to dissolve, keep the chloroform condensed and refluxed, add 1.14kg ethylene glycol and 9.7g 4-Dialkylaminopyridine, alcoholysis reaction for 2.5h, then heated to 75°C and vacuumed to -0.09MPa, the solvent chloroform was removed and condensed and collected in a storage tank for later use. Samples in the kettle were tested after removing the solvent in a vacuum oven The hydroxy-terminated low-molecular-weight PLA liquid has a hydroxyl value of 9.32 mgKOH / g, an acid value of 0.3 mgKOH / g, and a molecular weight of 12038 g / mol.

[0050] 2) Add 120kg of propylene carbonate and 1.685kg of 1,4-butanediol to the reaction kettle and stir evenly at room temperature, add 11.4g of organic phosphazene catalyst, react for 6 hours, then heat up to 90°C and vacuum for 2 hours to remove low boilers, Obtain the PPC t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com