Patents

Literature

30results about How to "Warm and breathable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

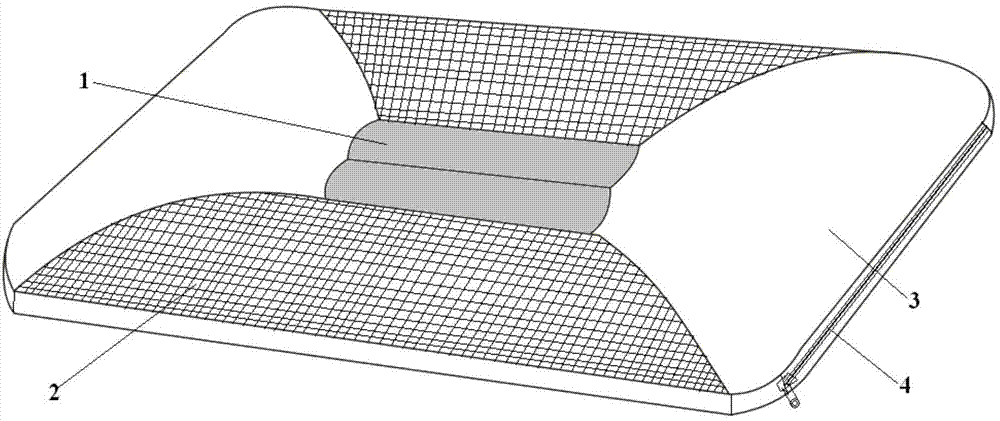

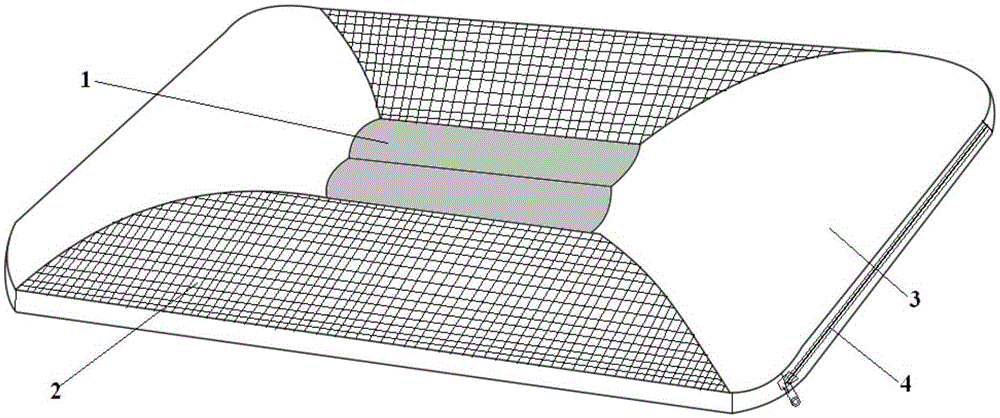

Chinese herbal medicine heath-care pillow

The invention provides a Chinese herbal medicine heath-care pillow. The Chinese herbal medicine heath-care pillow at least comprises pillow covers and Chinese herbal medicine bags located in the pillow covers and is composed of a head pillow, neck pillows and shoulder protective pillows, wherein the head pillow is located in the center of the Chinese herbal medicine heath-care pillow and is concave inwards, the two shoulder protective pillows are located on the left and right sides of the head pillow, the two neck pillows are located on the front and rear sides of the head pillow, the pillow covers of the head pillow and the neck pillows are made of pure cotton cloth, a semen cassiae bag is arranged in the head pillow, the neck pillows are filled with pearl wool, the pillow covers of the neck pillows are made of net-surface breathable cloth, and Chinese herbal medicine bags are arranged in the neck pillows. The Chinese herbal medicine heath-care pillow overcomes the defects in the background technology, is complete in function, is good in effect, fully fits the cervical vertebra of the human body and prevents the cervical vertebra from being pressed when a user sleeps.

Owner:QICHUN SHIZHEN HERBAL TECH

Anti-insect and anti-mite healthcare quilt and preparation method thereof

InactiveCN106283602APhase transition temperature is suitableImprove mechanical propertiesBiochemical fibre treatmentNon-woven fabricsHuman bodyAreca palm

The invention discloses an anti-insect and anti-mite healthcare quilt which comprises a quilt cover, a quilt interior fixing cover and a quilt interior filler, wherein the quilt interior filler is prepared from the following raw materials in parts by weight: 10-15 parts of pineapple leaf fiber, 10-15 parts of flax fiber, 3-5 parts of radix stemonae, 1-2 parts of flos chrysanthemi indici, 2-4 parts of pericarpium zanthoxyli, 2-4 parts of areca catechu, 1-2 parts of clove, 1-2 parts of myrrh, 1-2 parts of honeysuckle stem, 30-40 parts of polyethylene glycol terephthalate, 0.5-1 part of polyethylene glycol monooleate and 10-15 parts of functional aid. The healthcare quilt disclosed by the invention has the advantages of intelligent temperature control, good warmth keeping property and air permeability, resistance to heat and aging, high human comfort and good usability; meanwhile, the healthcare quilt has the healthcare functions of purifying air and promoting metabolism of human body, prevents insects and mites, realizes good cleanness, integrates environmental protection, warmth keeping and healthcare functions, and meets the market needs of higher level.

Owner:安徽军民被装保障有限公司

Hollow fiber blended fabric

InactiveCN103610248AGood moisture wicking functionWarm and breathableProtective garmentSpecial outerwear garmentsHollow fibrePolymer science

The invention discloses hollow fiber blended fabric. The hollow fiber blended fabric is formed by blended weaving of four kinds of hollow fibers which are Y-shaped cross section recycled polyester filament fibers, viscose hollow fibers, kapok fibers and apocynum venetum fibers. The hollow fiber blended fabric comprises, by weight, 23%-27% of Y-shaped cross section recycled polyester filament fibers, 14%-18% of viscose hollow fibers, 30%-34% of kapok fibers and 21%-33% of apocynum venetum fibers. Due to the fact that the fabric is formed by blended weaving of the four kinds of hollow fibers which are the Y-shaped cross section recycled polyester filament fibers, the viscose hollow fibers, the kapok fibers and the apocynum venetum fibers, the woven fabric has the advantages of being excellent in dry fit function, easy to clean, capable of being dried soon, cool, comfortable, capable of keeping warm, and breathable.

Owner:SUZHOU IND PARK YOUSHUN CLOTHING FACTORY

Polyester polyamide and cotton bamboo blending process

InactiveCN107287729ANot easy to breakReduce the number of stoppersSucessive textile treatmentsLoomsPolyamidePolyester

The invention relates to a polyester polyamide and cotton bamboo blending process. The process includes following steps: (1), selecting polyester polyamide blended yarn; (2), selecting cotton bamboo blended yarn; (3), measuring maximum stretching limit of the cotton bamboo blended yarn, namely maximum pressure value that can be applied to the cotton bamboo blended yarn; (4), putting the polyester polyamide blended yarn into a water steamer; (5), presetting the polyester polyamide blended yarn after being treated in the step (4); (6), adopting a hydraulic loom to blend the polyester polyamide blended yarn and the cotton bamboo blended yarn at the maximum pressure value in the step (3), wherein a nozzle of 75-40 in specification is adopted for traction of the polyester polyamide blended yarn, and a nozzle of 45-20 in specification is adopted for traction of the cotton bamboo blended yarn. The polyester polyamide and cotton bamboo blending process has the advantage that the defect that finally woven products are unsatisfactory in quality due to the fact that characteristics of the polyester polyamide blended yarn and the cotton bamboo blended yarn are different when the polyester polyamide blended yarn and the cotton bamboo blended yarn are adopted for blending can be overcome.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

Blended cashmere sweater textile fabric

The invention relates to a blended cashmere sweater textile fabric, which comprises the following components by weight: 70-80 parts of cashmere, 5-8 parts of stretched fine wool fiber, 4-5 parts of spun silk, 3-4 parts of soybean protein fibre, 3-5 parts of tencel, 3-5 parts of PTT fiber and 2-3 parts of conductive fiber. The blended cashmere sweater textile fabric is blended due to special raw material ratio, characteristic of each raw material fiber can be protruded, and various raw material advantages are combined, and the blended cashmere sweater textile fabric has the characteristics of beauty, good hand feeling, good elasticity, pilling resistance, high grade, and good warming permeability.

Owner:SUZHOU INST OF TRADE & COMMERCE

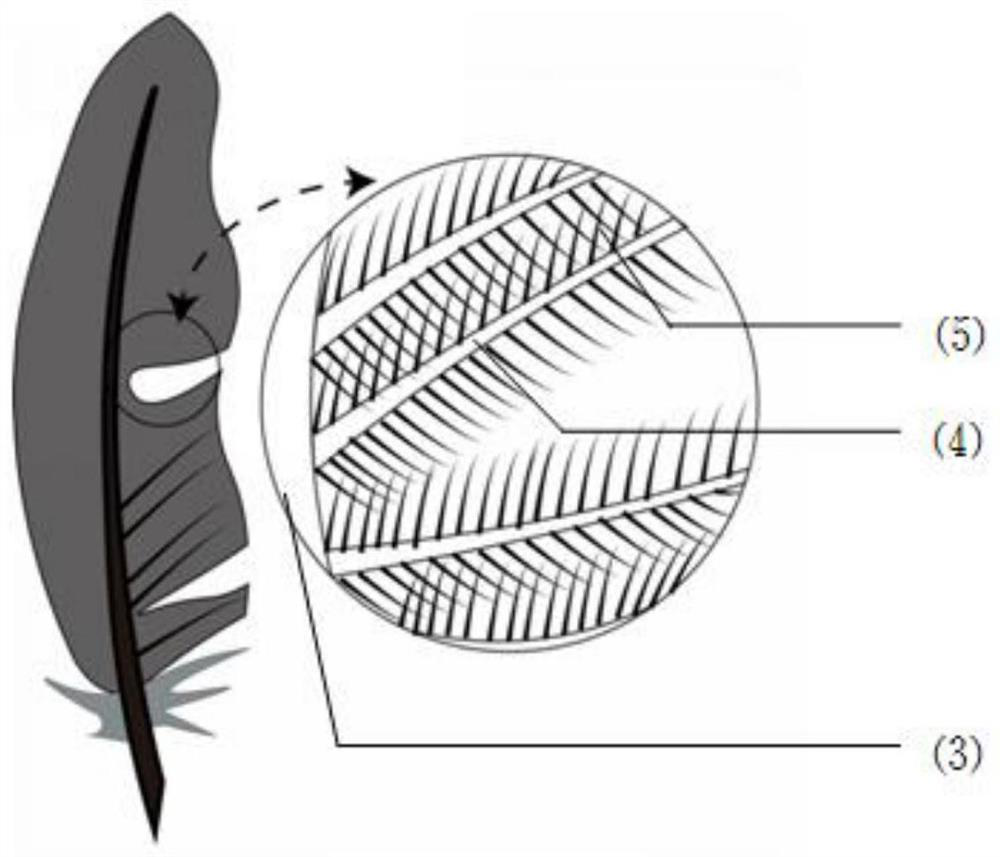

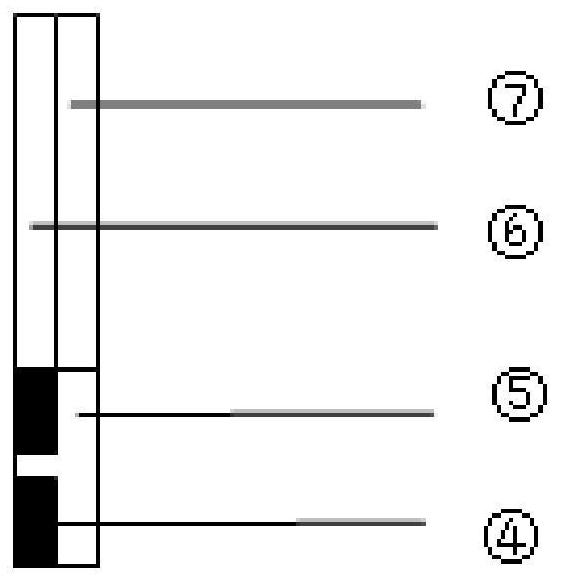

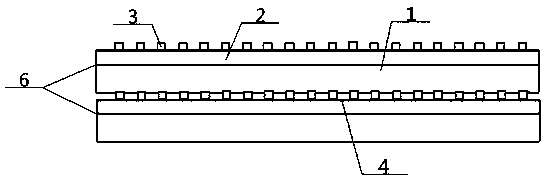

Bionic feather structure breathable warm-keeping knitted fabric and knitting method thereof

ActiveCN114000249AFacilitates microclimate adjustmentStay fresh and comfortableWeft knittingUndergarmentsEngineeringMechanical engineering

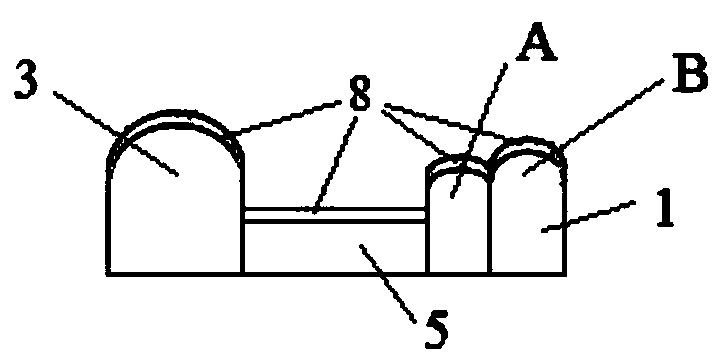

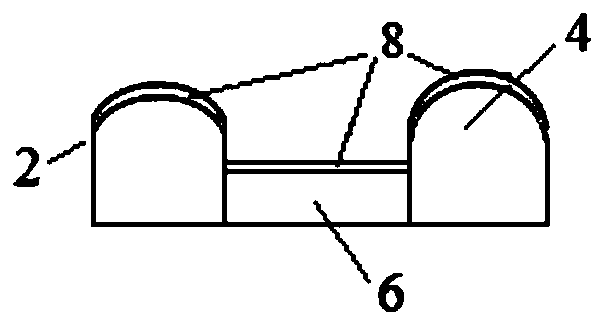

The invention relates to a bionic feather structure breathable warm-keeping knitted fabric and a knitting method thereof. The fabric comprises a surface layer (1) and an inner layer (2), a plurality of obliquely arranged circulating units are arranged on the surface layer (1), each circulating unit comprises bionic feather shafts (1), bionic feather branches (2) and bionic feather small branches (3), the bionic feather shafts (1) are provided with uniformly and obliquely spaced fine holes, the bionic feather shafts (1) are perpendicular to the inner layer (2) to form protrusions, the bionic feather branches (2) and the bionic feather small branches (3) are arranged on the two sides of the bionic feather shafts (1) in parallel and staggered with each other, and the bionic feather branches (2) and the bionic feather small branches (3) are perpendicular to the inner layer (2) to form grooves. The fabric is good in warmth retention and air permeability, overcomes the problems that domestic sports underwear fabric is single in tissue structure and the cold-proof air permeability needs to be improved, and is suitable for development of winter sports knitted underwear.

Owner:DONGHUA UNIV +1

Antifouling blended decorative cloth

InactiveCN108688269AWarm and breathableIncrease elasticitySynthetic resin layered productsMetal layered productsPolyesterSurface layer

The invention discloses an antifouling blended decorative cloth, which comprises following layers from top to bottom: a surface layer, a net like breathable layer, a basic material layer, and a lininglayer. The basic material layer is made of silver plated cloth. The silver plated cloth is prepared by weaving warps and wefts. The warps and wefts are all made of silver plated nylon fibers. The lining layer is made of cotton-bamboo blended cloth. The cotton-bamboo blended cloth is prepared by weaving warps and wefts. The warps and wefts are all made of cotton-bamboo blended filaments. The net like breathable layer is made of polyester fibers. The surface layer is made of cotton-polyester blended cloth, which is prepared by weaving warps and wefts. The warps and wefts are all made of cotton-polyester blended filaments. The provided antifouling blended decorative cloth has a strong anti-radiation and antistatic performance and a strong performance on removing odor and killing bacteria, isresistant to wear, has a stable size, and is breathable.

Owner:江苏正大易方科技有限公司

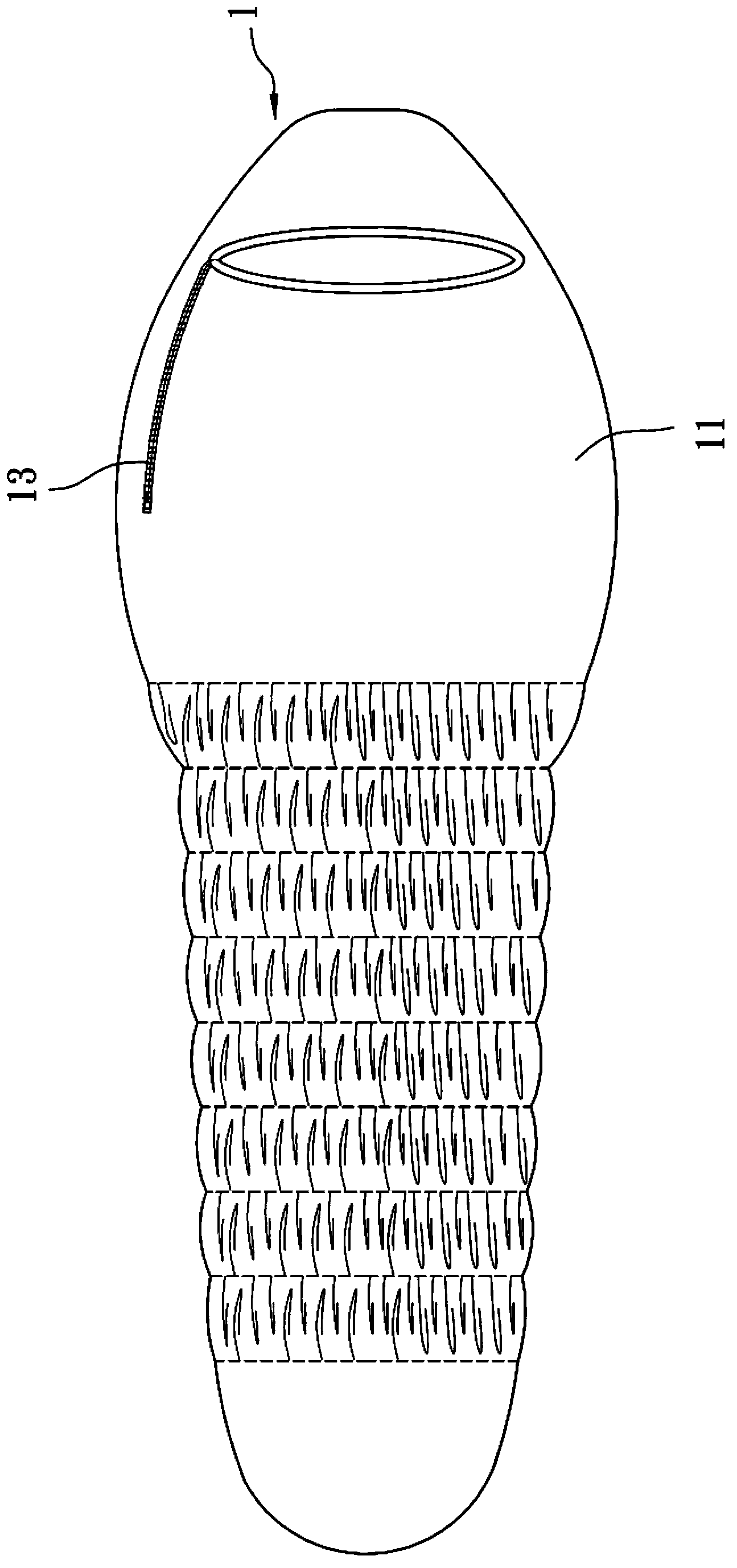

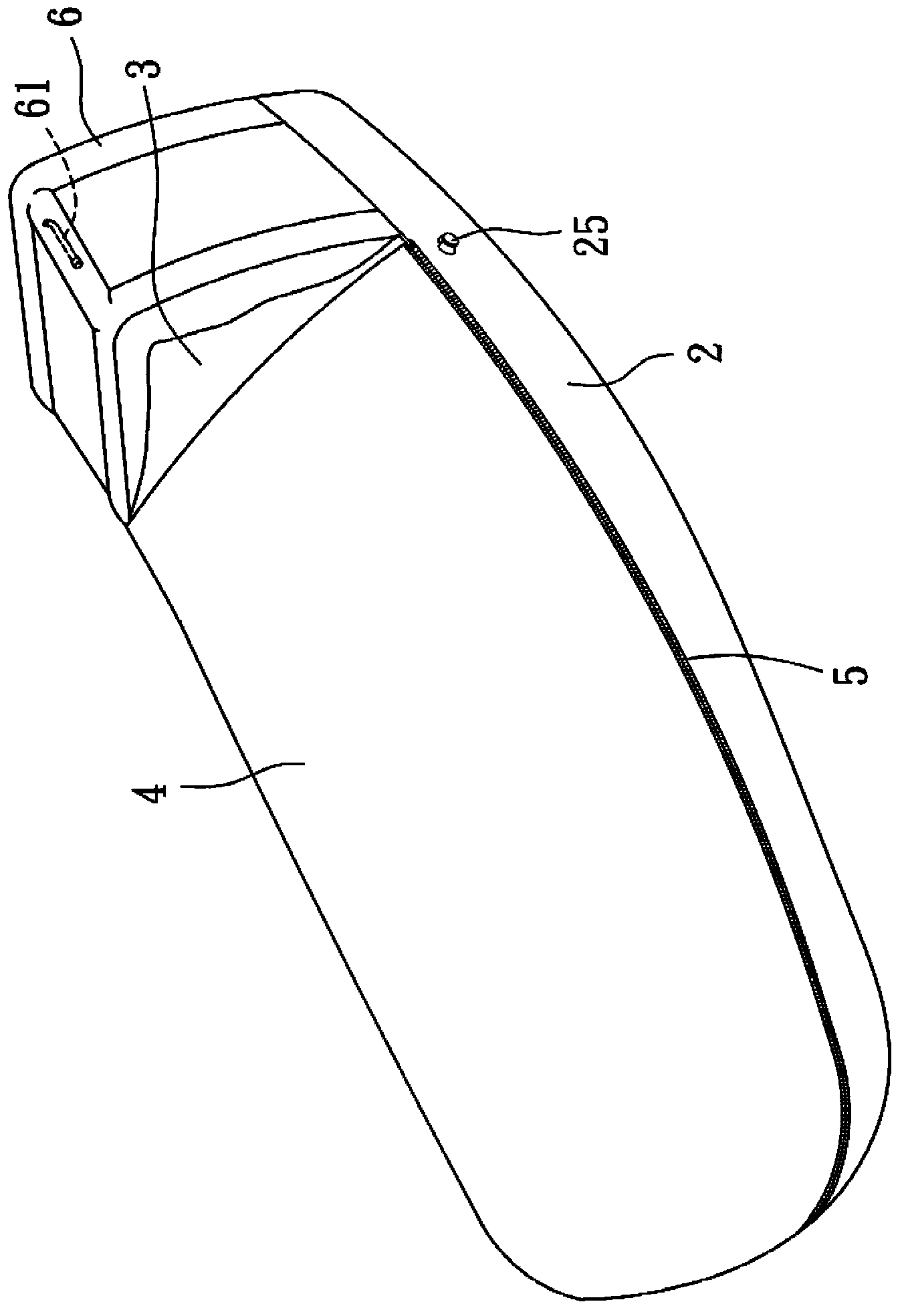

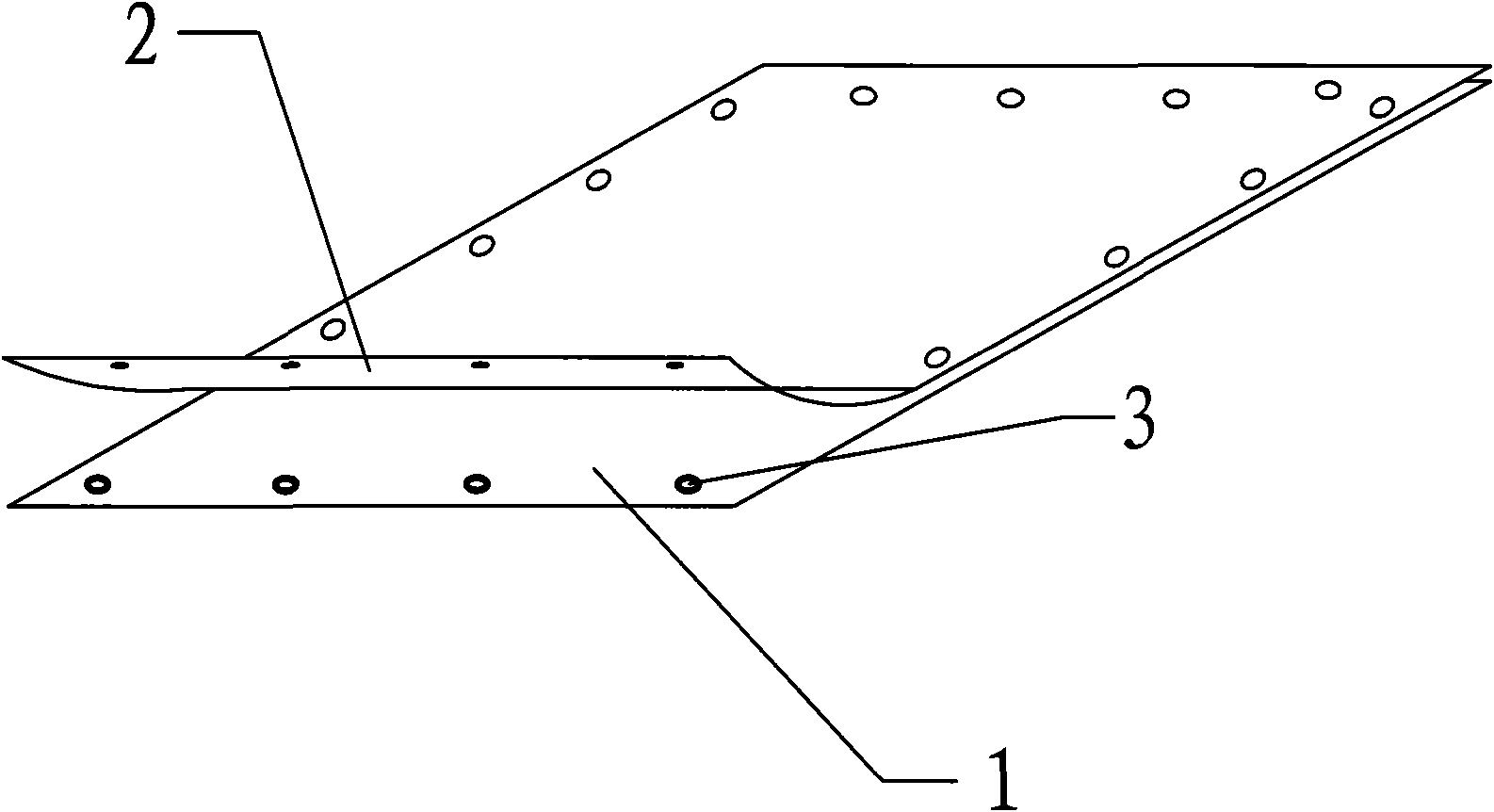

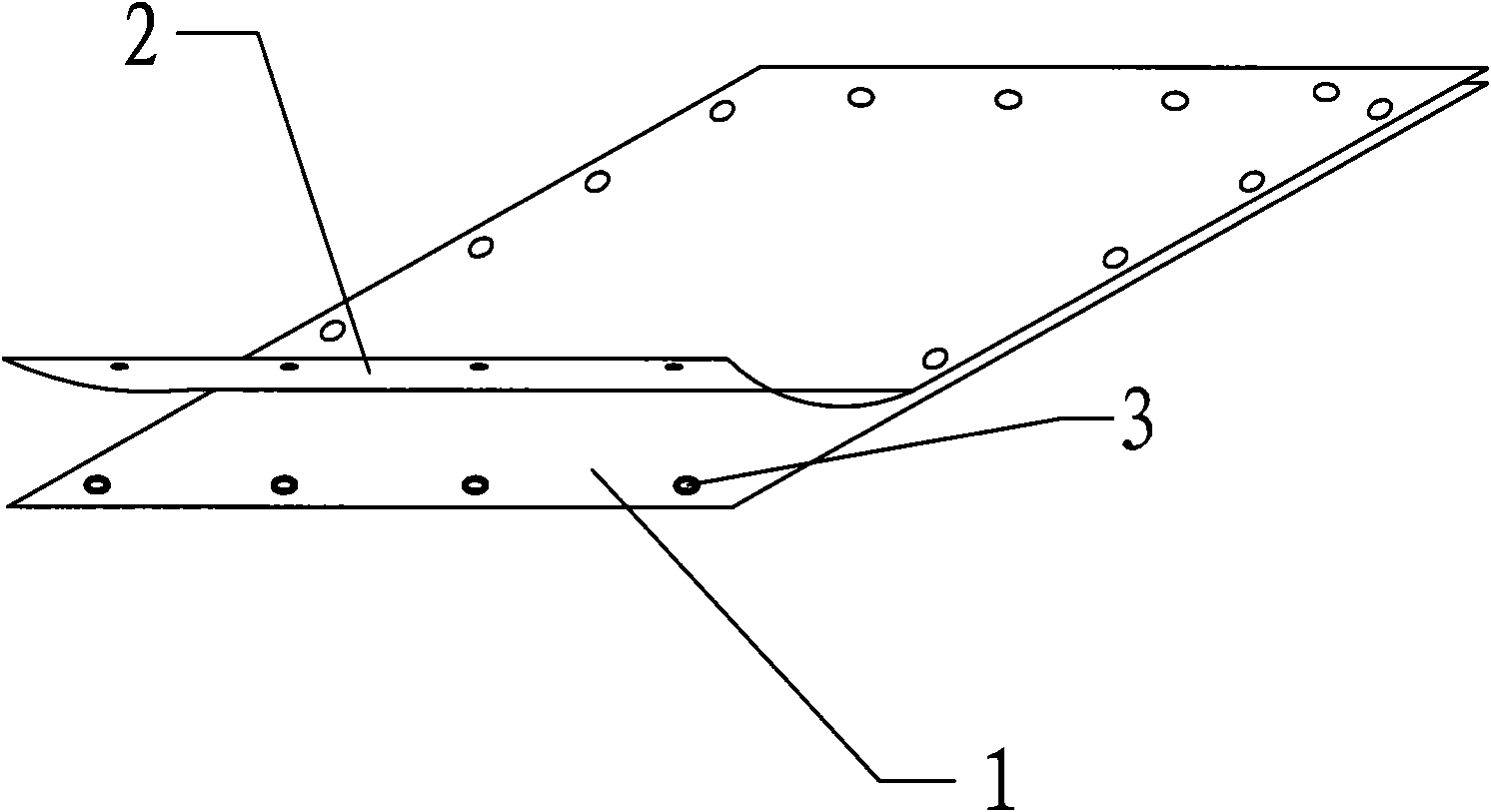

Sleeping bag

Disclosed is a sleeping bag. The sleeping bag comprises a cushion part and a covering part which forms a lying space together with the cushion part. The cushion part comprises a cushion surface layer, a cushion inner layer and a lower interlayer unit which is combined with the cushion surface layer and the cushion inner layer to define a lower inflation space; the covering part comprises a covering inner layer, a covering surface layer and an upper interlayer unit mounted between the covering inner layer and the covering surface layer; the lower inflation space is provided with a plurality of inflation channels and at least one a connecting channel, which is provided with a air port and connected with the inflation channels; the cushion part also comprises an inflation valve seat for opening and closing the air port. By increasing the thickness of the cushion part through air, the sleeping bag can enhance lying comfort; when the air is exhausted, the size of the sleeping bag can be reduced, so that the sleeping bag can be convenient to carry and store.

Owner:GAINMORETEX

Primary-secondary quilt

The invention relates to a primary-secondary quilt, mainly comprising a primary quilt and a secondary quilt, wherein the primary quilt and the secondary quilt are peripherally provided with buttons for connection. The primary-secondary quilt has two using condition, wherein in the first using condition, the secondary quilt and the primary quilt are separated for single use; and in the second condition, the secondary quilt and the primary quilt are connected through the buttons for concurrent use. The buttons can effectively fix the quilts without turnover or slip phenomenon, and the thickness of the quilt can be freely selected, thereby satisfying the life demands of people.

Owner:WUJIANG CITY JILI SILK PROD

Intelligent and anti-static fabric for woolen sweaters

The invention discloses an intelligent and anti-static fabric for woolen sweaters. The intelligent and anti-static fabric for woolen sweaters is characterized by being prepared from, by weight, 59-65 parts of wool fibers, 10-17 parts of cashmere, 12-17 parts of polyester, 3-8 parts of anti-pill fibers and 4-5 parts of spandex. The intelligent and anti-static fabric for woolen sweaters has the advantages that the intelligent and anti-static fabric for woolen sweaters is prepared by blending the raw materials according to the proportion, the characteristics of fibers of the raw materials are stressed, the advantages of the raw materials are integrated, and the fabric is attractive, good in hand touch, high in grade, low in cost, elastic and good in warm-keeping performance and breathability.

Owner:JIANGSU YAOZHANG SPORTING GOODS

Jute-wool blended fiber fabric

InactiveCN104188205AWarm and breathableHygroscopicTextiles and paperProtective garmentPolymer scienceFiber composition

The invention discloses a jute-wool blended fiber fabric. The jute-wool blended fiber fabric is formed by blending four fabric fibers including apocynum venetum fibers, ramie fibers, angora wool fibers and camel plush fibers in a woven mode, and comprises, by weight, 21% to 25% of the apocynum venetum fibers, 30% to 34% of the ramie fibers, 15% to 19% of the angora wool fibers and 22% to 34% of the camel plush fibers. The jute-wool blended fiber fabric is formed by blending the four fabric fibers including the apocynum venetum fibers, the ramie fibers, the angora wool fibers and the camel plush fibers in the woven mode, the jute-wool blended fiber fabric formed in the woven mode has the advantages of keeping warm and being breathable, soft, comfortable, capable of absorbing moisture and cool, and meanwhile the jute-wool blended fiber fabric is good in abrasion resistance, easy to wash and high in drying speed.

Owner:陈朝阳

Woolen sweater textile fabric

The invention discloses a woolen sweater textile fabric. The woolen sweater textile fabric is characterized by comprising the following components according to weighty by parts: 59 to 65 parts of wool fibers, 10 to 17 parts of cashmere, 10 to 20 parts of selenium enriched-fibers, 12 to 17 parts of terylene, 3 to 8 parts of anti-pill fibers, and 4 to 5 parts of spandex. The woolen sweater textile fabric is advantageous in that the fabric is blended by each raw material according to a proportion, so features of each raw material fiber can be displayed and all advantages of the raw material can be integrated; and the woolen sweater textile fabric has beautiful contour, great hand feeling, high grade, low cost, great elasticity and great warming and ventilating properties.

Owner:NANTONG GUANZHOU INT TRADE CO LTD

TPU composite fabric

InactiveCN111890747AImprove waterproof performanceGood deodorizing effectSynthetic resin layered productsWoven fabricsPolyesterPolymer chemistry

The invention provides a TPU composite fabric. The TPU composite fabric comprises base cloth and a TPU film adhered to the surface of the base cloth, wherein the base cloth is formed by interweaving warp yarns and weft yarns, the warp density of the warp yarn interwoven fabric is 90-150 pieces per centimeter, the weft density of the weft yarn interwoven fabric is 40-50 pieces per centimeter, the warp yarns are bamboo fiber yarns, and the weft yarns are mulberry silk and polyester drawn textured yarns which are alternately arranged; the TPU film is prepared from the following raw materials: TPUparticles, white carbon black, plant polyphenol, a leveling agent and a stripping aid; the TPU composite fabric is formed by bonding and compounding the TPU film and the base cloth, the base cloth isformed by blending the bamboo fiber yarns, the mulberry silk and the polyester drawn textured yarns, and the TPU composite fabric has good deodorization, air permeability and antibacterial and mildew-proof properties and is matched with the air-permeable and waterproof TPU film attached to the outer side, so that the waterproofness of the composite fabric is enhanced.

Owner:昆山市悦宏复合面料有限公司

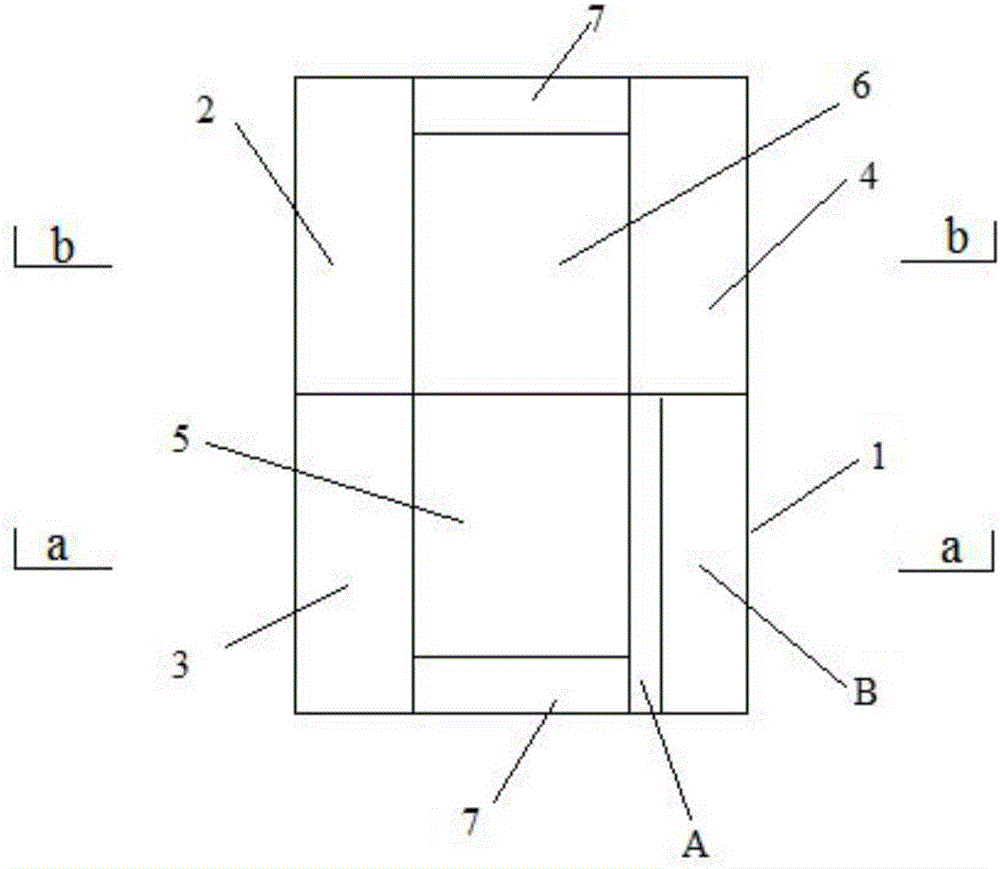

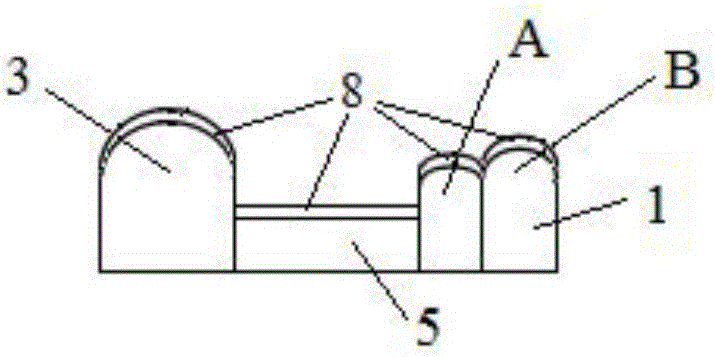

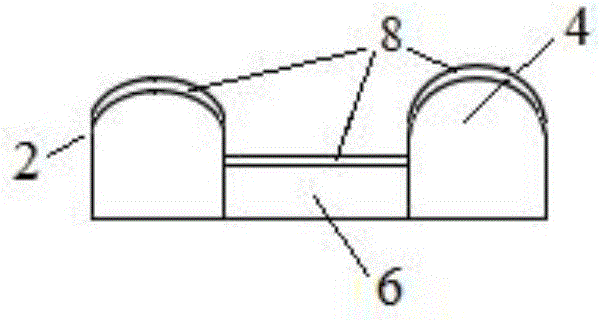

Chinese herbal medicine cervical-curvature healthcare pillow

ActiveCN106724518AConvenient treatmentImprove sleepingPillowsSenses disorderVertebraVeterinary medicine

The invention discloses a Chinese herbal medicine cervical-curvature healthcare pillow. The herbal medicine cervical-curvature healthcare pillow comprises neck pillows and headrests, wherein the neck pillows include a first neck pillow, a second neck pillow, a third neck pillow and a fourth neck pillow, the four neck pillows are respectively located on the left and right sides of the headrests in a two-two-parallel manner, and the heights of the four neck pillows are larger than the heights of the headrests; each neck pillow and each headrest comprises a case and Chinese herbal medicine bag; the four neck pillows are fixed with one another through sewing, and the nick pillows and the headrests are fixedly sewn together. The Chinese herbal medicine cervical-curvature healthcare pillow has the advantages that the pillow is designed according the length and thickness of the neck and the physiological and pathological features of human cervical vertebra, the unique convex head pillows and the concave headrests fit the natural curve of the cervical vertebra and the head, the neck is evenly supported, the curvature of the cervical vertebra is undestroyed, and cervical vertebra health is protected effectively.

Owner:郭振海

Novel sponge composite fabric

InactiveCN106926539ASoft textureComfortable to wearSynthetic resin layered productsClothingsMoisture permeationEngineering

The invention discloses a novel composite fabric and particularly provides a novel sponge composite fabric. The novel sponge composite fabric is formed by fixing and binding outer-layer cloth, a sponge and lining cloth. The novel sponge composite fabric can be directly used for garment manufacturing, the preparation process is simple and easy to carry out, and the novel garment fabric has the advantages that warmth is kept, moisture permeation is achieved, the surface is resistant to pilling and wrinkling, and garments are stiff.

Owner:WUXI JINSHUANG FABRICS TECH CO LTD

rubber outsole for protective boots

Owner:JIHUA 3539 SHOE MAKING

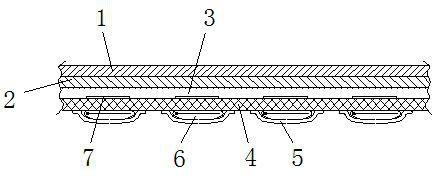

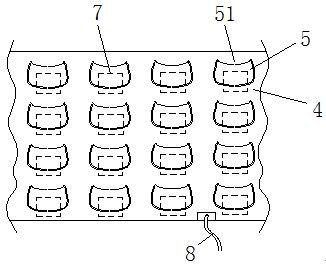

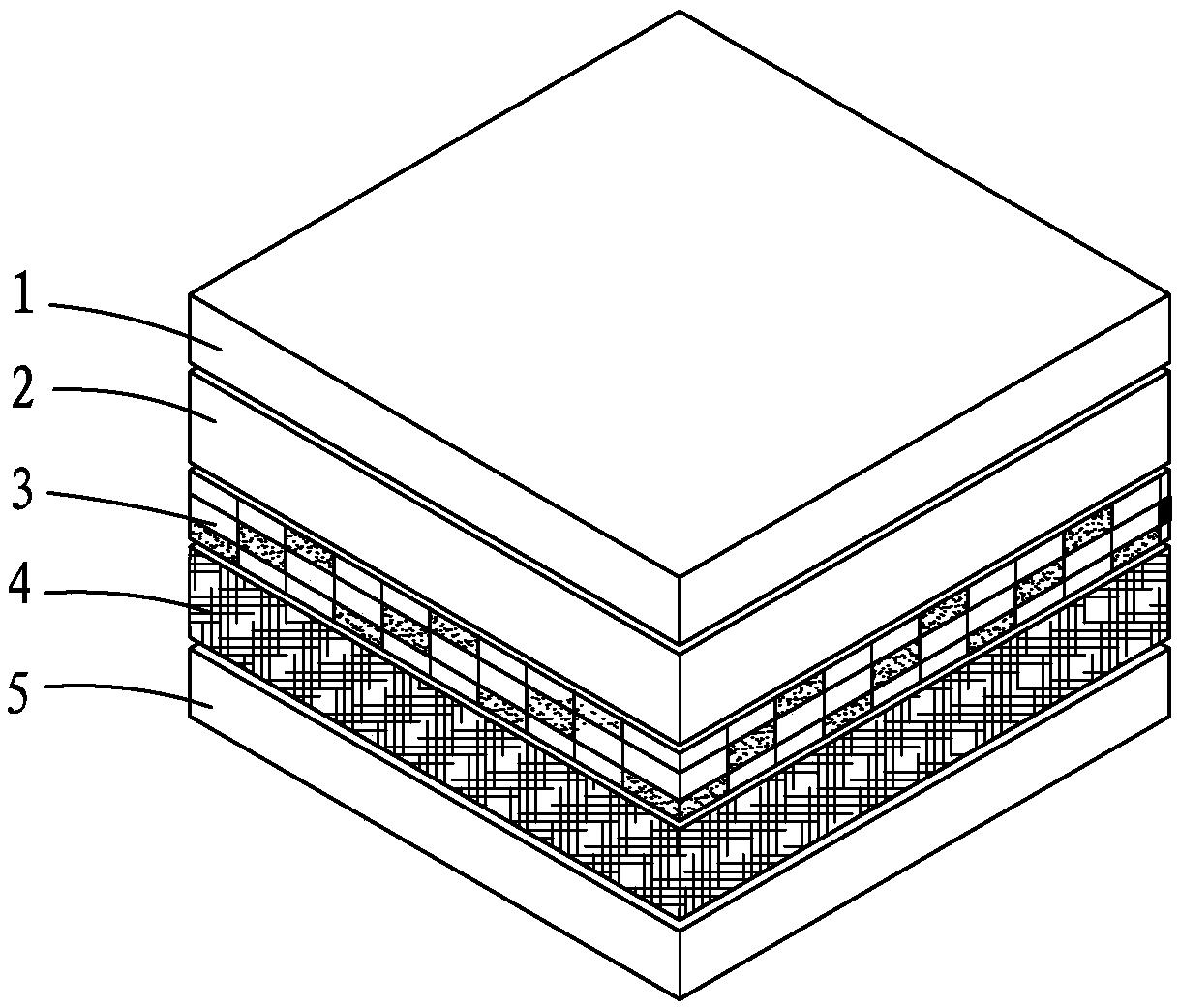

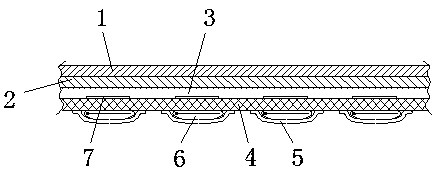

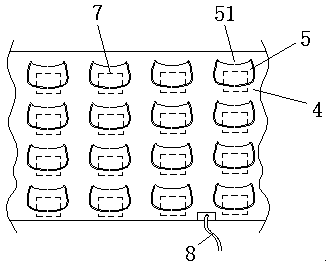

A kind of household bed sheet health care cloth

ActiveCN108688255BImprove surface comfortStrong warmth retentionSynthetic resin layered productsThermal insulationEngineering

The invention discloses a health-care cloth for household sheets, which comprises a fabric surface layer, a thermal fabric layer, a fabric base layer and a bottom fabric layer arranged sequentially from top to bottom, and the peripheral edges of the fabric surface layer and the thermal insulation fabric layer are sewn by needle and thread connected, the surrounding edges of the warm cloth layer are connected with the surrounding edges of the cloth base layer by needle thread sewing, the surrounding edges of the cloth base layer are connected with the surrounding edges of the bottom cloth layer by needle thread sewing, and the lower surface of the bottom cloth layer is distributed with A plurality of block cloth, the three sides of the block cloth are all connected to the bottom cloth layer by sewing, the invention uses the electric heating sheet to heat the health care medicine in the health care bag, so as to achieve the effect of traditional Chinese medicine fumigation, and has good Medical and health effects, the overall comfort of the fabric is good, full of elasticity, strong warmth retention, antibacterial, wear-resistant, warm and breathable.

Owner:江苏正大易方科技有限公司

Chinese herbal medicine health care pillow

ActiveCN104706128BPerceived resilience is goodWarm and breathableBiocideNervous disorderCotton clothSemen

The invention provides a Chinese herbal medicine heath-care pillow. The Chinese herbal medicine heath-care pillow at least comprises pillow covers and Chinese herbal medicine bags located in the pillow covers and is composed of a head pillow, neck pillows and shoulder protective pillows, wherein the head pillow is located in the center of the Chinese herbal medicine heath-care pillow and is concave inwards, the two shoulder protective pillows are located on the left and right sides of the head pillow, the two neck pillows are located on the front and rear sides of the head pillow, the pillow covers of the head pillow and the neck pillows are made of pure cotton cloth, a semen cassiae bag is arranged in the head pillow, the neck pillows are filled with pearl wool, the pillow covers of the neck pillows are made of net-surface breathable cloth, and Chinese herbal medicine bags are arranged in the neck pillows. The Chinese herbal medicine heath-care pillow overcomes the defects in the background technology, is complete in function, is good in effect, fully fits the cervical vertebra of the human body and prevents the cervical vertebra from being pressed when a user sleeps.

Owner:QICHUN SHIZHEN HERBAL TECH

Wool, cotton and cotton-polyester interwoven weft-knitted double-faced fleece fabric and manufacturing method

The invention relates to a wool, cotton and cotton polyester interweaving weft knitting double-faced pile fabric. According to the fabric, pure-cotton silvalin is adopted as looped pile inner yarn, wool is adopted as middle connection yarn, cotton polyester silvalin is adopted as surface layer yarn, the pure-cotton silvalin, the wool and the cotton polyester silvalin are woven on a single-face circular weft knitting fleece machine to form a stitched looped pile fabric, in the weaving process, the wool middle connection yarn generates wool exposed points on the outer surface of the cotton polyester fiber surface layer, and the wool exposed points account for 30-33% of the area of the cotton polyester fiber surface layer; the looped pile inner yarn is napped, the wool exposed points are sanded to obtain the weft knitting double-faced pile fabric with the pure-cotton gigging inner layer, the wool connection layer, the cotton polyester surface layer and the wool felt layer, wherein the pure-cotton silvalin accounts for 52-57%, the wool accounts for 7-22% and the cotton polyester silvalin accounts for 22-27%. The fabric has the advantages of being fine in suede, high in wool touch, soft and full in hand touch, good in heat retention property, good in breathability, good in mold holding nature, capable of resisting static electricity and low in price.

Owner:ANSHAN SHUNFENG TECH CO LTD

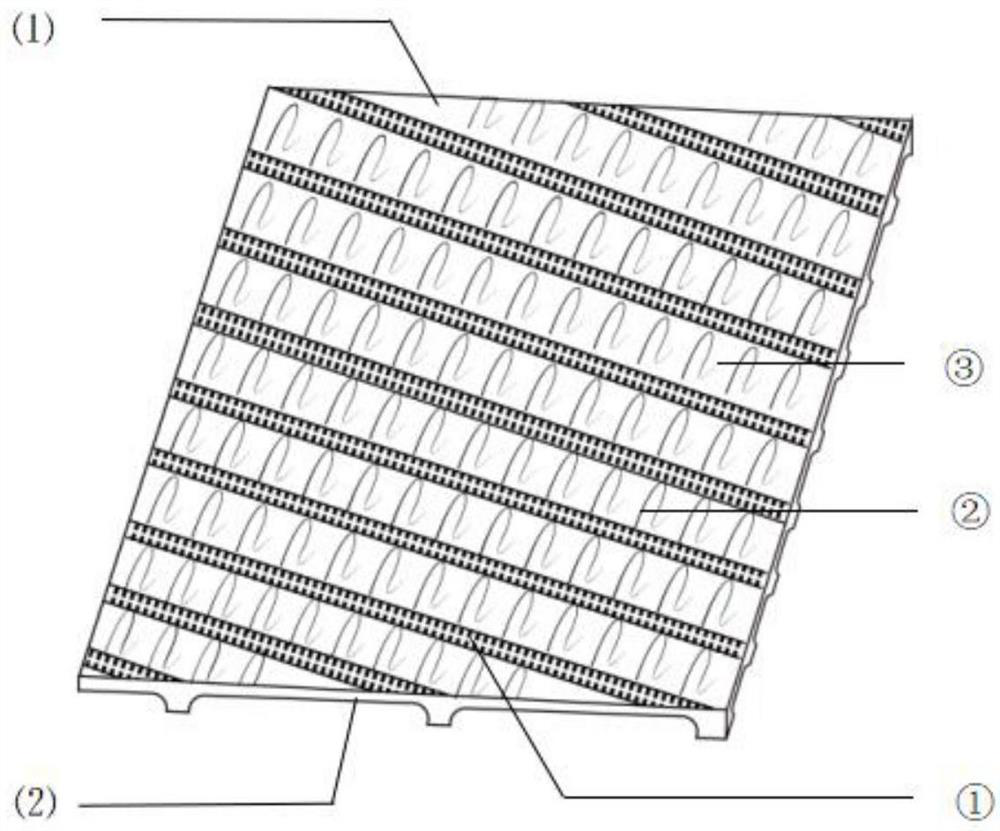

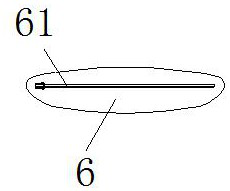

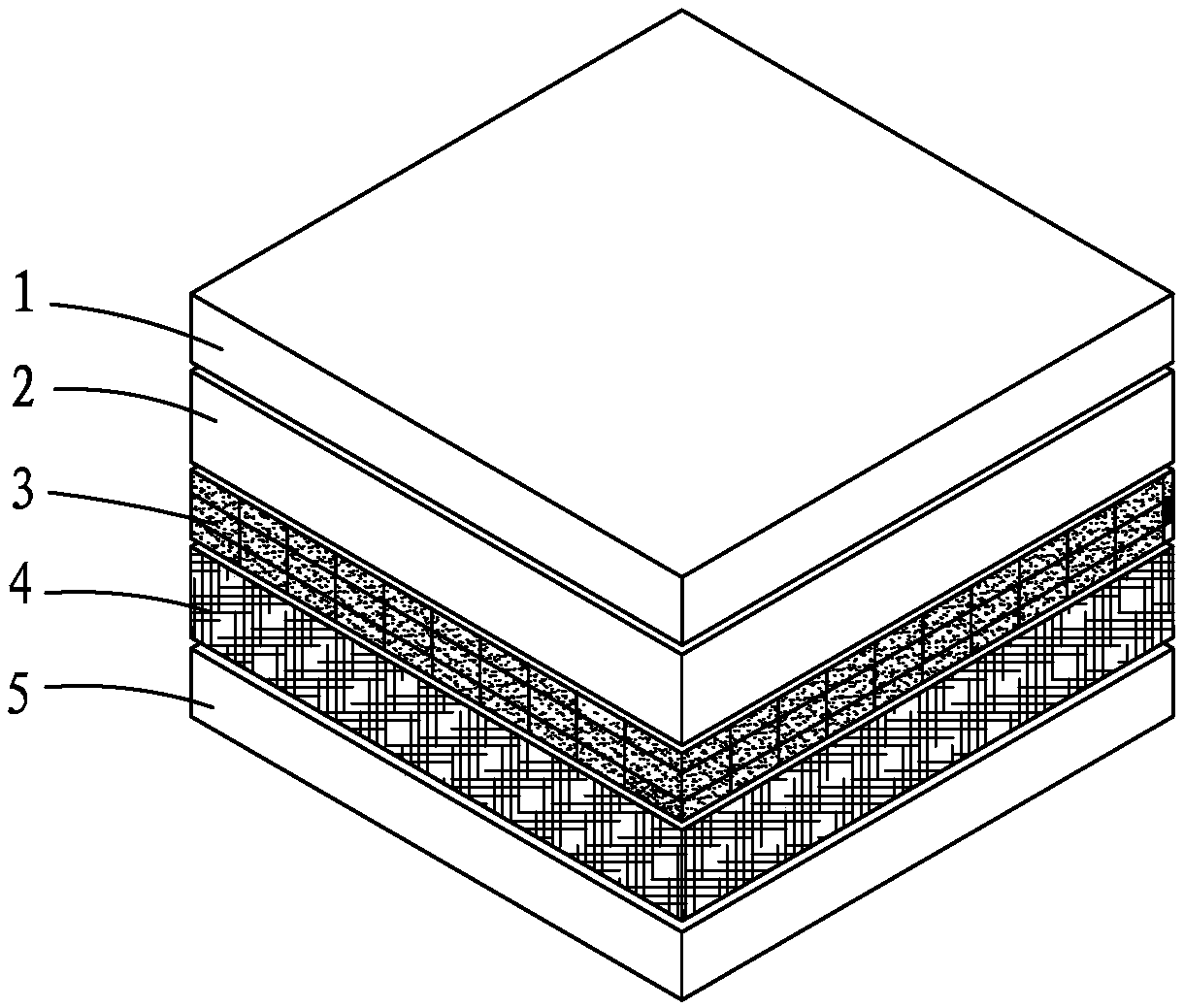

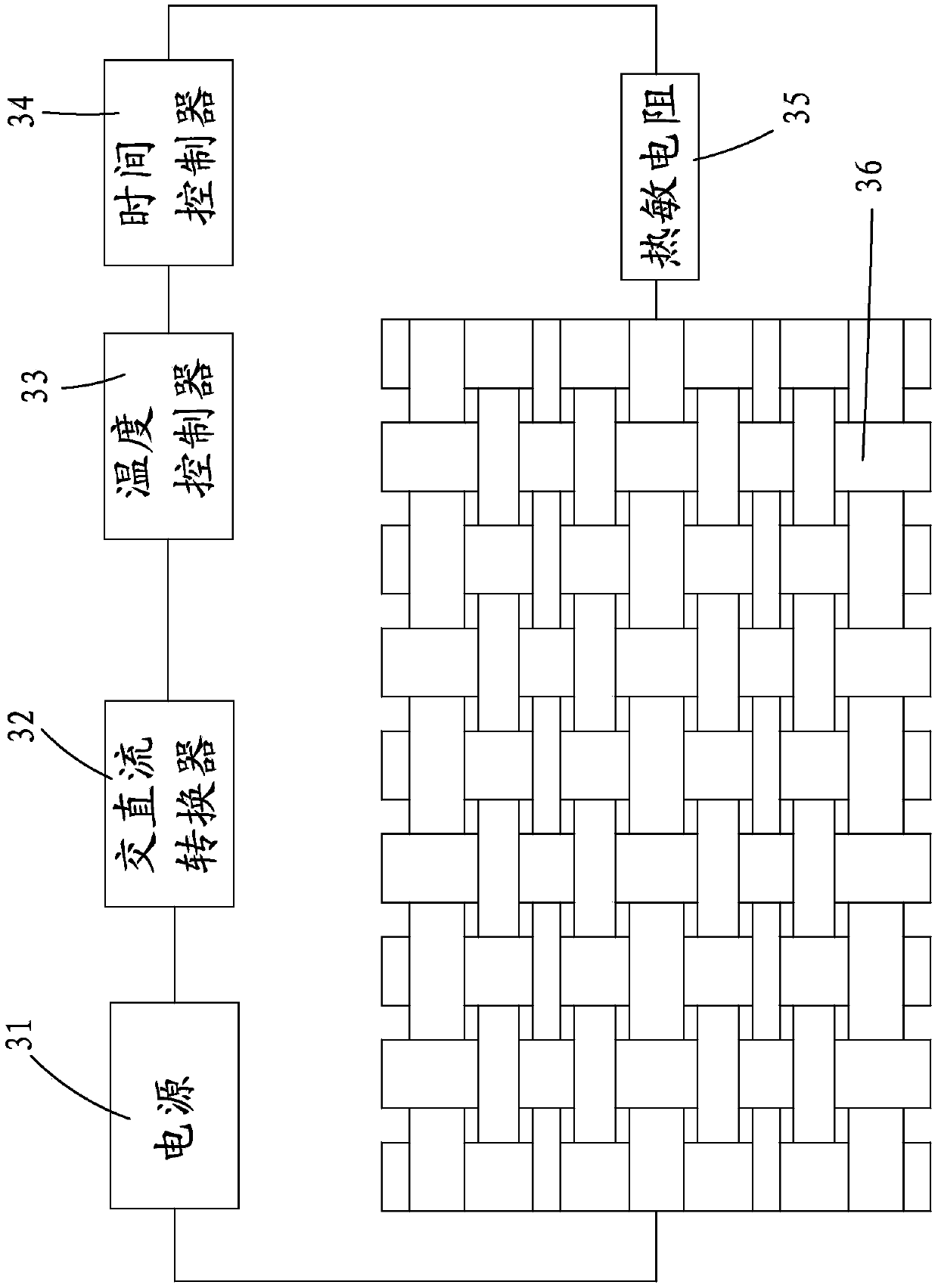

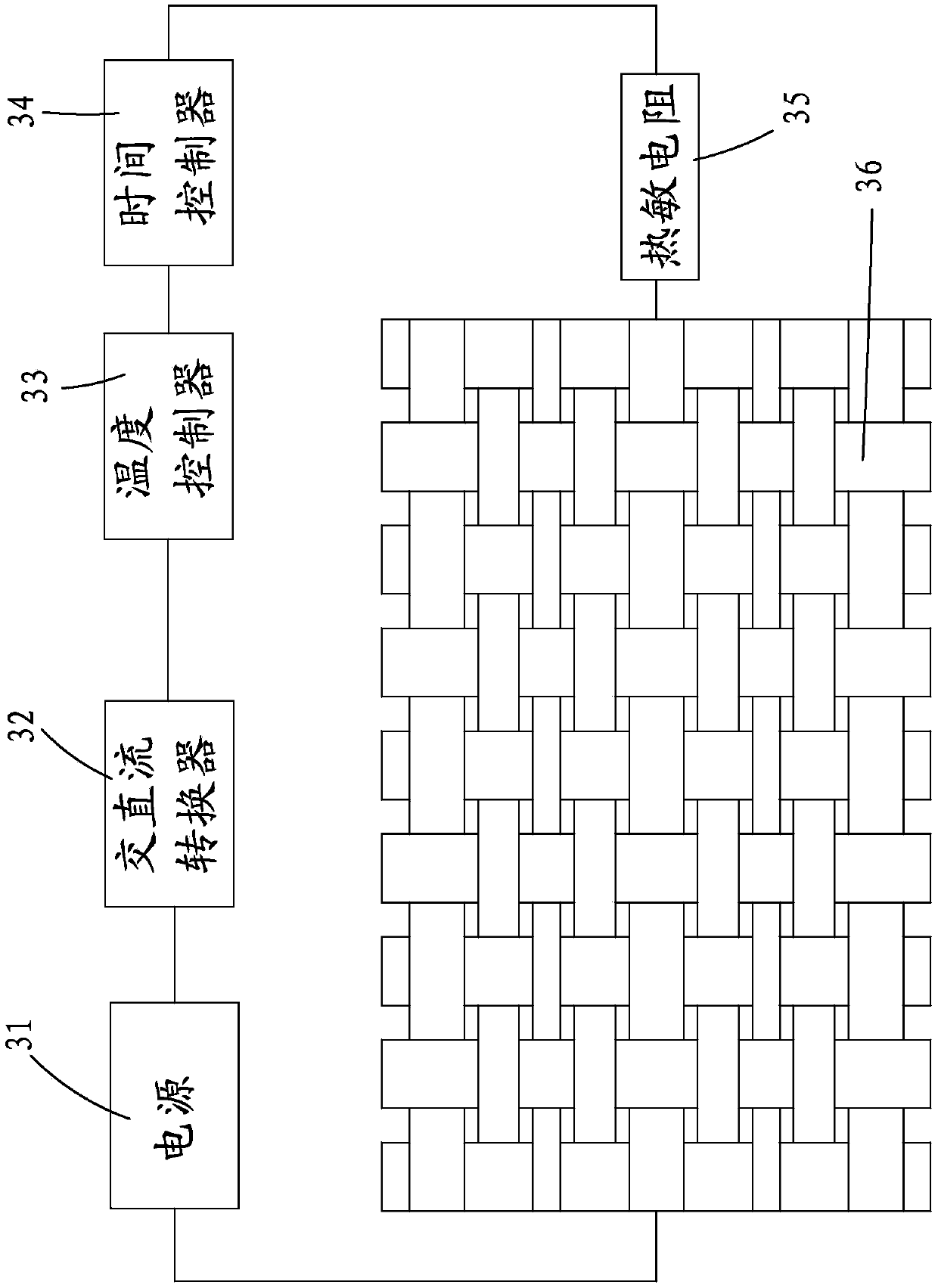

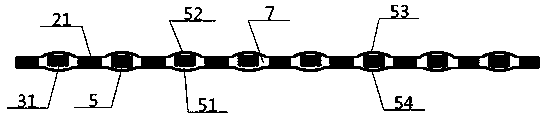

Bamboo carbon fiber mat core with infrared function and preparation process thereof

PendingCN109677050AGood value for moneyAnti-seismicStuffed mattressesLamination ancillary operationsFiberCarbon fibers

The invention provides a bamboo carbon fiber mat core with an infrared function and a preparation process thereof. The bamboo carbon fiber mat core comprises a first bamboo skin gridding cloth layer,a bamboo chip gridding cloth layer, a far infrared functional layer, a composite fiber felt layer and a second bamboo skin gridding cloth layer which are sequentially arranged from top to bottom; thefirst bamboo skin gridding cloth layer and the second bamboo skin gridding cloth layer each comprise a plurality of pieces of bamboo skin gridding cloths, and the bamboo chip gridding cloth layer comprises a plurality of pieces of bamboo chip gridding cloths; and the far infrared functional layer is obtained by sequentially connecting a power supply, an alternating-current and direct-current convertor, a temperature controller, a time controller, a thermistor and a carbon fiber gridding cloth layer in series. The bamboo carbon fiber mat core has the advantages of softness, comfort, shock resistance, warm retention, moisture retention and the like, and far infrared rays generated by carbon fibers of the bamboo carbon fiber mat core have the health care effects of improving the circulating system, adjusting autonomic nerves, improving an immunologic function, diminishing inflammation and the like.

Owner:CHONGQING SHENGFANG NEW MATERIALS TECH CO LTD +1

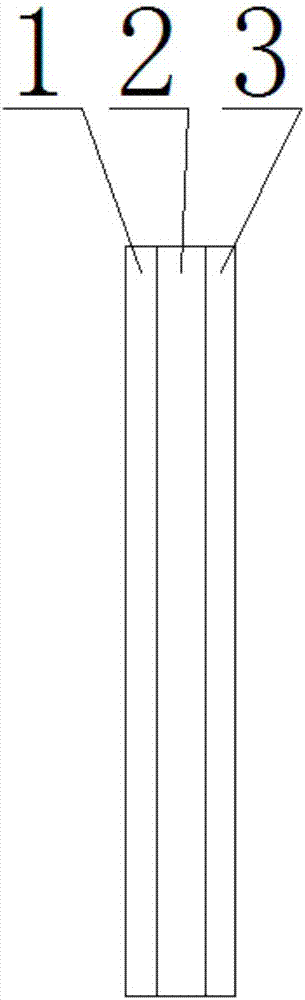

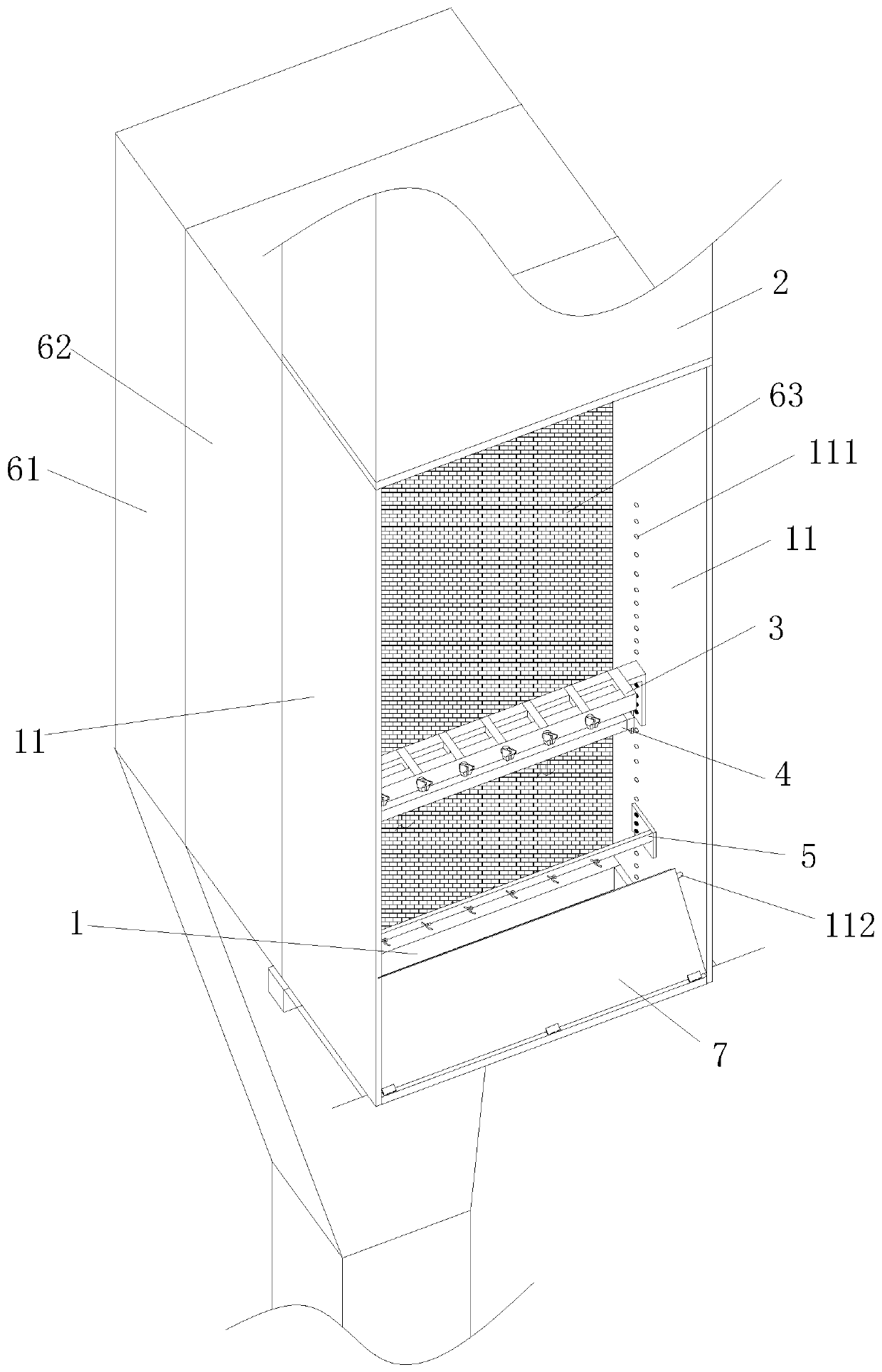

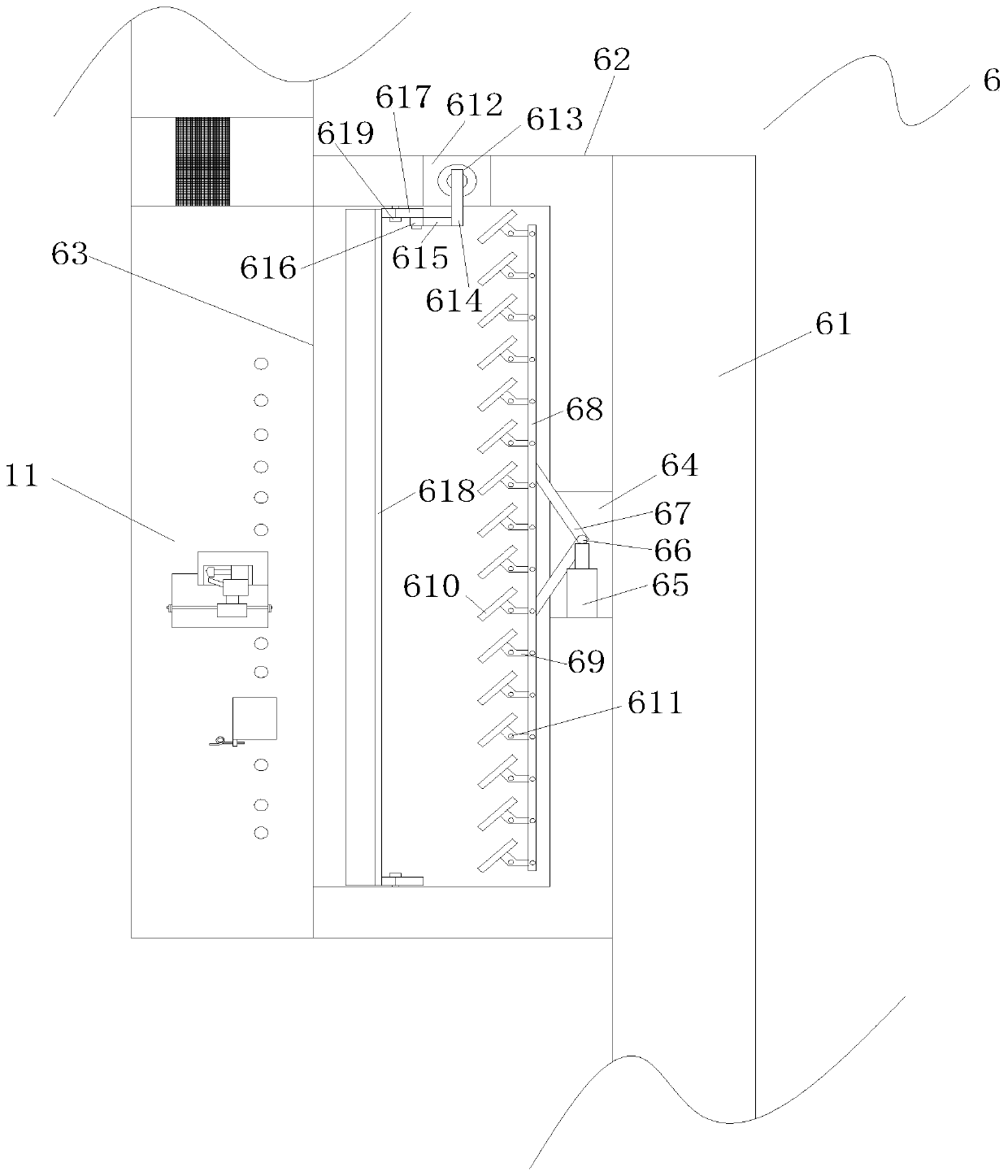

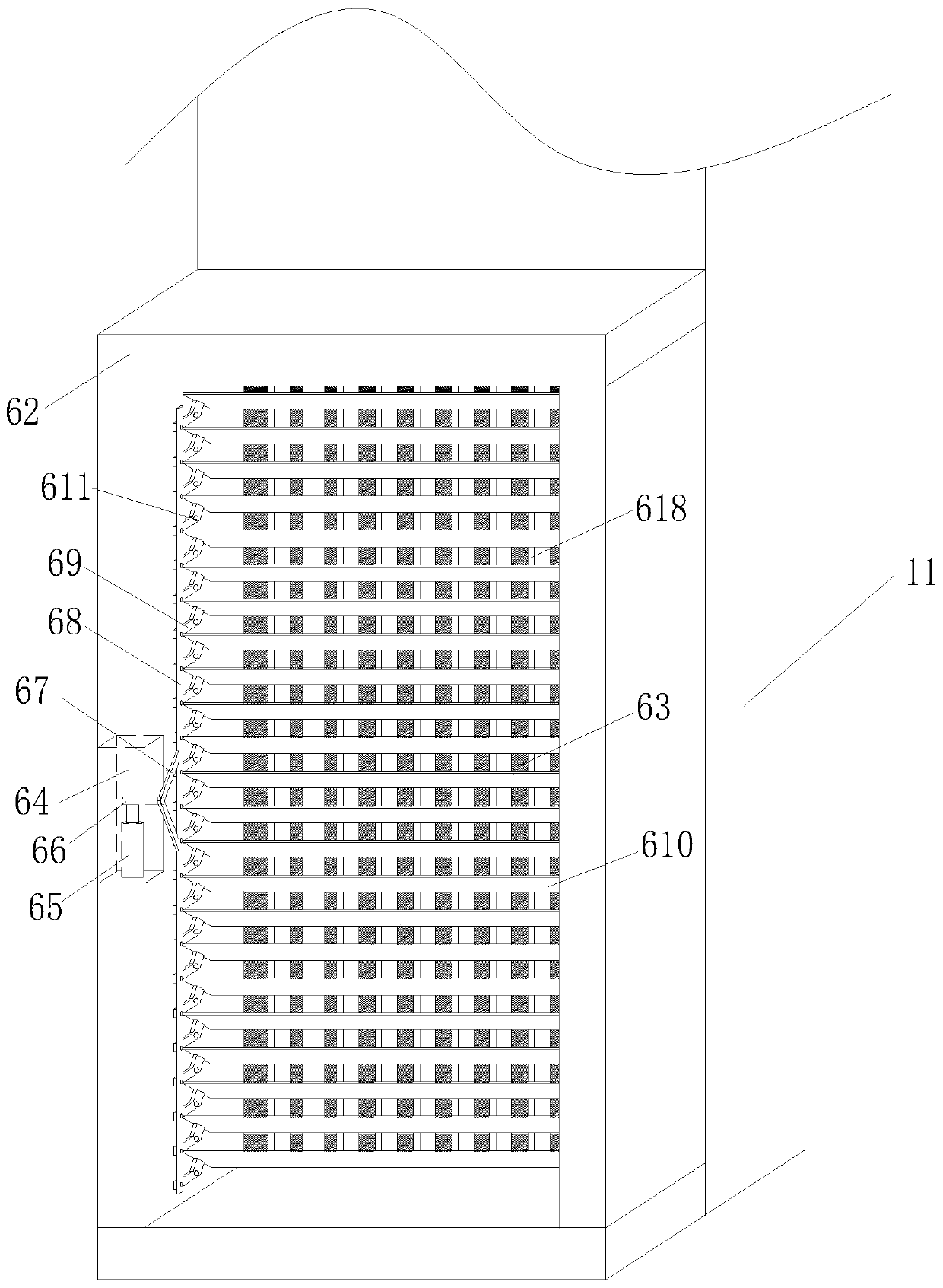

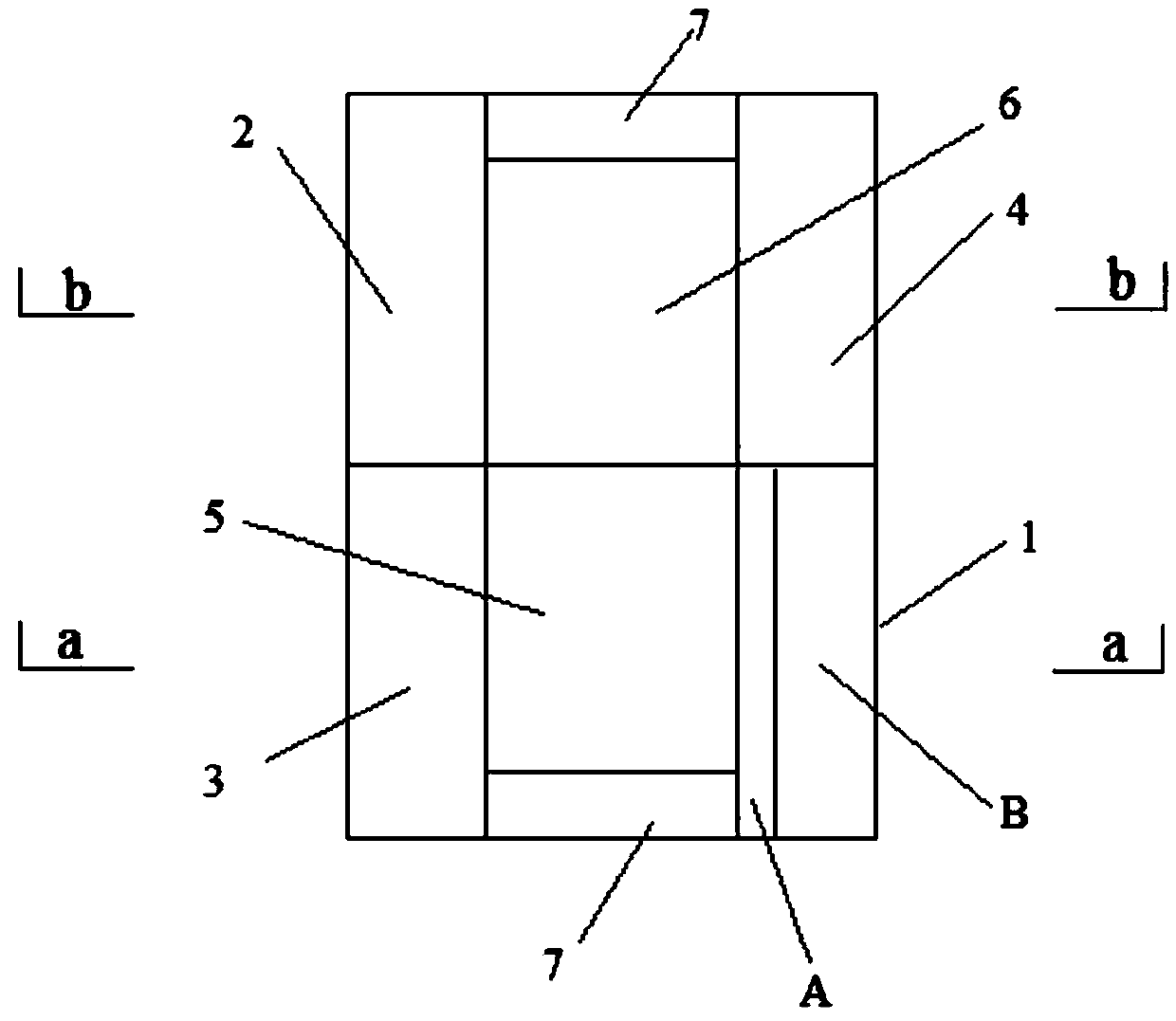

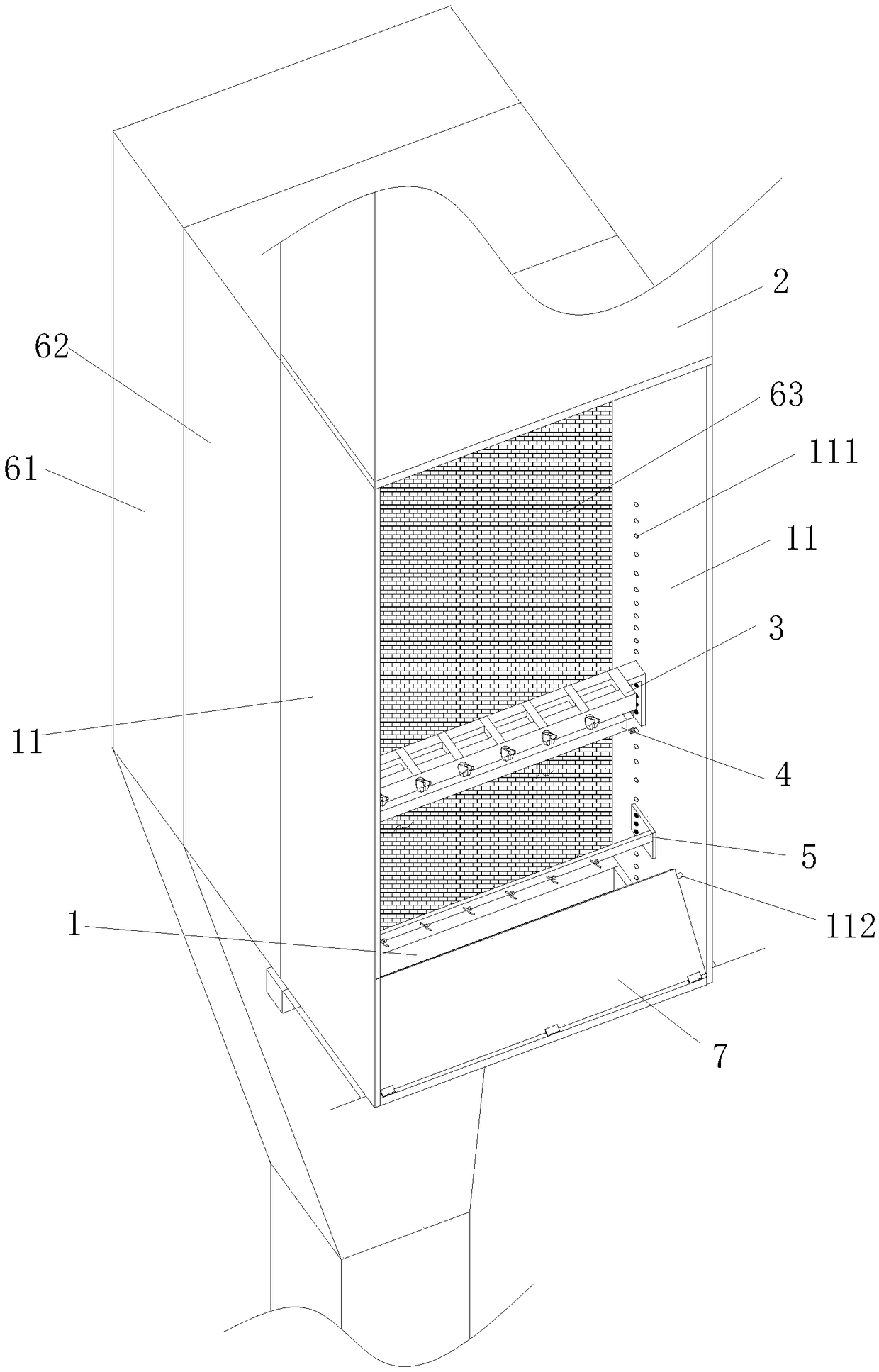

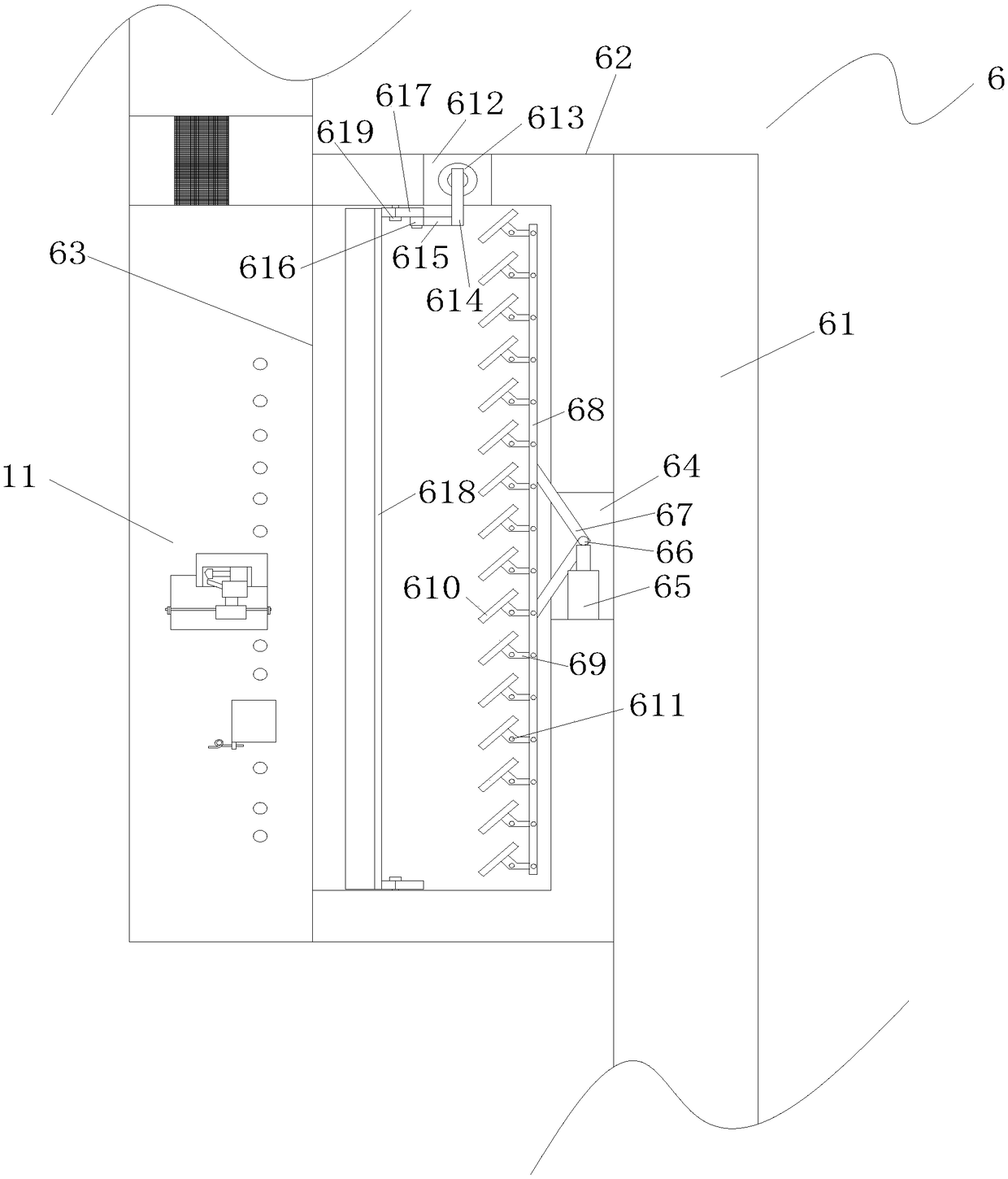

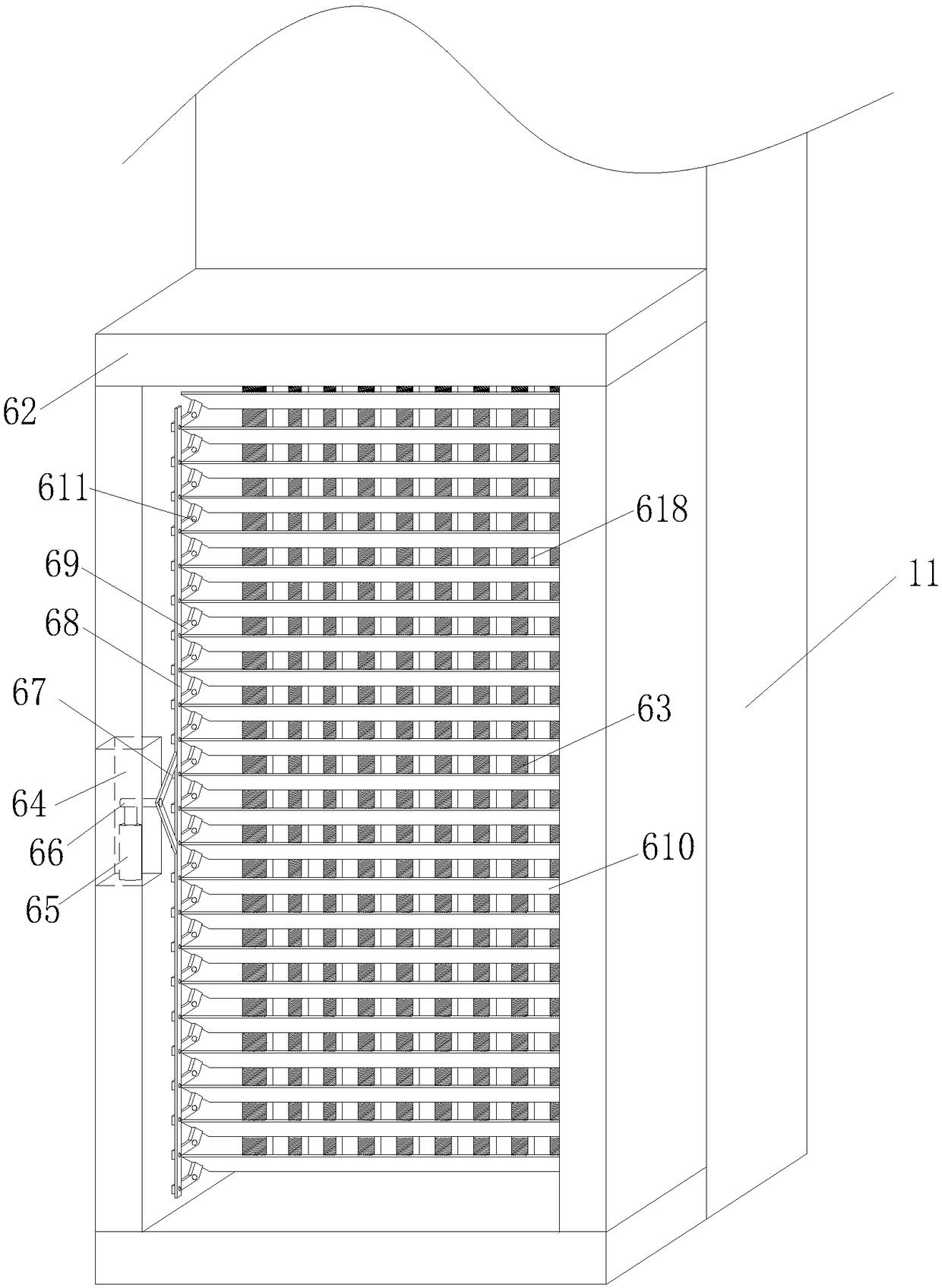

Unmanned automatic production equipment for wool-like nylon filament

The invention provides unmanned automated production equipment for wool-like polyamide filaments. The equipment comprises support plates arranged on two sides of a well mouth. Tops of the two supportplates are equipped with a spinning side-blowing air box. Multiple special-shaped sectional spinneret plates with spinneret holes are arranged in the spinning side-blowing air box. The spinneret holesare rectangular. A cooling air direction adjusting assembly is arranged behind the two support plates. The cooling air direction adjusting assembly is used for adjusting air direction and speed of cooling air such that set angles are formed between filament sections extruded by the spinneret holes of the special-shaped sectional spinneret plates and a spinning window. With surfaces of the supportplates as the basis, air blowing angles range from 30 to 60 degrees. Air speed ranges from 0.3M / S to 0.5M / S. therefore, the overall filament sections are not uniformly cooled. Cooled filaments are oiled when passing through a spinning nozzle support frame, fixed by stretching through a filament guiding assembly and then roll into the wool-like polyamide filaments. The unmanned automated production equipment can produce the wool-like polyamide filaments which have stiffness or rigidity of wool and are elastically bent.

Owner:FUJIAN JINJIANG TECH

Health-care quilt capable of relieving rheumatism and preparation method thereof

InactiveCN106263890APhase transition temperature is suitableImprove mechanical propertiesBlanketBed linenRadix AconitiKapok fiber

The invention discloses a health-care quilt capable of relieving rheumatism. The health-care quilt capable of relieving rheumatism comprises a quilt cover, a quilt core fixing cover and a quilt core filler, wherein the quilt core filler is prepared from the following raw materials in parts by weight: 10 to 15 parts of ramie fiber, 10 to 15 parts of kapok fiber, 2 to 4 parts of radix et rhizoma rhei, 2 to 4 parts of white paeony root, 1 to 2 parts of radix aconiti, 2 to 4 parts of saffron crocus, 1 to 2 parts of phryma leptostachya, 1 to 2 parts of rhizoma gastrodiae, 1 to 2 parts of achyranthes bidentata, 30 to 40 parts of polyethylene glycol terephthalate, 0.5 to 1 part of polyethylene glycol oleate and 10 to 15 parts of a functional additive. The health-care quilt provided by the invention has an intelligent temperature adjusting function, high warm-keeping and air-permeable properties, heat resistance, ageing resistance, high comfortable degree of a human body and high use usability, has health-care effects of purifying air and promoting metabolism of the human body, has the effects of dispelling wind, eliminating dampness, activating meridians and relieving pain, can effectively relieve rheumatism, integrates environmentally-friendly, warm-keeping and health-care functions, and meets the market requirements at a higher level.

Owner:安徽军民被装保障有限公司

A kind of Chinese herbal medicine cervical curvature health care pillow

ActiveCN106724518BAvoid coldAvoid cervical problemsPillowsSenses disorderVertebraVeterinary medicine

The invention discloses a Chinese herbal cervical vertebra curvature health care pillow, which includes a neck pillow and a head pillow. The neck pillow includes a first neck pillow, a second neck pillow, a third neck pillow and a fourth neck pillow. The four neck pillows have two Two juxtaposed ones are located on the left and right sides of the headrest, and the height of the four neck pillows is greater than the height of the headrest; the neck pillow and the headrest are composed of a jacket and a Chinese herbal medicine bag located in the jacket; the four neck pillows between the neck pillow and the head pillow are sutured and fixed. This invention is designed based on the length and thickness of the neck and combined with the physiological and pathological characteristics of the human cervical spine. The unique convex surface of the neck pillow and the groove design of the headrest better fit the natural curves of the cervical spine and head, allowing the neck to be more evenly supported. Prevent the curvature of the cervical spine from being destroyed and effectively protect the health of the cervical spine.

Owner:郭振海

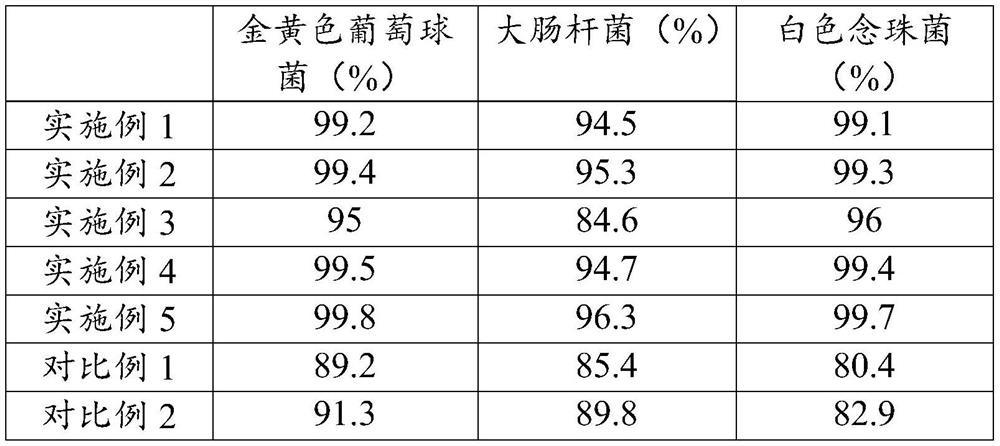

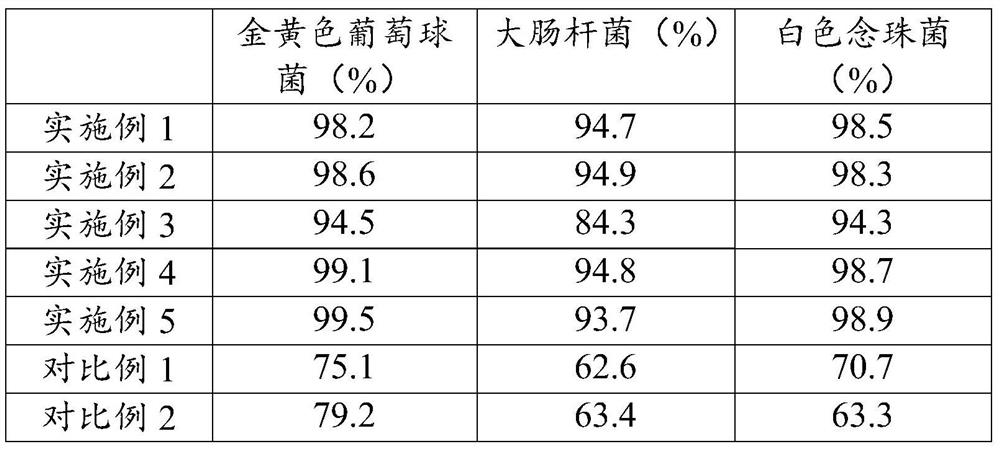

Cowhide collagen multifunctional health socks and its preparation method and application

ActiveCN108236133BMoisturizing and anti-crackingWarm and breathableWeft knittingHandkerchiefsBiotechnologyAnti bacterial

The invention provides a cattlehide collagen multifunctional health maintenance sock as well as a preparation method and application thereof and relates to the technical field of weaving of socks. Thehealth maintenance sock takes cattlehide collagen fibers as a functional component and has multiple effects of resisting to bacteria and removing odor, moisturizing and controlling crack, keeping warm and ventilating as well as nourishing skin. The preparation method of the cattlehide collagen multifunctional health maintenance sock comprises the step of weaving cattlehide collagen fiber blendedyarns to obtain the health maintenance sock. The preparation method takes the cattlehide collagen fibers as a raw material and the functional component, so that the health maintenance function of theobtained health maintenance sock is durable. The cattlehide collagen multifunctional health maintenance sock has durability when being applied to remission of dermatophytosis, antisepsis and deodorization as well as podoschisis prevention and can not lose effect after being washed for multiple times. The invention solves the technical problem that a natural multifunctional durable health maintenance sock and a preparation method do not exist in the prior art.

Owner:嘉兴奥克兰特种牛皮科技有限公司

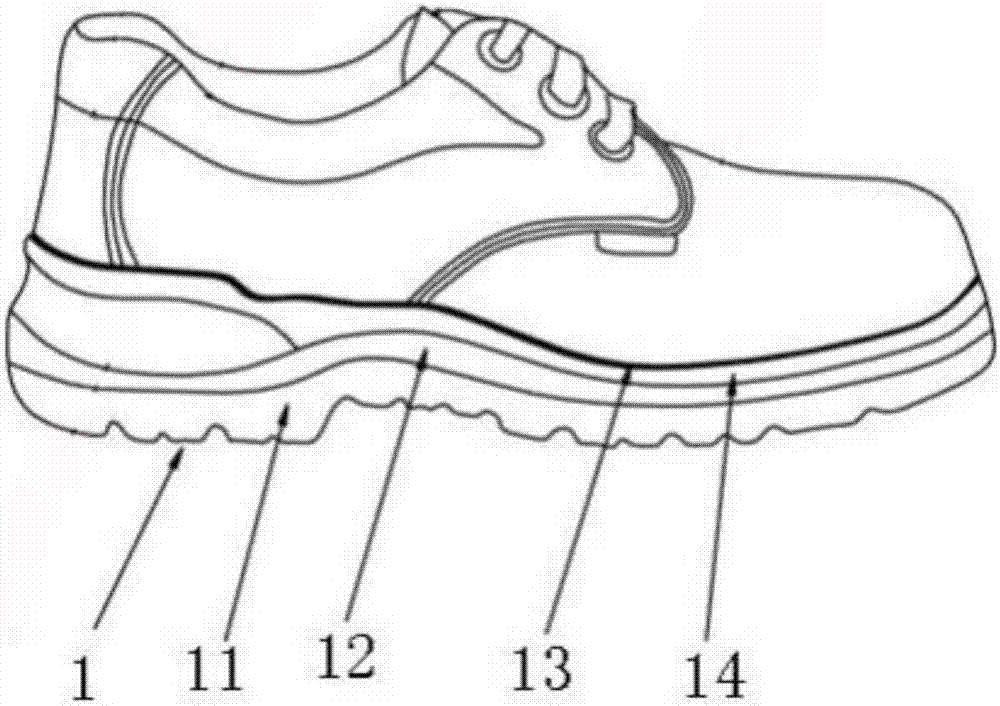

multifunctional protective shoes

The invention discloses a multifunctional protective shoe, which includes a shoe sole. From bottom up, the sole comprises an insulating layer lower bottom, an insulating layer upper bottom and an elastic buffer layer arranged under an insole. Molded antiskid lines formed by combination of profile isosceles right triangles and obtuse triangles are distributed on the outer surface of the insulating lower bottom, the insulating layer lower bottom comprises the following raw materials: chloroprene rubber, nitrile butadiene rubber, styrene-butadiene rubber, a composite accelerant, organic montmorillonite, N-methylene carboxyl-2-benzothiazole sulfenamide, sulfur, high aromatic oil, 1, 2-ethylene thiourea, mica powder, low temperature calcined kaolin, diethylene glycol and the like. All the components can reach synergistic effect, good compatibility, strong interface bonding strength, excellent insulation effect, good flame retardant performance, and the multifunctional protective shoe has good high and low temperature resistance and waterproof and antiskid performance, at the same time has greatly improved acid-base resistance, oil resistance and corrosion resistance, is wear resistant and does not deform, and also meets the requirements for functionality and comfortableness.

Owner:JIHUA 3539 SHOE MAKING

Unmanned automated production equipment for wool-like polyamide filaments

The invention provides unmanned automated production equipment for wool-like polyamide filaments. The equipment comprises support plates arranged on two sides of a well mouth. Tops of the two supportplates are equipped with a spinning side-blowing air box. Multiple special-shaped sectional spinneret plates with spinneret holes are arranged in the spinning side-blowing air box. The spinneret holesare rectangular. A cooling air direction adjusting assembly is arranged behind the two support plates. The cooling air direction adjusting assembly is used for adjusting air direction and speed of cooling air such that set angles are formed between filament sections extruded by the spinneret holes of the special-shaped sectional spinneret plates and a spinning window. With surfaces of the supportplates as the basis, air blowing angles range from 30 to 60 degrees. Air speed ranges from 0.3M / S to 0.5M / S. therefore, the overall filament sections are not uniformly cooled. Cooled filaments are oiled when passing through a spinning nozzle support frame, fixed by stretching through a filament guiding assembly and then roll into the wool-like polyamide filaments. The unmanned automated production equipment can produce the wool-like polyamide filaments which have stiffness or rigidity of wool and are elastically bent.

Owner:FUJIAN JINJIANG TECH

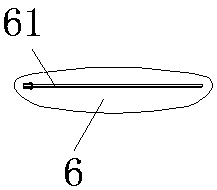

Household bed sheet health care cloth

ActiveCN108688255AImprove surface comfortStrong warmth retentionSynthetic resin layered productsSurface layerWear resistant

The invention discloses a household bed sheet health care cloth, which comprises following layers from top to bottom: a fabric surface layer, a warm keeping cloth layer, a cloth basic layer, and a bottom cloth layer. The peripheral edge of the fabric surface layer is connected to the peripheral edge of the warm keeping cloth layer through stitching; the peripheral edge of the warm keeping cloth layer is connected to the peripheral edge of the cloth basic layer through stitching; the peripheral edge of the cloth basic layer is connected to the peripheral edge of the bottom cloth layer through stitching; the lower surface of the bottom cloth layer is provided with a plurality of block shaped cloth; and three edges of each block shaped cloth are all connected to the bottom cloth layer throughstitching. Through an electric heating sheet, health care medicines in a health care bag are heated to achieve an effect of traditional Chinese medicine fumigation. The health care cloth has a good medical and health care effect, is comfortable and elastic, has a strong warm keeping performance, and has the antibacterial, wear-resistant, warm keeping and breathable functions.

Owner:江苏正大易方科技有限公司

Bamboo carbon fiber cushion core with infrared function and preparation method thereof

PendingCN109677049APromote blood circulationImprove joint painStuffed mattressesLamination ancillary operationsCushionThermistor

The invention provides a bamboo carbon fiber cushion core with an infrared function and a preparation method thereof. The bamboo carbon fiber cushion core includes a first bamboo skin grid cloth layer, a bamboo chip grid cloth layer, a far infrared functional layer, a composite fiber felt layer and a second bamboo skin grid cloth layer, and the first bamboo skin grid cloth layer, the bamboo chip grid cloth layer, the far infrared functional layer, the composite fiber felt layer and the second bamboo skin grid cloth layer are successively arranged from top to bottom; the first bamboo skin gridcloth layer the second bamboo skin grid cloth layer include a plurality of pieces of bamboo skin grid cloths correspondingly, and the bamboo chip grid cloth layer includes a plurality of pieces of bamboo chip grid cloths; and the far infrared functional layer is obtained by successive series connection of a power supply, an alternating current / direct current converter, a temperature controller, atime controller, a thermistor, and bamboo fibers and a carbon fiber composite felt layer. According to the bamboo carbon fiber cushion core, the characteristics of softness and comfortableness, earthquake resistance, thermal resistance, moisture preservation and the like, far infrared rays produced by carbon fibers of the bamboo carbon fiber cushion core has the health care effects of circulatorysystem improvement, autonomic nerve adjustment, immune function improvement, antiphlogosis and the like.

Owner:CHONGQING SHENGFANG NEW MATERIALS TECH CO LTD +1

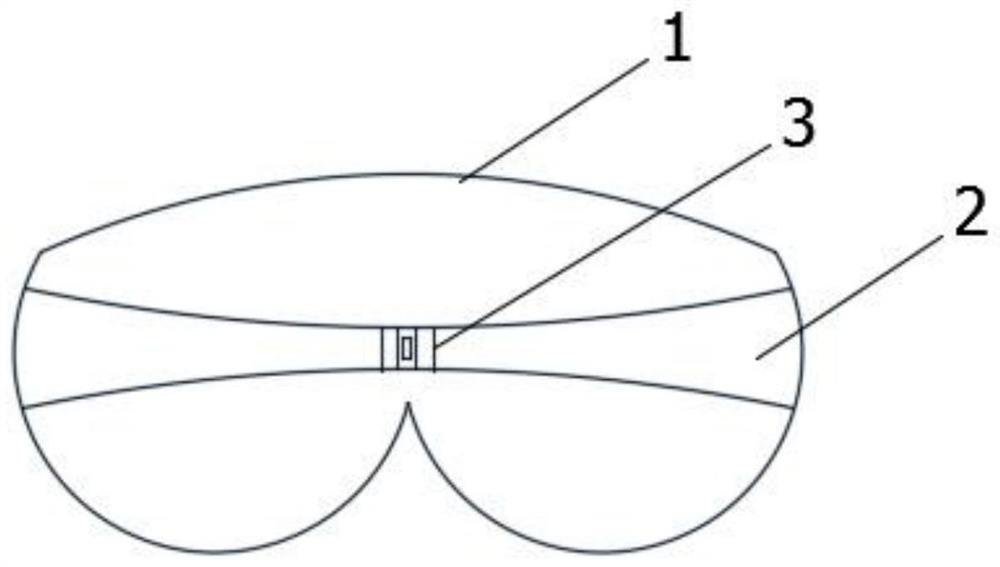

Alkene magnetic eyeshade

The invention discloses an olefinic magnetic eyeshade which comprises a binding band and an eyeshade body, each side edge of the eyeshade body is connected with the binding band in a two-point fixingmode, and the eyeshade body comprises a first surface layer made of emulation silk fabric and used for preventing dust, a second layer made of a graphene flocculus layer and used for heating, a thirdlayer made of a plurality of magnets arranged according to acupuncture points around the eyes and used for generating a micro magnetic field, and a bottom layer made of knitted fabric, in direct contact with eyes of a person and used for shading; an adjusting buckle is mounted on the bandage; and the second layer made of the graphene flocculus layer is heated through far infrared heating. According to the eyeshade, the two sides of the eyeshade are evenly stressed in a two-point fixing mode, the situation that eyes are tightened due to single-point fixing is avoided, the bandage is provided with the adjusting buckle, adjustment can be convenient, the graphene flocculus layer and the magnet layer are arranged, the eyes can be relaxed, and fatigue is relieved.

Owner:深睡(天津)科技发展有限公司

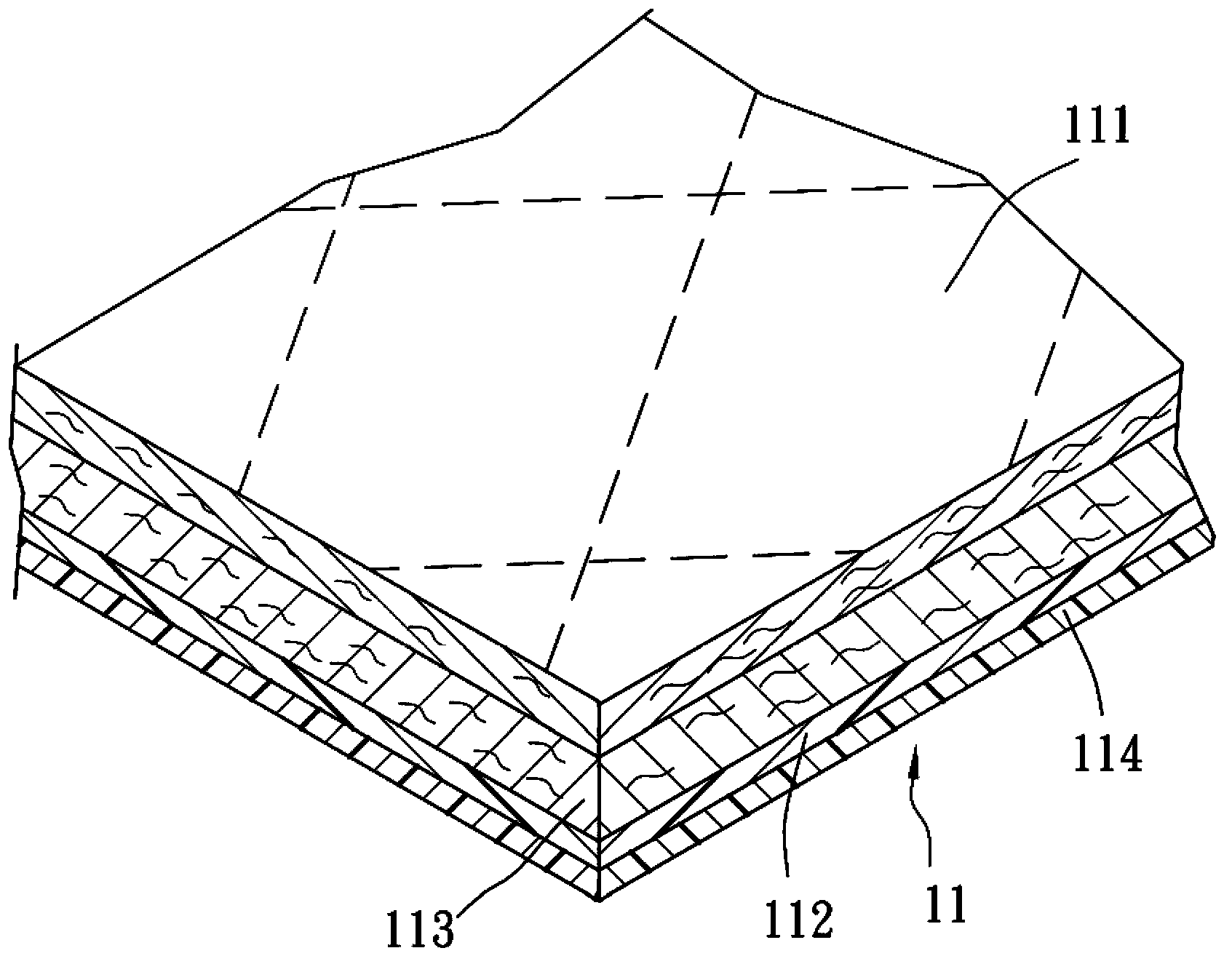

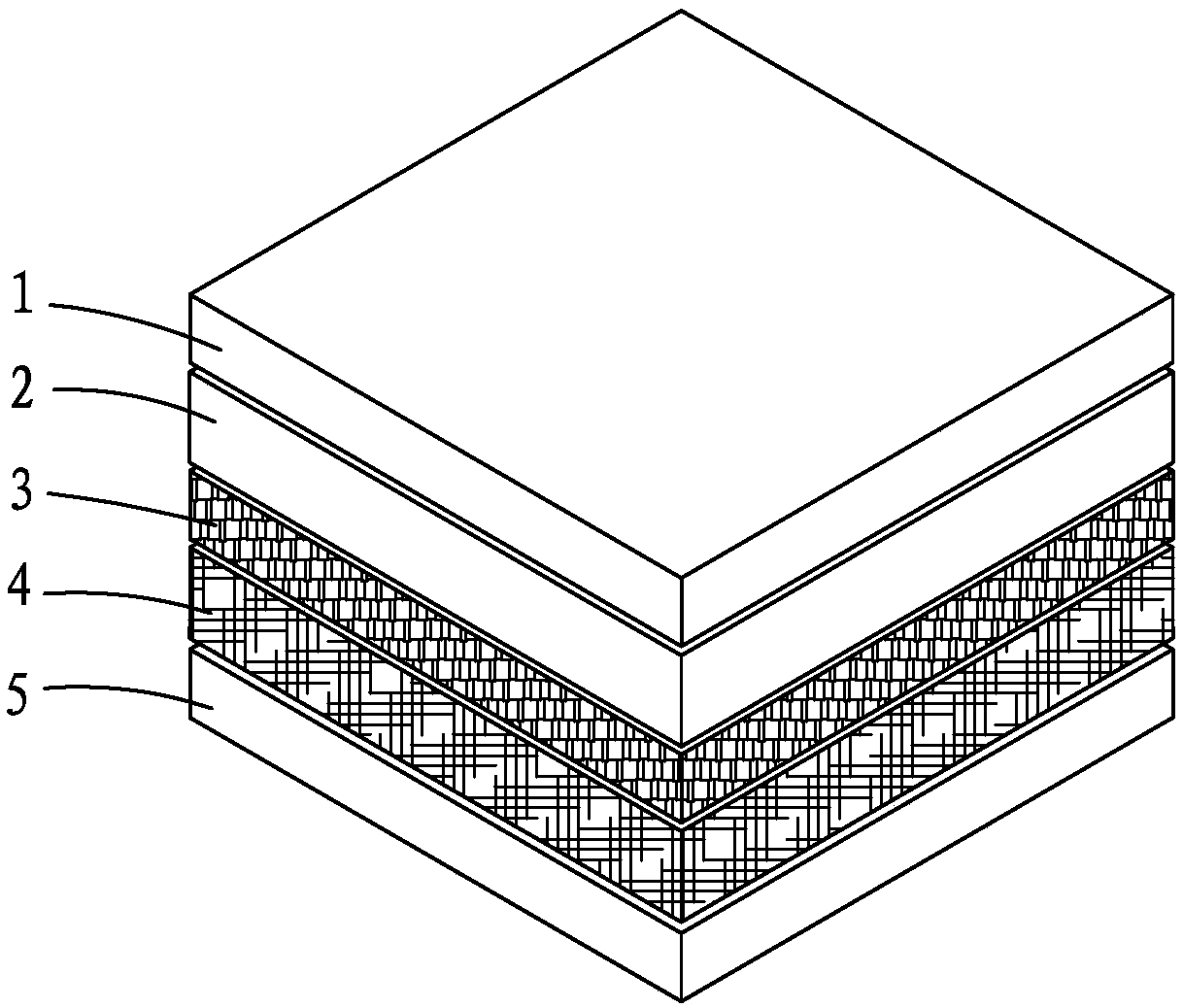

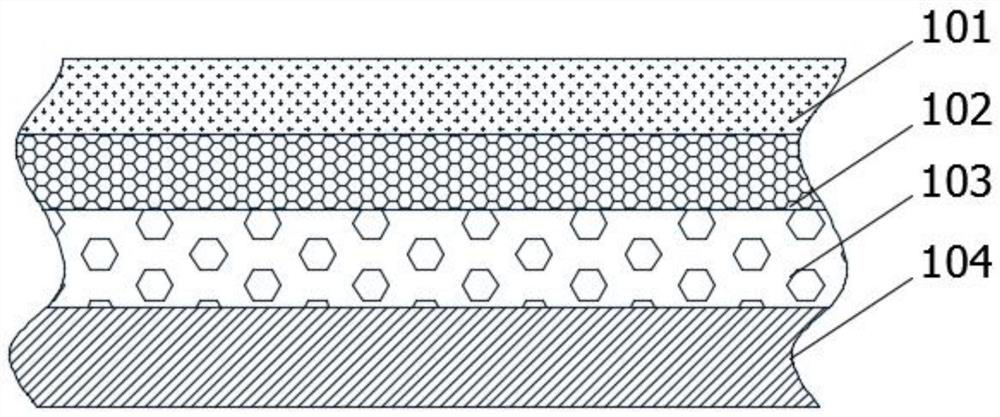

A bionic thermal insulation composite fabric

ActiveCN107443822BSoft touchReduce quality problemsSynthetic resin layered productsClothingsSolid structurePermeation

The invention discloses a biomimetic heat-preservation composite fabric which comprises at least two unit layers overlapped layer by layer, wherein each unit layer comprises a particle layer, a film layer and a base layer from top to bottom sequentially; the top surface of the base layer is adhered to the bottom surface of the film layer, the top surface of the film layer is adhered to the bottom surface of the particle layer, the particle layer comprises multiple micron-sized particles, the film layer is a breathable film with pores in the outer surface, the bottom surface of the particle layer and the top surface of the film layer permeate each other to form a permeation layer, the permeation layer comprises multiple capsules, each capsule comprises an air capsule and particles arranged therein, the outer capsule skin of the air capsule belongs to the film layer, and each particle is a hollow or solid structure and can be a calcium oxalate crystal particle. By such a design, not only can the advantages of lightweight, thinness, warmth keeping and breathability of the fabric be combined, but also the advantages of fine and soft touch, acid, alkali and high temperature resistance and insolubility in water can be achieved.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com