A bionic thermal insulation composite fabric

A thermal insulation composite and fabric technology, applied in the field of textile fabrics, can solve the problems of reducing the weight and thickness of fabrics, and achieve the effects of improving thermal retention, reducing overall quality, and thermal and breathable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

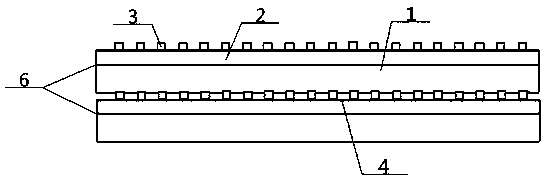

[0044] see figure 1 and figure 2 , a bionic thermal insulation composite fabric, comprising at least two unit layers 6 stacked layer by layer, the unit layer 6 is a layered structure; the unit layer 6 sequentially includes a particle layer 3, a film layer 2, and a base layer from top to bottom 1. The top surface of the base layer 1 is bonded to the bottom surface of the film layer 2, and the top surface of the film layer 2 is bonded to the bottom surface of the particle layer 3. The particle layer 3 is composed of a plurality of micron-sized particles 31, The membrane layer 2 is a gas-permeable membrane whose outer surface is provided with pores; the bottom surface of the particle layer 3 and the top surface of the membrane layer 2 penetrate each other to form a permeable layer 4, and the permeable layer 4 includes a plurality of capsule bodies 5. The body 5 includes an air capsule 51 and the particles 31 inside it, and the outer skin 52 of the air capsule 51 belongs to the ...

Embodiment 2

[0046] Basic content is the same as embodiment 1, the difference is:

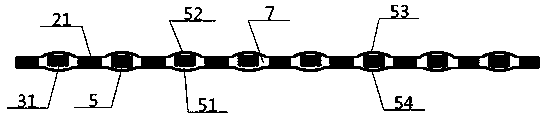

[0047] The outer capsule skin 52 of the air capsule 51 includes an upper capsule skin 53 and a lower capsule skin 54, the upper capsule skin 53 and the lower capsule skin 54 all belong to the film layer 2, and there is a gap between the upper capsule skin 53 and the lower capsule skin 54. An air capsule 51 containing still air 7 , the inside of which is provided with particles 31 . Preferably, the capsules 5 are arranged at intervals, and a spacer film block 21 is arranged between adjacent capsule bodies 5 , and the spacer film block 21 belongs to the film layer 2 .

Embodiment 3

[0049] Basic content is the same as embodiment 1, the difference is:

[0050] The particle 31 is a hollow or solid structure; when the particle 31 is a hollow structure, the volume of the inner cavity of the particle 31 is greater than the volume of the outer wall of the particle 31 . When the particle 31 is a hollow structure, its shape is preferably a sphere, an ellipsoid, an olive or other spheroids. When the particles 31 have a solid structure, preferably the particles 31 are micron-sized calcium oxalate crystal particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com