A kind of ultra-light moisture-absorbing and sweat-wicking double-sided weft-knitted square fabric and its production method

A moisture-absorbing, sweat-wicking, ultra-lightweight technology, applied in weft knitting, dyeing, fabric surface trimming, etc., can solve problems such as the inability to meet the needs of clothing fabrics, and achieve a fashionable, quick-drying effect, and good moisture conduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

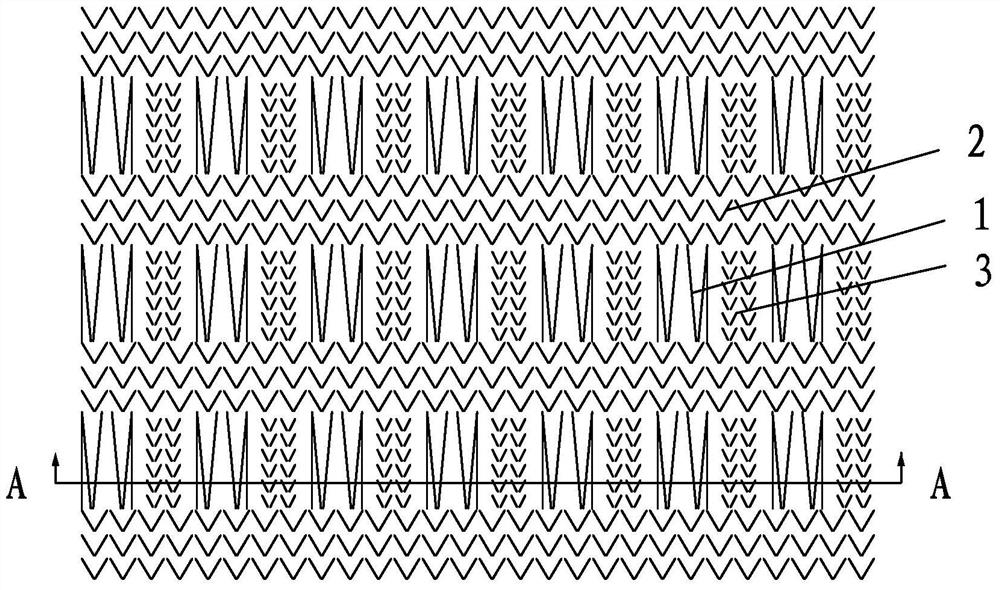

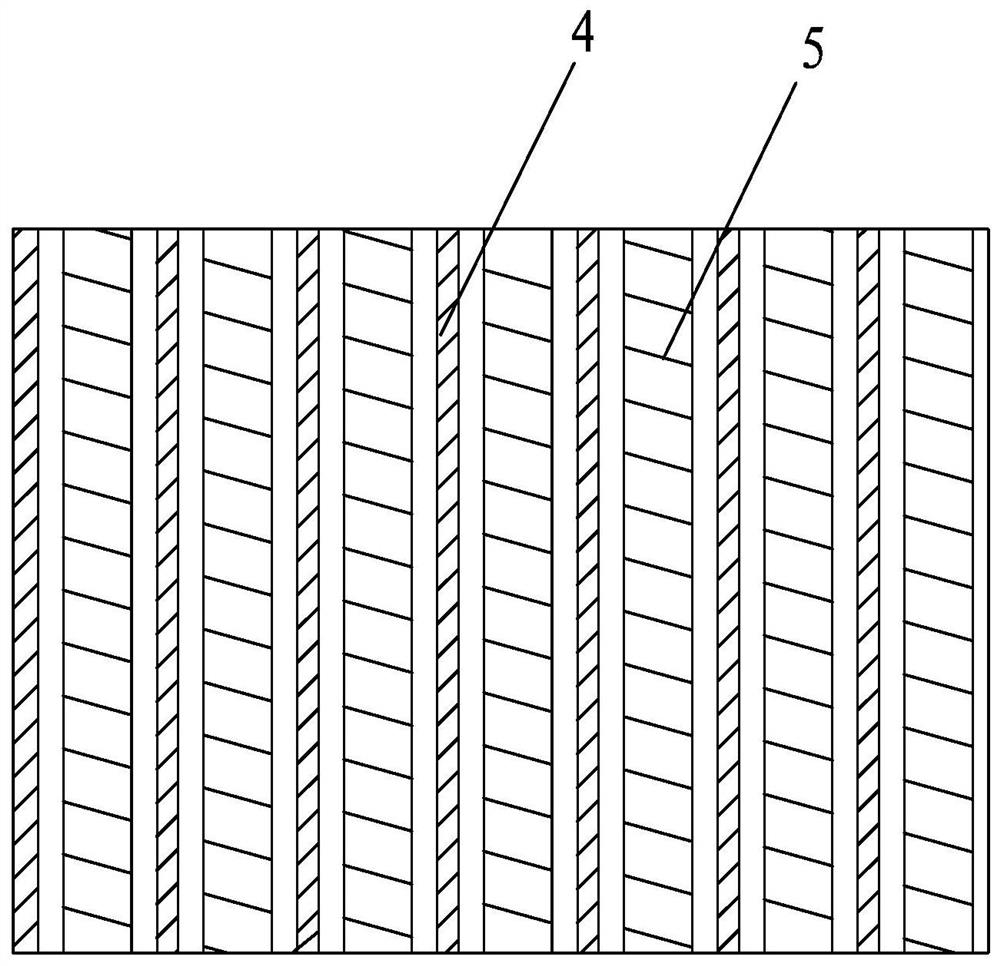

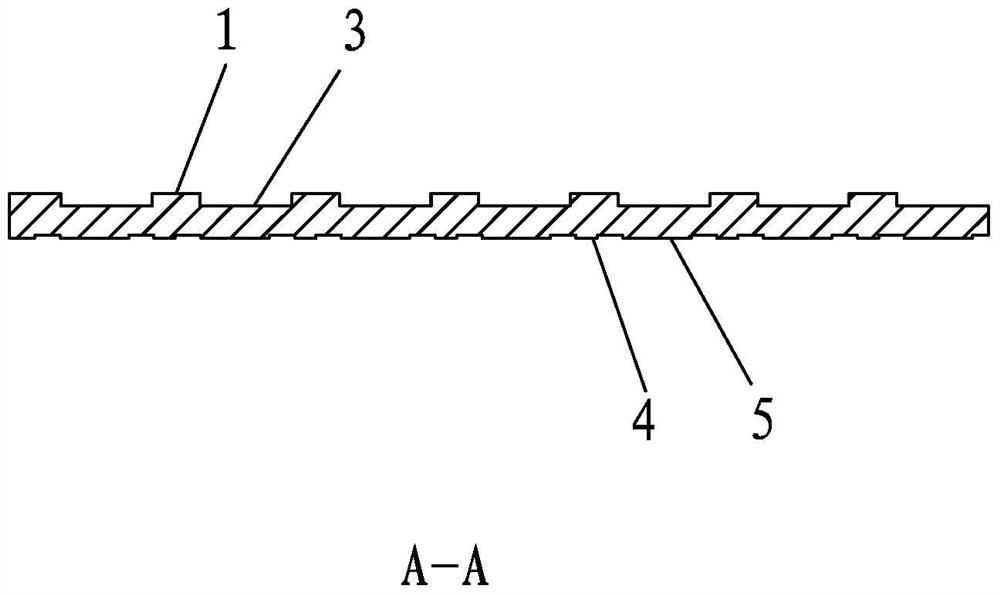

[0056] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0057] like figure 1 and figure 2 shown, an ultra-lightweight moisture-wicking double-sided weft-knitted checkered fabric composed of 50D / 48F fine denier polyester filament and 50D / 48F fine-denier polyester Stretch yarn interwoven, treated and finished with a moisture-wicking finishing aid.

[0058] The mass ratio of the fine denier polyester filament to the fine denier polyester elastic yarn is 65%:35%. What needs to be explained here is that the above-mentioned raw materials and mass ratios are used for weaving, so that the woven double-sided weft knitted fabric has a gram weight per square meter of less than 100, and both sides of the fabric have concave-convex structures and effects.

[0059] In this embodiment, as Figure 1-3 As shown, the ultra-light moisture-wicking double-sided weft-knitted fabric has a fabric layer, and the fabric l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com