Anti-wrinkle imitated silk fabric and processing technology thereof

A technology of imitating silk and fabrics, applied in the direction of filament/thread forming, knitting, fiber type, etc., which can solve the problems of poor elasticity and easy wrinkling, and achieve the effects of low cost, good moisture absorption and perspiration, and improved anti-wrinkle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

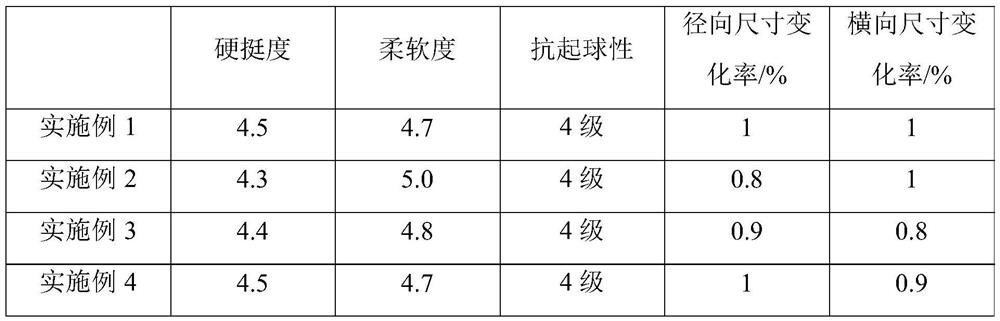

Examples

Embodiment 1

[0021] A kind of anti-wrinkle imitation silk fabric and its processing technology

[0022] Anti-wrinkle imitation silk fabric, the fabric is made of composite yarn of anti-wrinkle PET fiber filament and spandex core-spun yarn and real silk yarn, the composite filament of the anti-wrinkle PET fiber filament and spandex core-spun yarn is located on the outside of the fabric, and the real silk The yarn is located on the inner side of the fabric, and the composite yarn of the anti-wrinkle PET fiber filament and the spandex core-spun yarn completely covers the real silk yarn.

[0023] The mass ratio of the wrinkle-resistant PET fiber filament to the spandex core-spun yarn in the composite yarn of the above-mentioned anti-wrinkle PET fiber filament and spandex core-spun yarn is 2:1. The preparation of the above-mentioned crease-resistant PET fiber filaments includes the following steps: putting the PET slices and viscose fibers into an oven for drying and pretreatment respectively; ...

Embodiment 2

[0031] A kind of anti-wrinkle imitation silk fabric and its processing technology

[0032] Anti-wrinkle imitation silk fabric, the fabric is made of composite yarn of anti-wrinkle PET fiber filament and spandex core-spun yarn and real silk yarn, the composite filament of the anti-wrinkle PET fiber filament and spandex core-spun yarn is located on the outside of the fabric, and the real silk The yarn is located on the inner side of the fabric, and the composite yarn of the anti-wrinkle PET fiber filament and the spandex core-spun yarn completely covers the real silk yarn.

[0033] The mass ratio of the wrinkle-resistant PET fiber filament to the spandex core-spun yarn in the composite yarn of the above-mentioned anti-wrinkle PET fiber filament and spandex core-spun yarn is 2.5:1.5. The preparation of the above-mentioned crease-resistant PET fiber filaments includes the following steps: putting the PET slices and viscose fibers into an oven for drying and pretreatment respective...

Embodiment 3

[0042] A kind of anti-wrinkle imitation silk fabric and its processing technology

[0043] Anti-wrinkle imitation silk fabric, the fabric is made of composite yarn of anti-wrinkle PET fiber filament and spandex core-spun yarn and real silk yarn, the composite filament of the anti-wrinkle PET fiber filament and spandex core-spun yarn is located on the outside of the fabric, and the real silk The yarn is located on the inner side of the fabric, and the composite yarn of the anti-wrinkle PET fiber filament and the spandex core-spun yarn completely covers the real silk yarn.

[0044] The mass ratio of the wrinkle-resistant PET fiber filament to the spandex core-spun yarn in the composite yarn of the above-mentioned anti-wrinkle PET fiber filament and spandex core-spun yarn is 3.5:2. The preparation of the above-mentioned crease-resistant PET fiber filaments includes the following steps: putting the PET slices and viscose fibers into an oven for drying and pretreatment respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com