Walk-needle control mechanism of computer transversal knitting machine

A technology of flat knitting machine and control mechanism, which is applied in weft knitting, knitting, textiles and papermaking, etc. It can solve the problems that the knitting efficiency cannot be really improved, the track of the needle selector is long, and automatic knitting cannot be realized, and the structure is simple. , high working stability, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

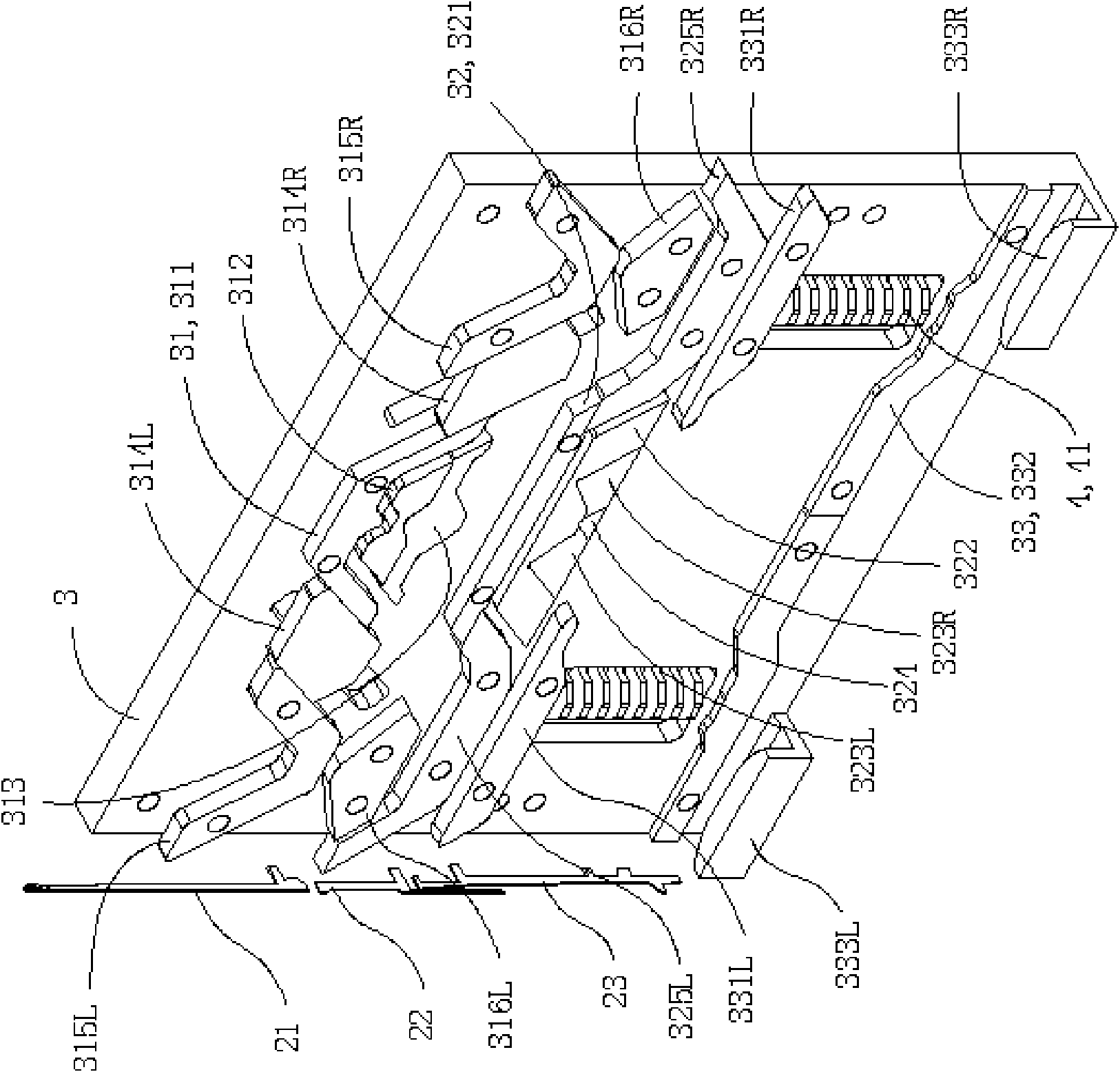

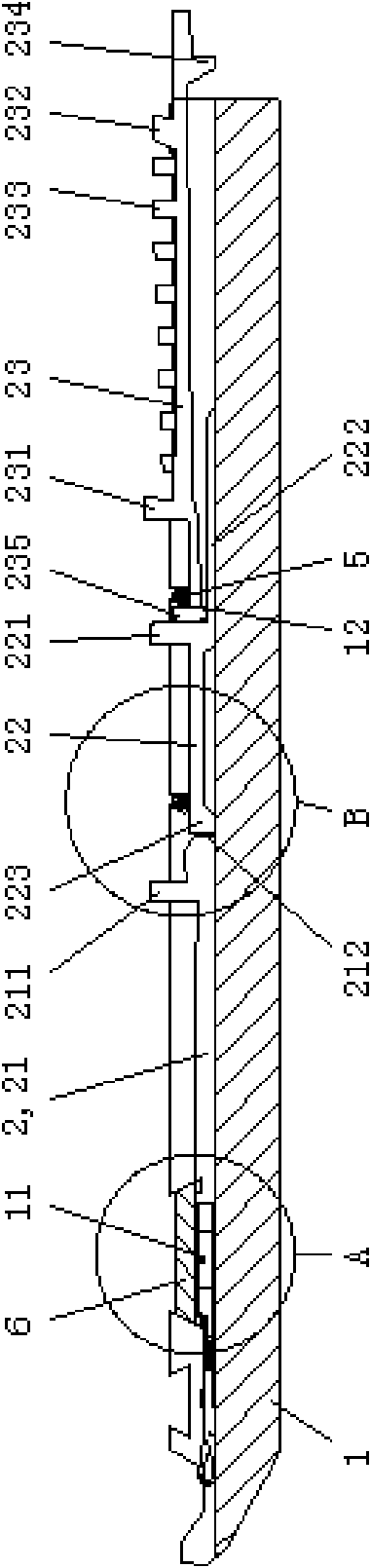

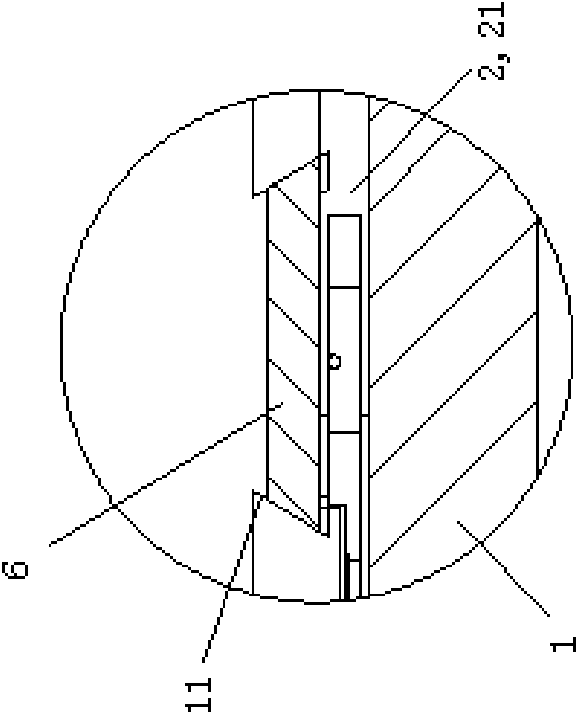

[0036] See Figure 1 to Figure 4, the present invention has a needle bed 1, a number of needle slots are arranged horizontally on the needle bed 1, and a group of knitting needle assemblies 2 that can move longitudinally and a cam that cooperates with the knitting needle assembly 2 is arranged on the top of the needle bed 1 in each needle slot. Bottom plate 3, each tissue needle assembly 2 includes knitting needles 21, pusher jacks 22 and needle selector jacks 23 arranged in sequence, the bottom of knitting needles 21 is provided with needle butt 211, and the tail is provided with a pushed part 212 perpendicular to its moving direction; The needle piece 22 is provided with a push butt 221, the front end is a rectangular push needle part 223, and the rear part is provided with a slender tail part 222 close to the bottom of the needle groove; the needle selector 23 is provided with an upper needle butt 231 and a lower needle butt. 232, selector butt 233 and reset heel 234, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com