Mold servo grabbing mechanism of intelligent robot welding assembly automatic production line tool

An automated production line and intelligent robot technology, applied in household appliances, other household appliances, household components, etc., can solve problems such as poor accuracy of product positioning, risk of personal injury, long mold change time, etc., to achieve large room for improvement and safety High, easy to take and place the effect of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

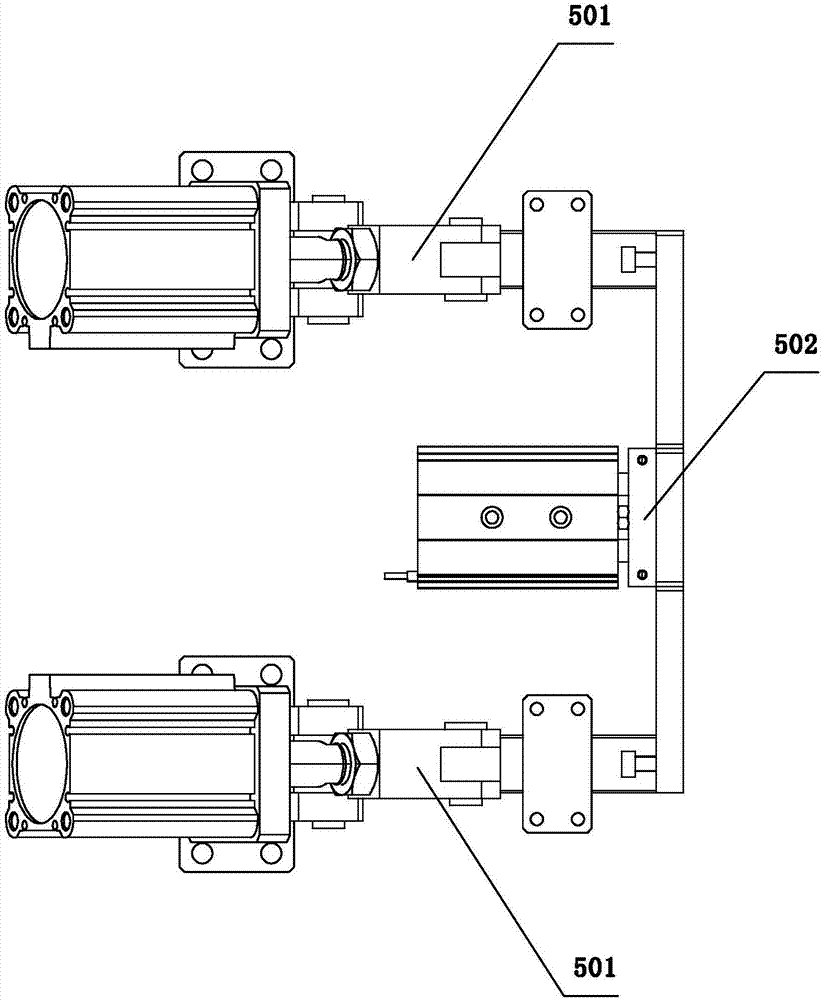

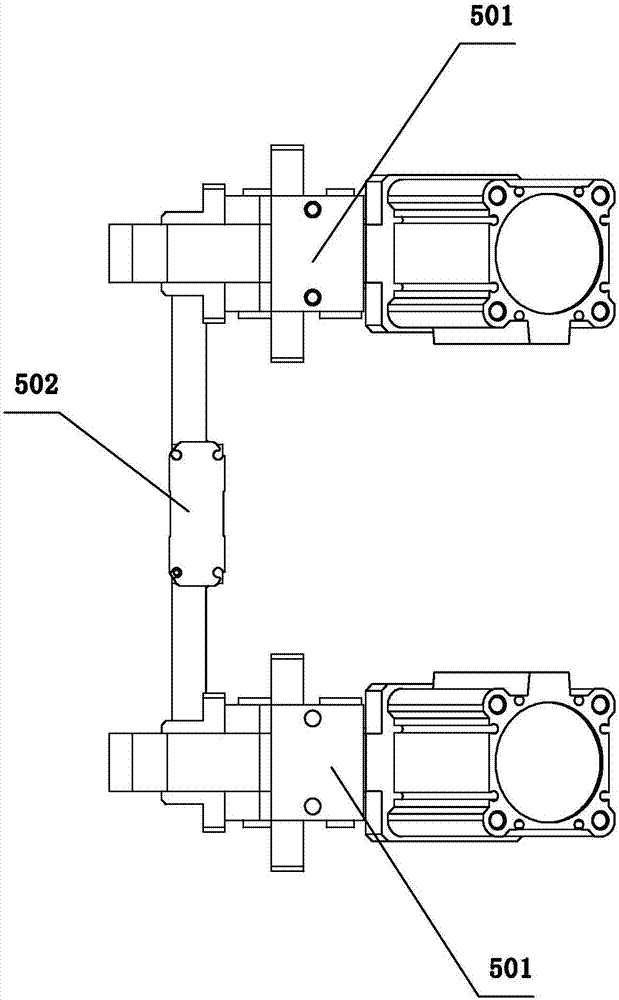

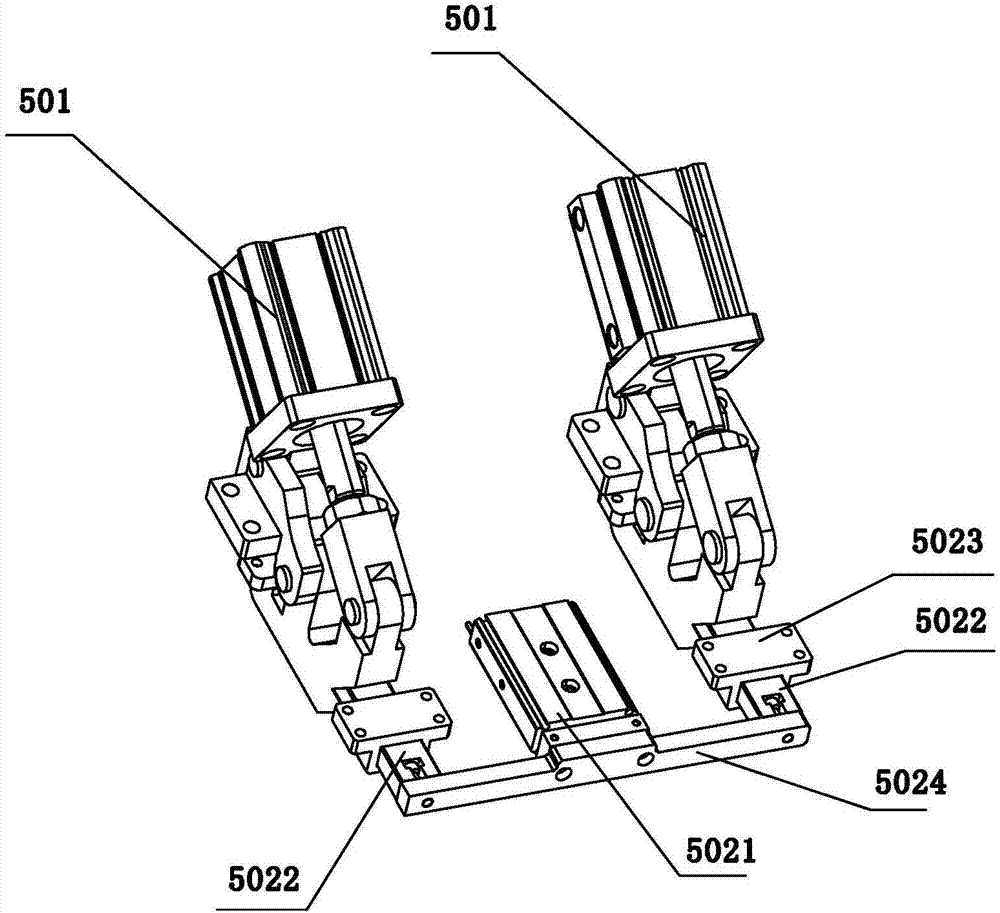

[0039] Such as Figure 1 to Figure 10 As shown, the intelligent robot welding assembly automation production line tooling mold servo grabbing mechanism includes a fixed bracket 1, a running bracket 2 and a transmission device 3, and the fixed bracket 1 is a double fixed bracket 1, including 2 sub-supports 101, 2 sub-supports The support 101 is divided on the two sides, and each of the two sub-supports 101 is provided with a rack 102, and the rack 102 is arranged longitudinally; the running support 2 includes a general support 201 and a base 202, and the transmission device 3 A gear 301 is arranged on each side, and the transmission device 3 is arranged on the running support 2, and the running support 2 and the fixed support 1 are connected through the transmission of the gear 301 and the rack 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com