Grabbing and press-fitting complete equipment with flexible adjustment function for producing pyrophyllite blocks for diamonds

A complete set of equipment, diamond technology, applied in the field of robots, can solve the problems of increasing production costs, not using robots yet, reducing production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

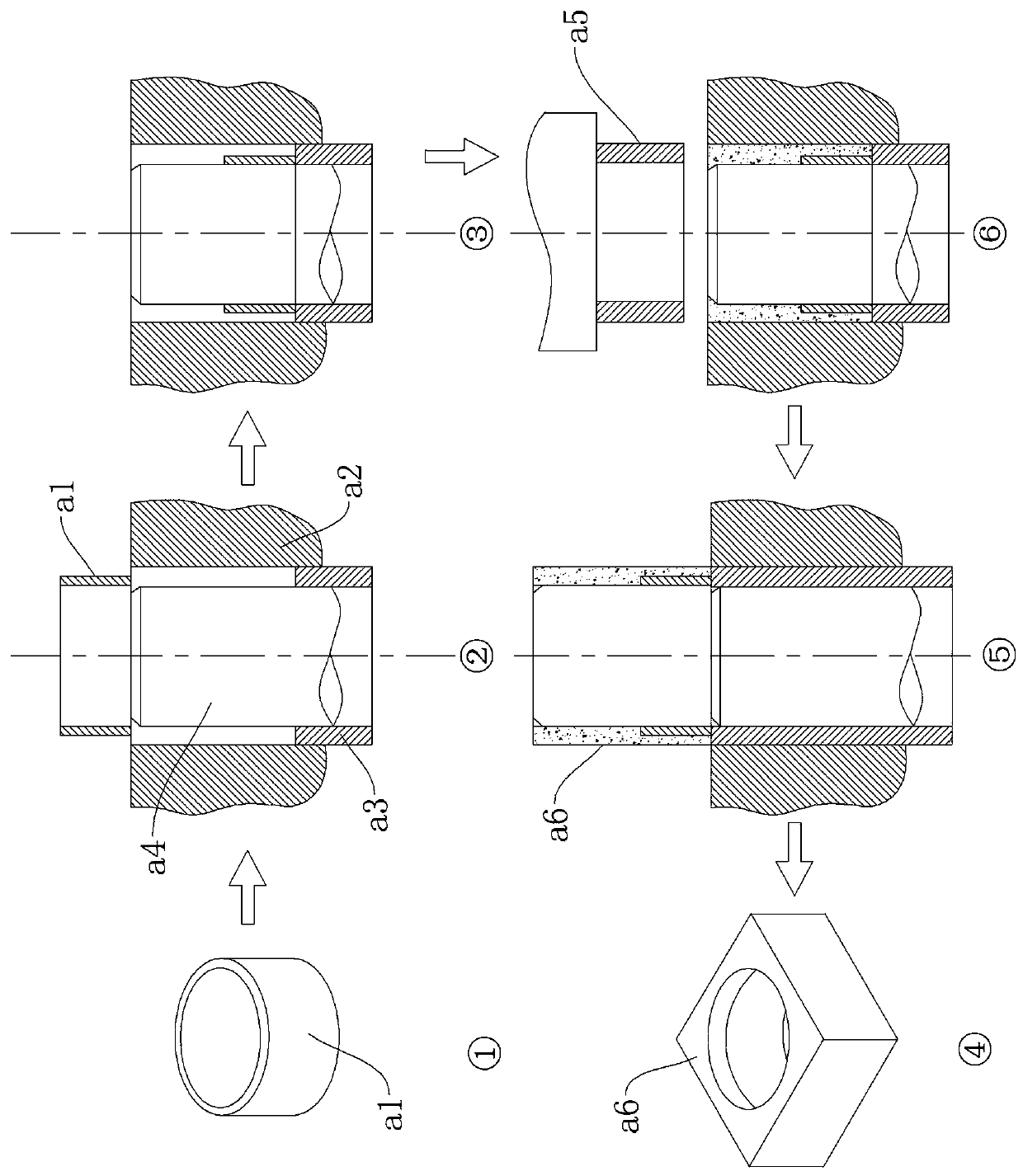

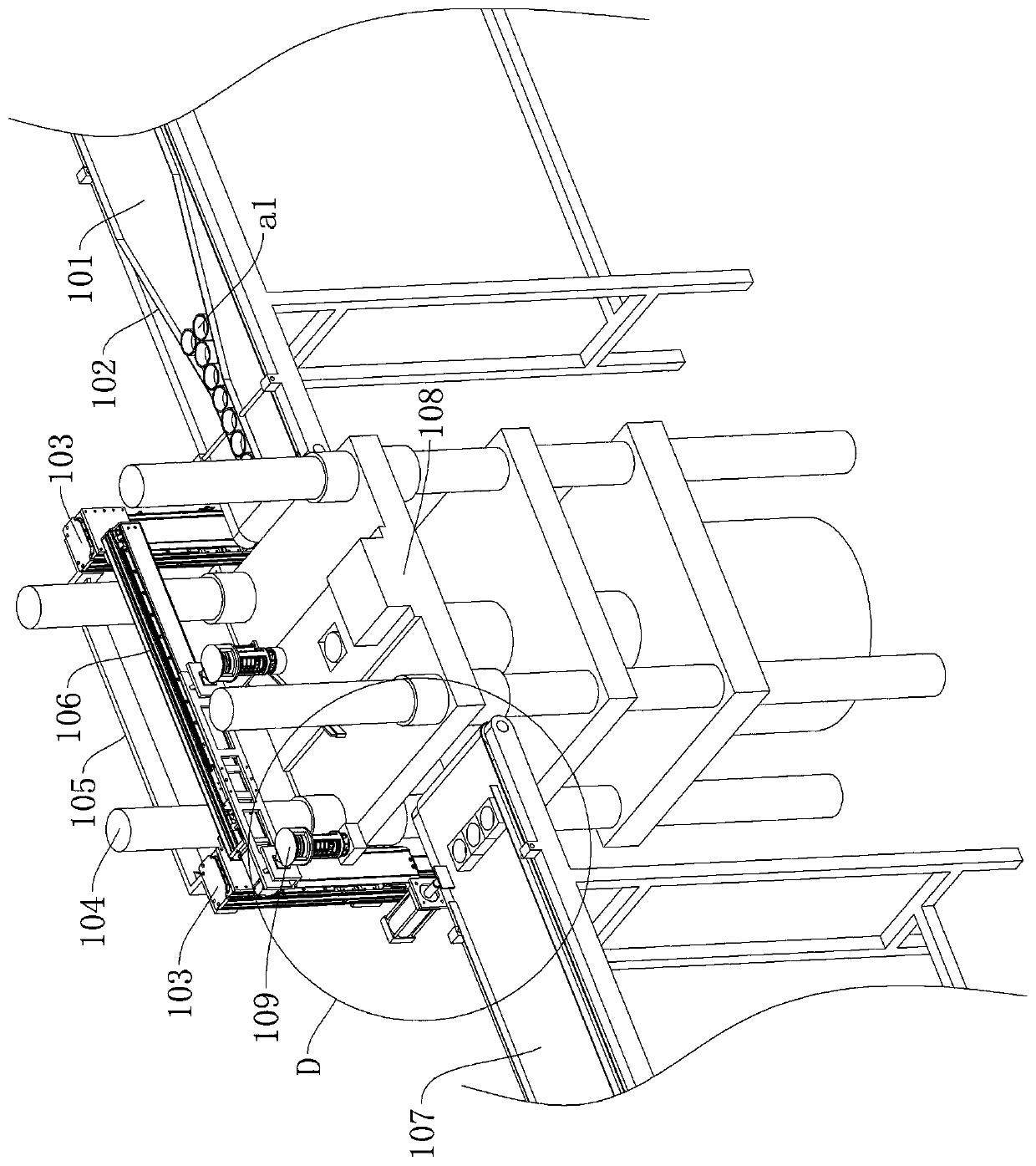

[0060] Embodiment one, see Figure 1-20 , which can realize the production of smooth and adjustable diamond pyrophyllite blocks, including the feeding belt, the feeding belt and the grabbing and pressing machine arranged in a straight line;

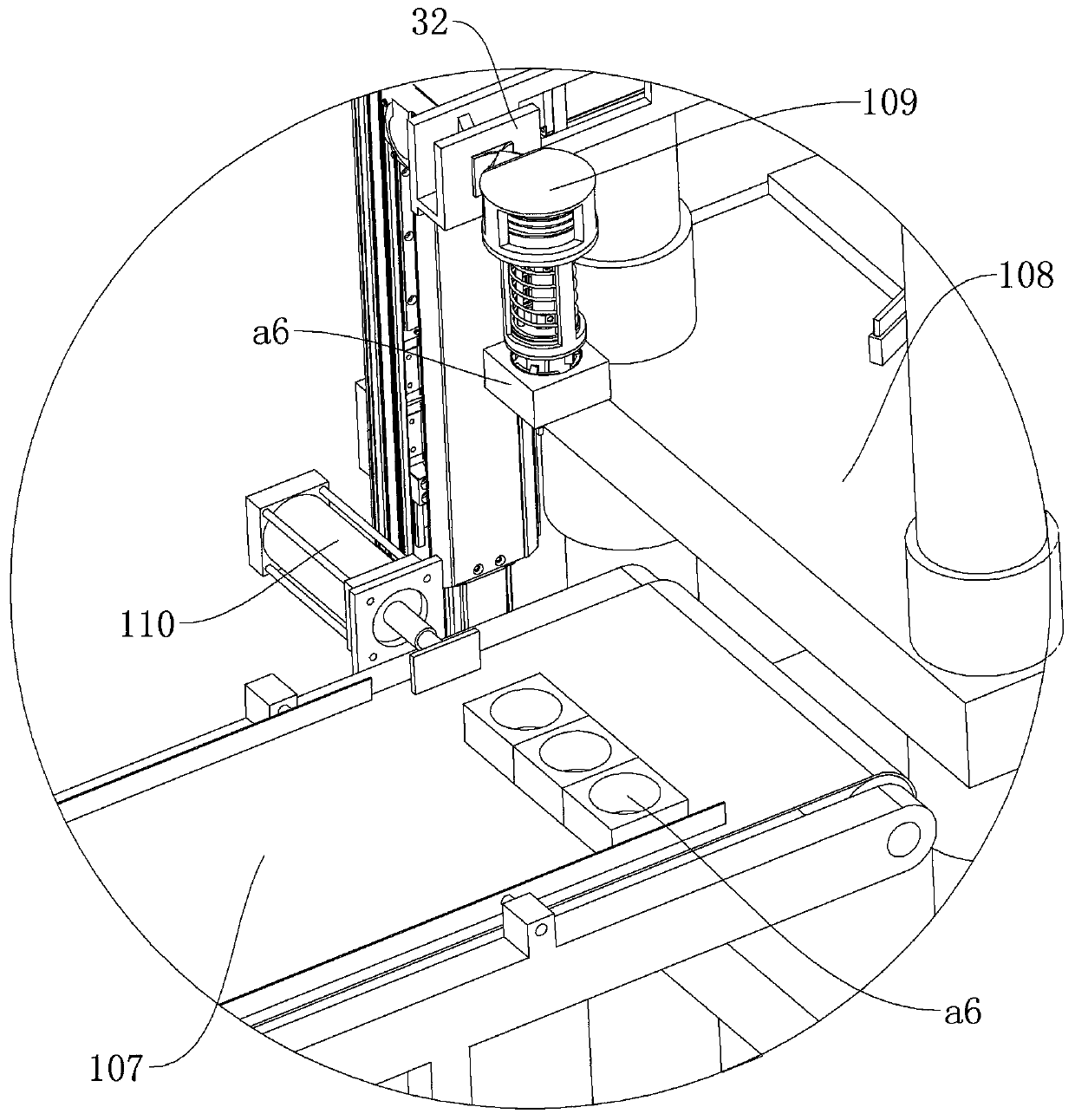

[0061] The grabbing and pressing machine includes a working platform, which is installed on four columns; the lower mold assembly of the forming die is installed in the middle of the working platform, and a jacking hydraulic cylinder or air cylinder is arranged below the working platform It can drive the lifting of the lower mold assembly of the forming mold located in the middle of the working platform;

[0062] A workpiece moving device is installed on the side of the working platform. The workpiece moving device includes a vertical lifting linear module and a horizontal translation linear module. The fixed parts of the vertical lifting linear module are installed on the working platform, and the vertical lifting The moving part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com