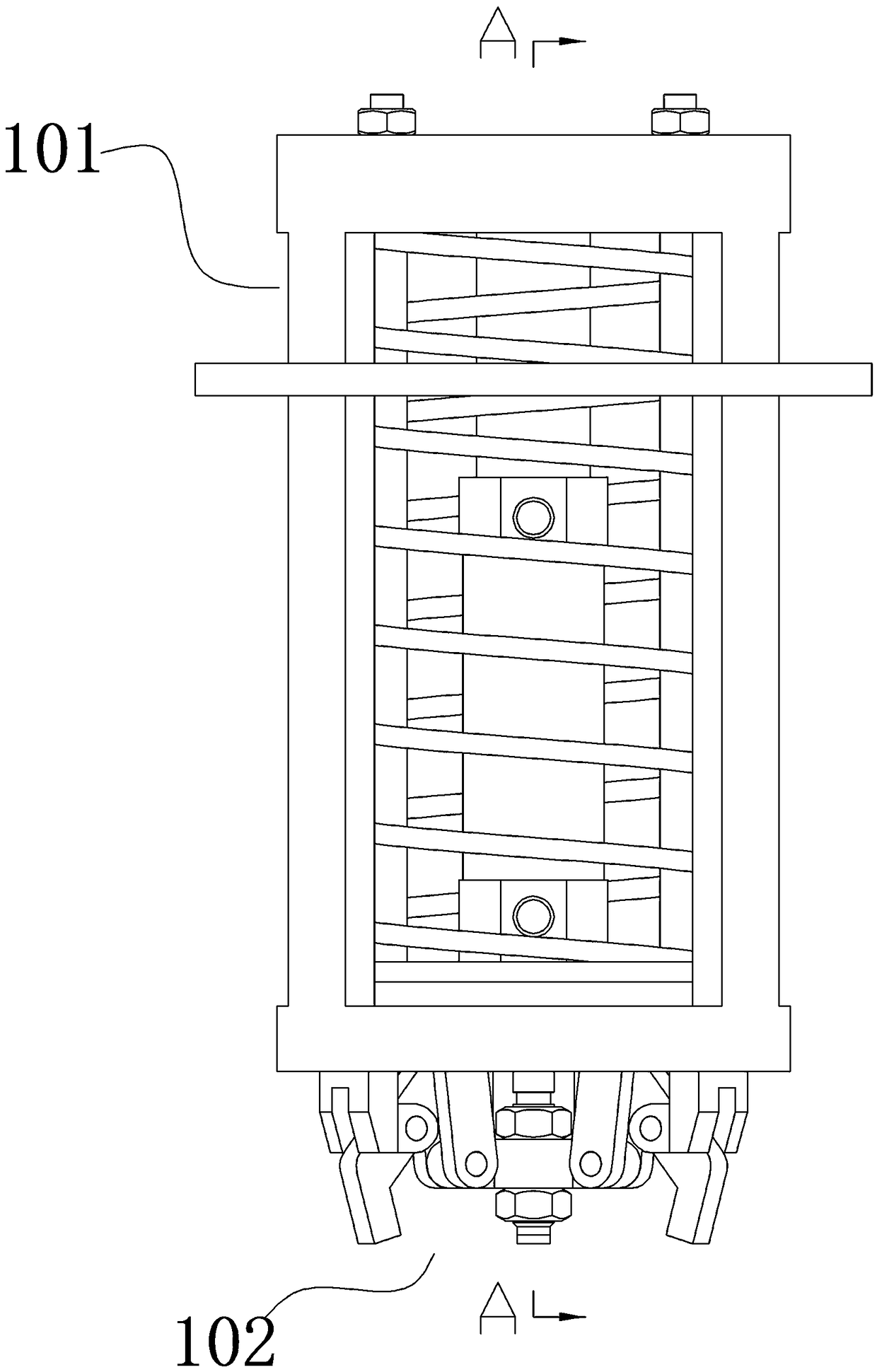

Inner support grabbing and mold pressing manipulator for cylindrical inner wall workpiece

A technology of cylindrical surfaces and manipulators, applied in the directions of manipulators, metal processing, manufacturing tools, etc., can solve the problems of non-assisted positioning and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

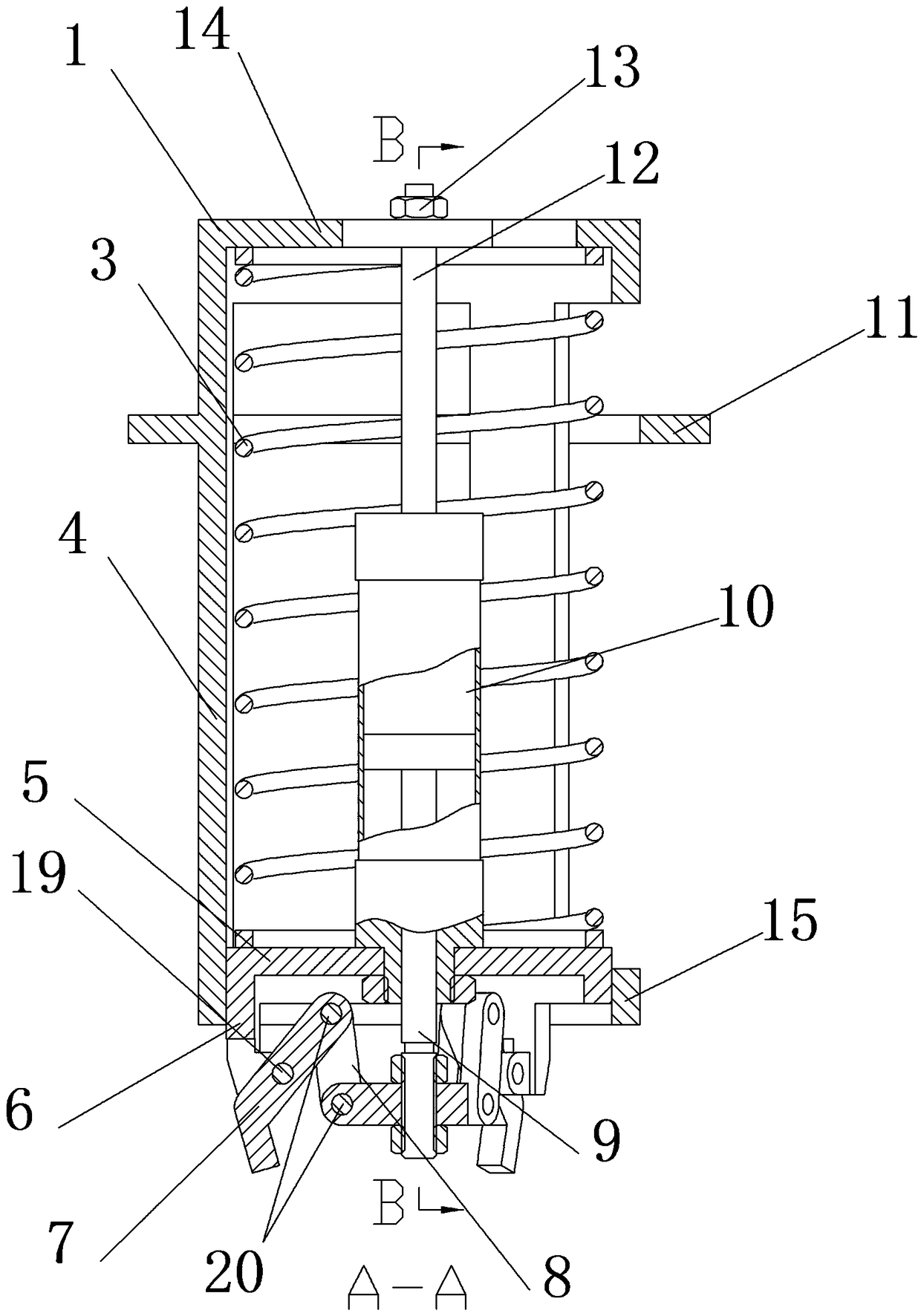

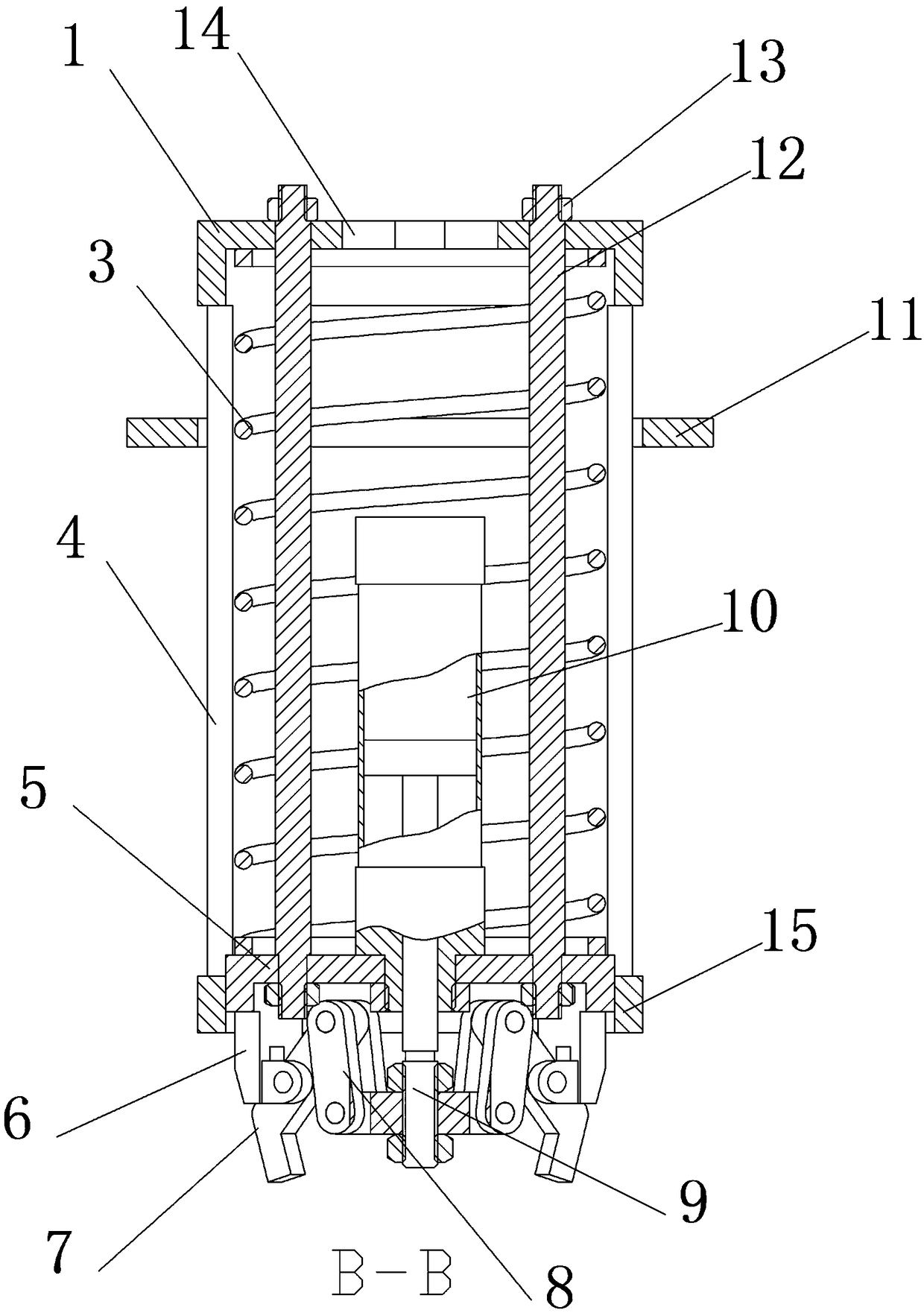

[0037] Embodiment: An inner-supported grasping and mold-pressing manipulator for cylindrical inner wall workpieces, characterized in that the manipulator includes an external cylindrical sleeve and a grasping device installed in the sleeve,

[0038] The grabbing device includes a disc-shaped main body matching the diameter of the inner cylindrical surface of the sleeve; at least three same inner support mechanisms arranged on the lower surface of the disc-shaped main body and evenly distributed; installed on the disc The middle part of the upper surface of the disc-shaped main body, and passes through the disc-shaped main body to its lower surface, and is connected to the telescopic linear motion driver of the inner support mechanism; the running direction of the movable part of the linear motion driver is the same as the axial direction of the disc-shaped main body; the The disc-shaped main body is set inside the sleeve and can slide along the inner surface of the sleeve; on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com