Clamping head for fuel rod replacing device

A fuel rod and chuck technology, which is applied in the directions of reactor fuel elements, reactors, and greenhouse gas reduction, can solve the problem of unreliable holding of fuel rods, and achieve the effect of safe, reliable and simple structure for grabbing fuel rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

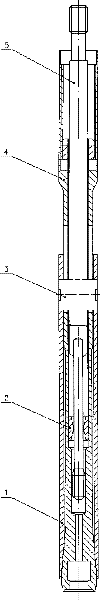

[0023] Such as figure 1 As shown, a collet for a fuel rod replacement device sequentially includes a locking sleeve 1, an elastic collet tube 4, a flared expansion tube 2 and a mandrel 5 from outside to inside;

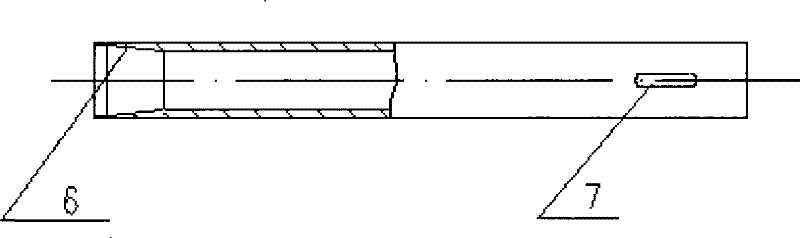

[0024] Such as figure 2 As shown, the lower part of the locking sleeve 1 has a flared conical surface 6;

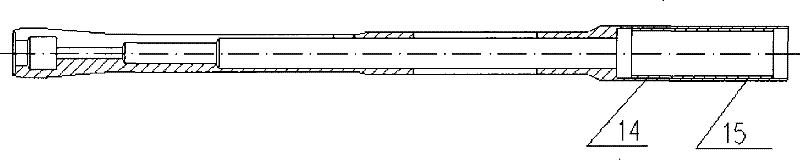

[0025] The lower part of the collet tube 4 is located in the locking sleeve 1, and the inside of the head of the collet tube 4 is matched with the head of the fuel rod, as Figure 4 and Figure 5 As shown, there are three longitudinal thin grooves 17 on the lower end of the collet pipe 4, and the thin grooves 17 are evenly distributed along the circumference, and the lower end of the pipe wall is evenly divided into three pieces; the collet pipe 4 is overheated, so that The part with the thin groove 11 in its lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com