Electro-hydraulic grab bucket mechanism for portal crane

A technology of gantry cranes and grabs, which is applied in the direction of load hanging components, transportation and packaging, etc. It can solve the problems of uncontrollable grabbing force, low efficiency, and poor controllability of grabbing goods. To achieve the effect of expanding the scope of work application, increasing output value and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

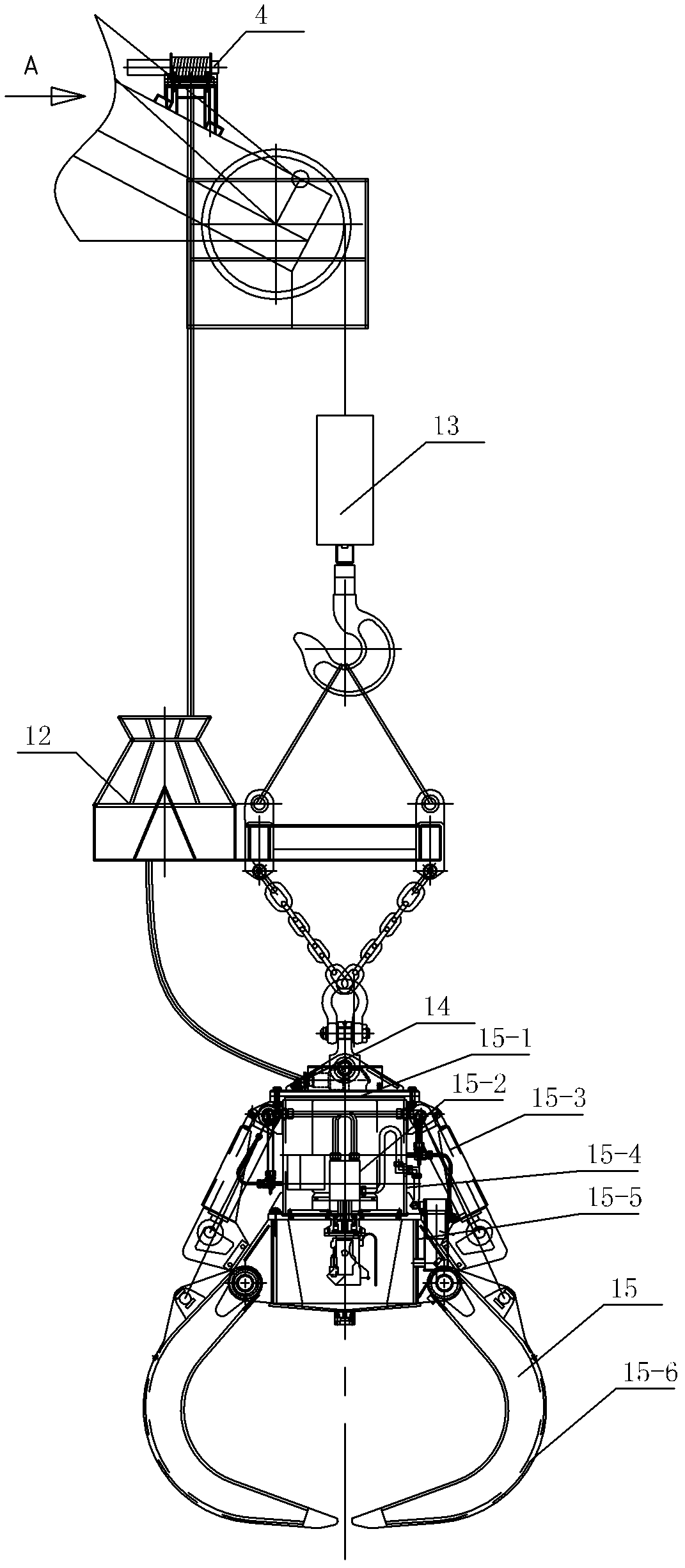

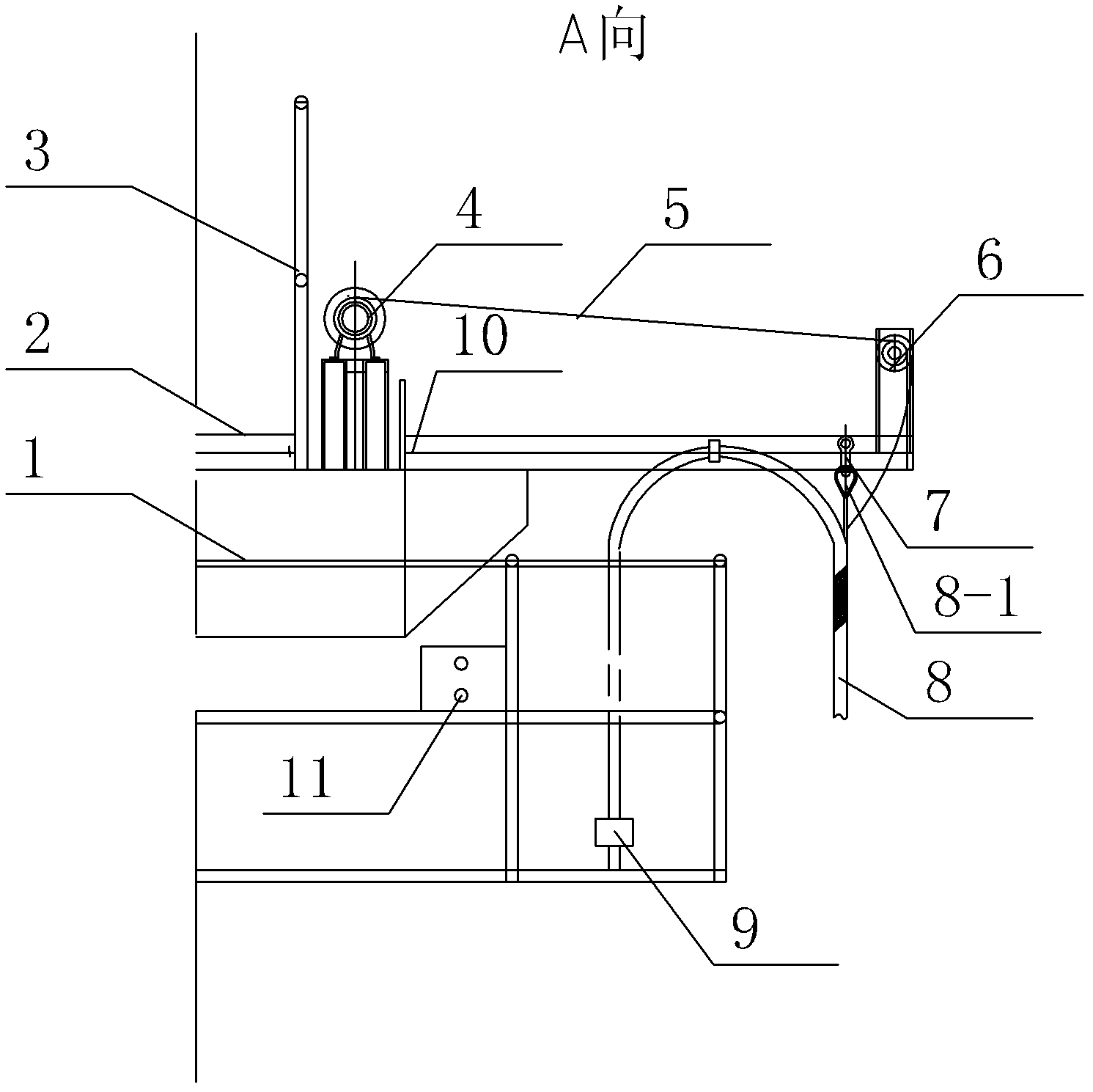

[0011] like Figure 1~Figure 2 As shown, the present invention includes an operating platform 1, a hoisting mechanism 4, a pulley mechanism 6, a cable 8, a base support 10, a cable receiving basket 12, a hook 13 and a grab bucket 15, and the base support 10 is located at the top of the gantry crane, The console 1 and the lifting mechanism 4 are located on the base support 10, the pulley mechanism 6 is located on the upper surface of the head of the base support 10, the hook 13 is connected to the lower end of the pulley mechanism 6 through the wire rope 5, and the cable receiving basket 12 is located on the cable 8; The upper end of the cable 8 is connected to the console 1 , and the lower end is connected to the grab bucket 15 ; the grab bucket 15 is located at the lower end of the hook 13 .

[0012] Described console 1 is provided with operating han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com