Method for correcting position during the glass grabbing process of manipulator of manipulator glass stacking system

A calibration method and manipulator technology, applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of short service life, high cost, troublesome installation, etc., and achieve long service life, convenient maintenance, and easy installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings, and this manufacturing technique is clear to those skilled in the art.

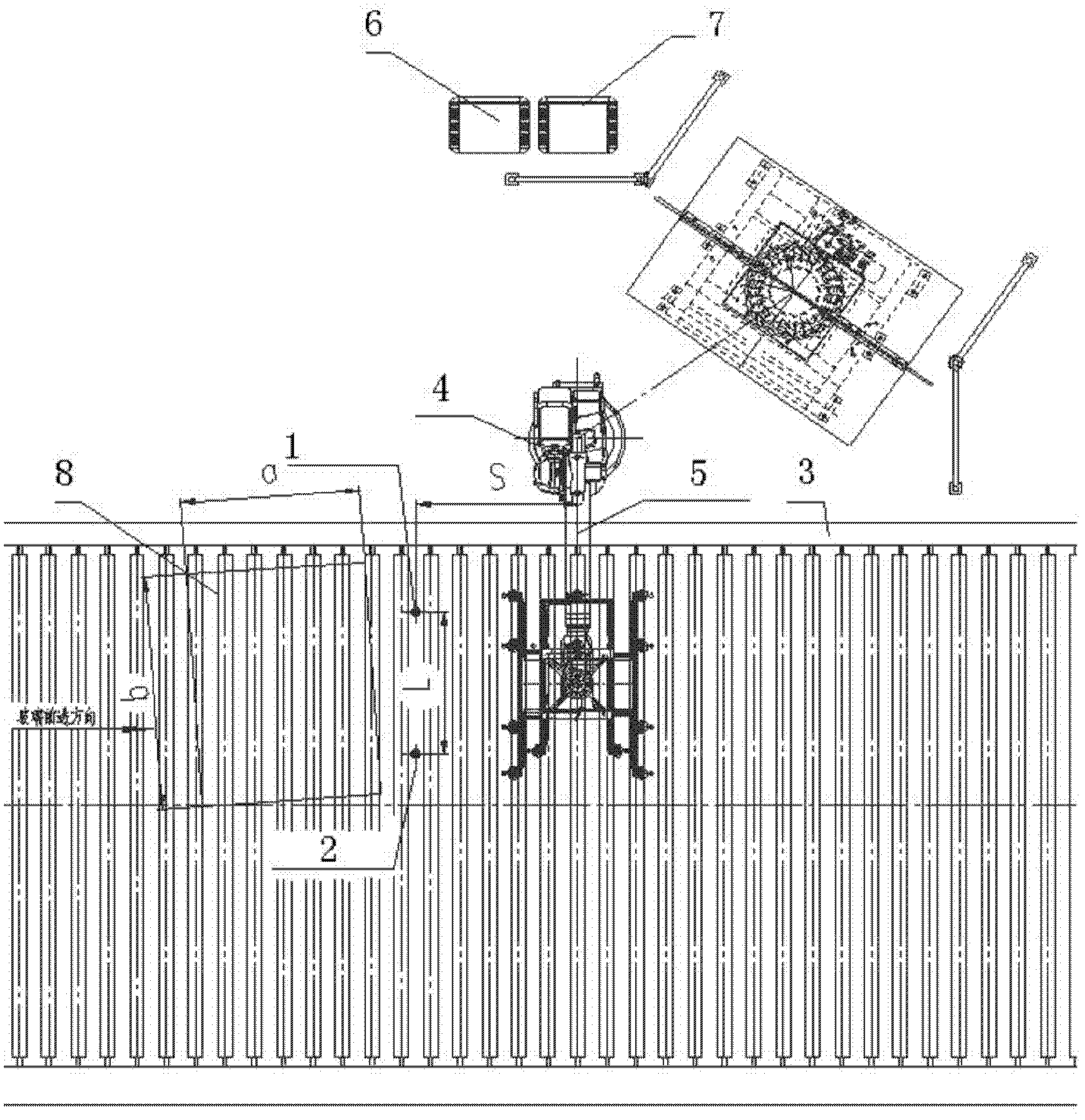

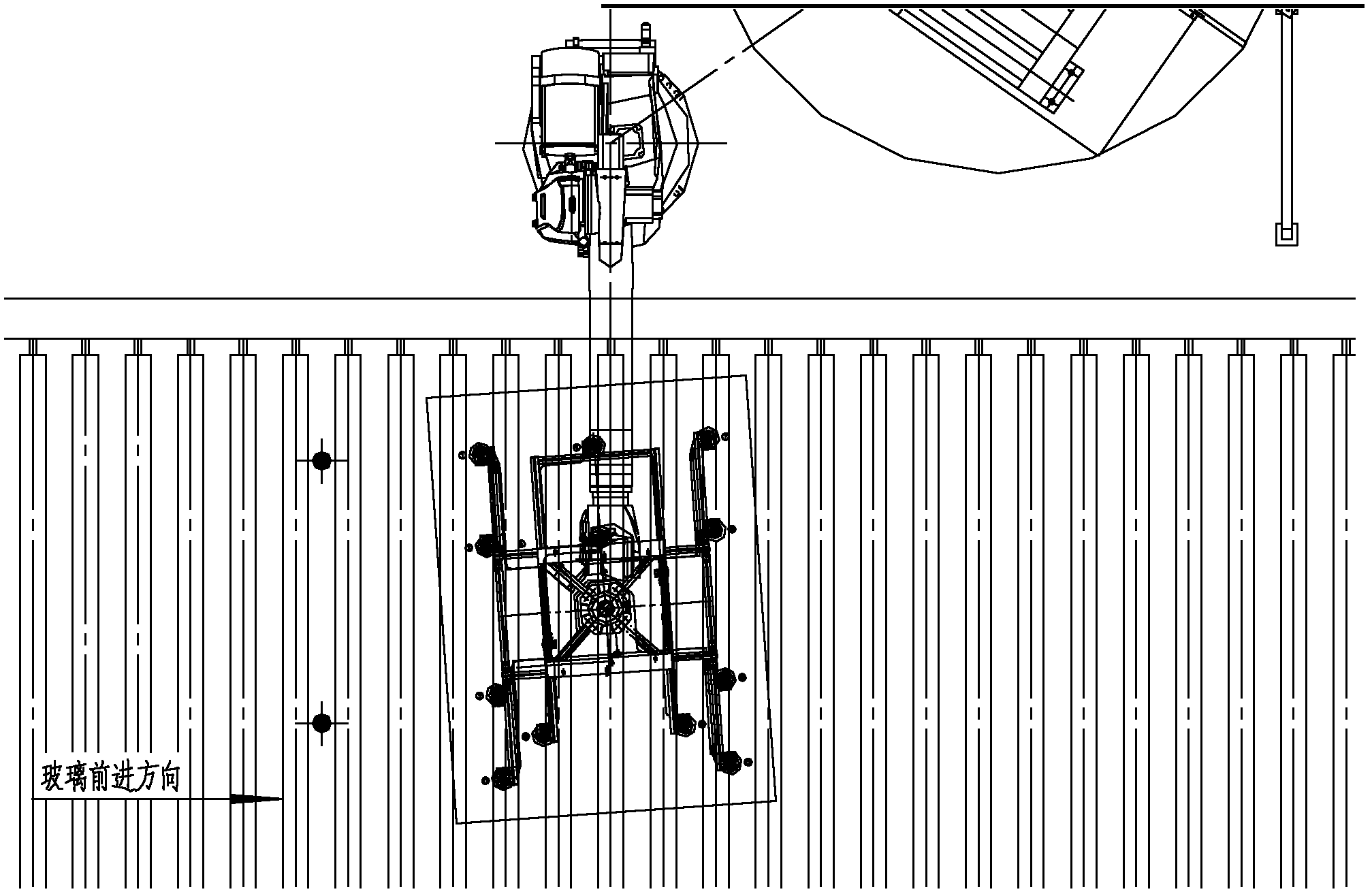

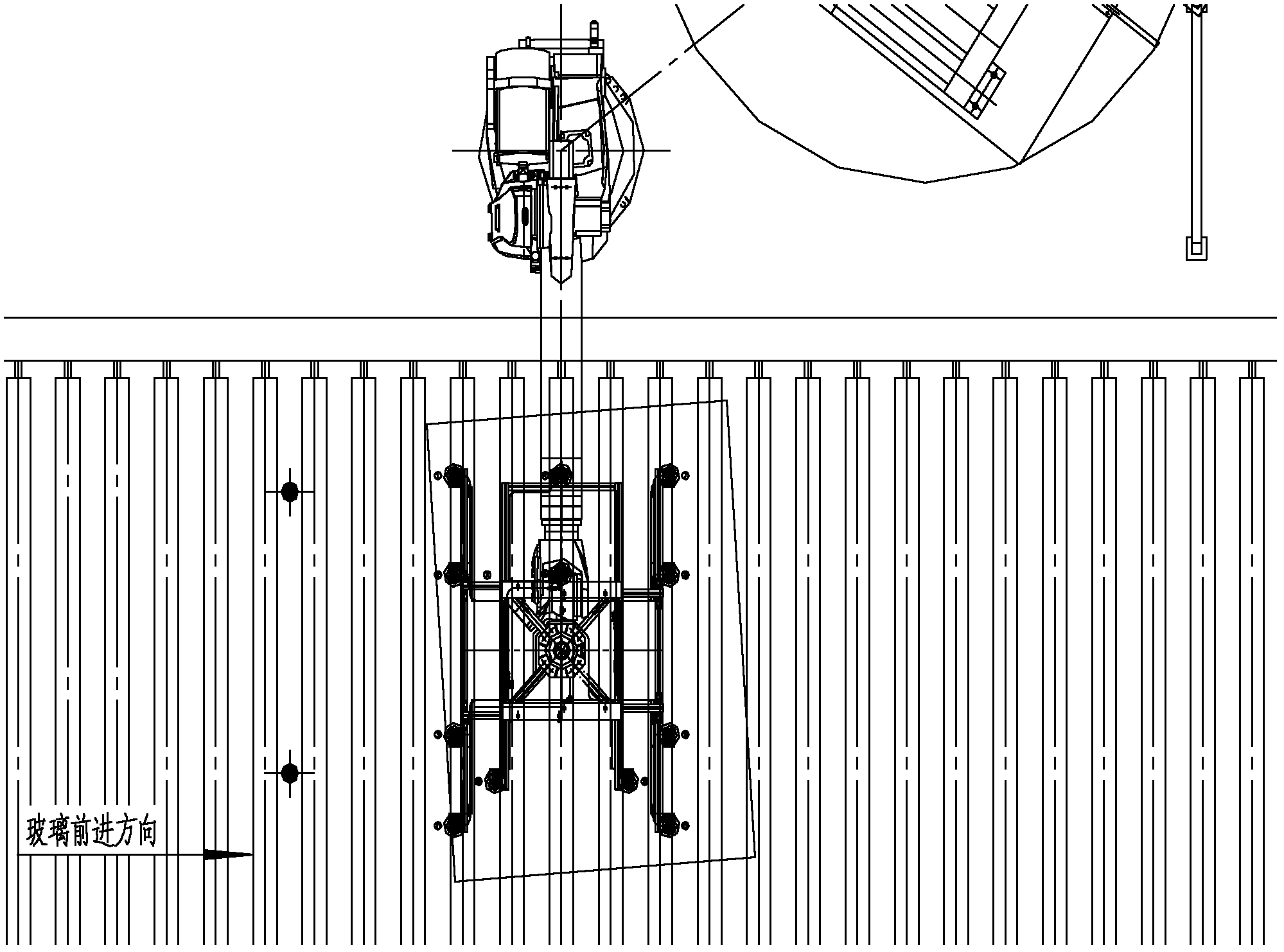

[0014] Such as figure 1 , figure 2 and image 3 As shown, photoelectric sensor I and photoelectric sensor II are installed at S upstream of the center of the manipulator. The distance between the two photoelectric sensors is 1 (1.5m, the specific size can be adjusted according to the actual situation). The photoelectric sensor is connected to the control cabinet (PLC) of the manipulator. When the glass passes the photoelectric sensor: the photoelectric sensor senses the edge of the glass and sends out a signal. The dimensions of the glass are axb (length x width). The photoelectric sensor signal is connected to the control system, and the deflection angle value and the grabbing time point are calculated and processed by PLC and provided to the manipulator control system.

[0015] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com