Printer

A technology for printers and printing units, applied in typewriters, printing, etc., can solve problems such as tilting and falling, deviation from the center of gravity, and difficulty in ensuring printing quality, and achieve the effects of improving control performance, avoiding deviation problems, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

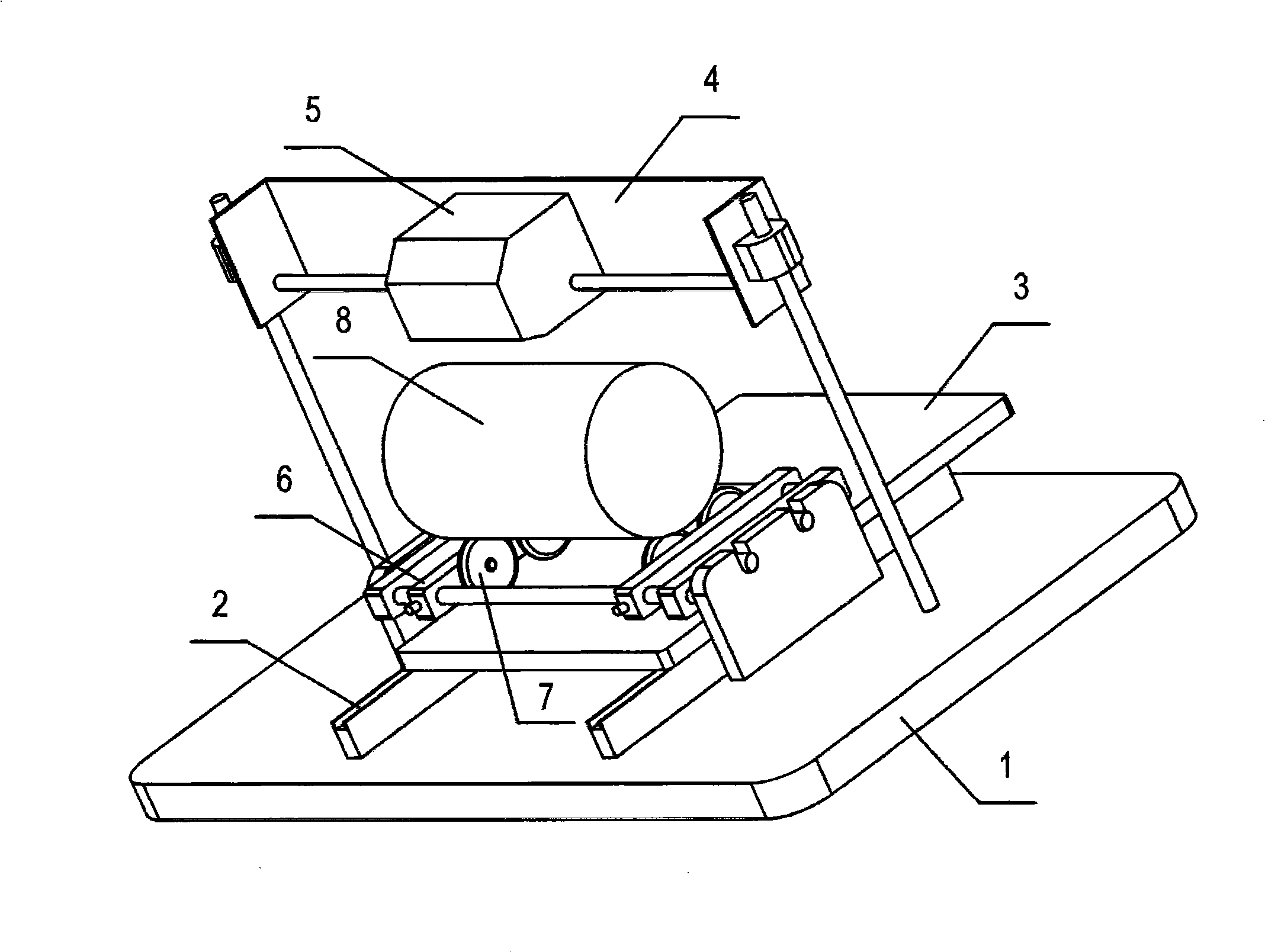

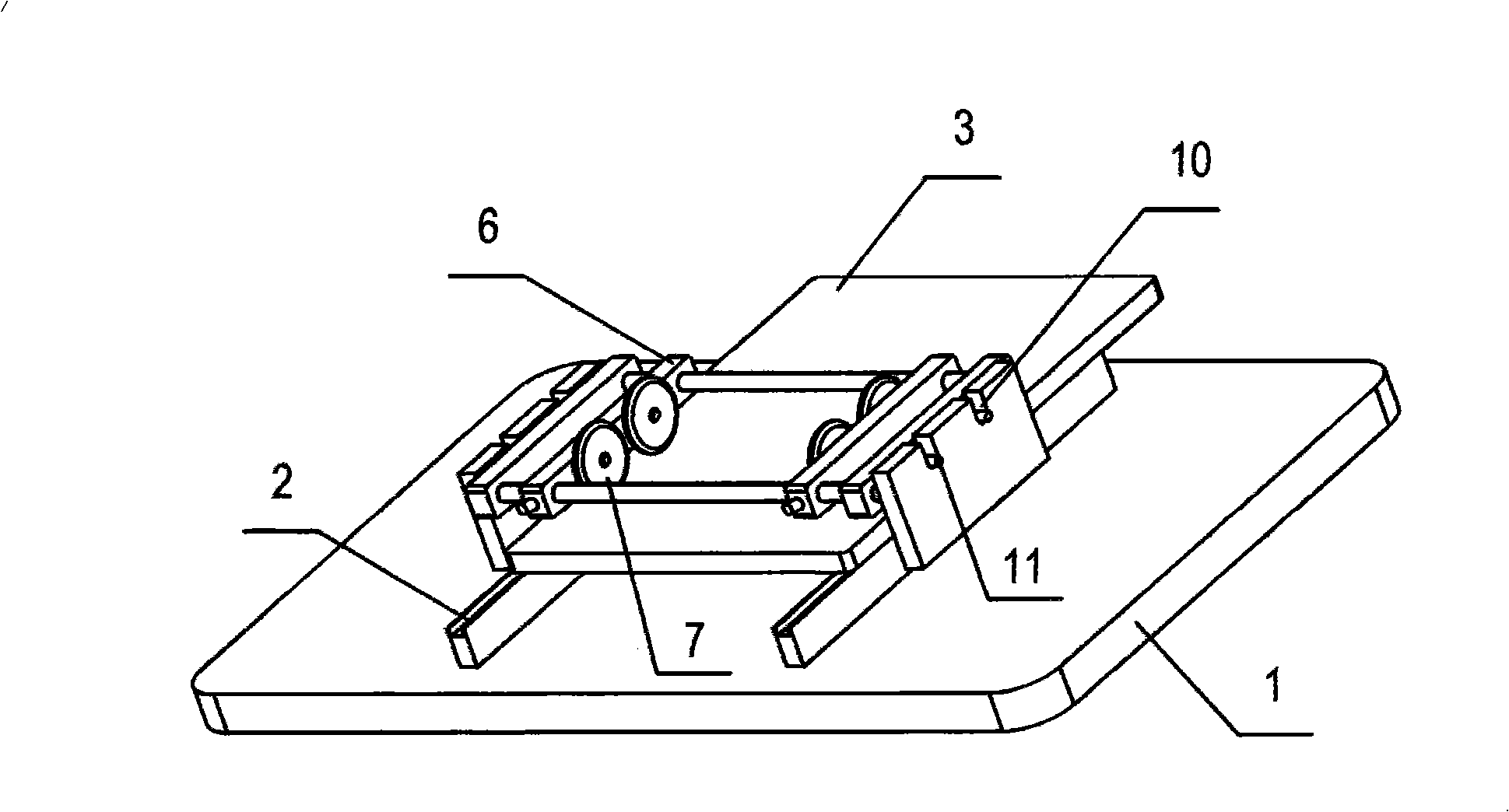

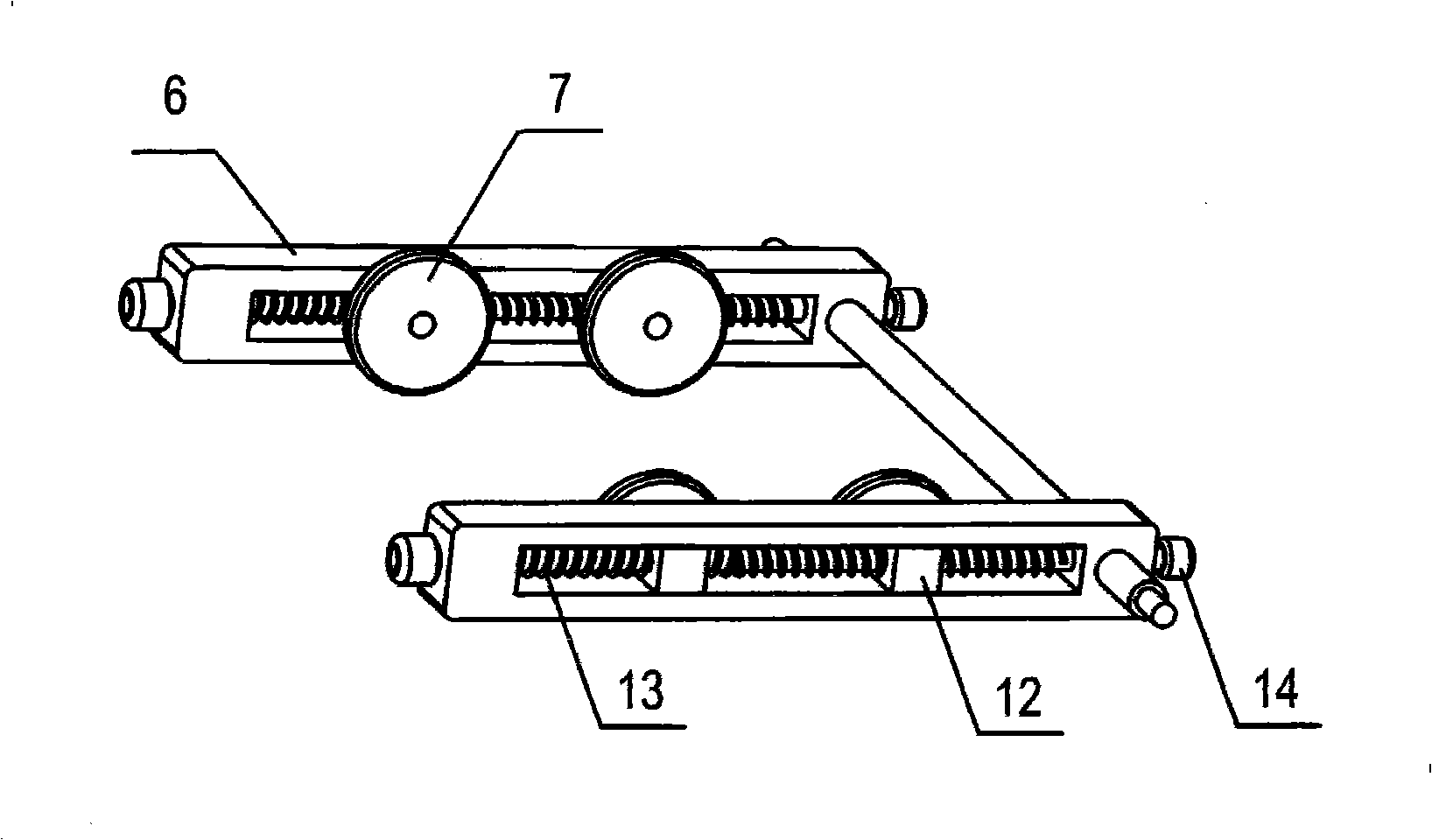

[0012] Such as figure 1 As shown, the printer of the present invention includes a base 1, a guide rail 2 is arranged on the base 1, and the tray 3 can move longitudinally along the guide rail 2 relative to the base 1 under the drive of a stepping motor (not shown in the figure), and the base 1 is mounted on the tray 2 The printing unit 4 is set above the top of the printing unit 4, and the printing unit 4 is equipped with a print head 5 that can move back and forth in the left and right directions. The base 1 is also provided with a detachable conversion frame 6, and the left and right sides of the conversion frame 6 are arranged symmetrically. For the roller 7, the roller 7 can rotate relative to the conversion frame 6 under the driving of the rolling friction force generated on the surface of the tray 3 when the pallet 3 moves longitudinally, and the wheel shaft of the roller 7 is connected with the conversion frame 6 through a bearing (not shown in the figure); The unit 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com