Welding tool for assembling electric hoist roller stand

A technology of welding tooling and electric hoist, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing the difficulty of component production, achieve the effects of improving welding quality, moving smoothly, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

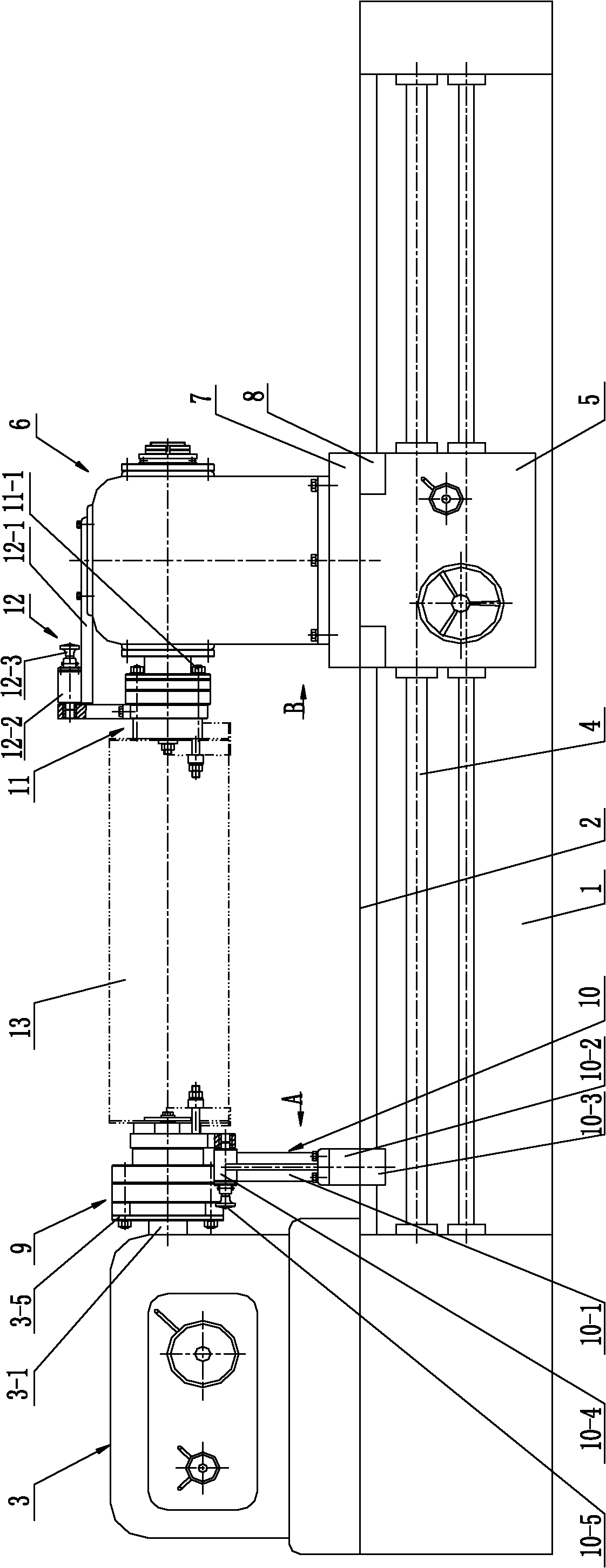

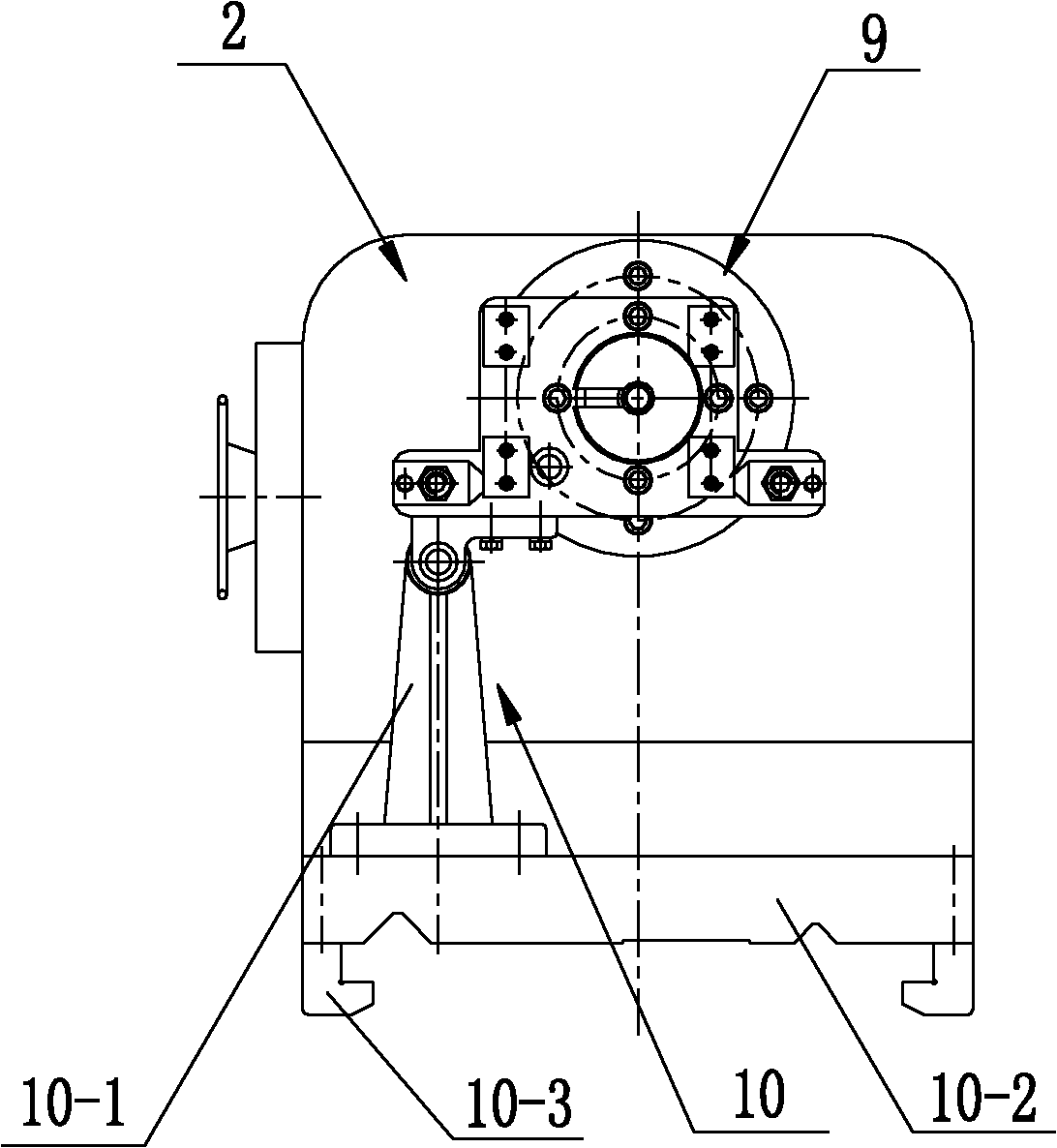

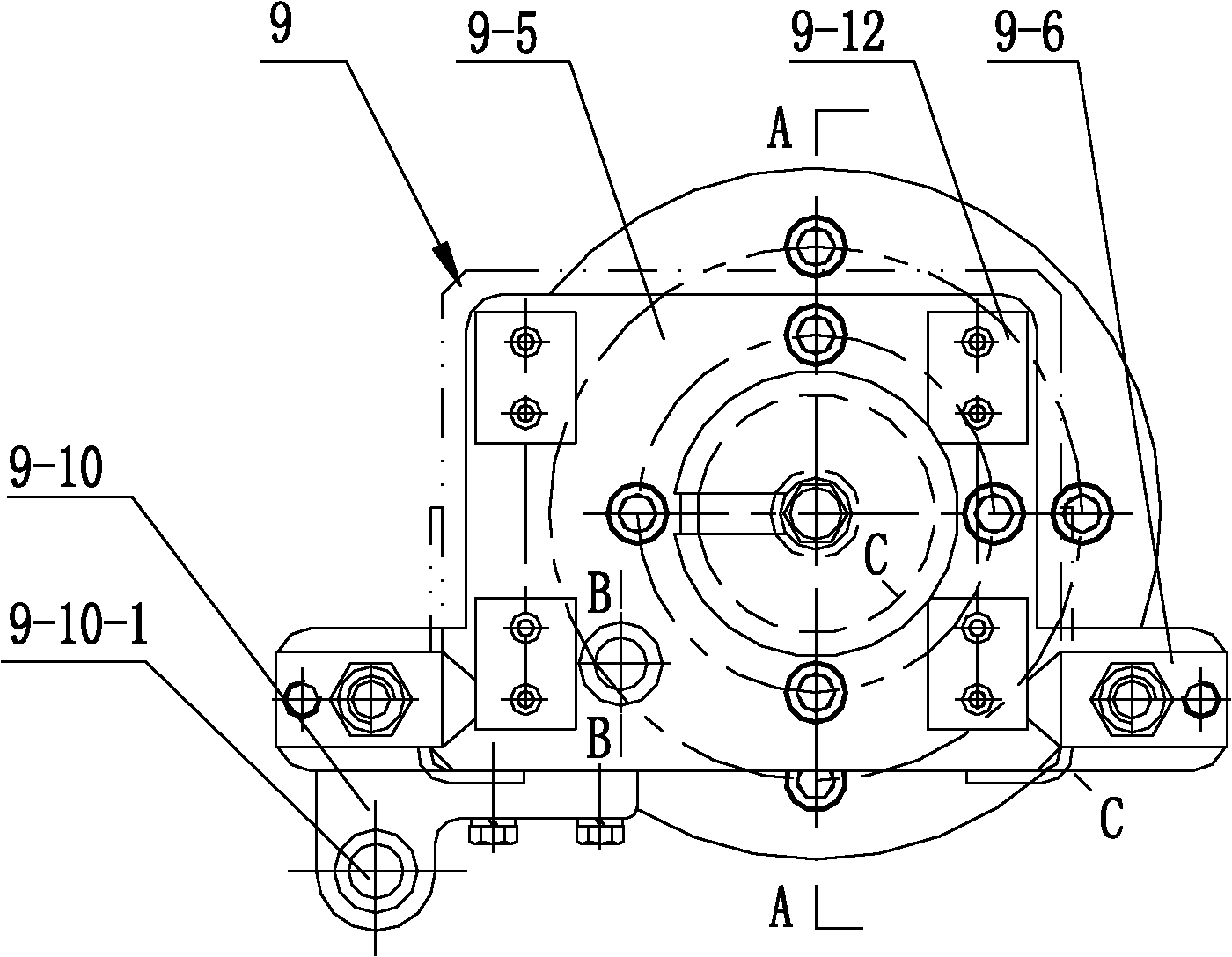

[0017] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are cited hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings: Please refer to figure 1 , figure 2 and Figure 7 A welding tool for assembling the electric hoist reel support, including a bed 1, a bed guide rail 2, a headstock 3, a lead screw 4 connected to the headstock 3, a slide box 5 mounted on the lead screw 4, and The tailstock device 6 connected with the slide box 5, the tailstock device 6 is installed on the bed guide rail 2 through the tailstock connecting plate 7 and the tailstock hook plate 8, and the headstock 3-2 of the headstock is locked The nut 3-3, the locking disc 3-5 and the connecting shaft 3-4 are equipped with a bearing side support mechanism 9, corresponding to the positioning device 10 on the bed guide rail 2 below the bearing side support mechanism 9, and the tailstock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com