Lifting hand grab of steel wire ring

A traveler and gripper technology, applied in the directions of load hanging components, transportation and packaging, can solve the problems of affecting work efficiency, spreading, and the traveler is prone to shaking, etc., and achieves the effect of improving work efficiency and stable movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

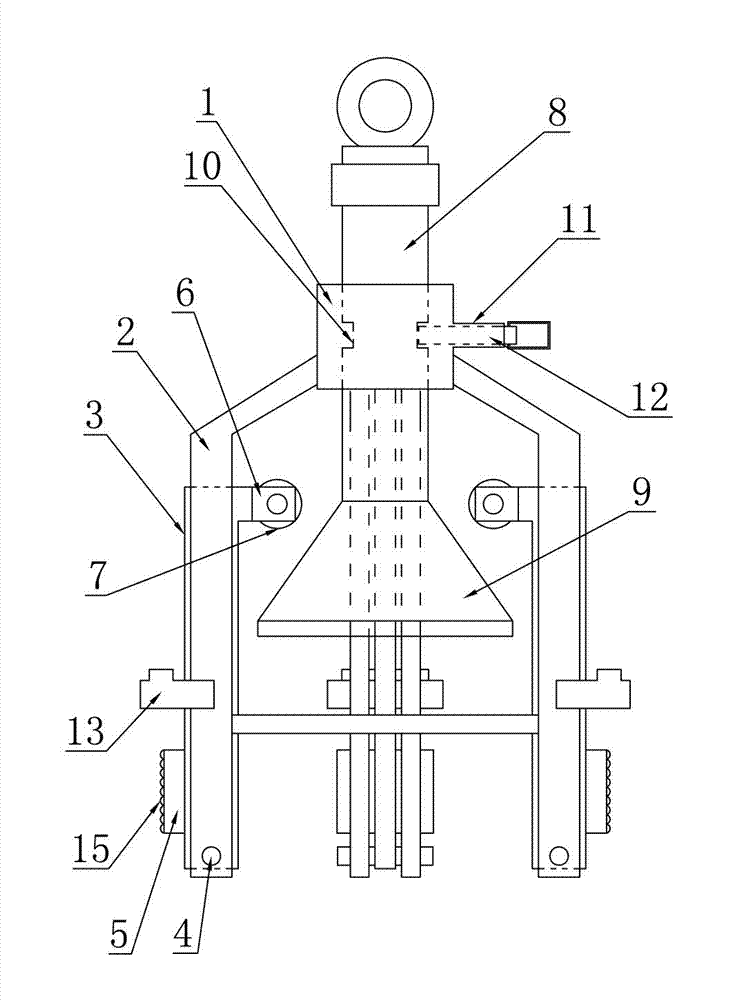

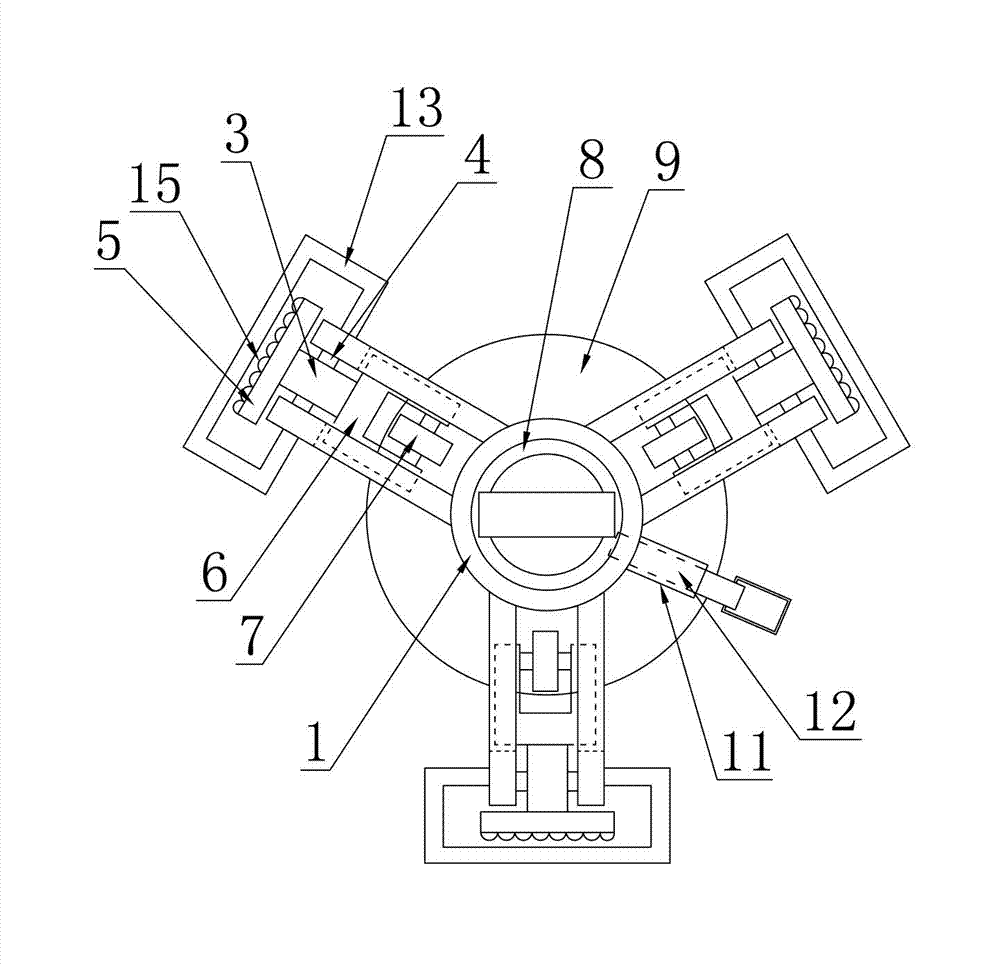

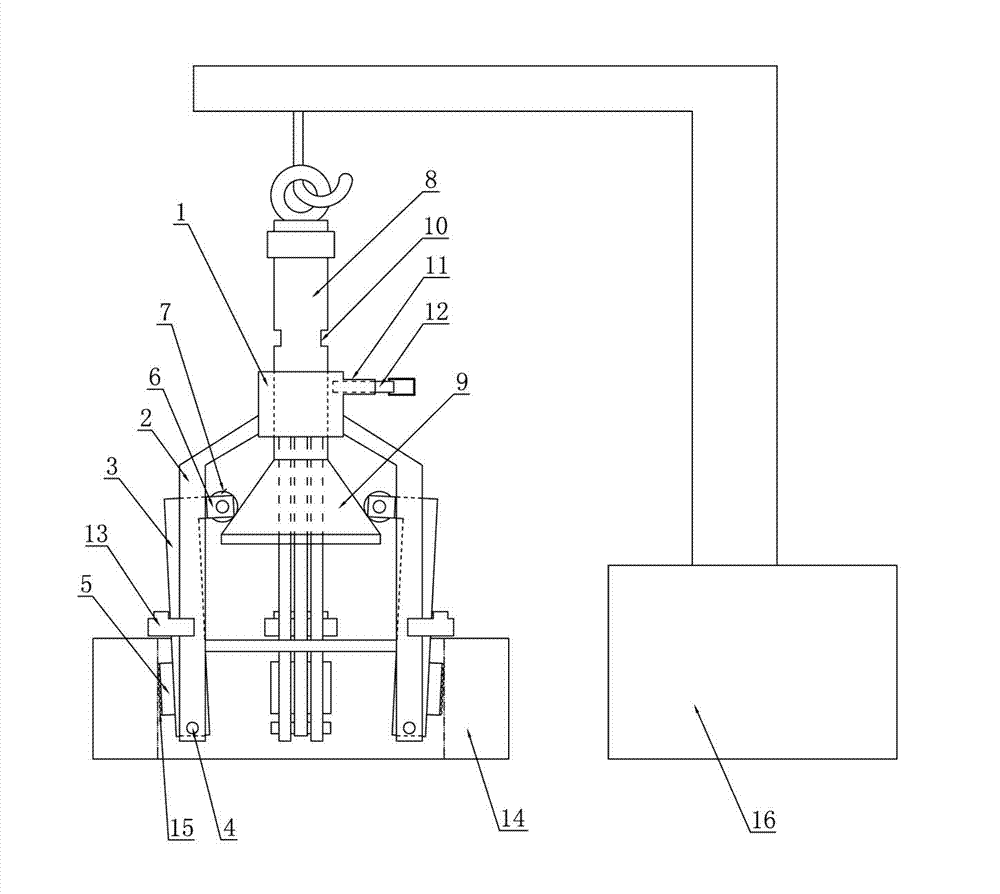

[0014] Such as figure 1 , figure 2 , image 3 As shown, the said bead hoisting gripper includes: an annular seat 1, at least three gripper brackets for supporting the annular seat 1 are evenly arranged on the outer wall of the annular seat 1 along its circumference. In this embodiment, On the outer wall of the ring seat 1, three handle brackets 2 for supporting the ring seat 1 are evenly arranged along its circumference, and each handle bracket 2 is respectively provided with a hinged arm 3, and the lower end of each hinge arm 3 is respectively connected to The shaft 4 is hinged to the bottom end of its corresponding grip bracket 2, and a brace block 5 is respectively arranged on the outer side wall of each articulated arm 3 and above the corresponding connecting shaft 4, and each articulated arm The upper ends of the upper ends are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com