Special gripper for location on cutting of thimble

A special fixture and thimble technology, used in positioning devices, clamping, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

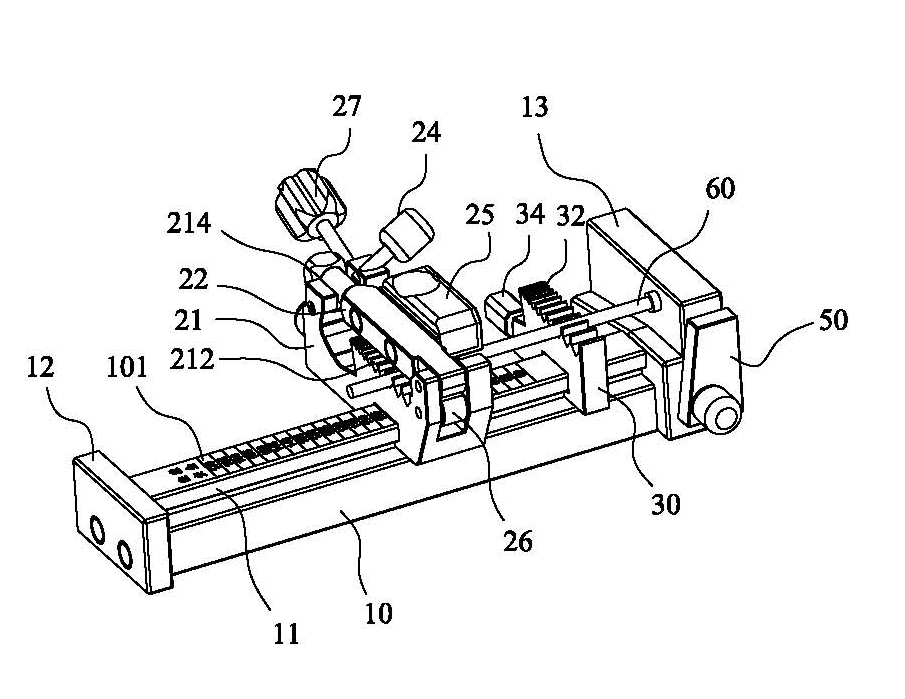

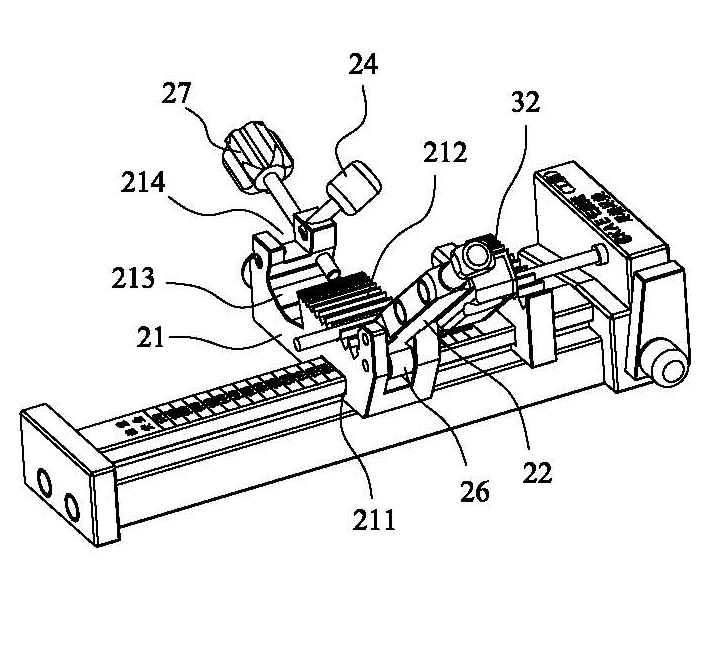

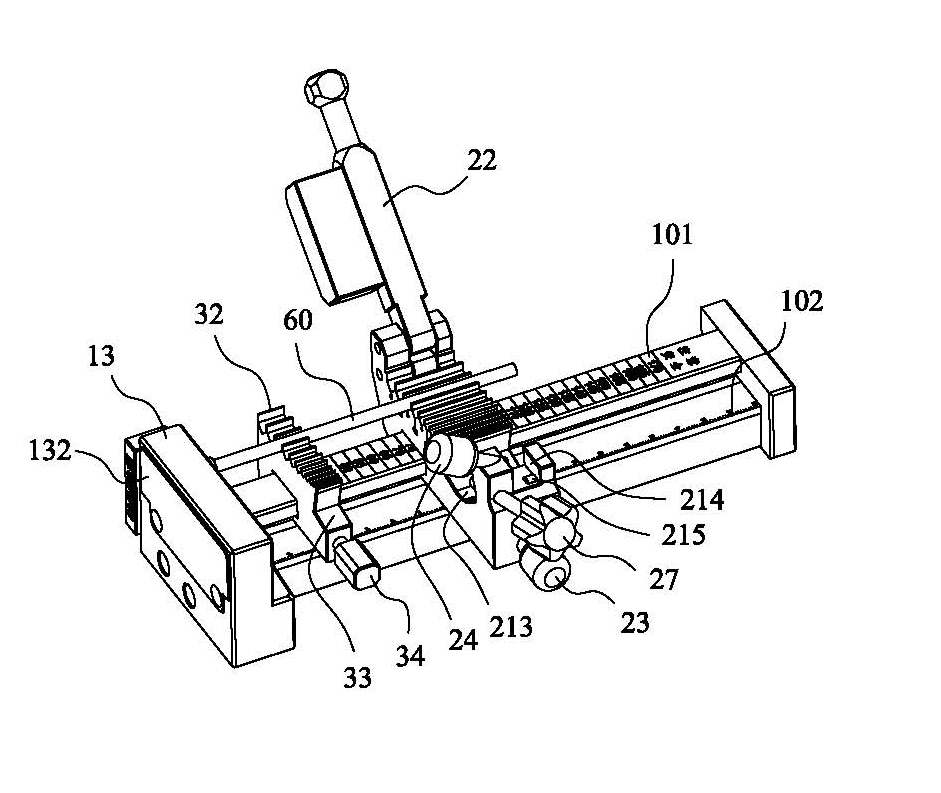

[0037] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the base 10, the clamping device 20 and the supporting slider 30.

[0038] The base 10 is provided with a T-shaped linear slide rail 11, the front end of the linear slide rail 11 is provided with a front baffle 12, and the front baffle 12 is detachably connected to the base 10; the rear end of the linear slide rail 11 is provided with Back suction plate 13, this back suction plate 13 also detachable type is connected on the base 10, and back suction plate 13 is used for the tail end of suction-type fixed thimble 60, and back suction plate 13 has the concave cavity 131 of opening backward, many A magnet 40 is placed in the concave cavity 131, and a rear cover 132 is arranged on the concave cavity 131, and the magnet 40 can be easily replaced by opening the rear cover 132. And, a standard block gauge 50 is installed on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com