Novel sleeper component protecting cover

A technology of protective cover and sleeper, applied in the field of railway equipment, can solve problems such as pollution of components and parts, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

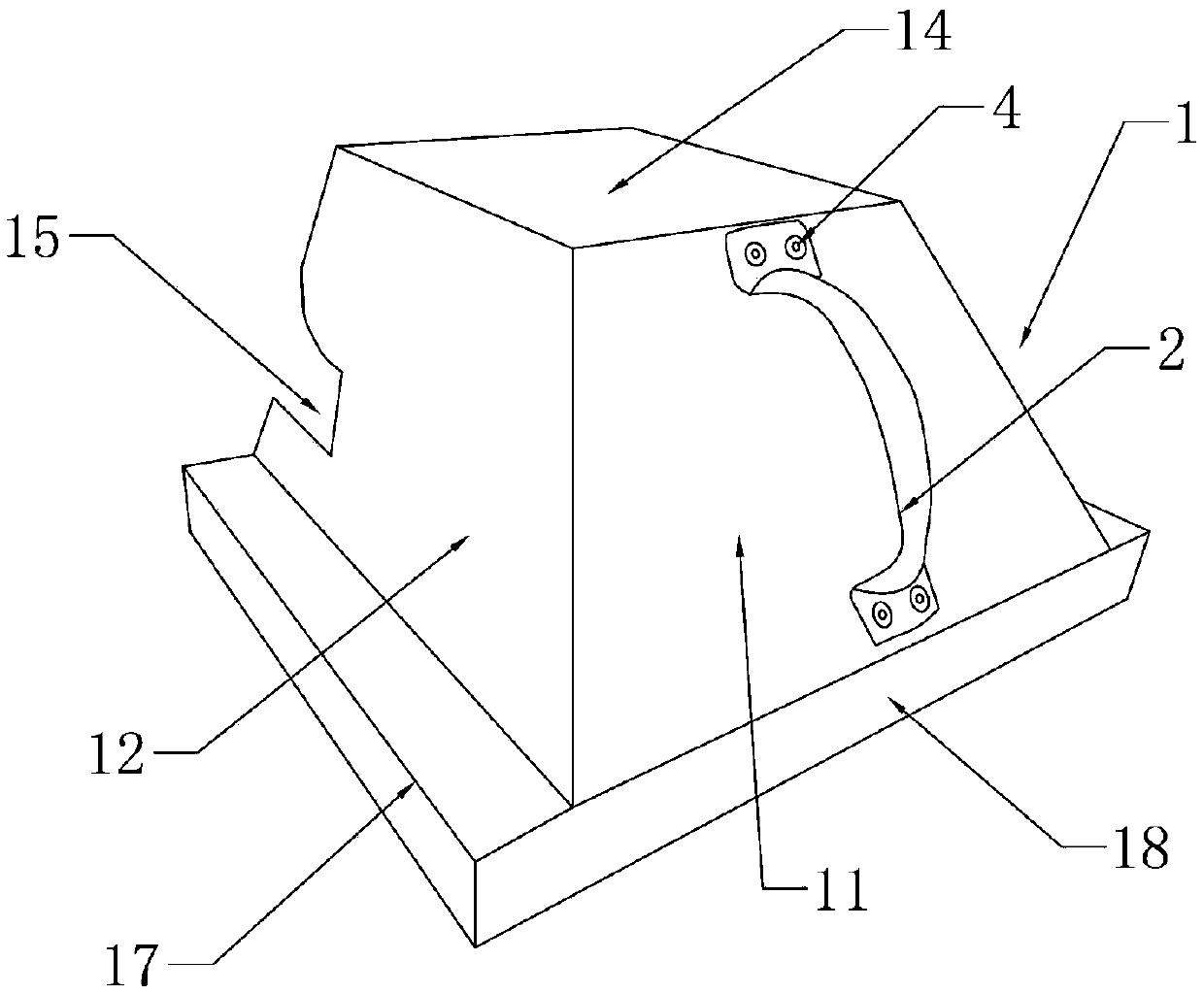

[0020] A new type of protective cover for sleeper components, such as figure 1 , 2 As shown, it includes a cover body (1), and the cover body (1) includes two side surfaces (12, 13), a top surface (14) and a front surface (11); the front surface (11) is screwed (4) A handle (2) is fixed; the free side of the top surface (14) is provided with a vertically downward limit baffle (16); each of the two sides (12, 13) is provided with a rail bottom matching card slot (15); the bottom of the two sides (12, 13) is provided with a stepped base (17), the base is connected with the front extension plate (18), the cover (1), The base (17) cooperates with one side of the sleeper to form a hollow cavity for accommodating components.

[0021] Wherein, the first side (12) of the cover body is provided with a card slot (15) matching with the bottom of the rail.

Embodiment approach

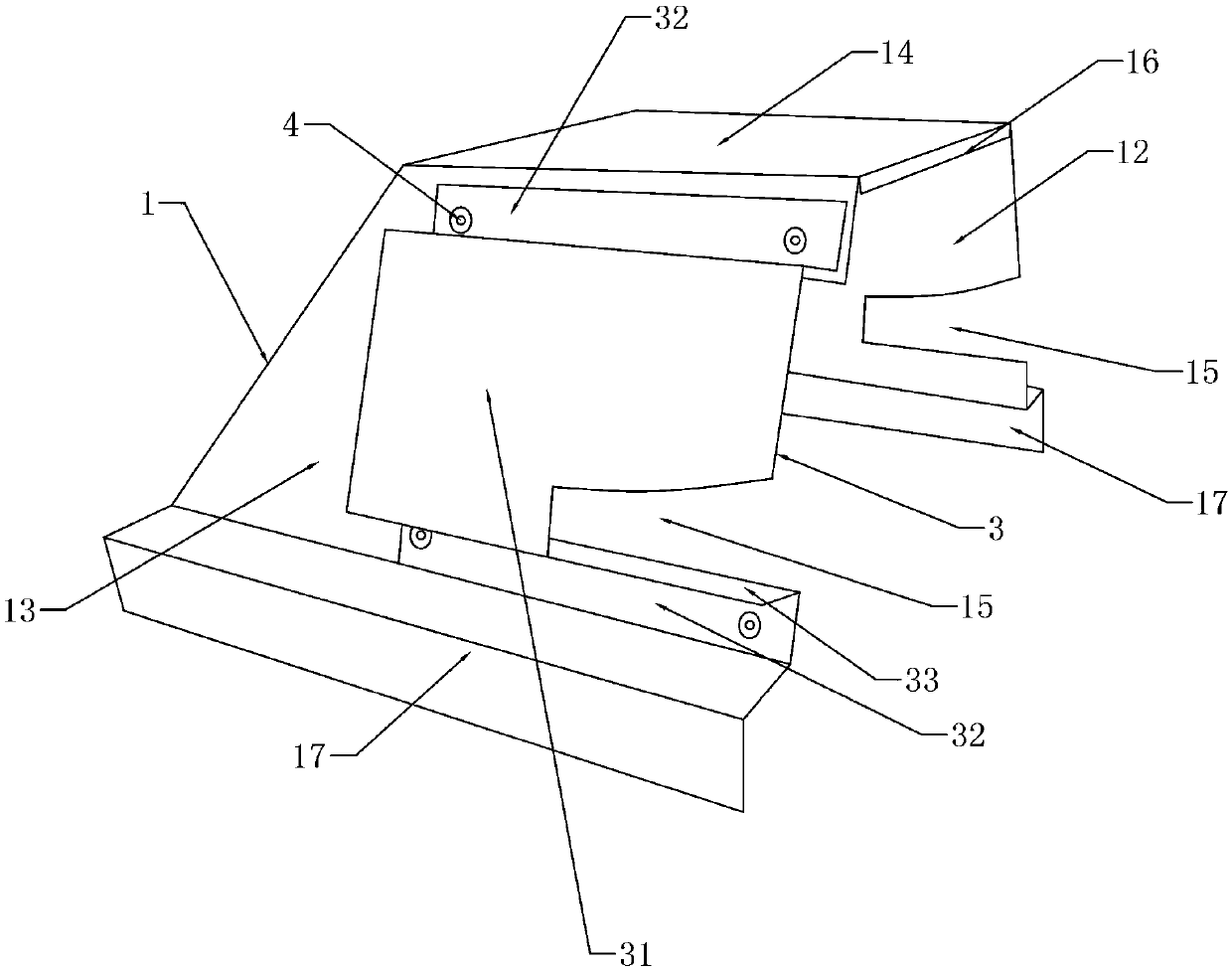

[0022] As an embodiment, an additional cover (3) is provided on the second side (13) of the cover, and the additional cover (3) includes a rectangular plate (31), two side plates (33) and two The flange side (32) vertically connected with the two side plates; the additional cover body (3) is fixed on the second side of the cover body (13) through the two flanges (32), and the second side of the cover body (13) The position parallel to the rectangular plate (31) is hollowed out; the rectangular plate (31) is provided with a slot (15), and the slot (15) is connected to the slot (12) of the first side (12) of the cover body. 15) Correspondingly; the second side (13) of the cover is provided with a convex plate perpendicular to the side, and the convex plate is connected to the vertical surface of the additional cover (3) away from the card slot (15) and seals One side of the additional cover (3).

[0023] Wherein, the length of the bottom side of the card slot (15) is 7cm; the h...

Embodiment 2

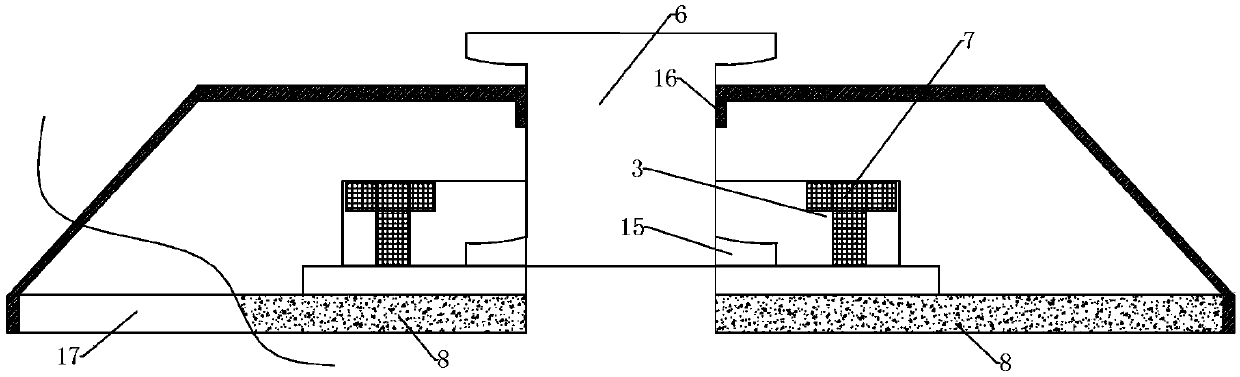

[0026] A new type of protective cover for sleeper components, such as Figure 4 As shown, it includes a cover body (1), and the cover body (1) includes two side surfaces (12, 13), a top surface (14) and a front surface (11); the front surface (11) is screwed (4) A handle (2) is fixed; the free side of the top surface (14) is provided with a vertically downward limit baffle (16); each of the two sides (12, 13) is provided with a rail bottom matching card slot (15); the bottom of the two sides (12, 13) is provided with a stepped base (17), the base is connected with the front extension plate (18), the cover (1), The base (17) cooperates with one side of the sleeper to form a hollow cavity for accommodating fasteners.

[0027] Wherein, the length of the bottom side of the card slot (15) is 7cm; the height of the limit baffle (16) is 2cm; the height and width of the base (17) are 3cm, and the length is 26cm; The top surface is 20.6cm long and 17cm wide; the extension board is 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com