Hinge for furniture

A furniture and hinge technology, applied in door/window fittings, folding panels, construction, etc., can solve the problems of unfavorable hinge installation, complex assembly steps, small cup body space, etc., and achieve simple and reasonable structure, low production cost, cup The effect of large body space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

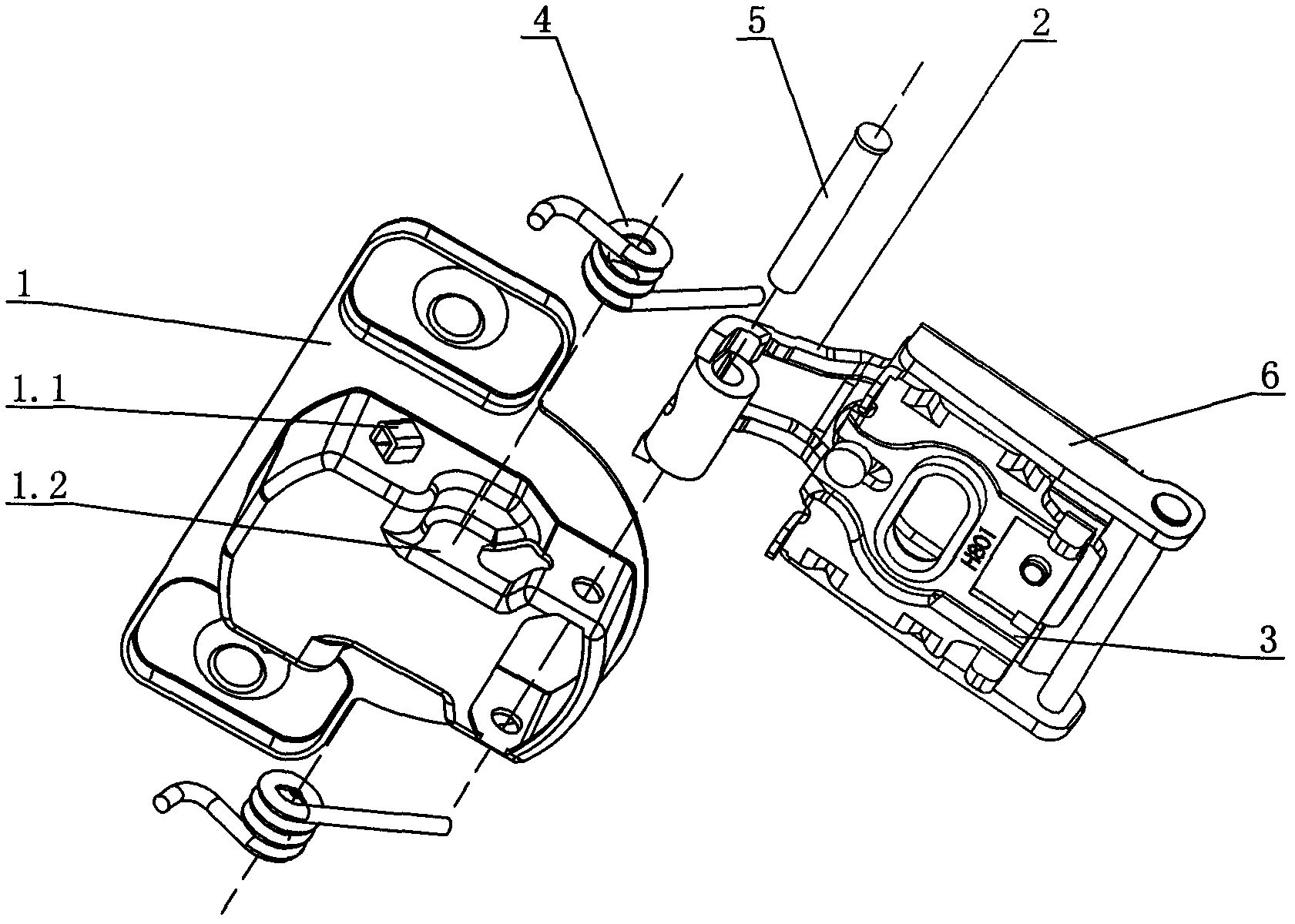

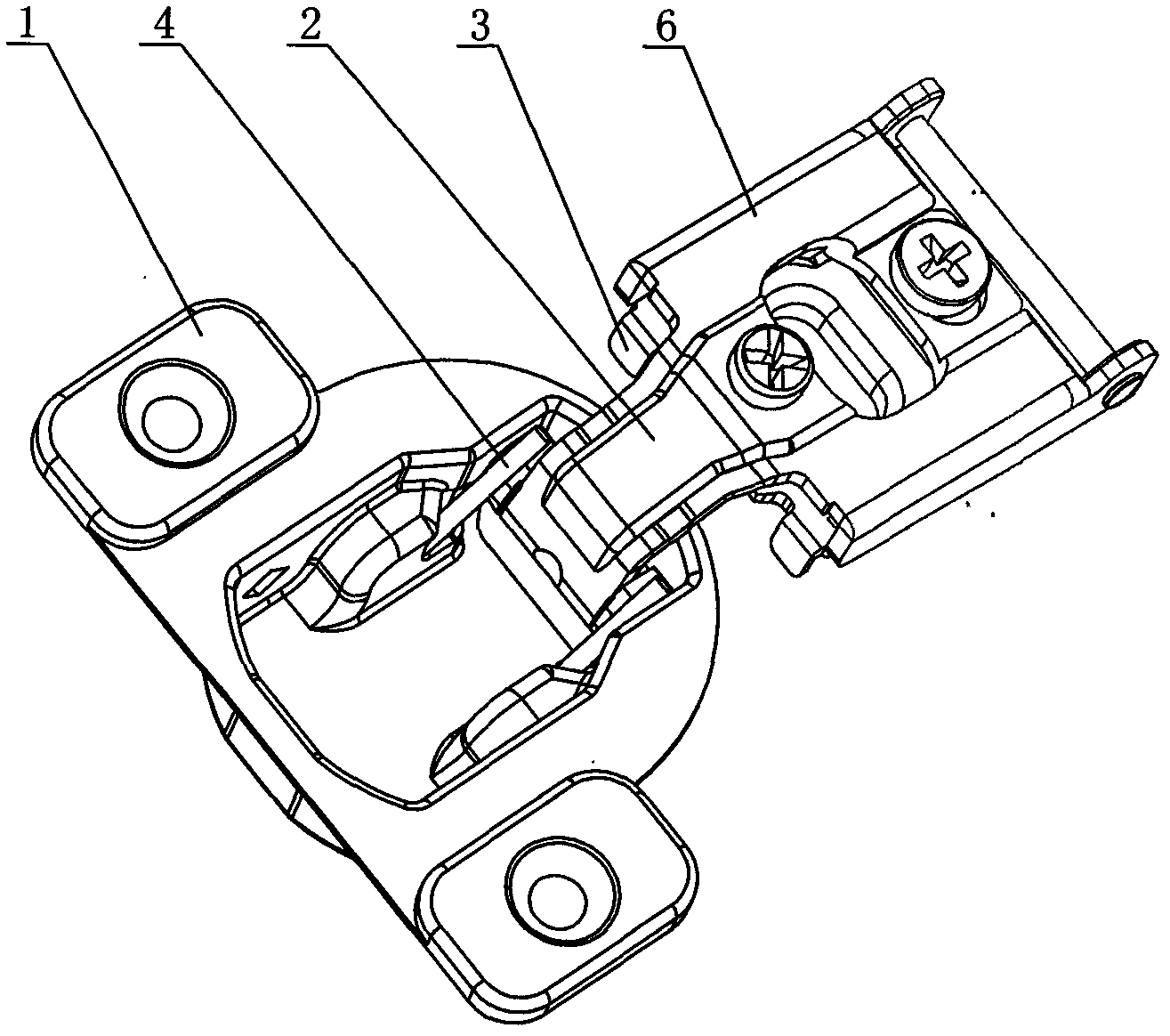

[0021] see Figure 1-Figure 3 , the hinge for this furniture, including the hinge cup seat 1 arranged on the furniture door body, and the base 3 arranged on the main body of the furniture, the base 3 is provided with an adjustment cover 6, and the adjustment cover 6 is connected to one end of the hinge arm 2 , the hinge cup seat 1 is hinged with the other end of the hinge arm 2 through the torsion spring 4 and the rotating shaft 5 provided on the left and right sides of the hinge cup seat 1, and the left and right sides of the hinge cup seat 1 are provided with buckles 1.1, and the torsion spring 4 is connected to the buckle position 1.1, the other foot rests on the articulated arm 2.

[0022] In this embodiment, the buckle 1.1 and the hinge cup seat 1 are integrally formed by stamping. The buckle 1.1 can also be separately arranged on the hinge cup seat 1 by welding, or screwing, or riveting, or buckling.

[0023] Wherein, the button position 1.1 is a button hole. The pin ...

no. 2 example

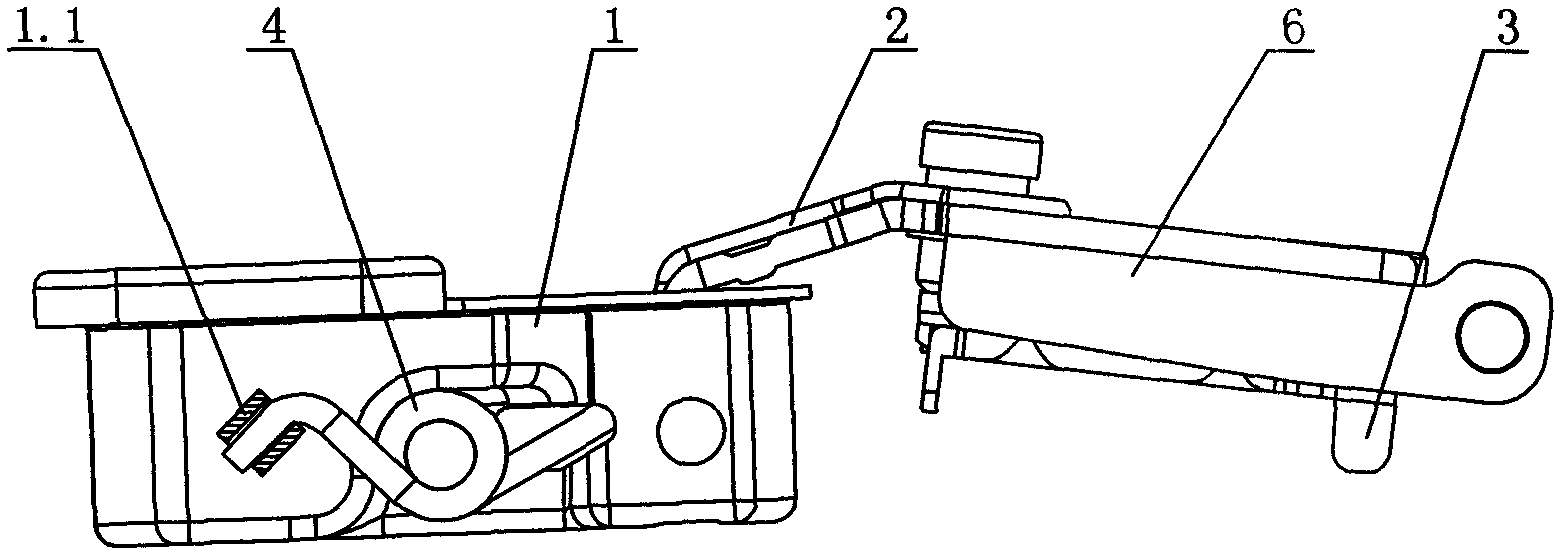

[0025] see Figure 4 , The main difference between the hinge for furniture and the first embodiment is that the buckle 1.1 is a hook. Other parts not described are the same as those of the first embodiment and will not be repeated.

no. 3 example

[0027] see Figure 5 , The main difference between the hinge for furniture and the first embodiment is that the end of the foot connected to the torsion spring 4 and the buckle 1.10 is bent into a hook shape, and buckles the buckle 1.1. Other parts not described are the same as those of the first embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com