Splicing auxiliary device for furniture production

An auxiliary device and furniture technology, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of easy tilting of furniture, inability to fix furniture, low work efficiency, etc., and achieve the effect of saving manpower and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

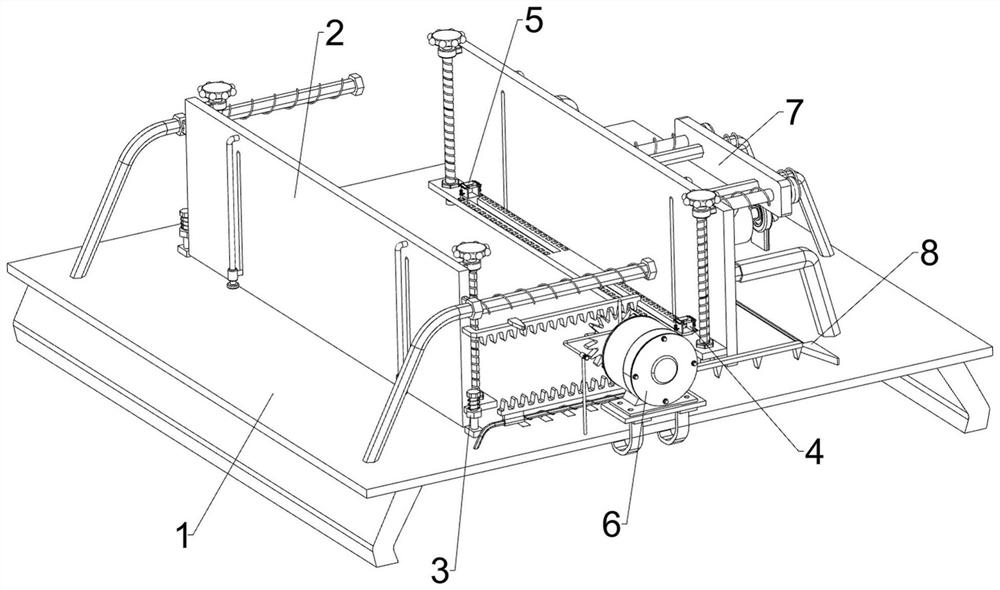

[0025] A splicing aid for furniture production, such as Figure 1-7 As shown, it includes a mounting base 1, a placement component 2 and a clamping component 3. The mounting base 1 is provided with a placement component 2 that is placed by sliding, and the mounting base 1 is provided with a clamp that is clamped by sliding. Tight component 3.

[0026] When using the device, the staff puts the furniture to be spliced on the placement component 2, and then clamps it through the clamping component 3. After clamping, the staff splices the furniture. After the splicing is completed, the staff will furniture removed.

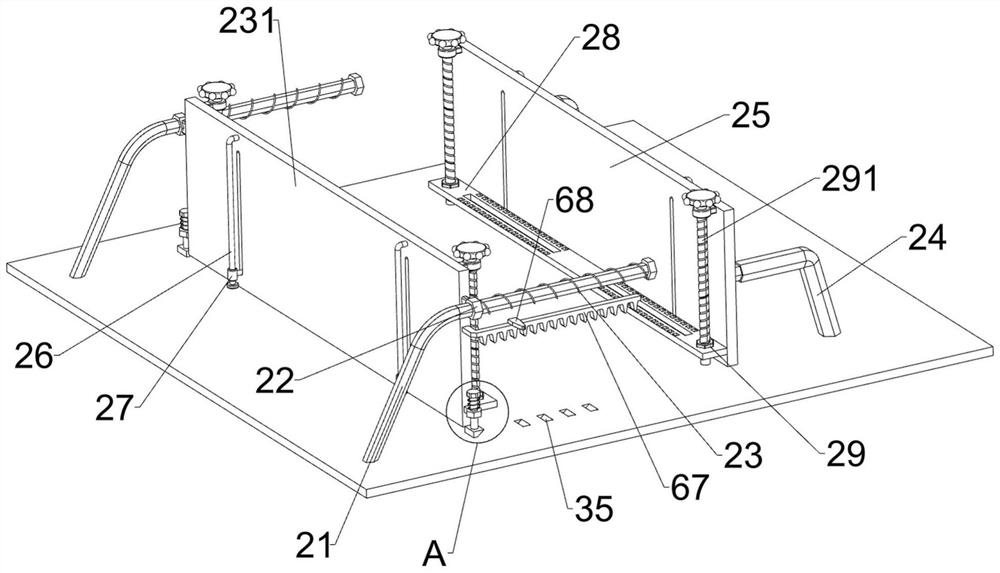

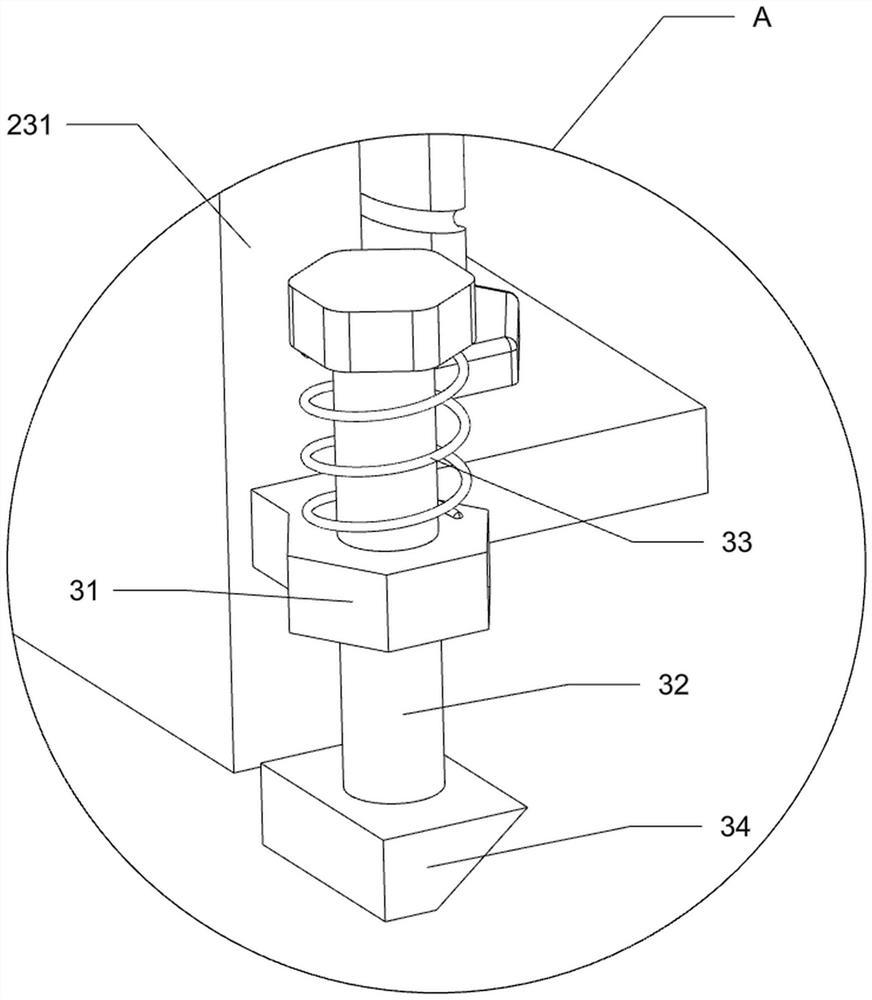

[0027] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the placement assembly 2 includes a first prismatic guide rod 21, a first sliding sleeve 22, a first spring 23, a left mounting plate 231, a telescopic rod 24, a right mounting plate 25, a cylindrical guide rod 26, a second sliding Cover 27, place plate 28, nut 29 and screw mandrel 291, th...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 with Figure 4 As shown, a clamping assembly 4 is also included, and the clamping assembly 4 includes a slide block 42, a square plate 43, a second guide sleeve 44, a second slide bar 45, a third spring 46 and a second wedge-shaped block 47, placed Both the front and the rear of the plate 28 are provided with chute 41, inside the chute 41, a slide block 42 is slidably arranged, the left and right sides of the slide block 42 are all provided with a square plate 43, and the outside of the square plate 43 is provided with a second guide sleeve 44 , the second guide sleeve 44 is provided with a second slide bar 45 slidingly, and a third spring 46 is wound between the second slide bar 45 and the second guide sleeve 44, and the bottom of the second slide bar 45 is provided with a first Two wedge-shaped clamping blocks 47 are provided with two rows of second clamping slots 48 at the front and rear of the placement plate 28 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com