Straightening device for reinforcing steel bar machining

A straightening device and steel bar processing technology, which is applied in the field of steel bar straightening, and can solve the problems of rear device collision and lack of transition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

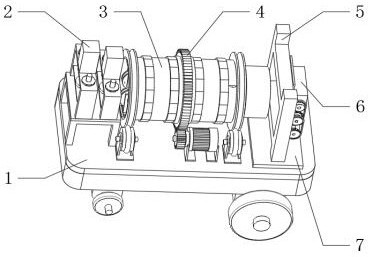

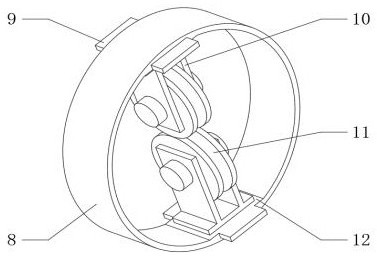

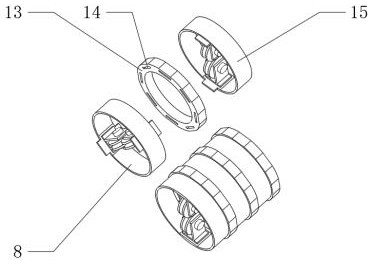

[0036] A straightening device for steel bar processing, such as Figure 1-7As shown, it includes base plate 1 and straightening assembly 3, the top outer wall of base plate 1 is fixedly connected with discharge assembly 2, the top outer wall of base plate 1 is fixedly connected with support plate 7, and the top outer wall of support plate 7 is fixedly connected with stand 5, stand 5 The outer wall of one side is fixedly connected with the feeding assembly 6, and the outer wall of the straightening assembly 3 is fixedly connected with the rotary assembly 4; the straightening assembly 3 includes a sleeve one 8 and a plug plate 9, and the inner wall of the sleeve one 8 is provided with symmetrically distributed laps. Platform 12, the outer wall on one side of the plug plate 9 is welded to the outer walls on both sides of the platform 12, the central outer wall of the platform 12 is fixedly connected with a bracket 10, and the inner wall of the bracket 10 is connected with a pressi...

Embodiment 2

[0043] A straightening device for steel bar processing, such as Figure 1-8 As shown, in order to solve the steel bar discharging problem; This embodiment makes the following improvements on the basis of Embodiment 1:

[0044] The discharge assembly 2 includes a support frame 34 and a platen 35, the bottom outer wall of the support frame 34 is fixedly connected to the top outer wall of the bottom plate 1, the bottom outer wall of the platen 35 is fixedly connected to the top outer wall of the support frame 34, and the top outer wall of the platen 35 is fixedly connected with Beam frame 1 37, the top outer wall of beam frame 1 37 is fixedly connected with oil cylinder 38, the quantity of oil cylinder 38 is two, and the piston rod of one of oil cylinder 38 is connected with connector 1 by thread, and the outer wall of connector 1 bottom is fixedly connected with knife block 36. The outer wall at the bottom of another oil cylinder 38 is fixedly connected with the beam frame 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com