Traction motor

A technology for motors and shafts, applied in the direction of electromechanical devices, electric components, casings/covers/supports, etc., can solve problems such as deterioration of motor durability, doubts about motor quality and reliability, etc., to prevent motor noise and vibration, quality The effect of improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is an example, and those skilled in the art to which the present invention belongs can realize it in different forms. Therefore, it is not limited to the embodiments described here.

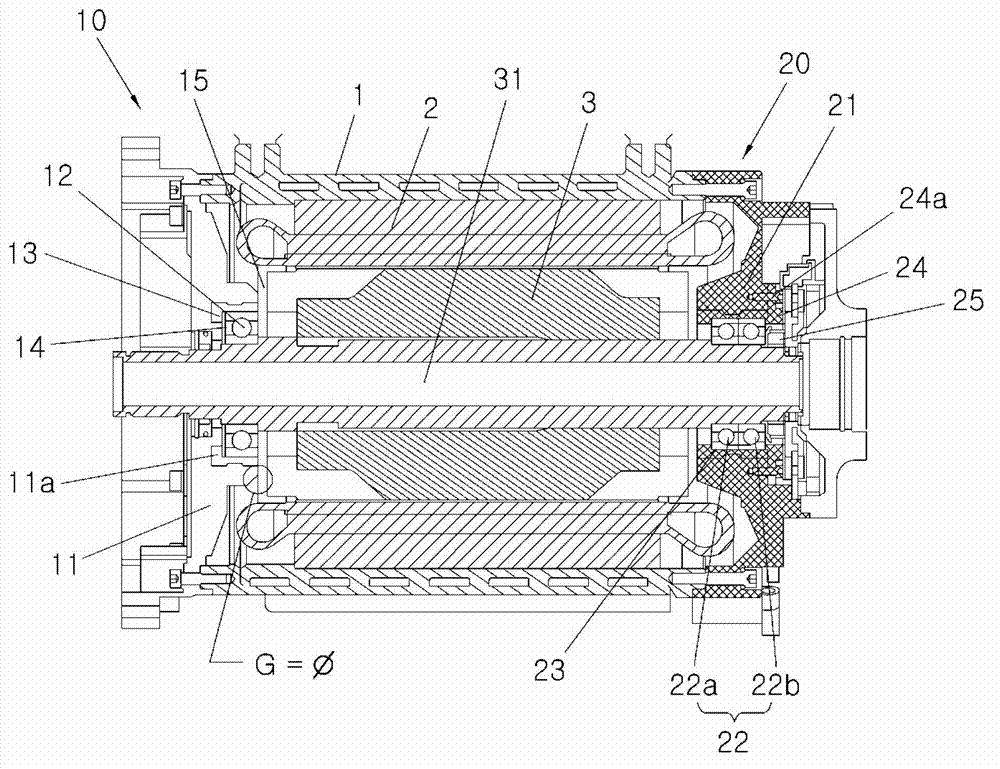

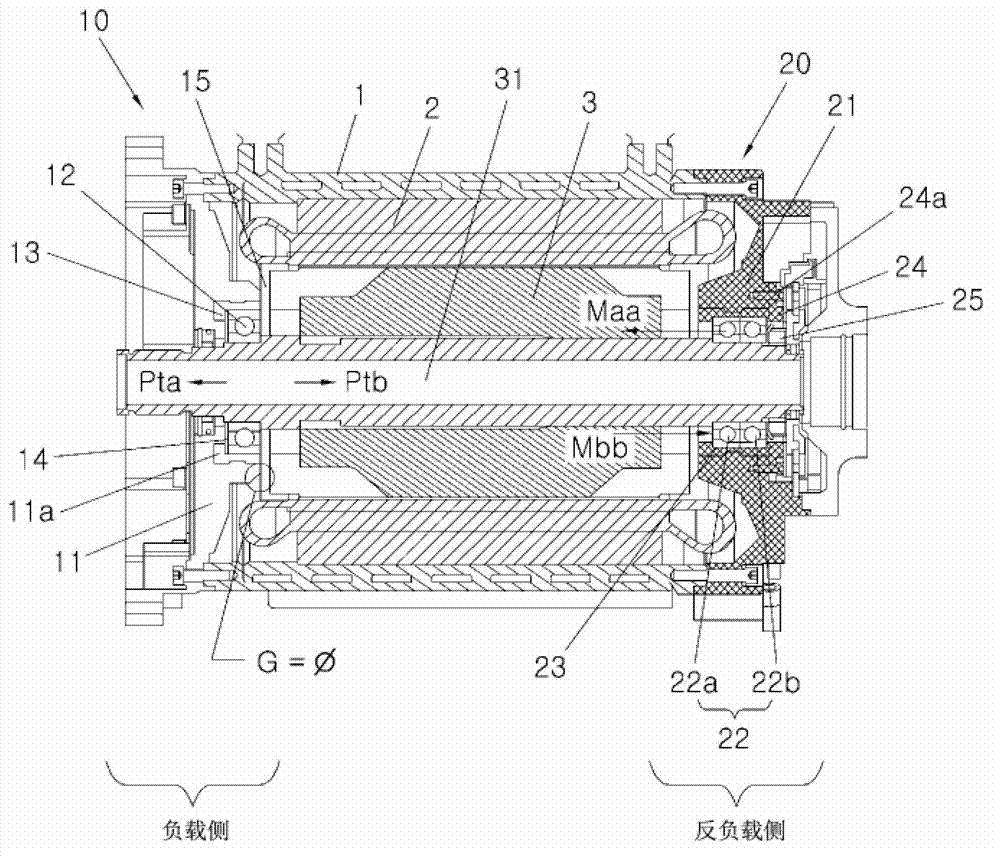

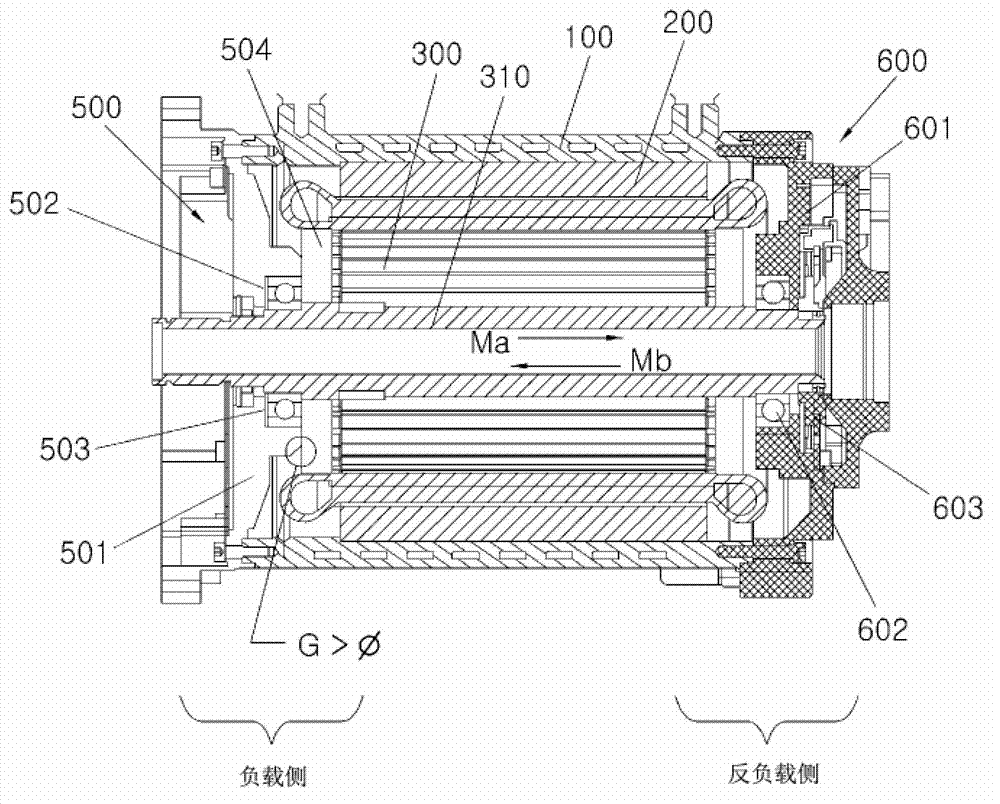

[0042] figure 1 is a cross-sectional view of a traction engine using a bearing-supported rotating shaft according to an embodiment of the present invention.

[0043] As shown in the figure, the traction engine includes a stator assembly 2 arranged in the casing 1, and a rotor assembly 3 surrounded by the stator assembly 2 and having a rotating shaft 31; the left and right sides of the rotating shaft 31 have a pair of supports 10, 20 to support the rotating shaft 31.

[0044] The pair of supporting parts 10, 20 are divided into supporting the left side ( figure 1 ) of the load side support part 10; the support is located on the right side of the opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com