Patents

Literature

148 results about "Constant linear velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

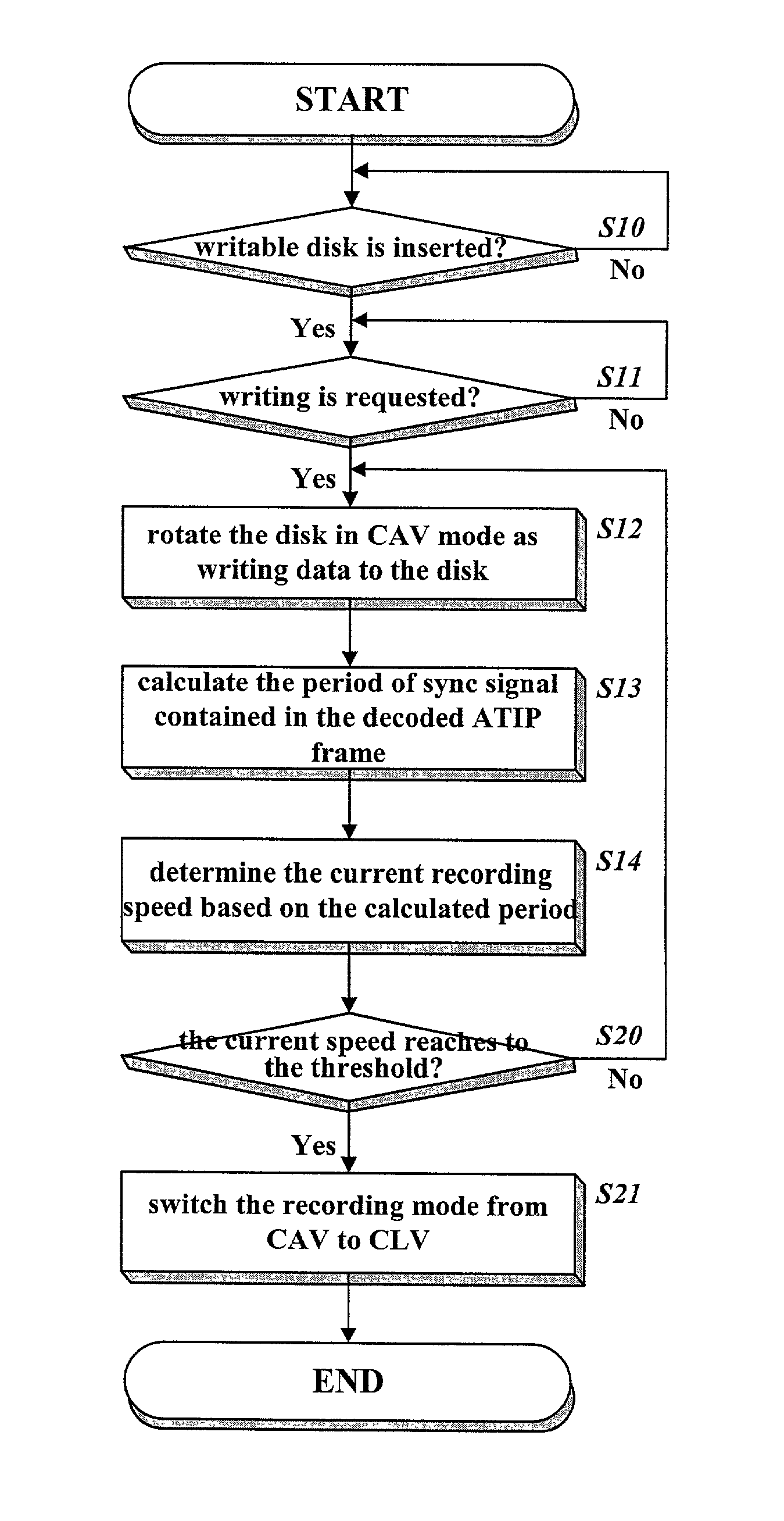

In optical storage, constant linear velocity (CLV) is a qualifier for the rated speed of an optical disc drive, and may also be applied to the writing speed of recordable discs. CLV implies that the angular velocity (i.e. rpm) varies during an operation, as contrasted with CAV modes. The concept of constant linear velocity was patented in 1886 by phonograph pioneers Chichester Bell and Charles Tainter.

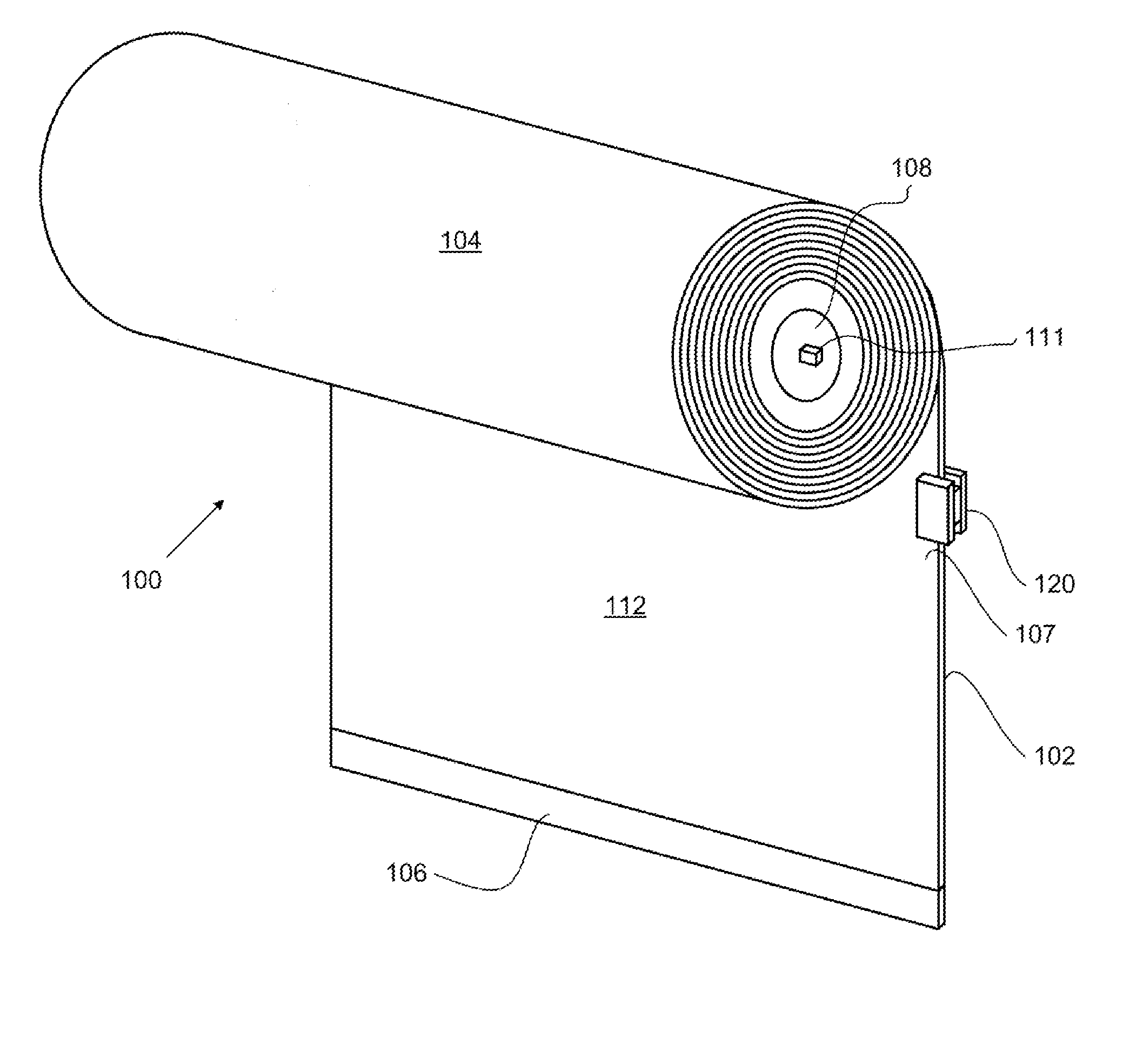

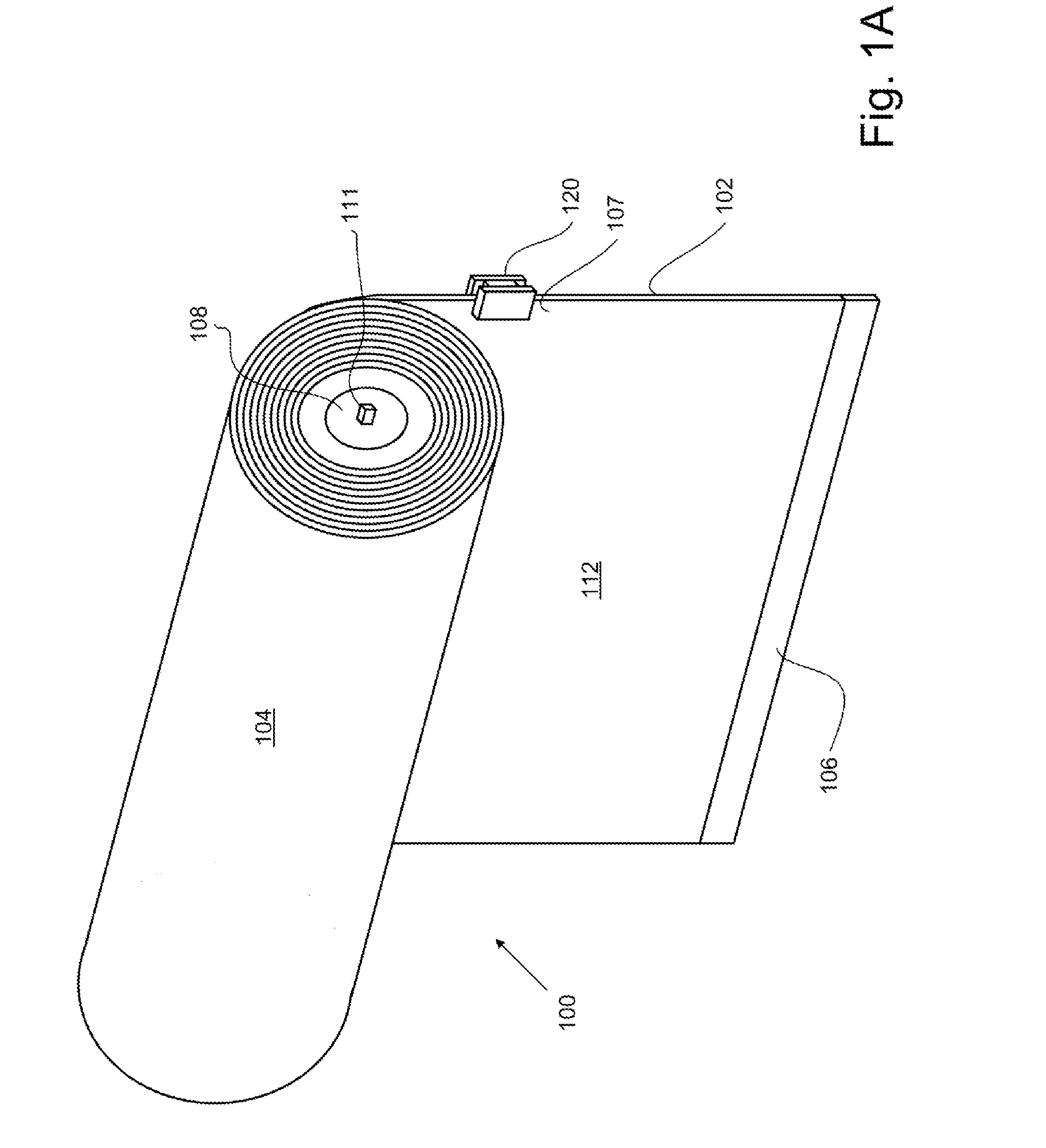

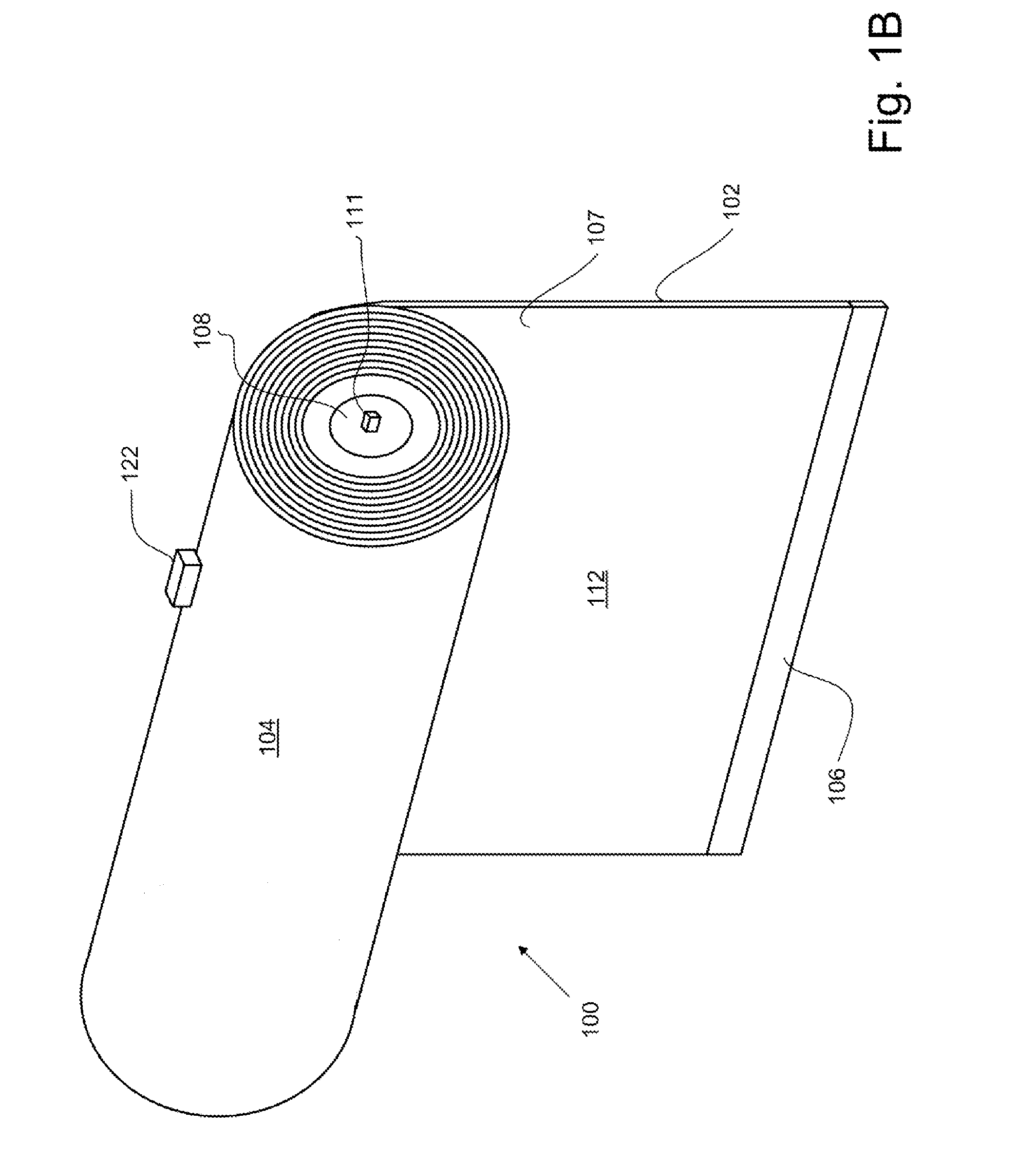

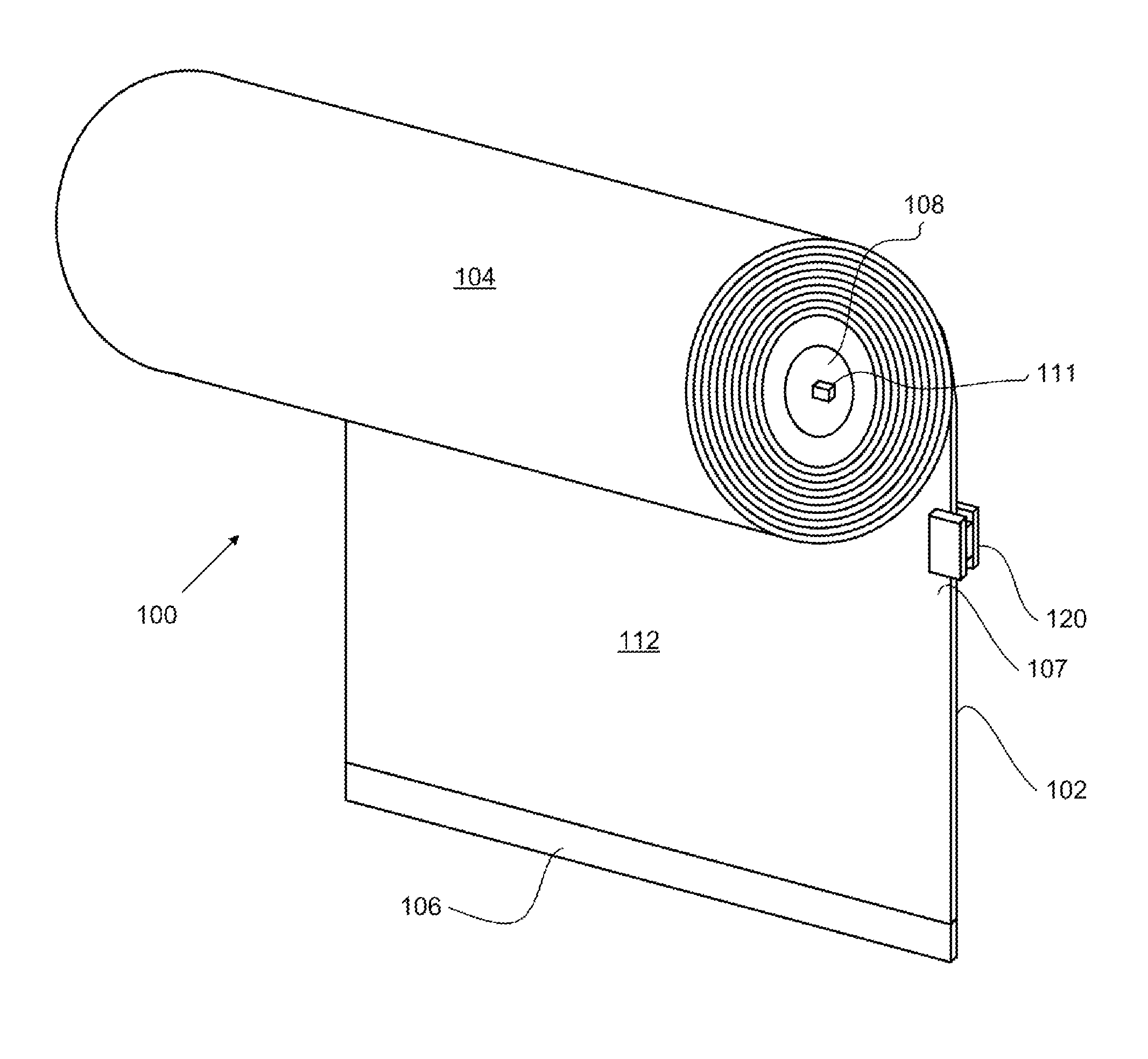

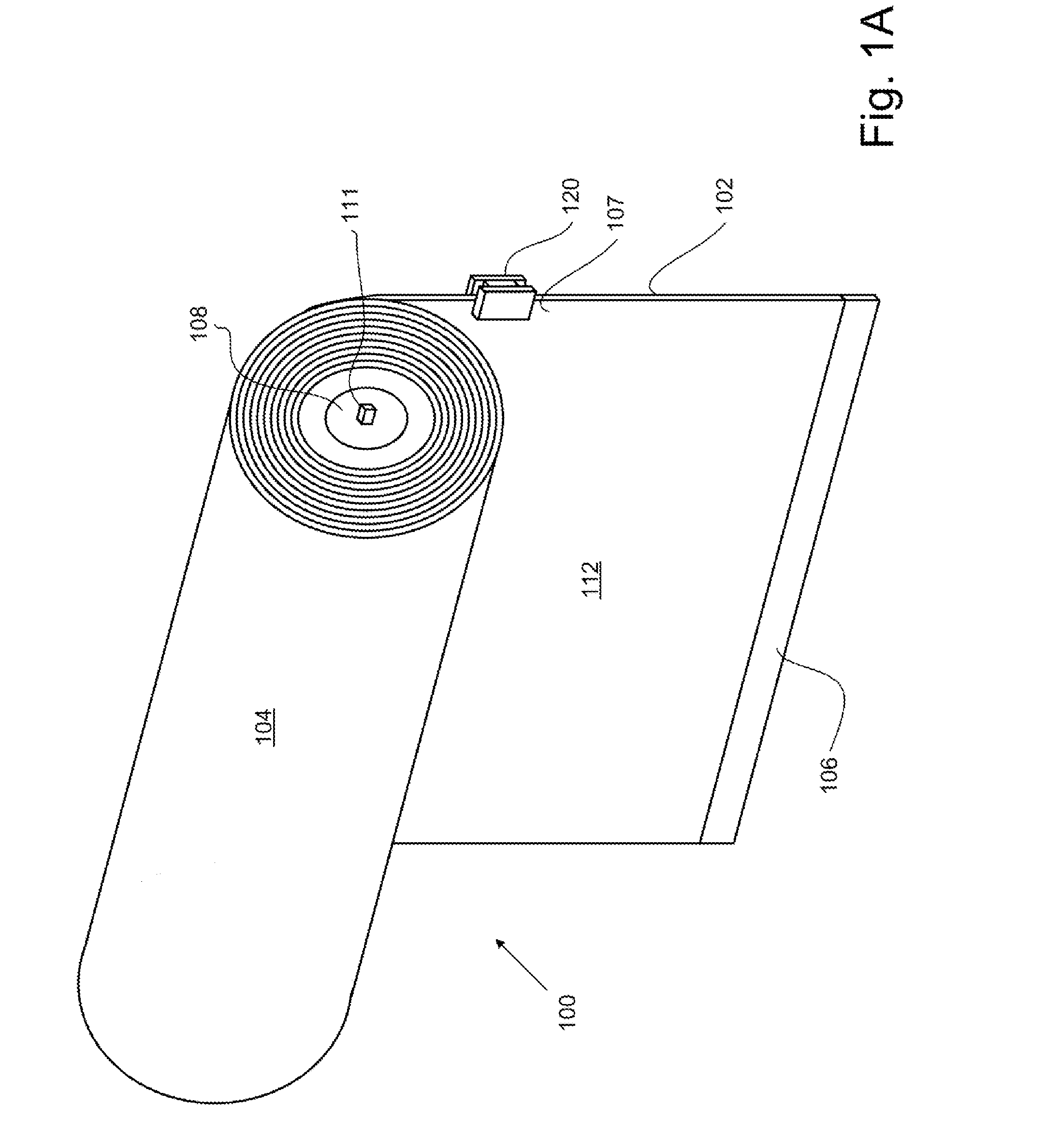

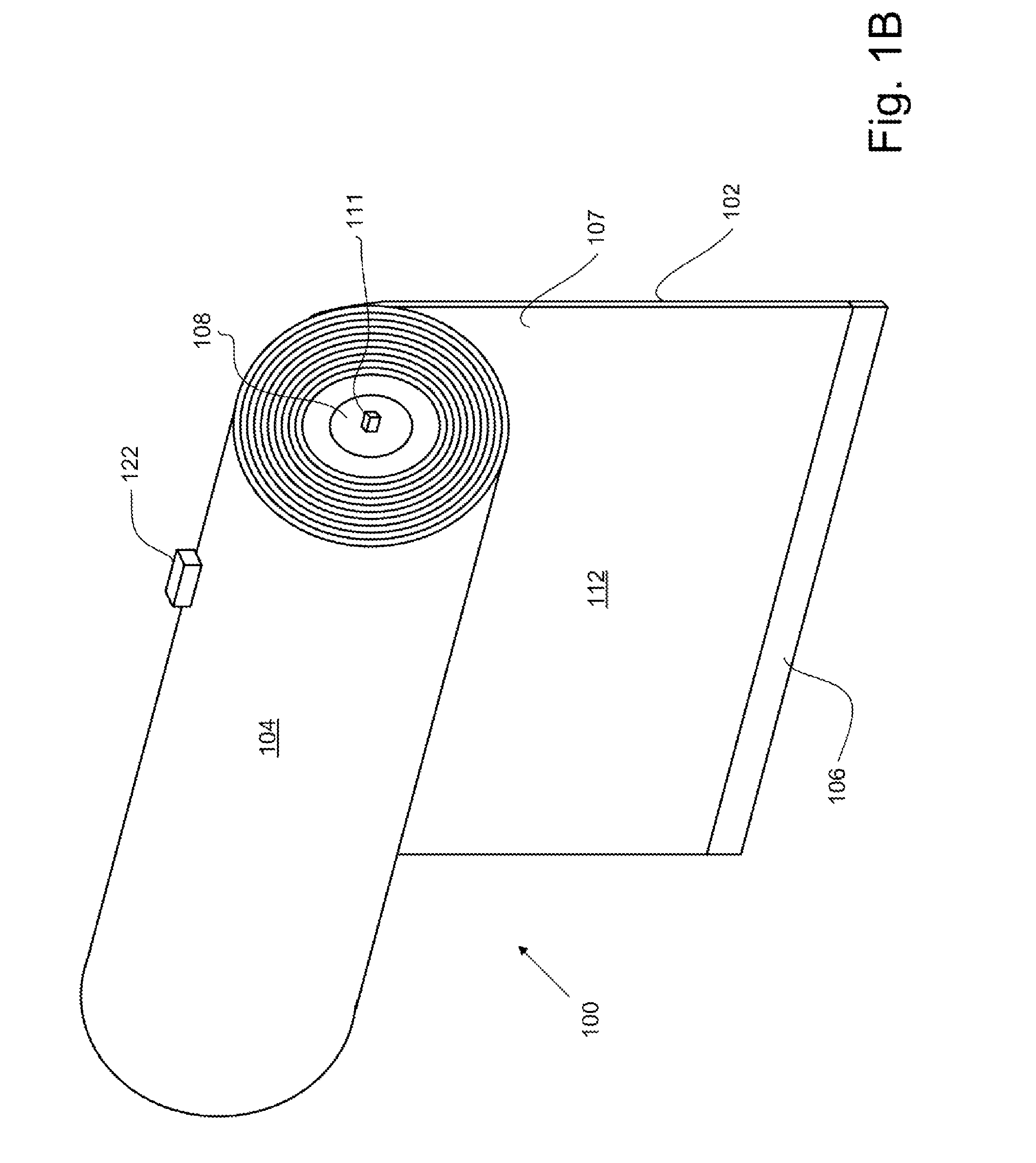

System and method for controlling one or more roller shades

Presented is a roller shade system that includes a flexible shade material having a lower end, a rotatably supported roller tube that windingly receives the shade material, a stepper motor that operably engages the roller tube to rotate the roller tube to move the lower end of the shade material between a first position and a second position, an optical sensor configured for capturing an image frame of the shade material at linear positions along the shade material as the lower end of the flexible shade material moves from the first position to the second position, and a stepper motor controller configured for controlling the frequency of input pulses to the stepper motor to move the lower end of the flexible shade material from the first position to the second position at a substantially constant linear velocity in response to position information obtained from the plurality of captured image frames.

Owner:CRESTRON ELECTRONICS

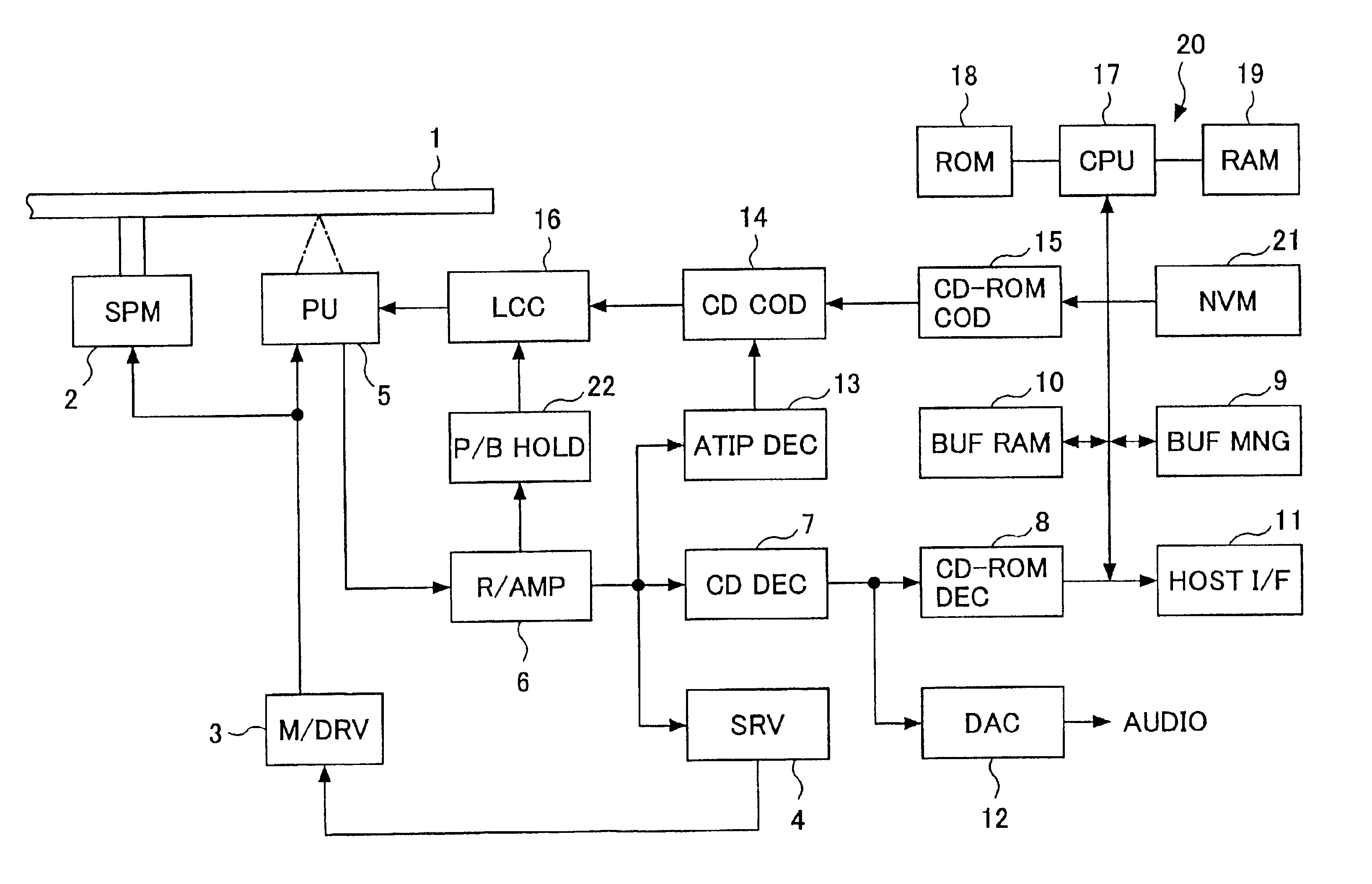

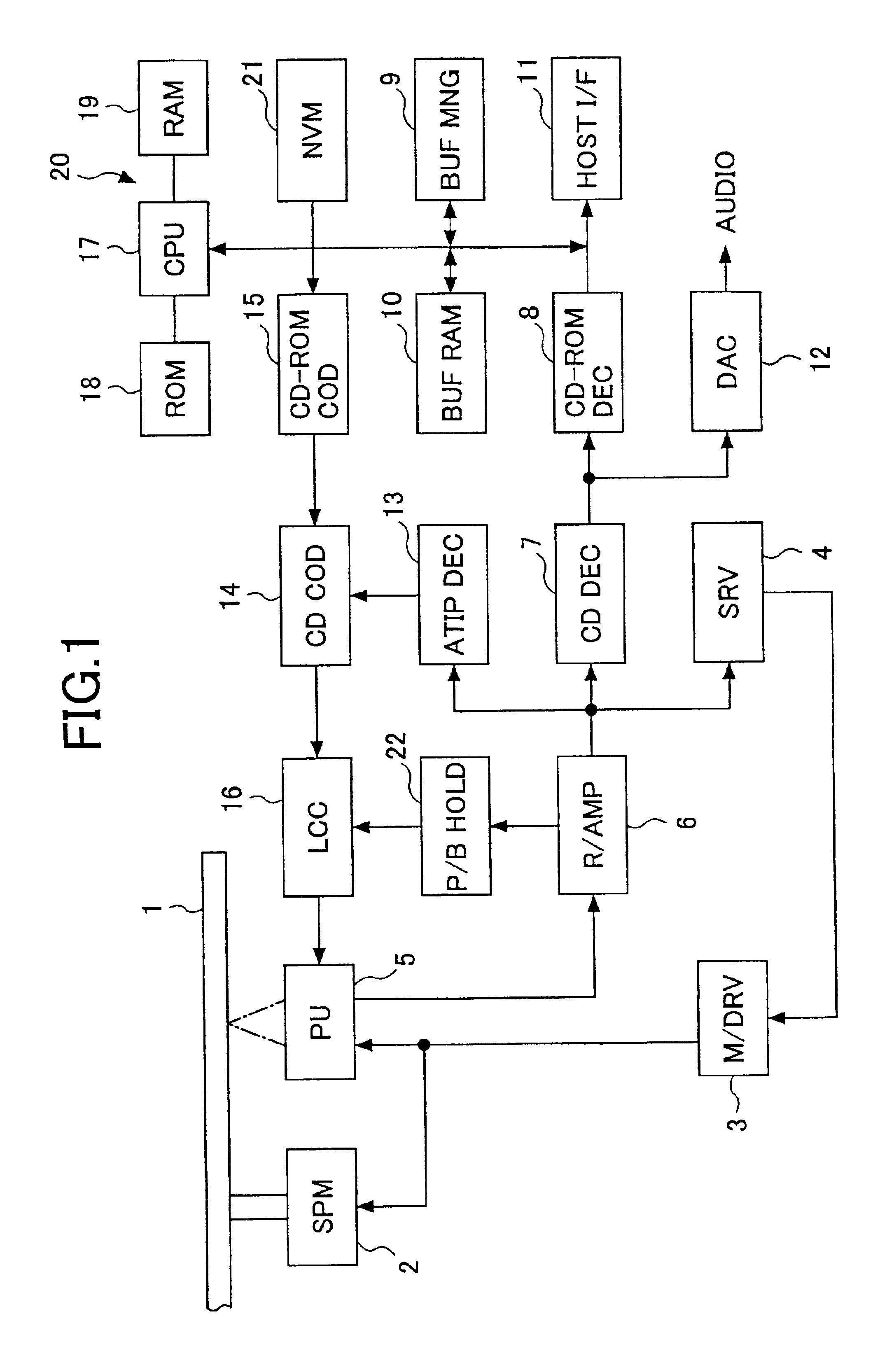

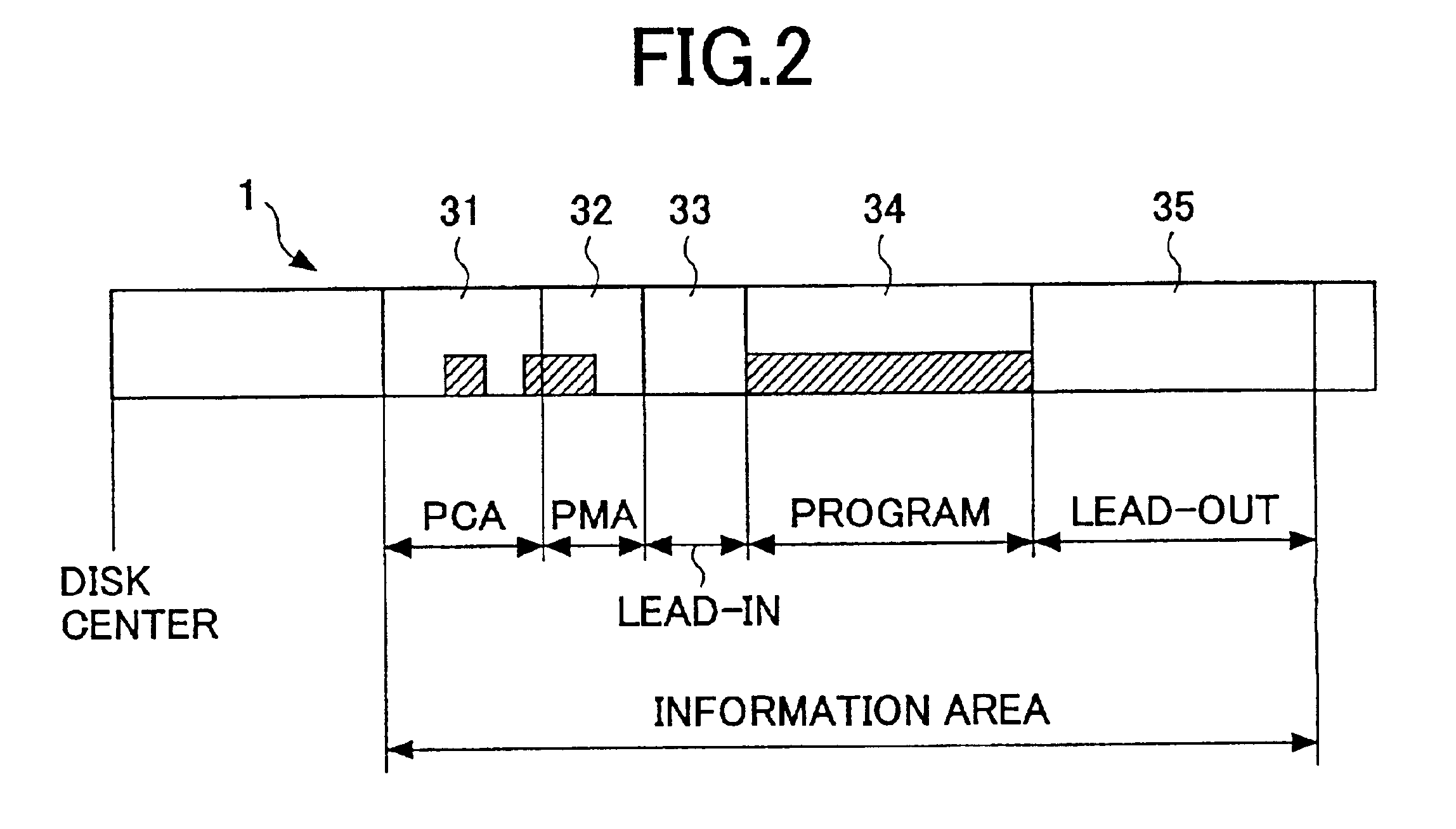

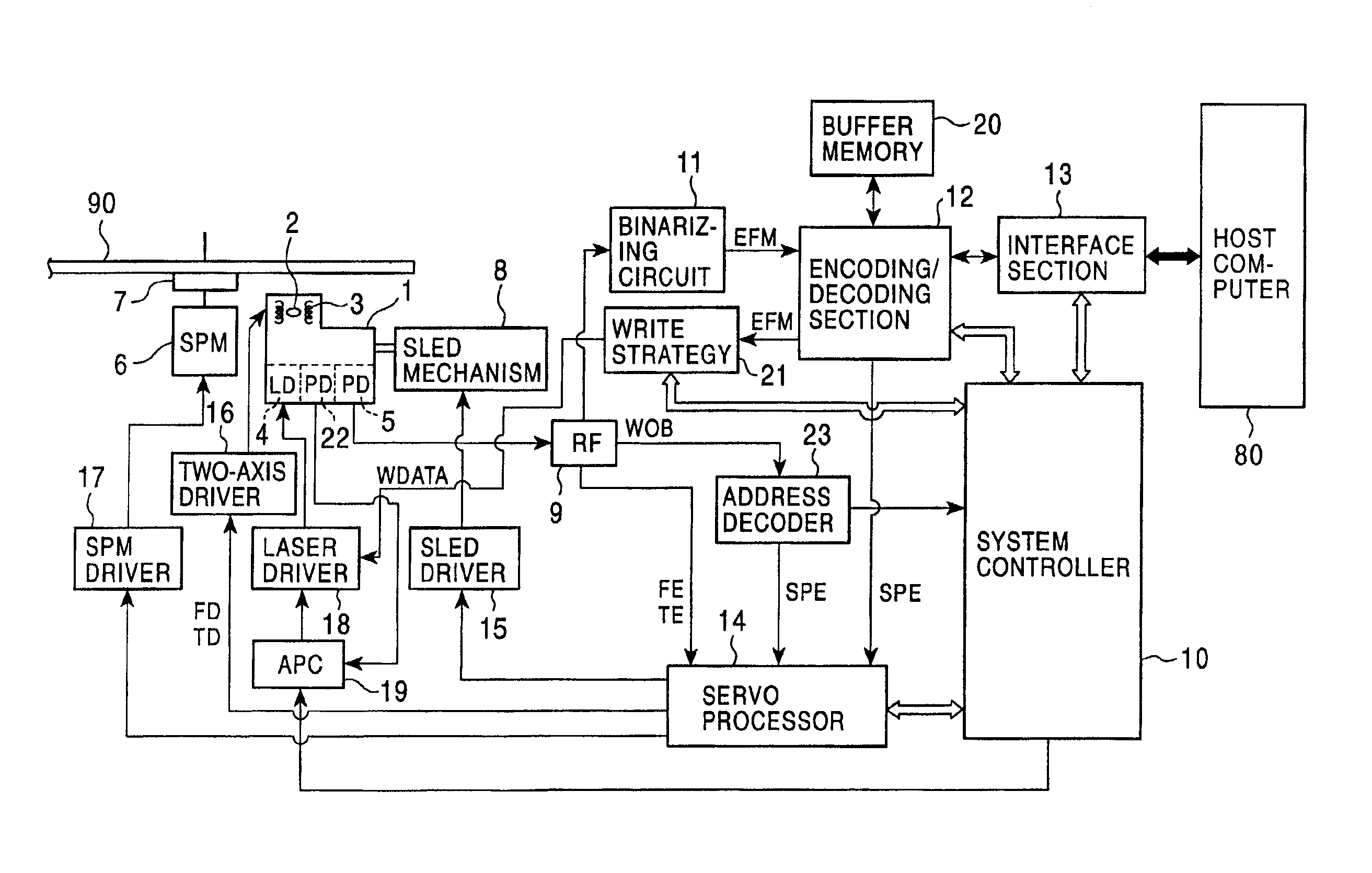

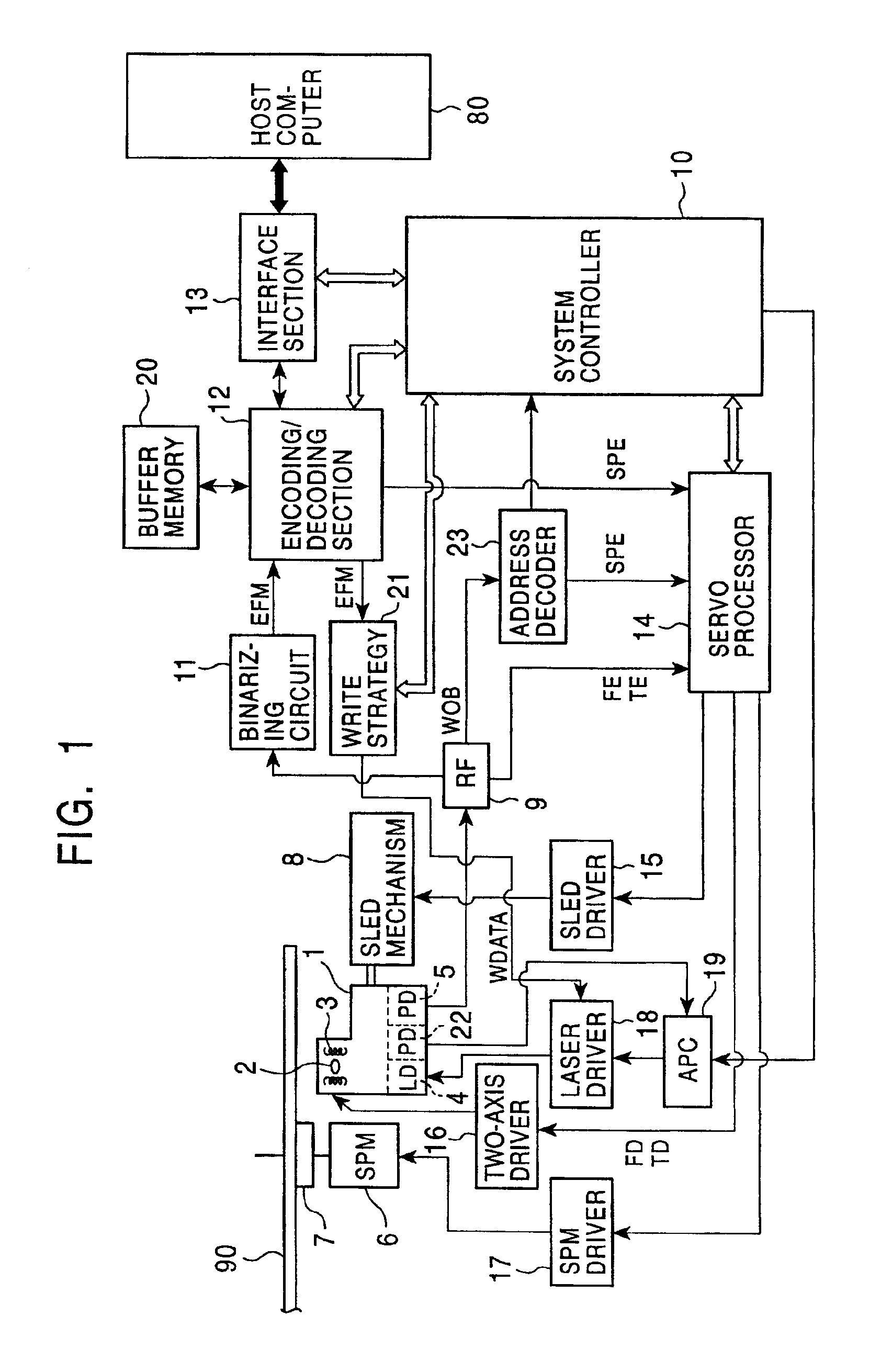

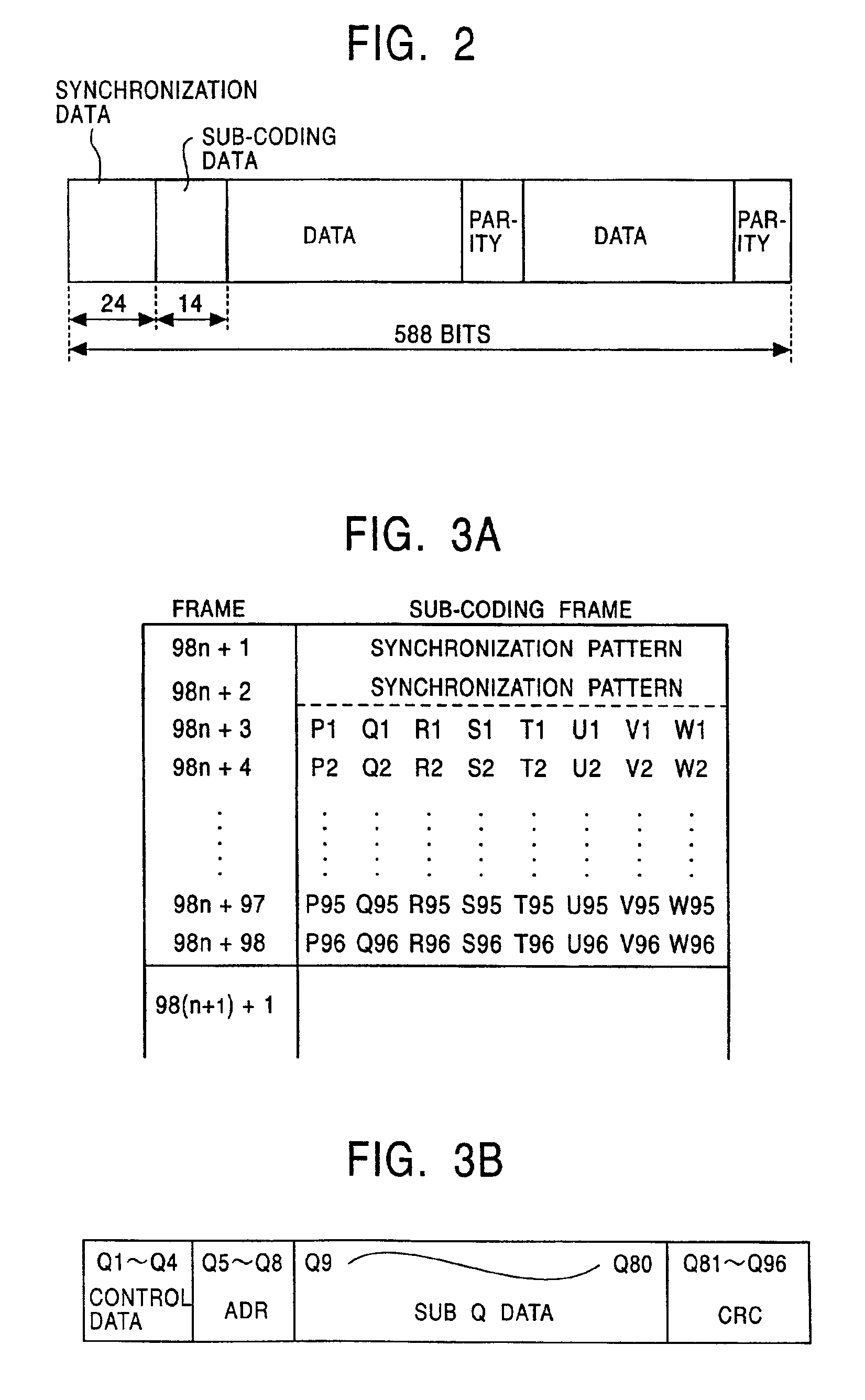

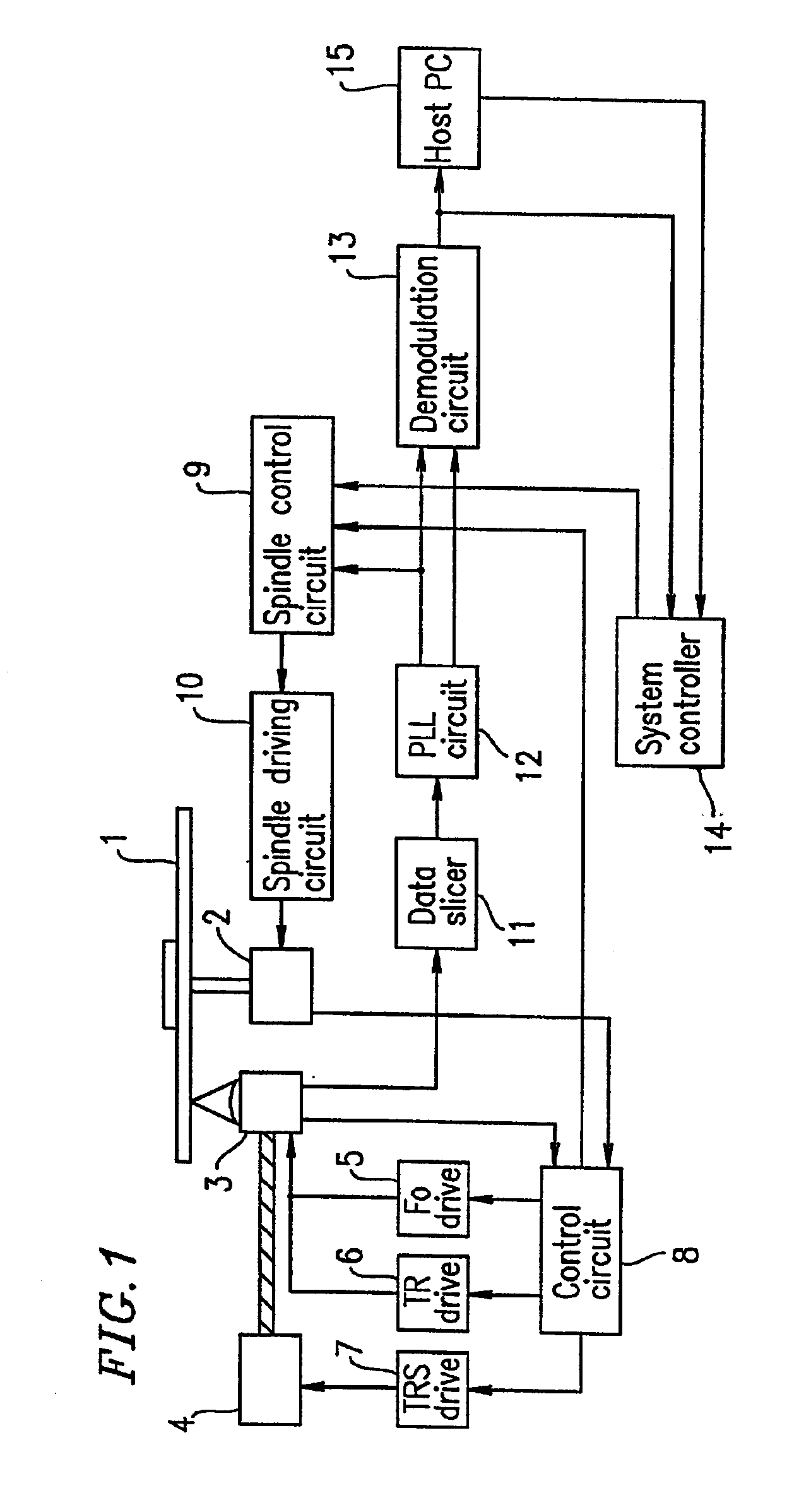

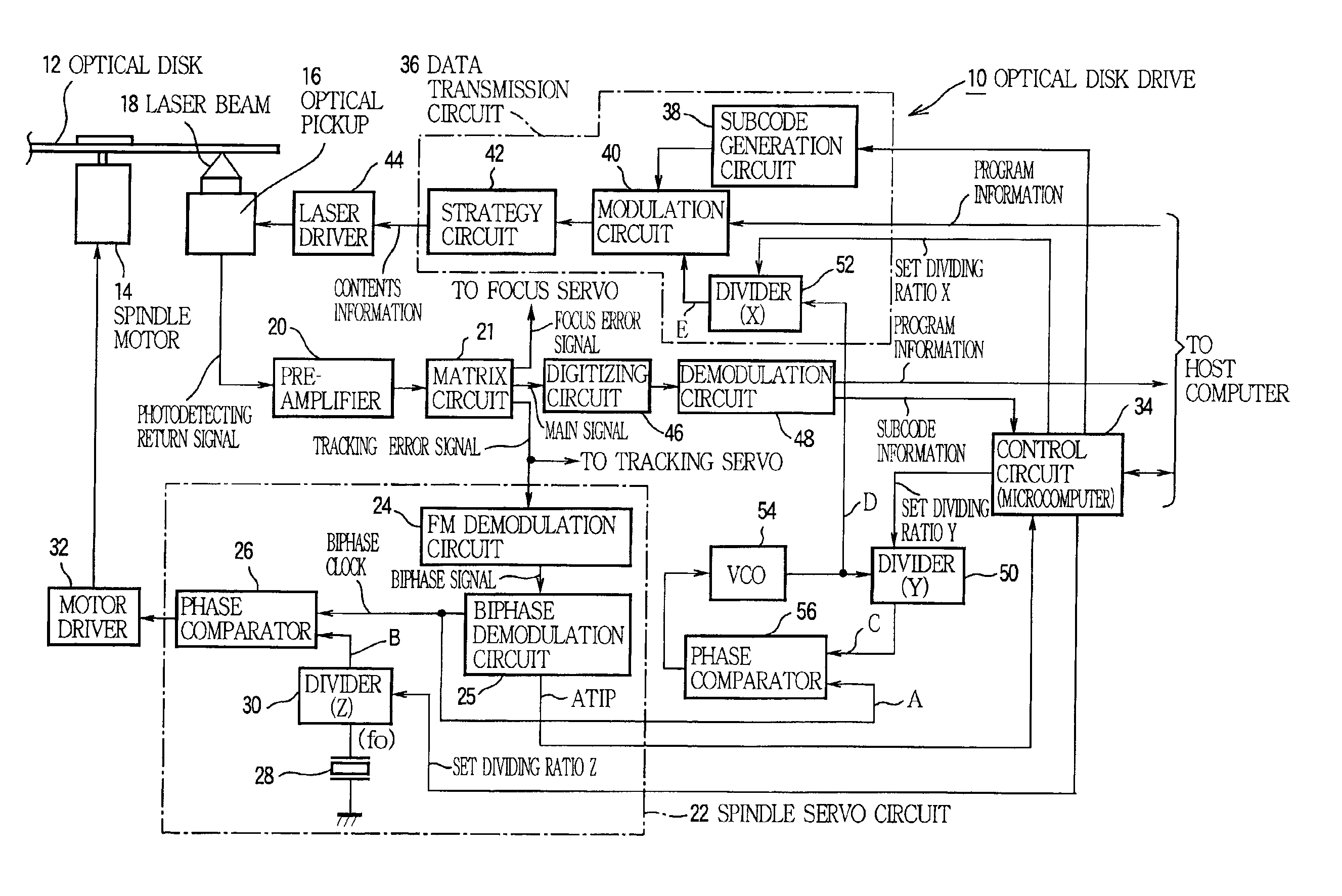

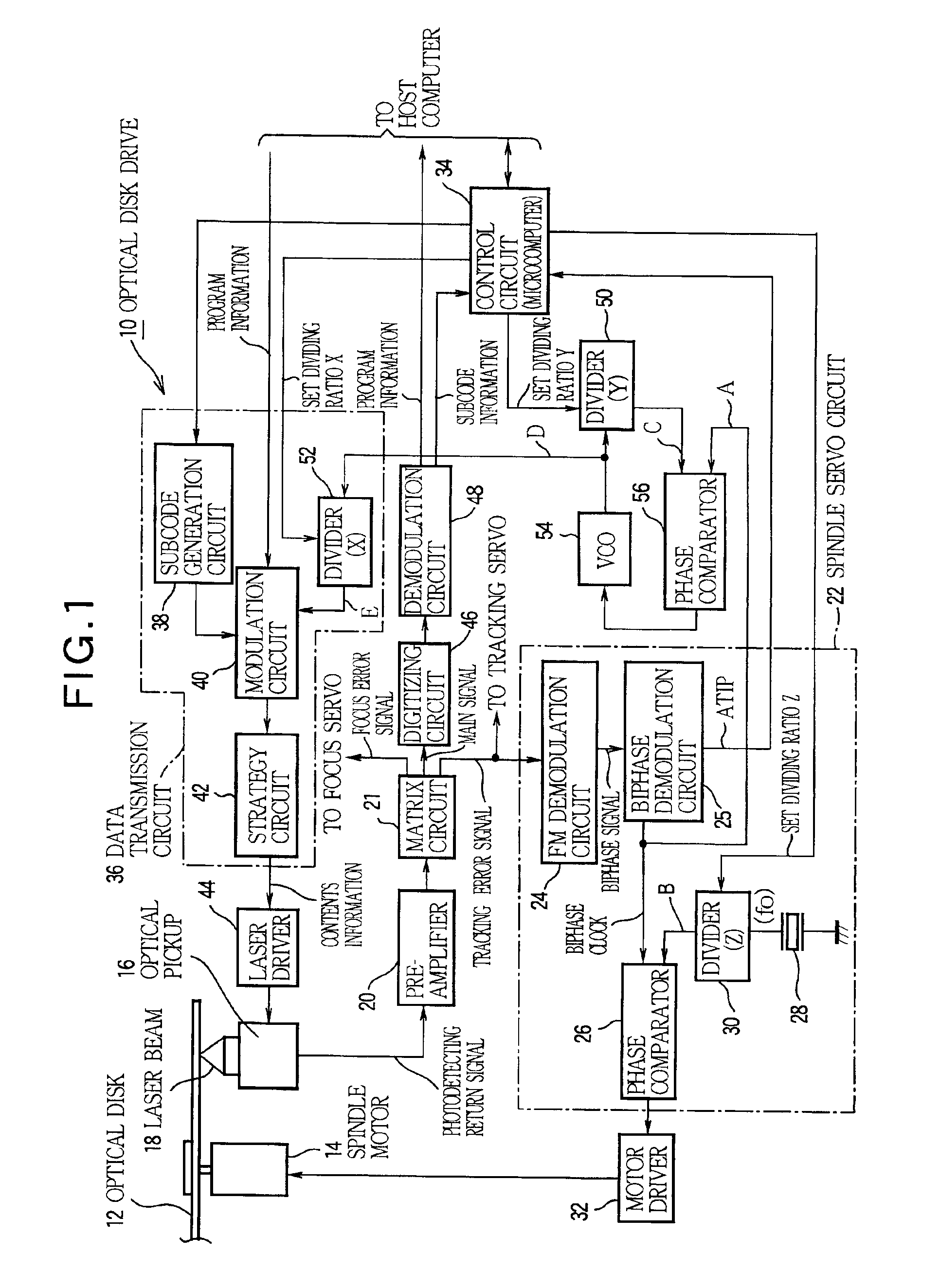

Optical disk drive, its optical recording control method and data processing apparatus

InactiveUS6891786B2Make the starting of the recording opeIncrease speedCombination recordingDisposition/mounting of recording headsConstant linear velocityLight beam

In an optical disk drive, an OPC is performed prior to a start of recording of an optical disk by accessing a power calibration area of the disk with a light beam emitted by a light source while the disk is rotated at a constant linear velocity. An optimum recording power for the light source during the recording is determined based on results of the OPC. A highest linear velocity of linear velocities is changed to a next highest linear velocity for a controlled velocity of a disk rotation device during a subsequent OPC. It is detected whether the OPC and the determination are normally performed after one of the linear velocities is set. The controlled velocity during the recording is set to an angular velocity corresponding to the one of the linear velocities at which the OPC and the determination are normally performed.

Owner:RICOH KK

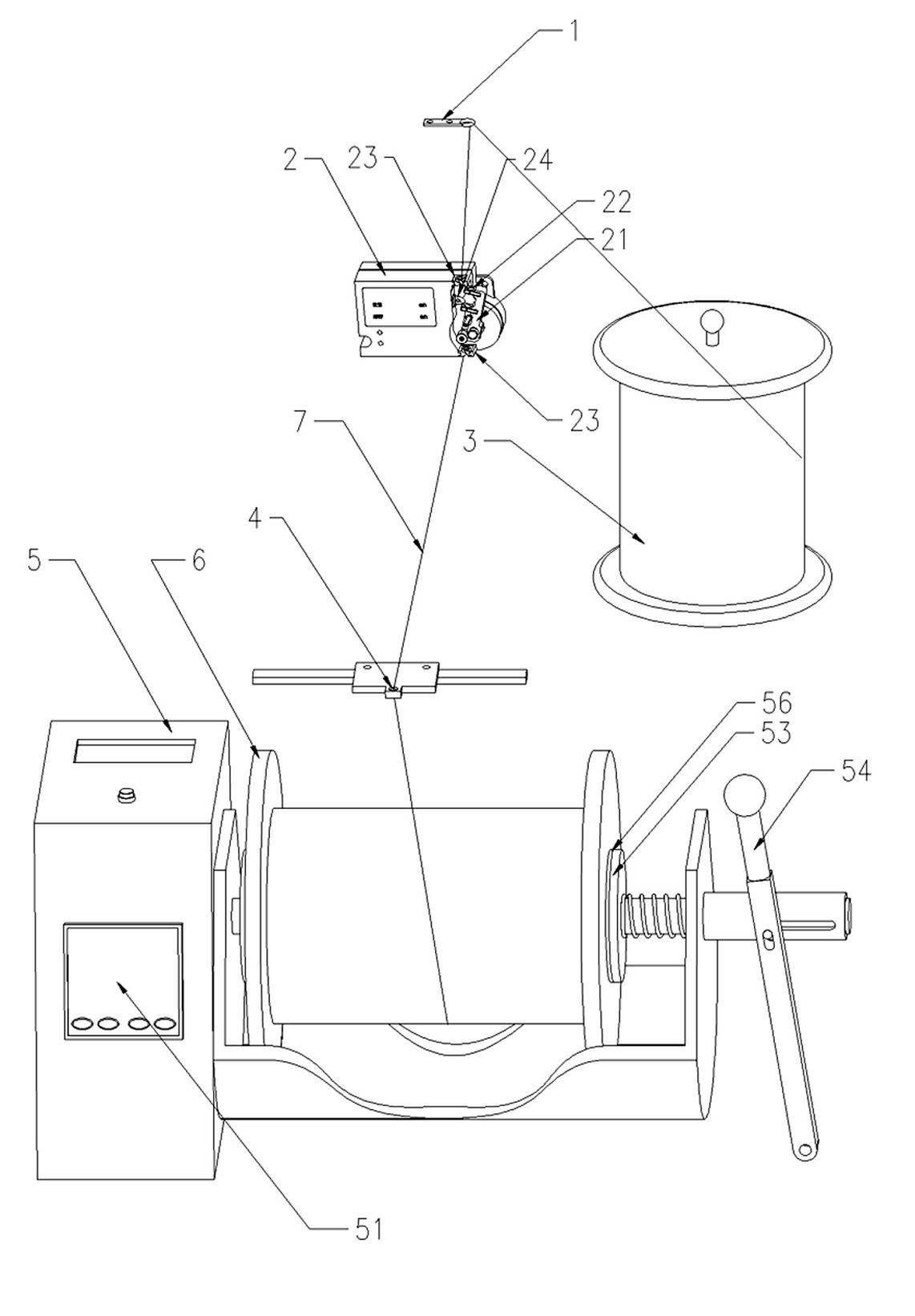

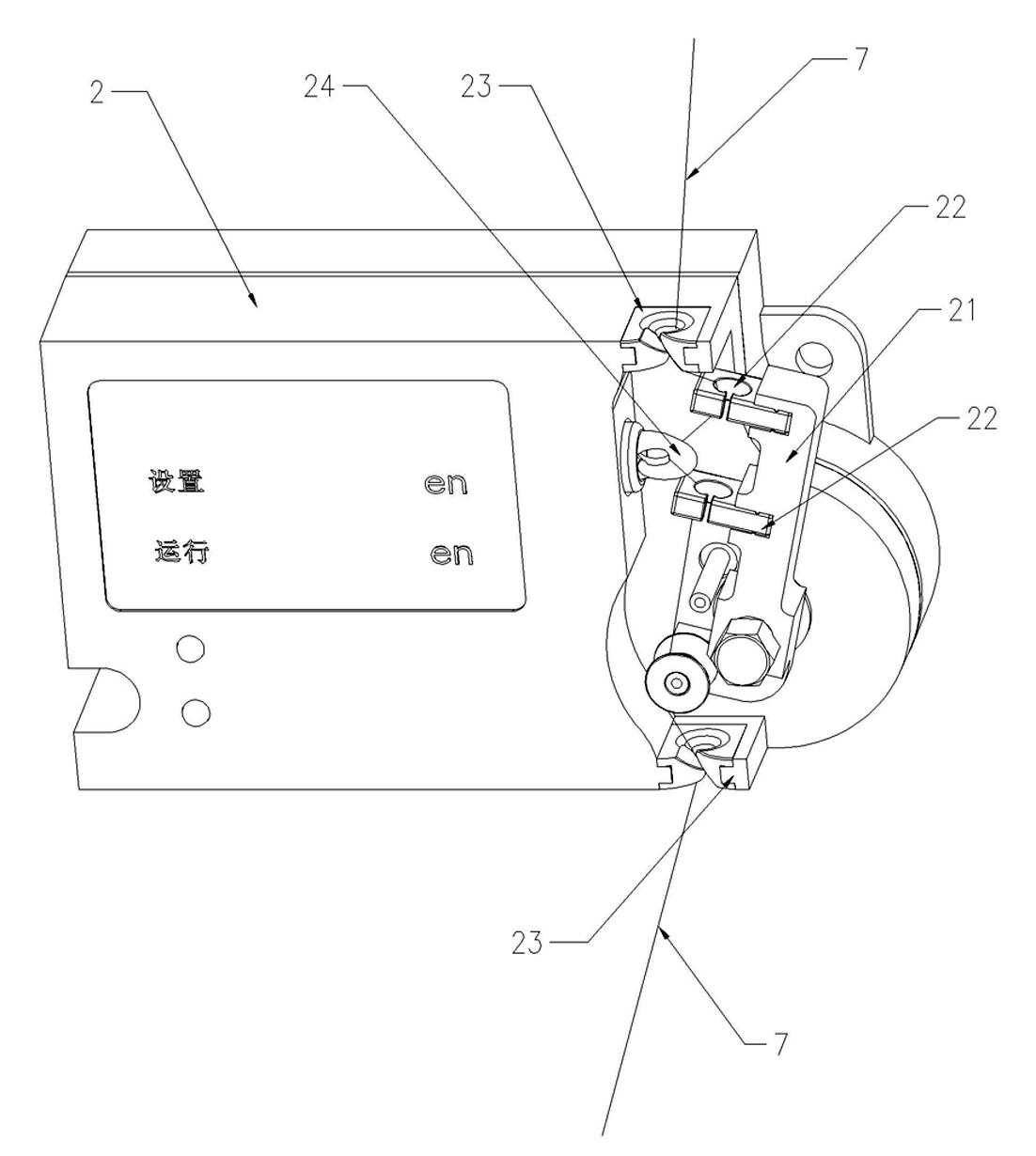

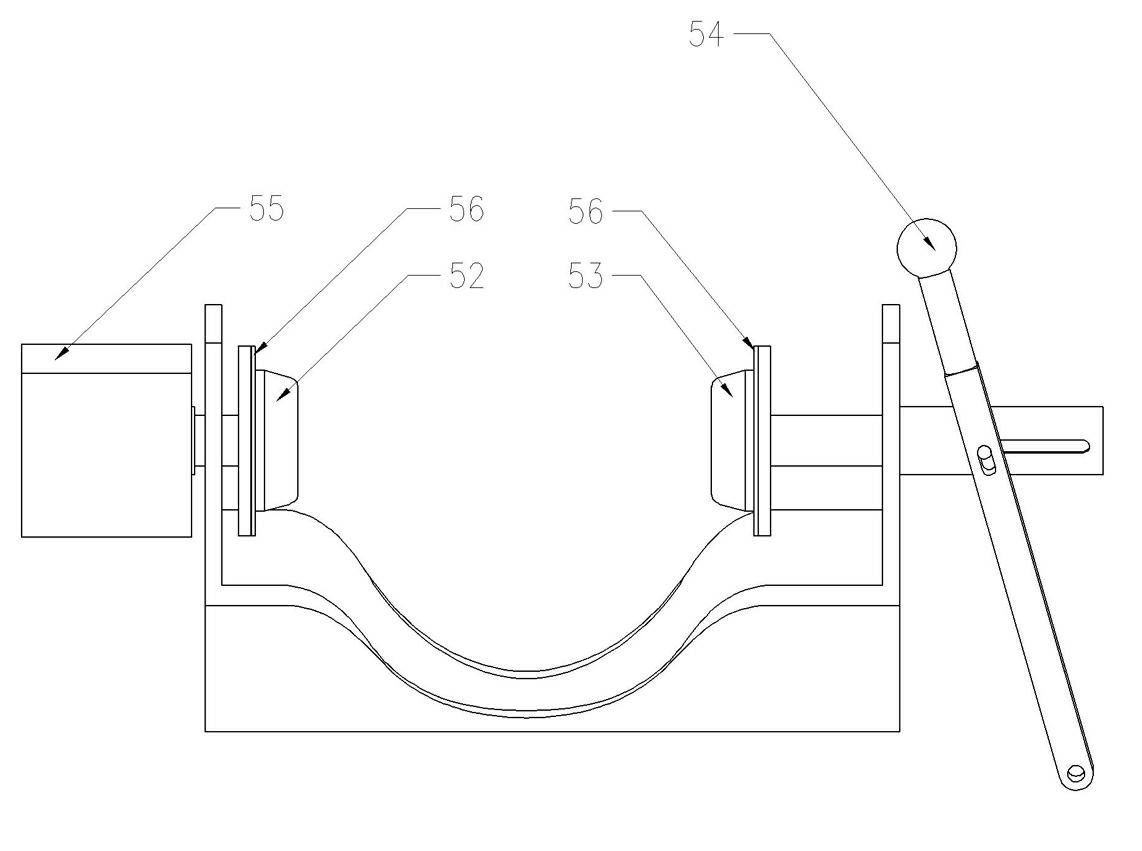

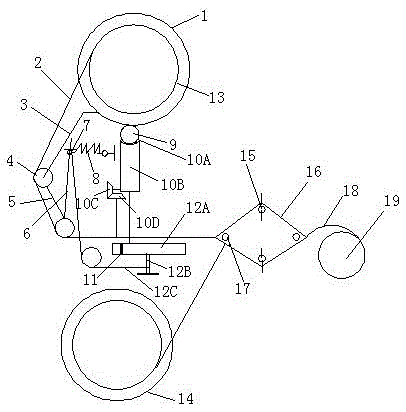

Intelligent rewinding machine

InactiveCN102107800AOvercome the non-parallelismClamp firmlyFilament handlingYarnConstant linear velocity

The invention discloses an intelligent rewinding machine with constant linear velocity, constant tension and fixed wire length, comprising a linear velocity sensor, a tension automatic controller and a single spindle transmission control device, wherein a transmission cone table is directly fixed on an output shaft of a motor; a movable cone table is movably connected with a handle via a pin; the linear velocity sensor has the functions of detecting broken lines, linear velocity and length counting. When a tension detecting hook on the tension automatic controller detects that the tension of yarns is oversize, a swinging arm is controlled to rotate an angle so as to reduce the yarn bending degree of the flowing yarns and reduce the winding tension of the yarns, and vice versa. A computer controller on the single spindle transmission control device receives signals sent by the linear velocity sensor and controls the rotation speed and the broken lines of the motor to warn. As the gradual increasing winding diameter of the tube, the rotation speed of the tube is controlled to gradually slow, so that the winding linear velocity is constant; when the length of the yarns reaches the set value or the broken line signal is received, the power supply of the motor is cut off and the warning light twinkles.

Owner:平国民

Recording apparatus and recording method

InactiveUS6904008B2Reduction in accessibilityReduce data transferTelevision system detailsRecord information storageRecord statusConstant linear velocity

A method and apparatus for recording data wherein the amount of light reflected from a disk is detected, and it is determined according to the amount of reflected light whether the disk is a recordable disk or a rewritable disk. The disk is controlled according to the result of determination such that it is rotated at a constant angular velocity (CAV) or at a constant linear velocity (CLV) and recording is executed. Further, rotation driving control of the disk is selected according to factors other than the type of the disk, such as according to whether random recording is allowed or not, according to a recording state in the disk, according to whether an alternative area is provided or not, according to a recording start position, or according to whether initialization is required or not. CLV control or CAV control is appropriately selected for a disk at recording to suppress a reduction in accessibility and a reduction in data transmission rate.

Owner:SONY CORP

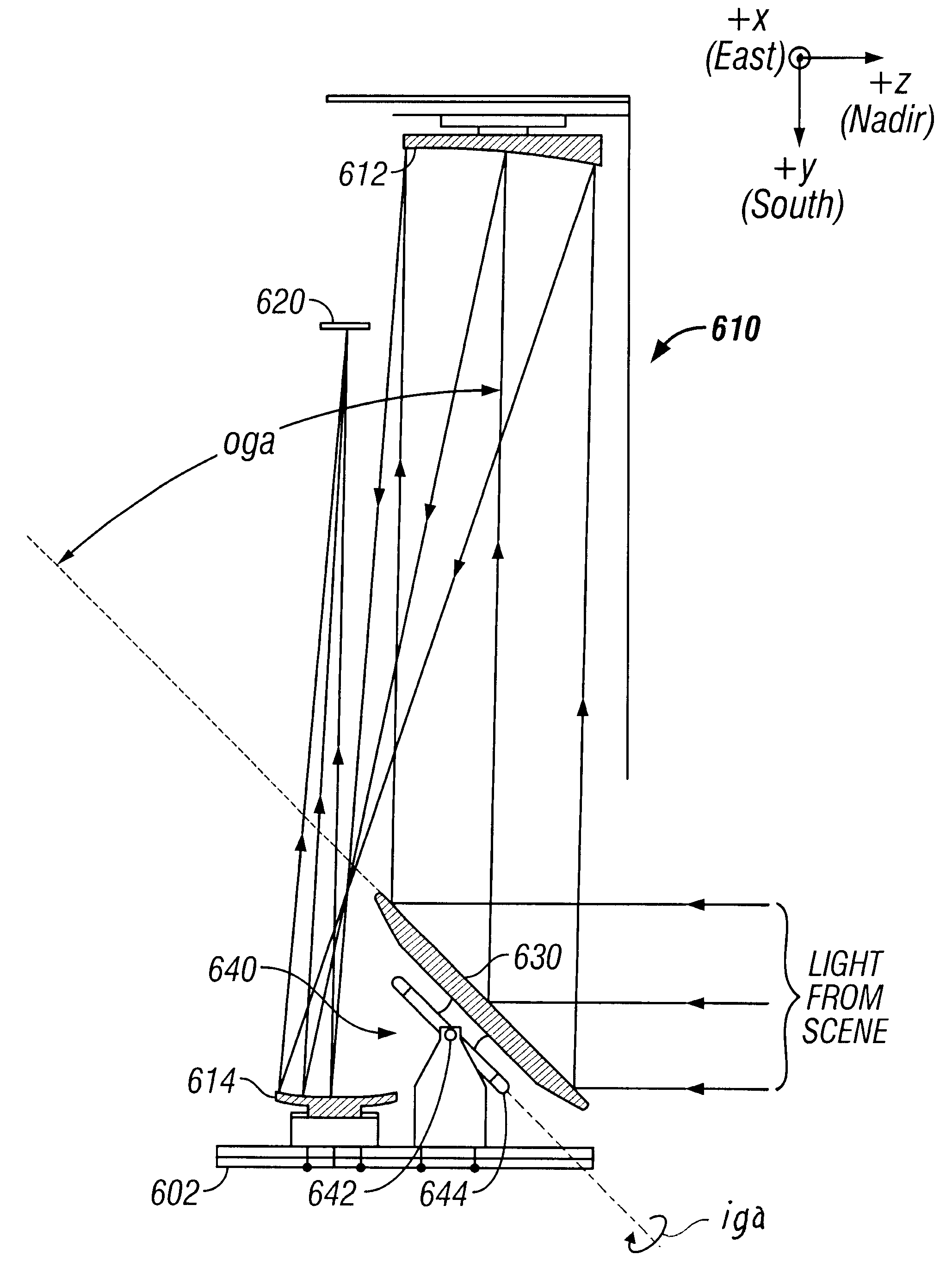

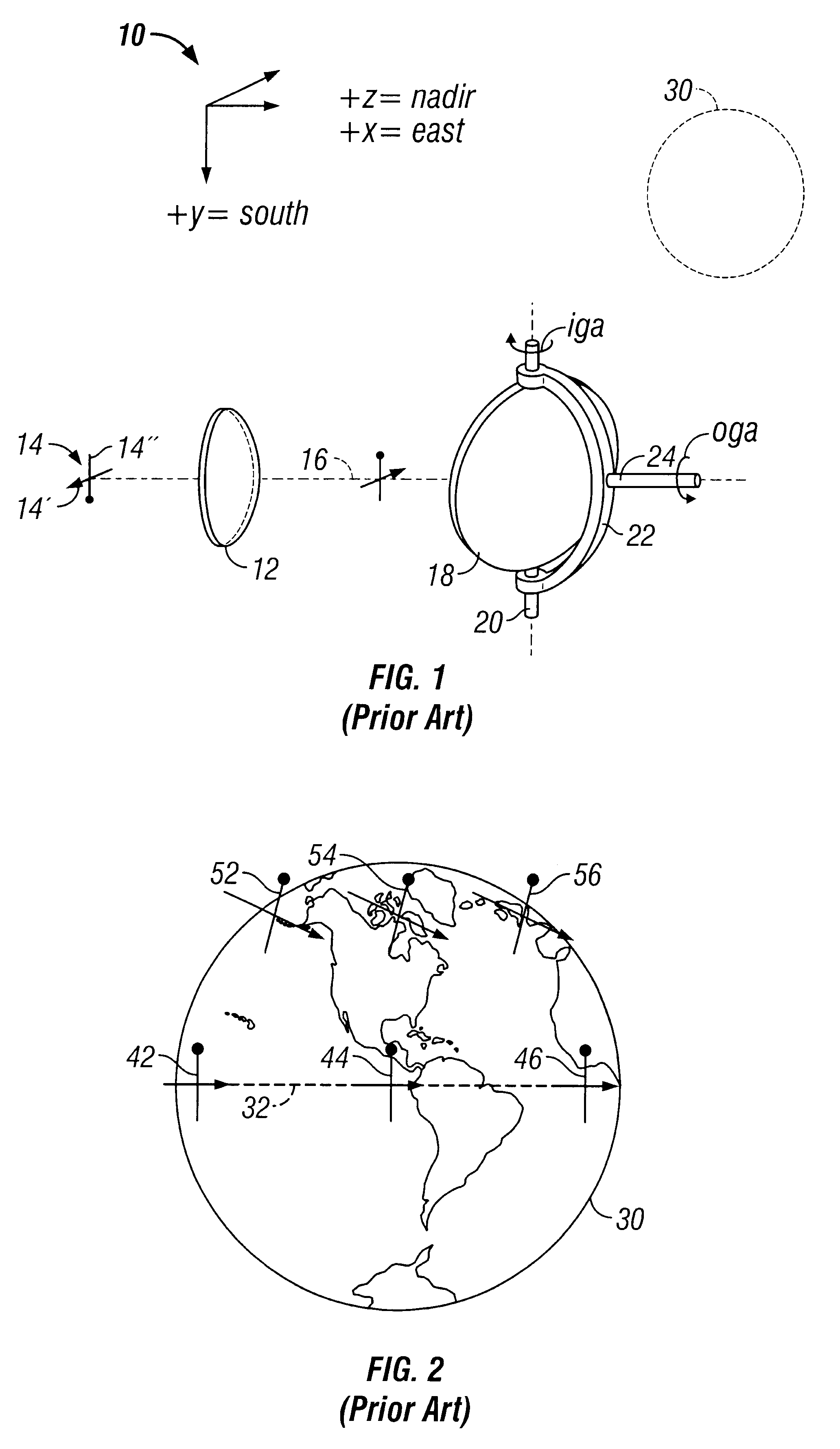

Method and apparatus for imaging a field of regard by scanning the field of view of an imaging electro-optical system in a series of conical arcs to compensate for image rotation

InactiveUS6555803B1Photometry using reference valueBeam/ray focussing/reflecting arrangementsConstant linear velocityPlane mirror

A two-dimensional field of regard is scanned with a single plane mirror in the object space of a telescope, maintaining a fixed relationship between the rotational direction of scan and the projection of the telescope's focal plane. The two dimensional field of regard is covered by a series of conical arcs, each arc being scanned by rotation at constant angular velocity about the inner axis of the two-axis system. This scanning system accommodates applications such as TDI that require an opto-mechanical scan with a constant linear velocity (magnitude and direction) in the focal plane. Shading of IR images is mitigated by calibration at the ends of each scan line and by a scan geometry that minimizes changes in reflection angle.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

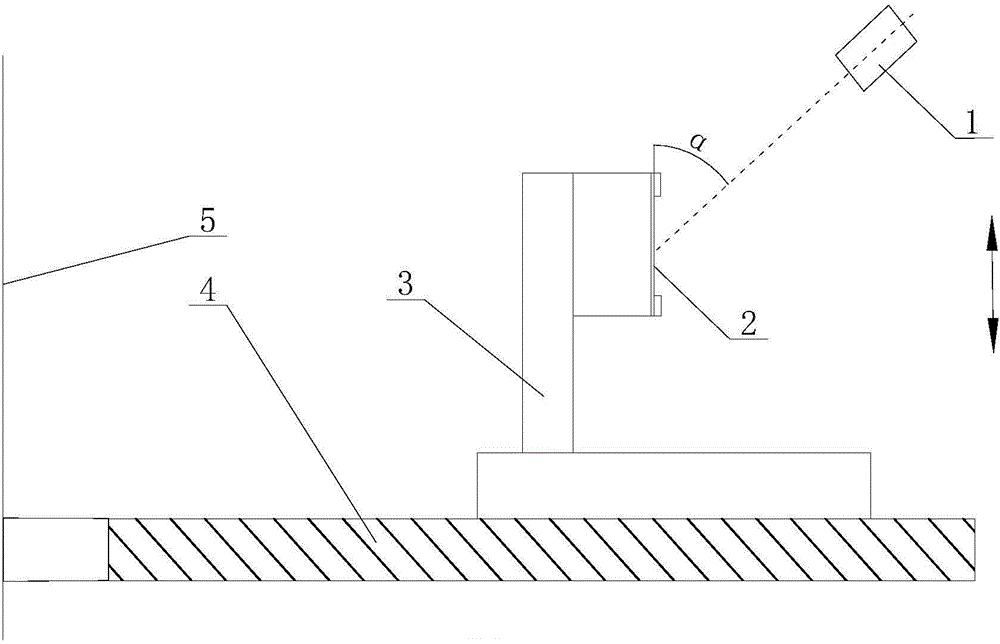

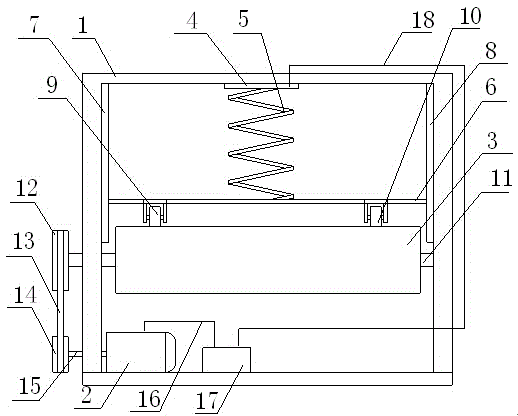

Constant-linear-velocity warp pacing device for weaving of crinkled crepe fabric

ActiveCN105544073AReduce braking resistanceReliable linear controlLoomsConstant linear velocityLinear control

The invention discloses a constant-linear-velocity warp pacing device for weaving of crinkled crepe fabric. The device comprises a tooth form warp beam disc, crepe warps, a stopping hook, a rotary shaft, a dual-tension rod, a tension rod, a check ring, a spring, a gear, a worm, a worm gear, a bevel gear, a carrier gear, a winding gear, a winding rod, a winding wire, a crepe warp beam, a ground warp beam, a heald frame, a shed, wefts, the fabric and a winding roller. The braking resistance of each warp beam is reduced automatically and linearly as the backing-off diameter of the warp beam is reduced, constant warp run-in is realized, and the device has the advantages of being automatic, reliable, capable of achieving linear control and convenient to operate and maintain.

Owner:IANGSU COLLEGE OF ENG & TECH

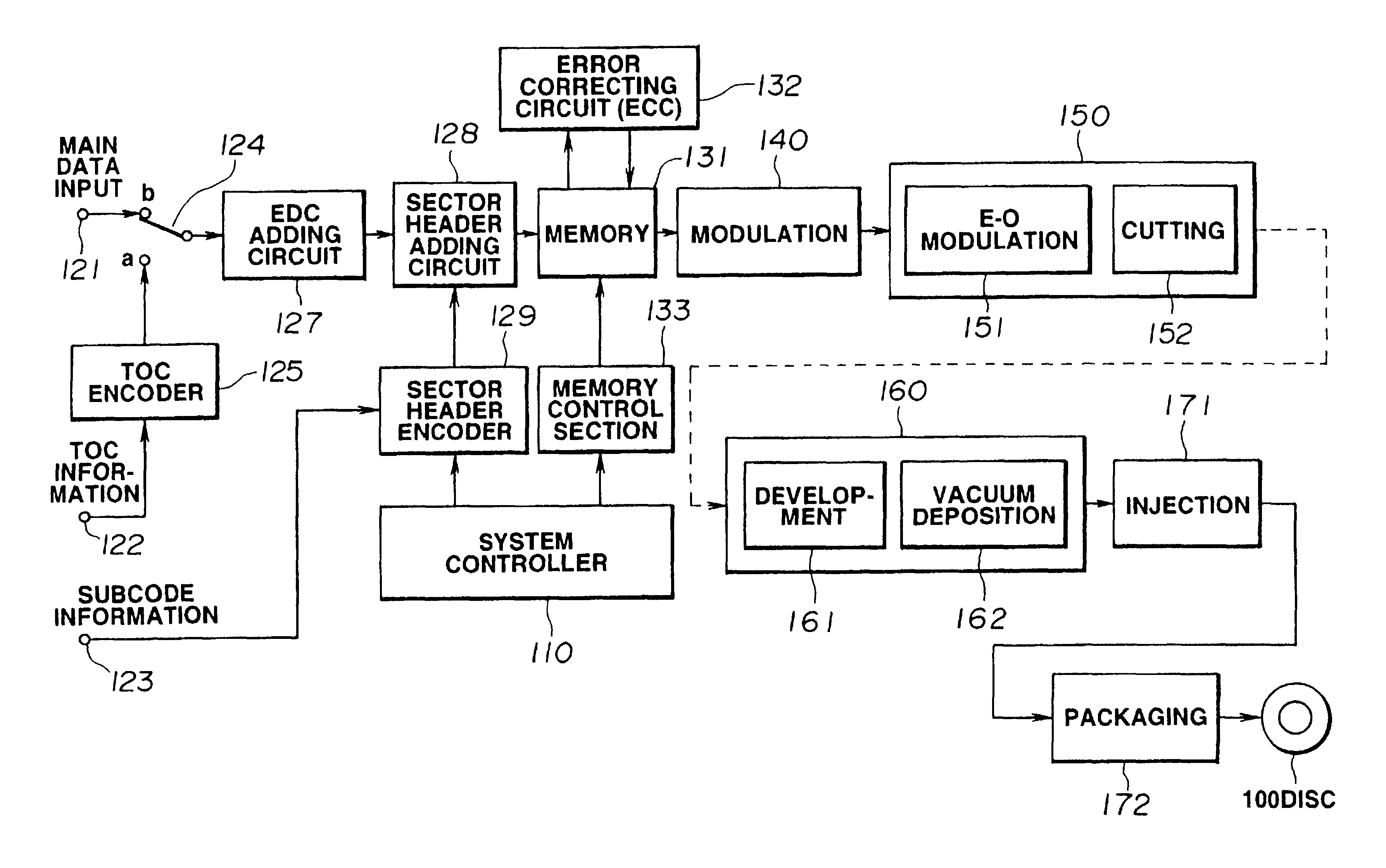

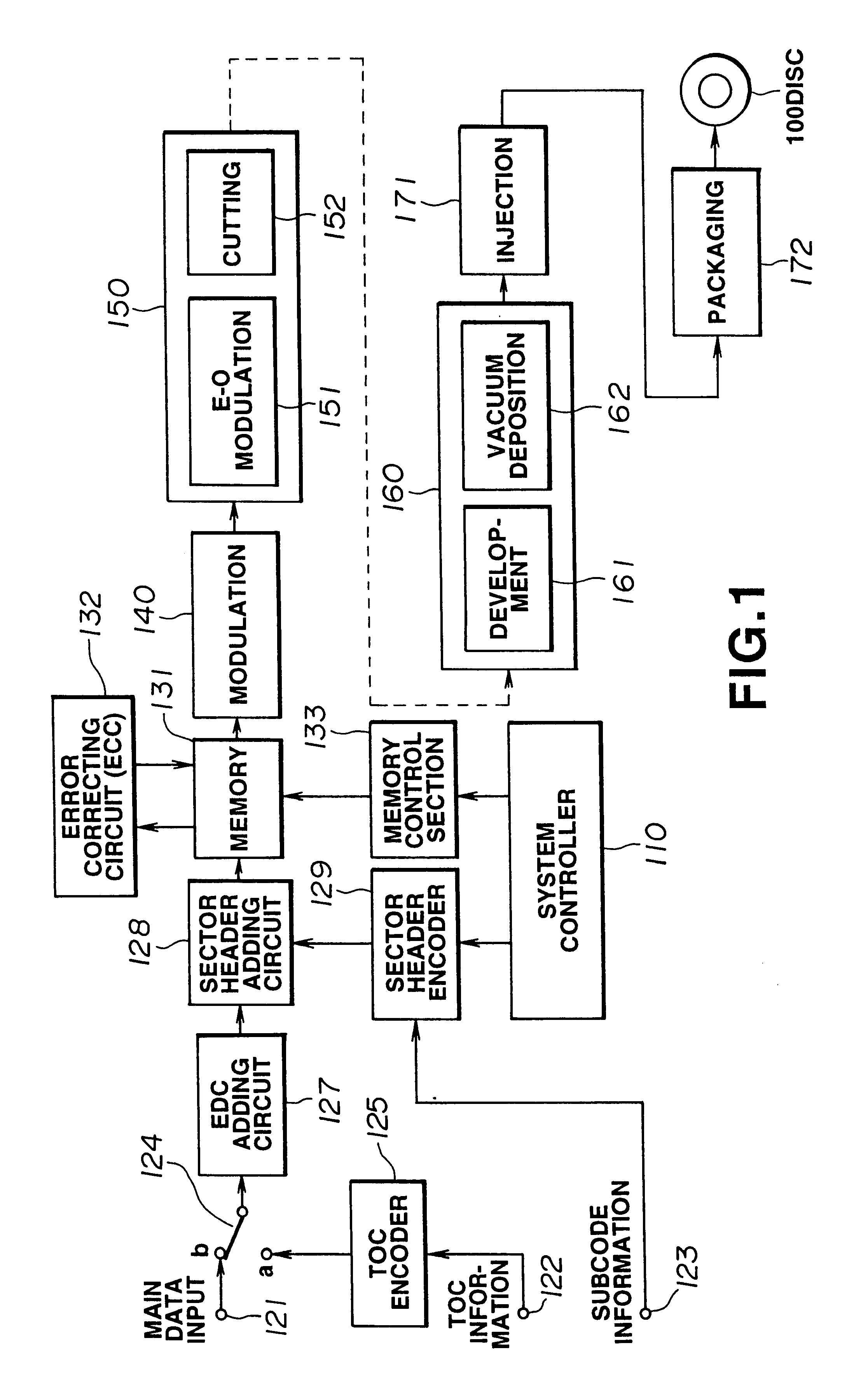

Optical disk having a particular format to store user-selected data, such as video data or computer files, including a dedicated TOC region

InactiveUSRE38638E1Fast accessEasy accessTelevision system detailsData representation error detection/correctionComputer hardwareConstant linear velocity

A method of reproducing data from an optical disk having a diameter less than 140mm, a thickness of 1,2mm and a recording area divided into a lead-in area, and a program area, and wherein said data is recorded as pits representing modulated, error-correction encoded user information in sectors in user tracks in said program area and representing modulated, error-correcting encoded control information in sectors in one of said lead-in area or said program area, with said control information including addresses of respective user tracks, the tracks having a track pitch in the range of 0.646µm to 1.05µm, said method comprising the steps of rotating said disk to obtain a constant linear velocity; projecting a pickup light beam through a lens for optically reading the rotating disk, said pickup light beam having a spatial frequency I=» / 2NA, where the spatial frequency I is less than the track pitch, » is the wavelength of the pickup light beam and NA is the numerical aperture of the lens; demodulating the data read from said disk; error correcting the demodulated data; separating the error corrected data into control information and user information; and using said control information to access and read selected user tracks in response to access instructions from a user.

Owner:SONY CORP

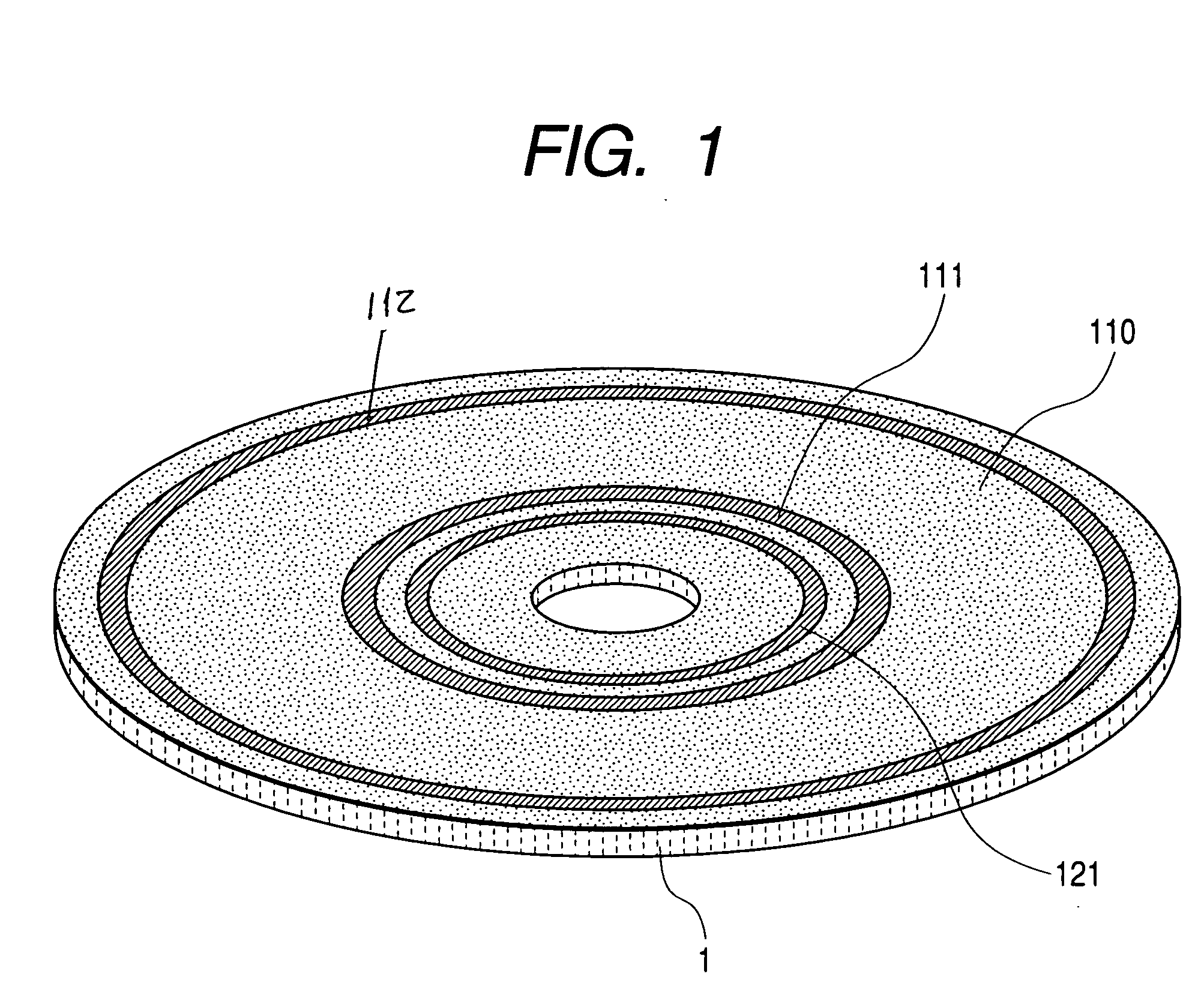

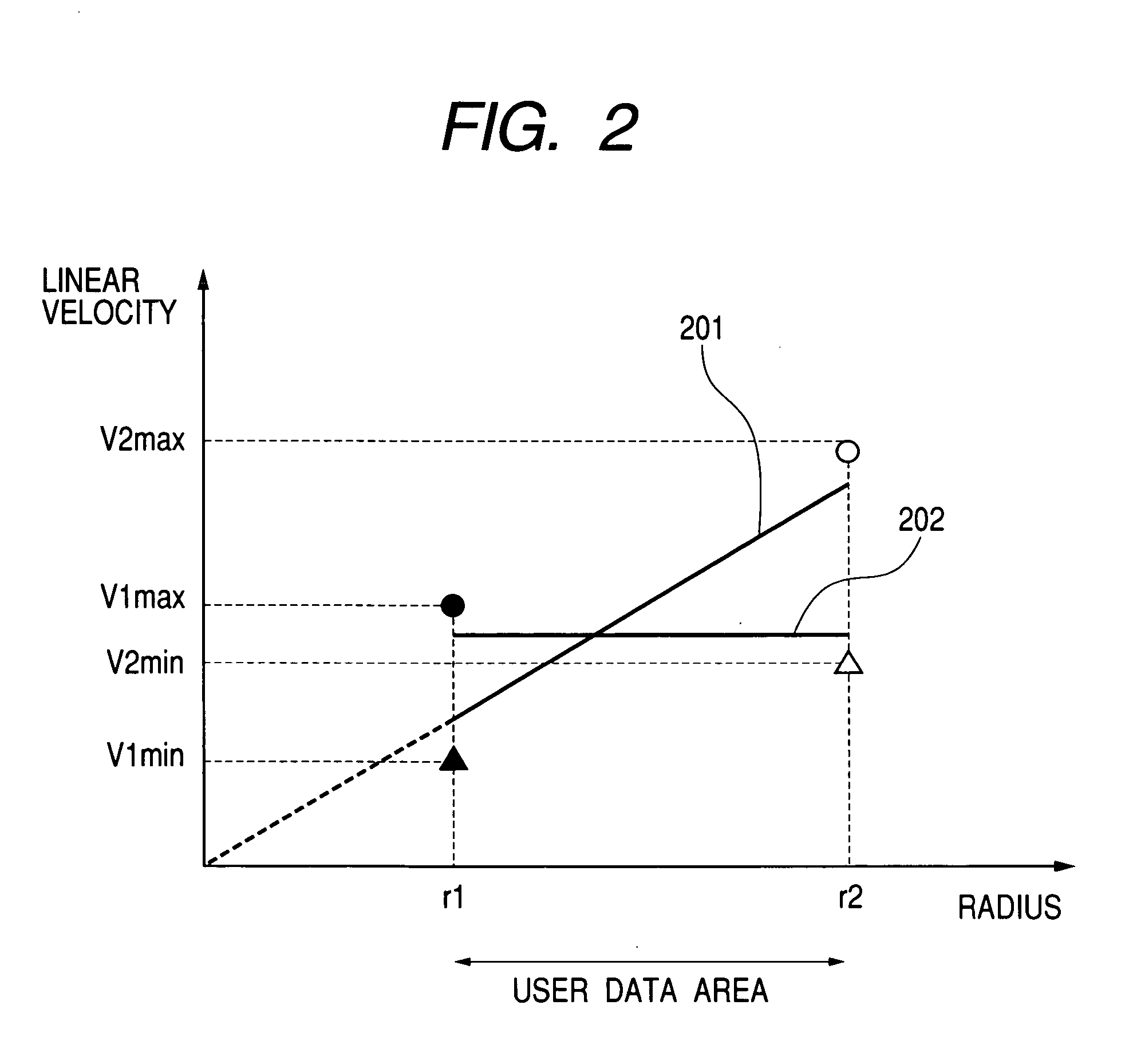

Information recording medium and its control method and information recording/reproducing method

InactiveUS20050063264A1Reduce manufacturing costImprove signal qualityFilamentary/web record carriersRecord information storageConstant linear velocityComputer science

An information recording medium includes data concerning a maximum linear velocity (V1max) and a minimum linear velocity (V1min) at a first location on the medium and a maximum linear velocity (V2max) and a minimum linear velocity (V2min) at a second location on the medium, are recorded at a predetermined location on said medium, and at the first and second locations both of which are located at different locations on the medium, performing selectively CLV / CAV (Constant Linear Velocity / Constant Angular Velocity) control or alternatively a CLV / CAV-hybrid control.

Owner:HITACHI LTD

System and method for controlling one or more roller shades

Owner:CRESTRON ELECTRONICS

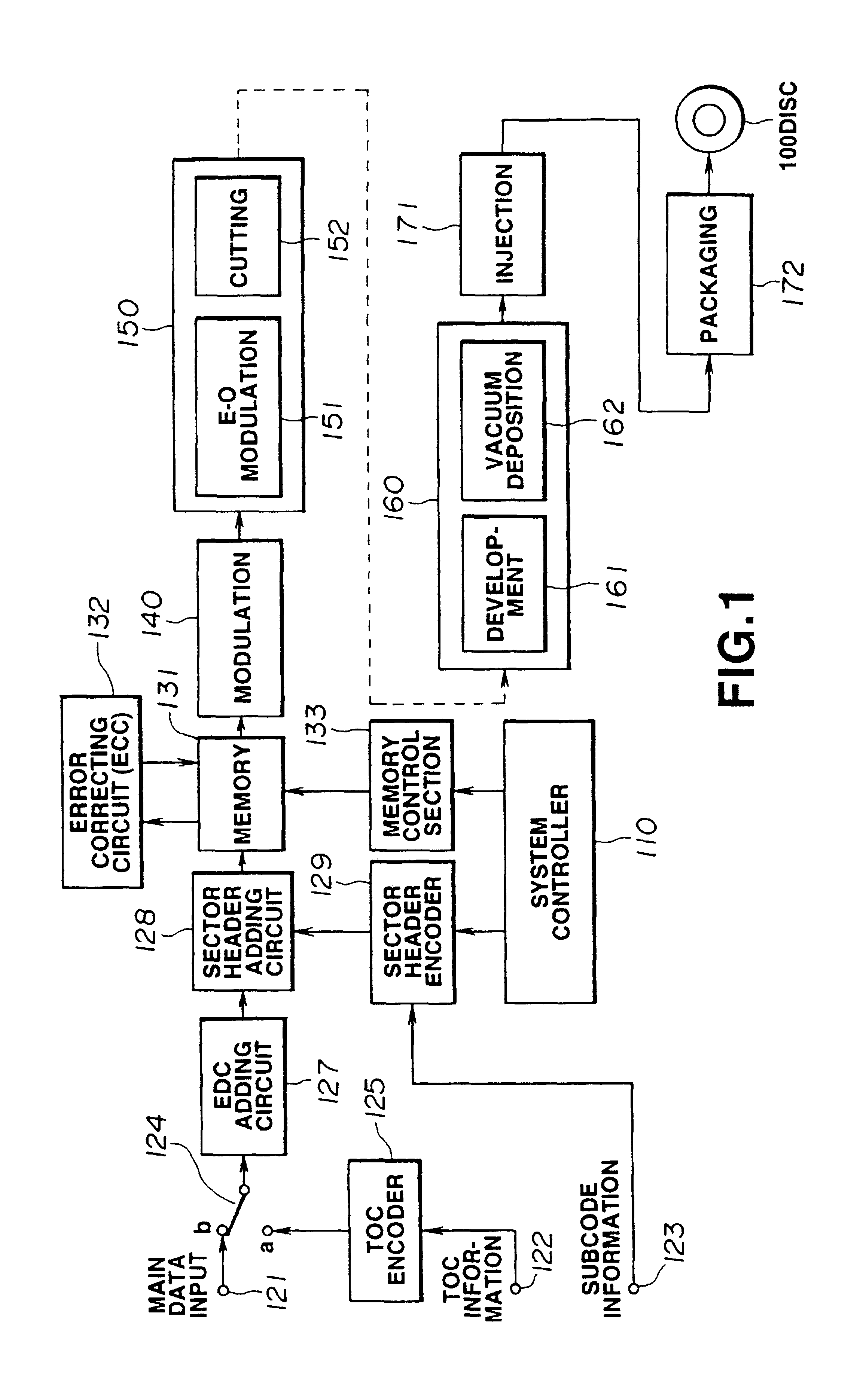

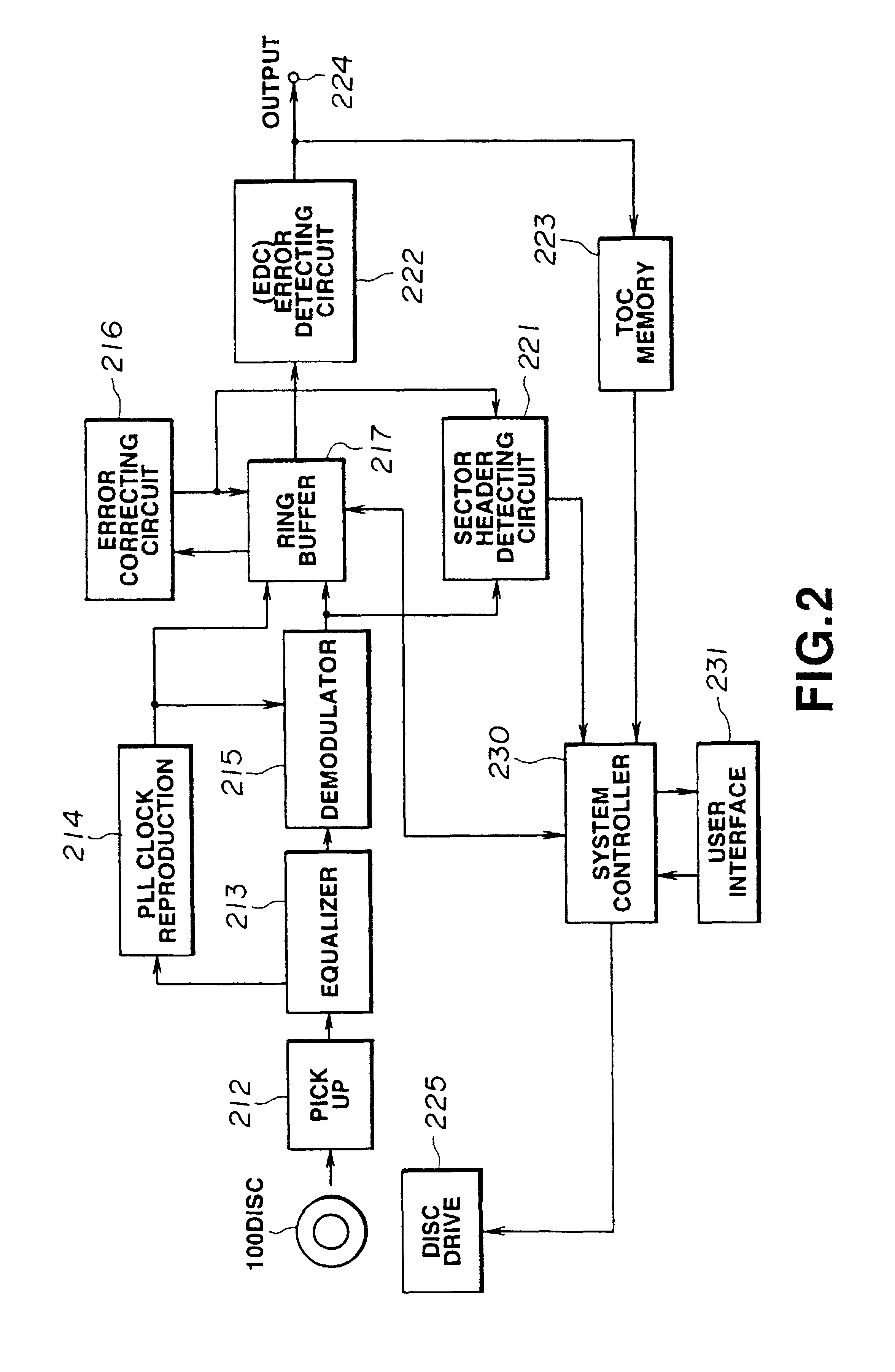

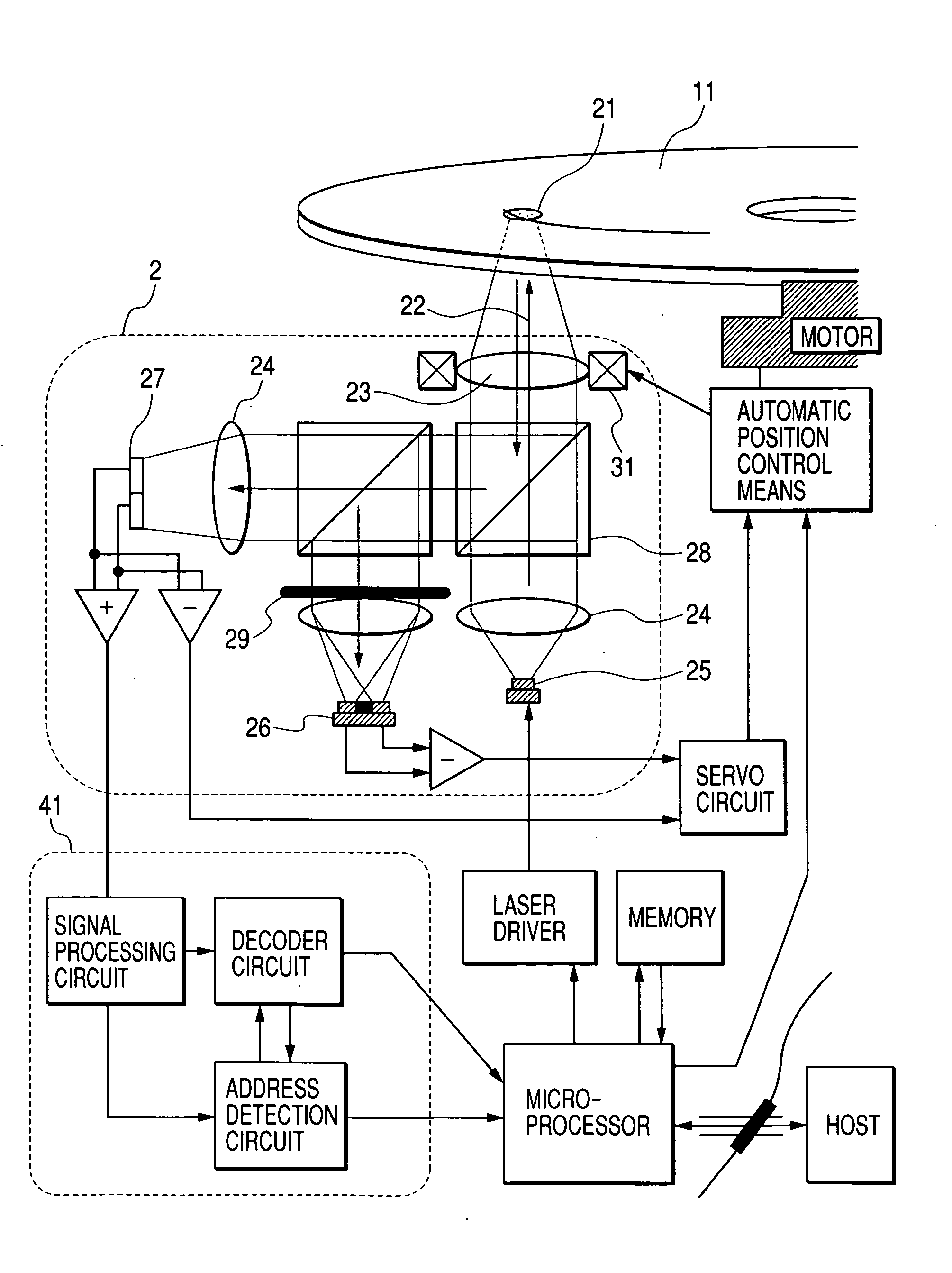

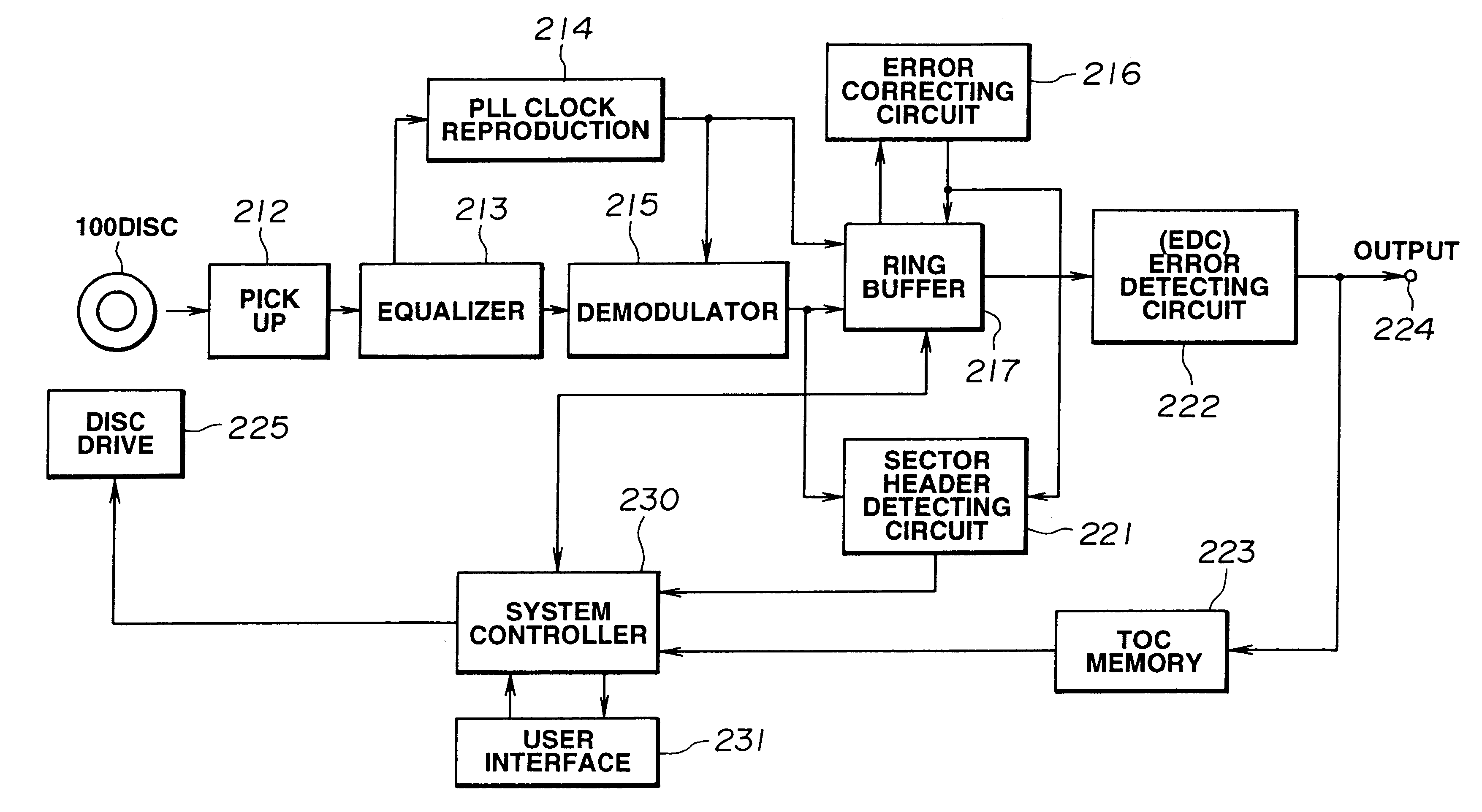

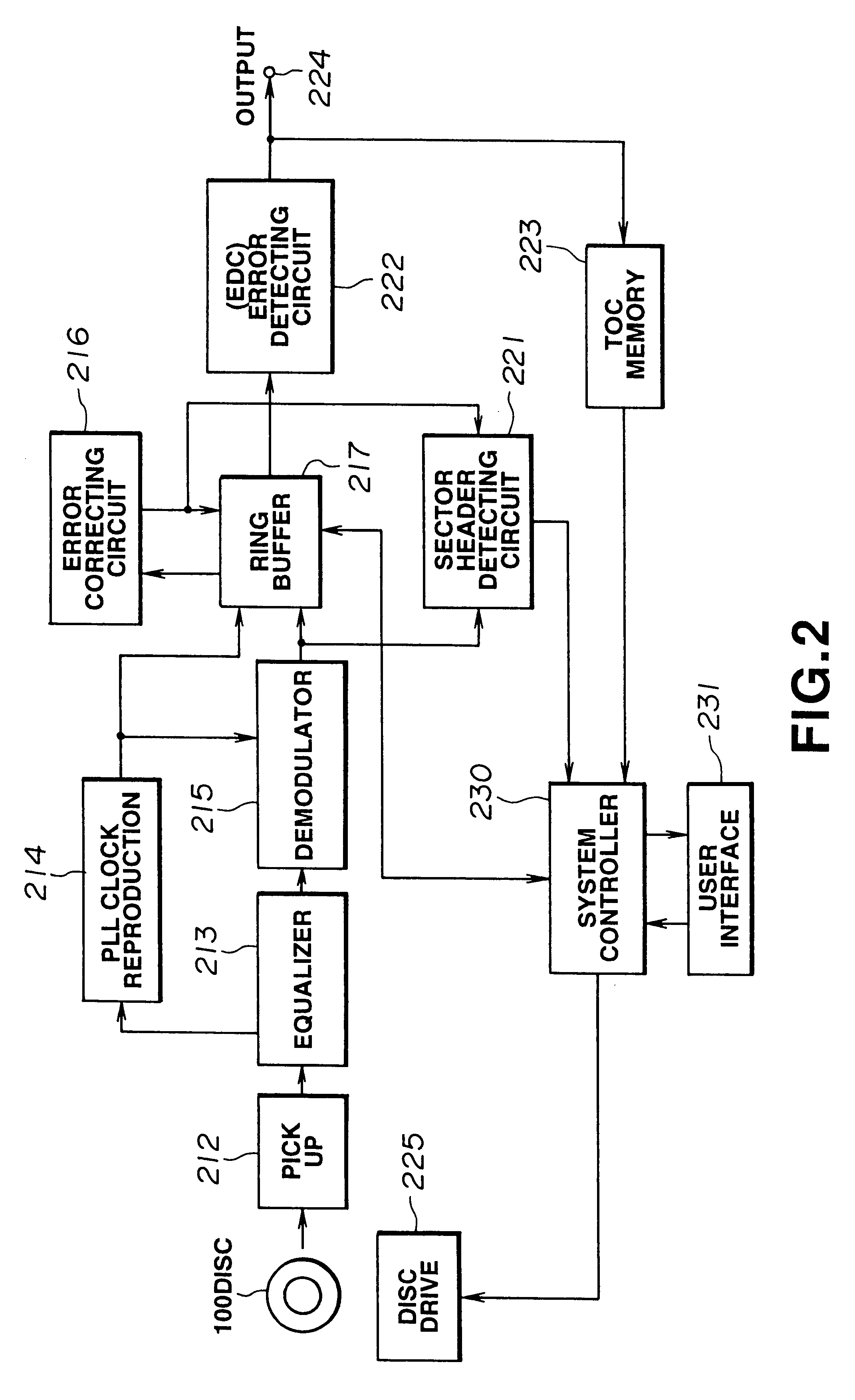

Method and apparatus for recovering TOC and user information from an optical disk and using the TOC information to access user tracks

InactiveUSRE38502E1Fast accessEasy accessTelevision system detailsData representation error detection/correctionConstant linear velocityLight beam

A method of reproducing data from an optical disk having a diameter less than 140mm, a thickness of 1,2mm and a recording area divided into a lead-in area, and a program area, and wherein said data is recorded as pits representing modulated, error-correction encoded user information in sectors in user tracks in said program area and representing modulated, error-correcting encoded control information in sectors in one of said lead-in area or said program area, with said control information including addresses of respective user tracks, the tracks having a track pitch in the range of 0.646µm to 1.05µm, said method comprising the steps of rotating said disk to obtain a constant linear velocity; projecting a pickup light beam through a lens for optically reading the rotating disk, said pickup light beam having a spatial frequency I=» / 2NA, where the spatial frequency I is less than the track pitch, » is the wavelength of the pickup light beam and NA is the numerical aperture of the lens; demodulating the data read from said disk; error correcting the demodulated data; separating the error corrected data into control information and user information; and using said control information to access and read selected user tracks in response to access instructions from a user.

Owner:SONY CORP

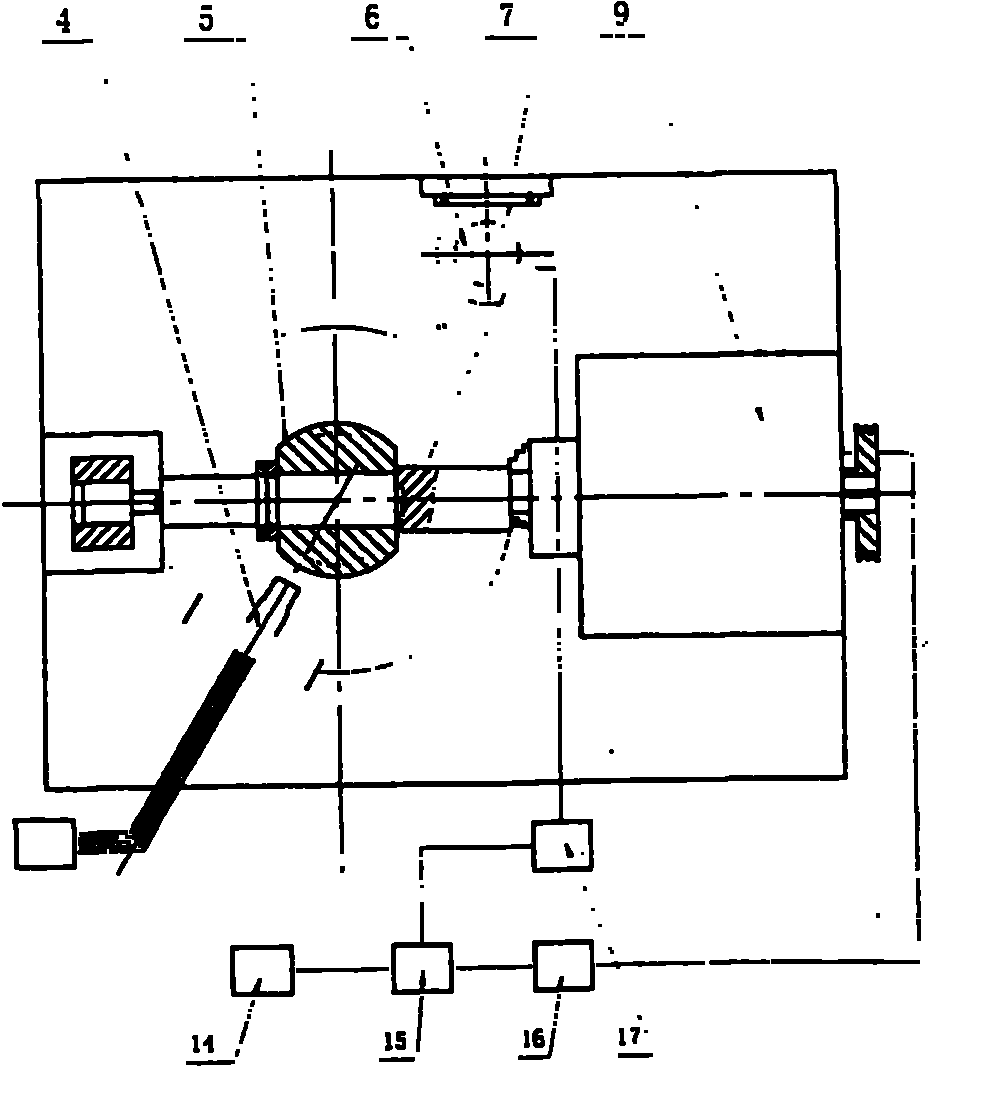

Speed-variable supersonic flame spraying spherical device

InactiveCN101954322AUniform thicknessAvoid unevennessLiquid surface applicatorsMolten spray coatingElectricityConstant linear velocity

The invention provides a speed-variable supersonic flame spraying spherical device which comprises a revolving platform, an auxiliary belt wheel, a shaft, a sprayer, a ball table, an auxiliary motor belt wheel, an auxiliary motor, a clamp, a head stock, a main motor, a main shaft, a main belt wheel, a main motor belt wheel, a touch screen, a PLC (Programmable Logic Controller), a main frequency converter, an auxiliary frequency converter and the like, wherein the ball table, the clamp, the main shaft and the main belt wheel are connected, the main shaft passes through the head stock, the main motor is connected with the main motor belt wheel, the sprayer is fixed on the revolving platform, the auxiliary belt wheel, the shaft and the revolving platform are connected, the auxiliary motor is connected with the auxiliary motor belt wheel, the touch screen and the PLC are both electrically connected with the main frequency converter, the main motor and the auxiliary frequency converter by leads, the PLC is provided with a program which can generate continuously changing angular velocity according to the change of the turning radius of each point on a spherical surface, but keeps a constant linear velocity, as well as is provided with a constant rotating speed program of the sprayer, and moreover, a function relation exists between the angular velocity of the spherical surface and the rotating angle of the sprayer. Uniform and consistent coatings with required thickness can be obtained by selecting proper rotating velocity programs of the main shaft and the revolving platform on the touch screen.

Owner:江苏江恒阀业有限公司

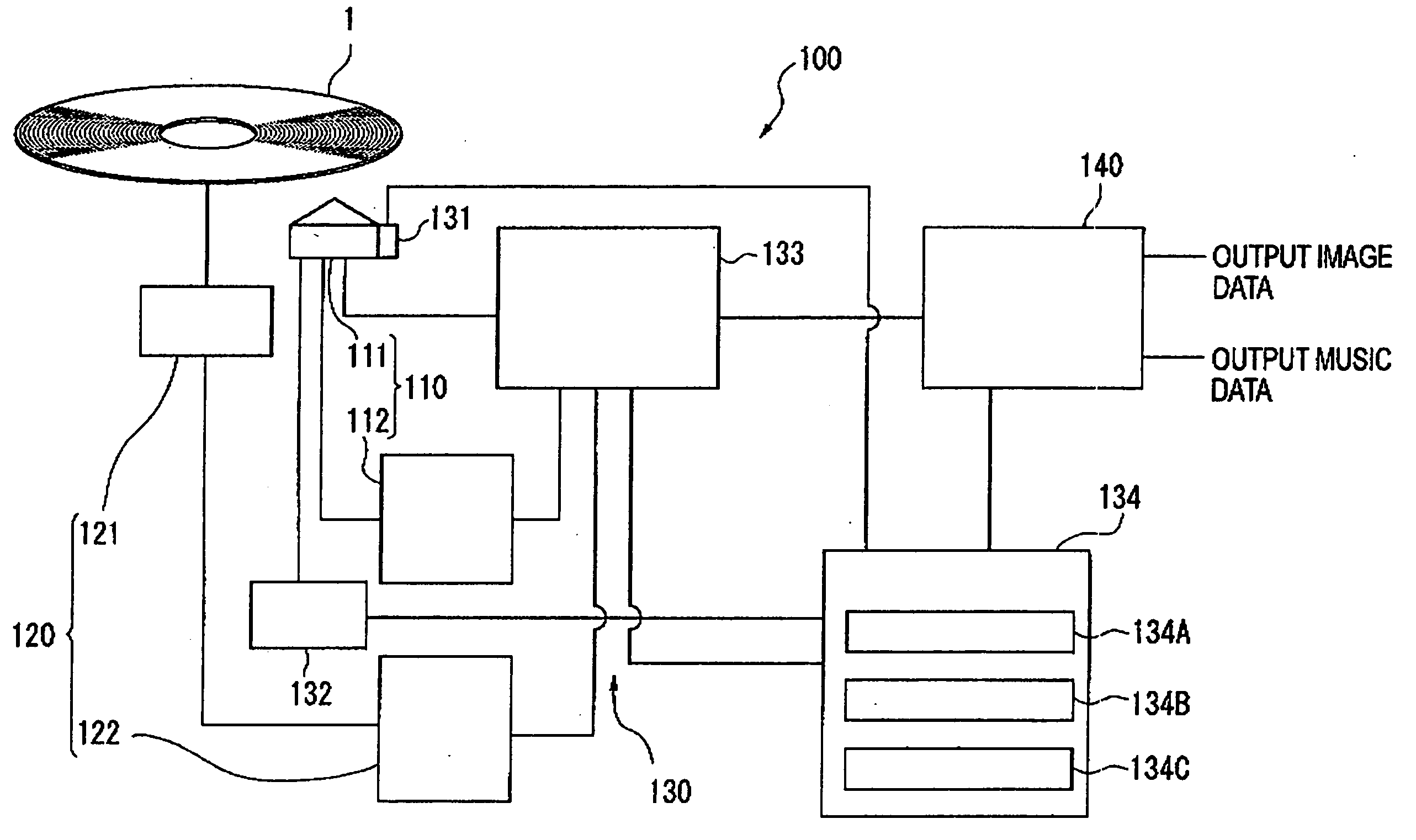

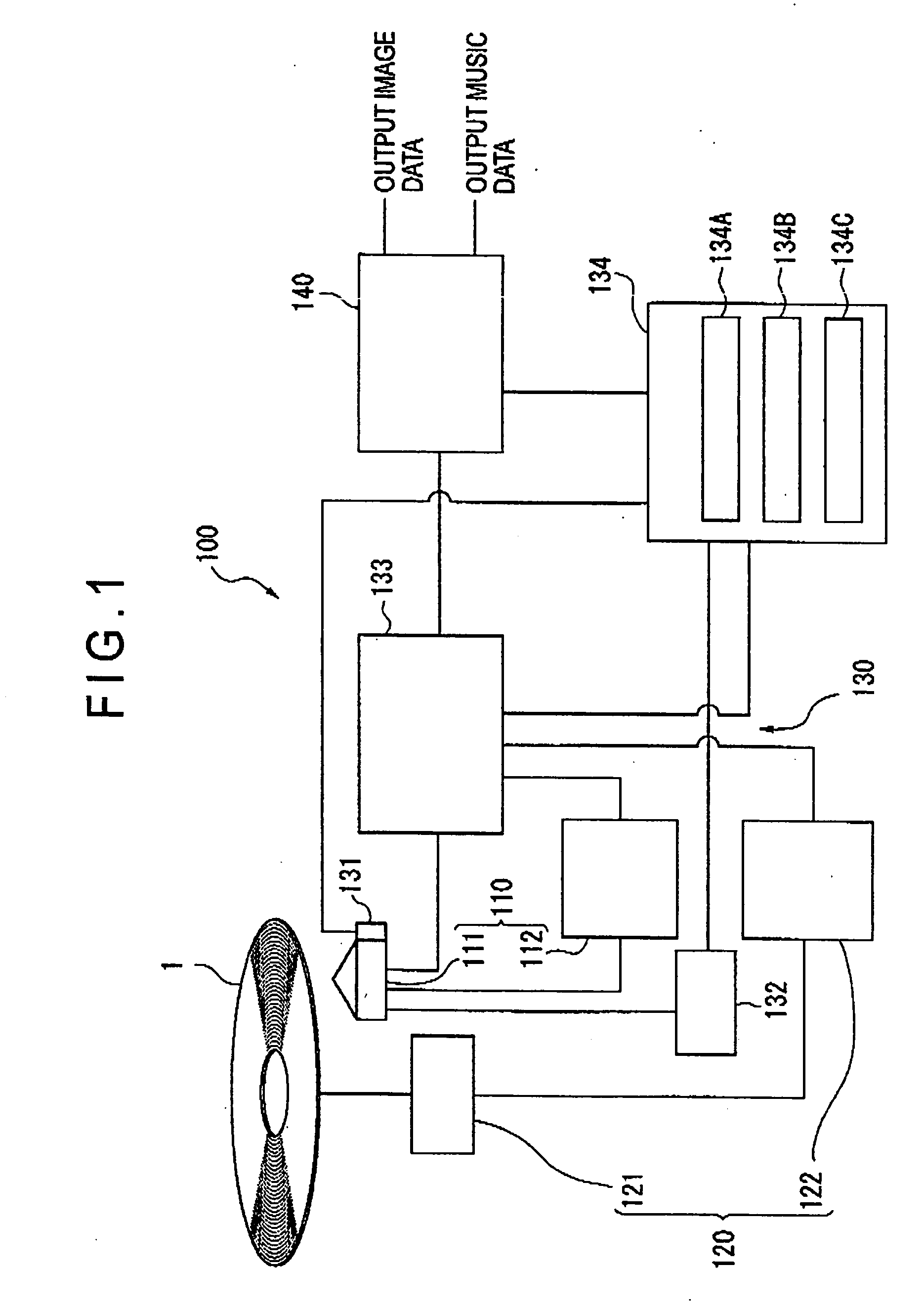

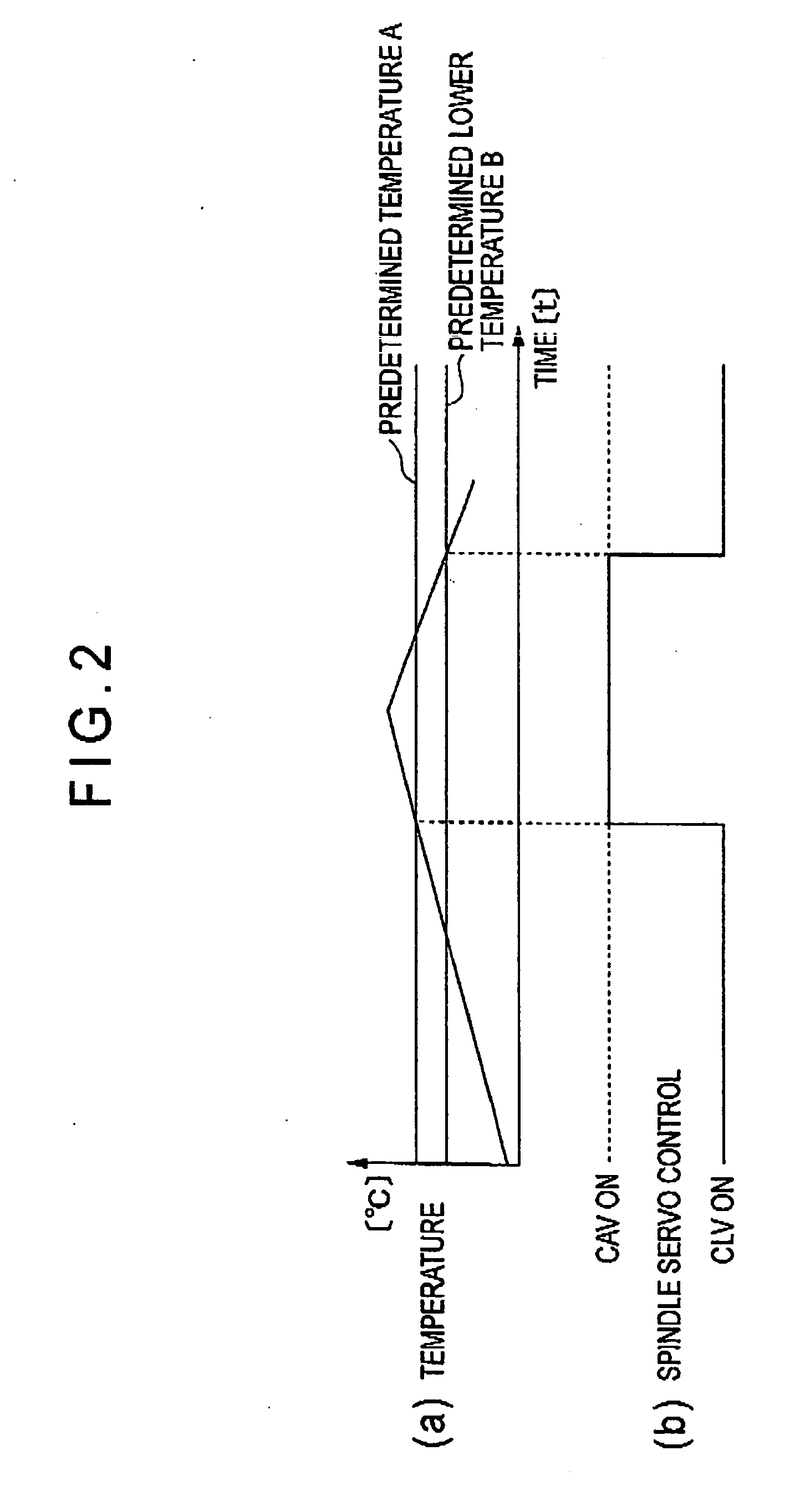

Rotation control device, method thereof, program thereof, recording medium storing the program, and information processing apparatus

InactiveUS20050002301A1Combination recordingRecord information storageInformation processingConstant linear velocity

A temperature sensor (131) detects a temperature of a spindle motor (121) of a rotary drive unit (120) for rotating a disk-shaped recording medium (1), and a temperature information acquiring unit (134A) acquires the temperatures as temperature information. An eccentricity detector (132) detects a drive voltage level, and an eccentricity information acquiring unit (134B) acquires the drive voltage level as eccentricity information. When a determining unit (134C) determines that the temperature is higher than a predetermined temperature or that the drive voltage level is higher than a predetermined voltage, a servo controller (133) switches a rotation mode from constant liner velocity to constant angular velocity. That enables stable information processing over a long time with a simple strucure for constant linear velocity.

Owner:PIONEER CORP

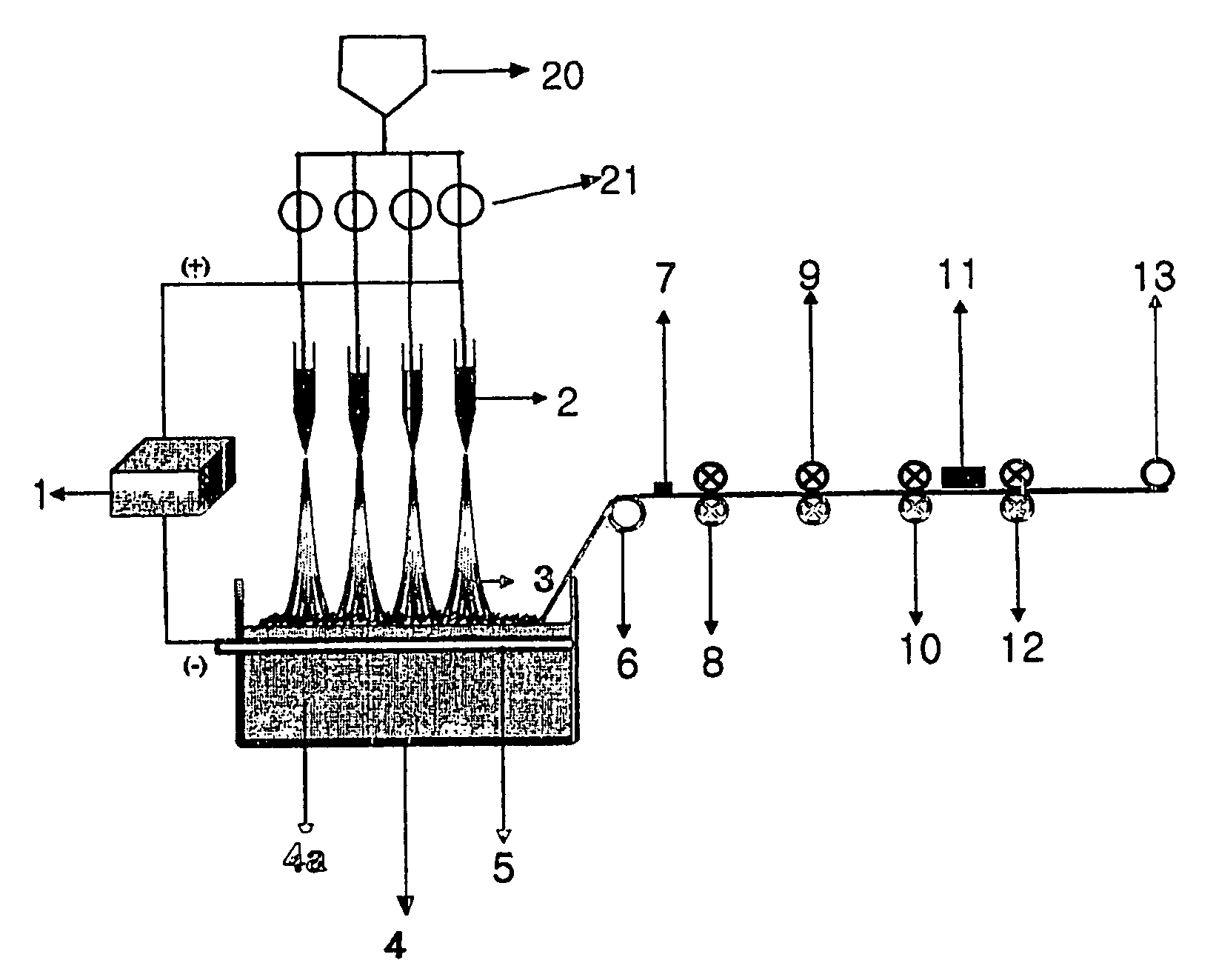

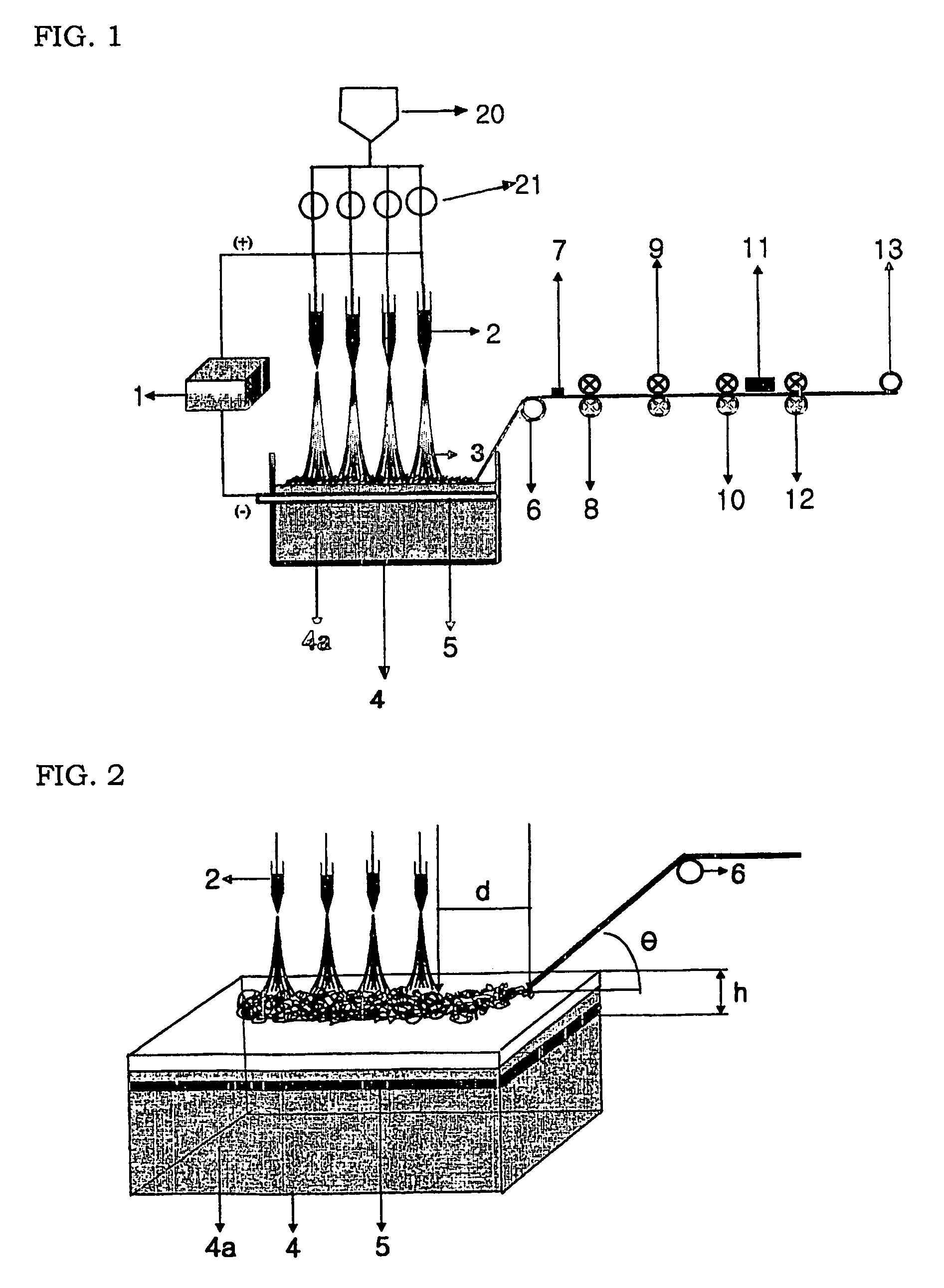

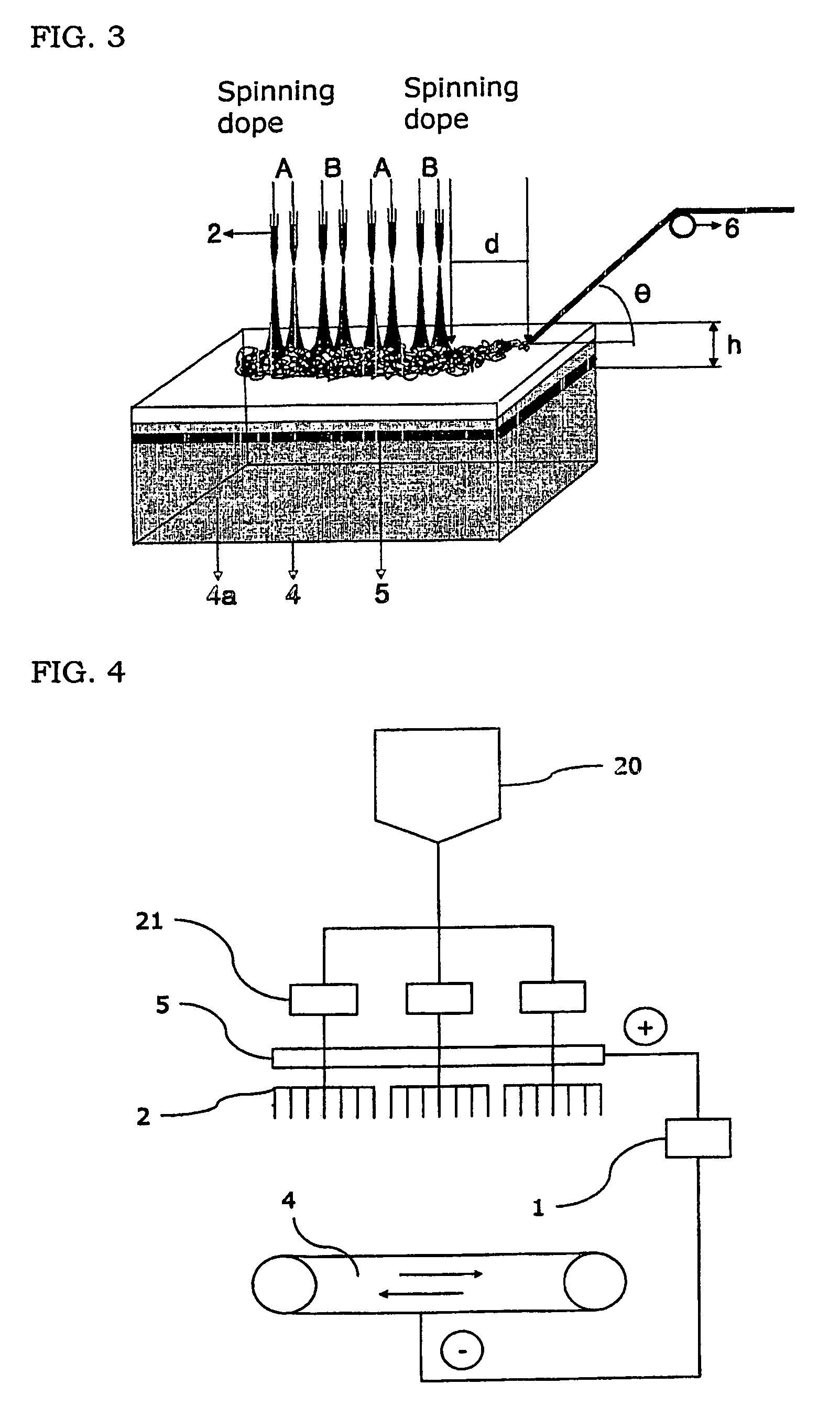

Process of preparing continuous filament composed of nano fiber

The present invention relates to a process of preparing a continuous filament composed of a nano fiber, wherein nano fibers are prepared by spinning a polymer spinning dope in a spinning dope main tank (20) onto the surface of water or organic solvent (4a) of a collector (4), which contains water or inorganic solvent (4a) and has a conductive material (5) with a high voltage applied sunken in the water or organic solvent (4a), through nozzles (2) with a high voltage applied, and the nano fibers are pressed, drawn, dried and wound while being pulled by a rotary roller (6) rotating at a constant linear velocity from the location spaced more than 1 cm from one end of a dropping spot. The present invention can prepare a continuous filament composed of a nano fiber by an electrospinning method and a continuous process.

Owner:FINETEX TECH GLOBAL +2

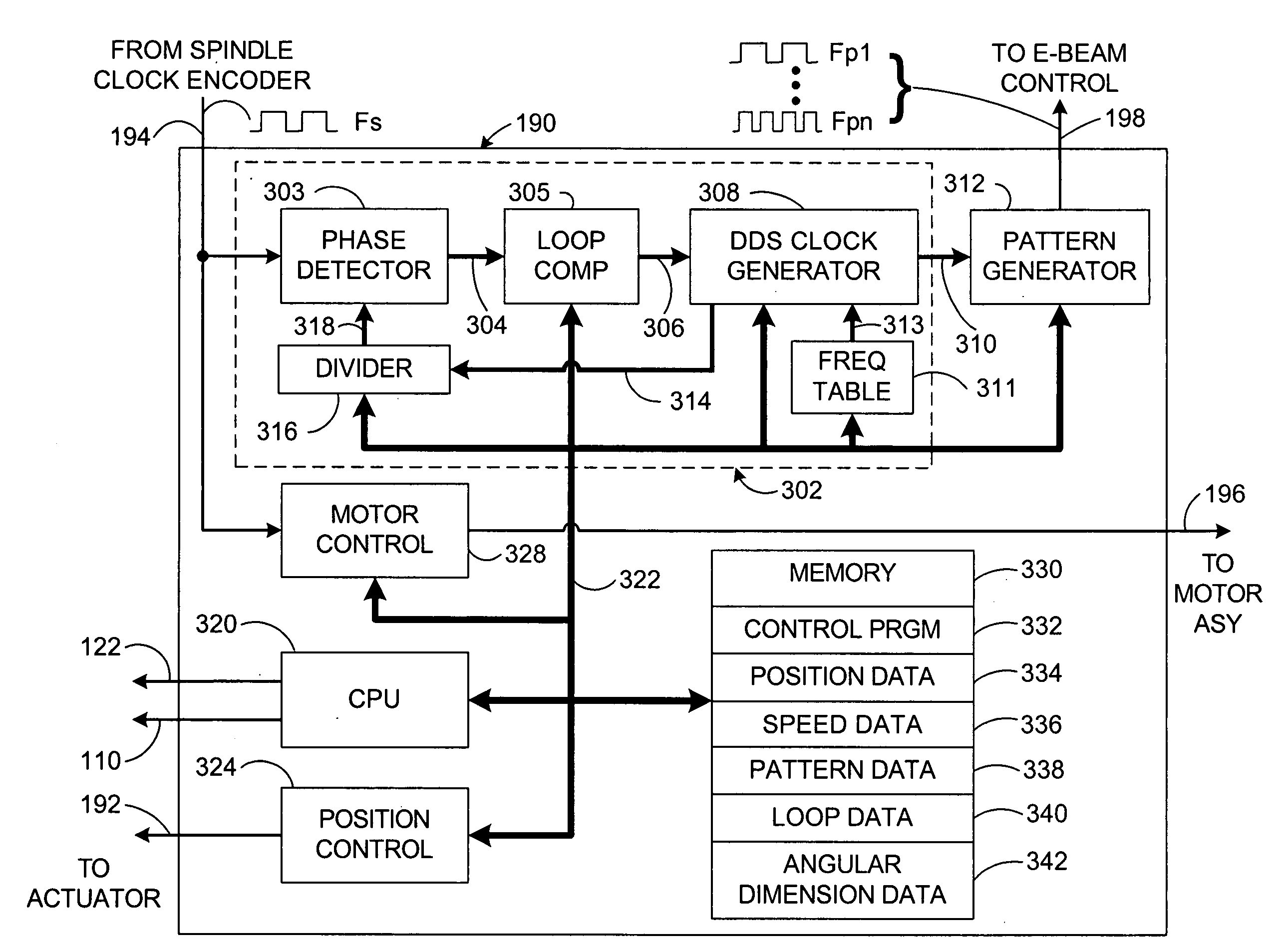

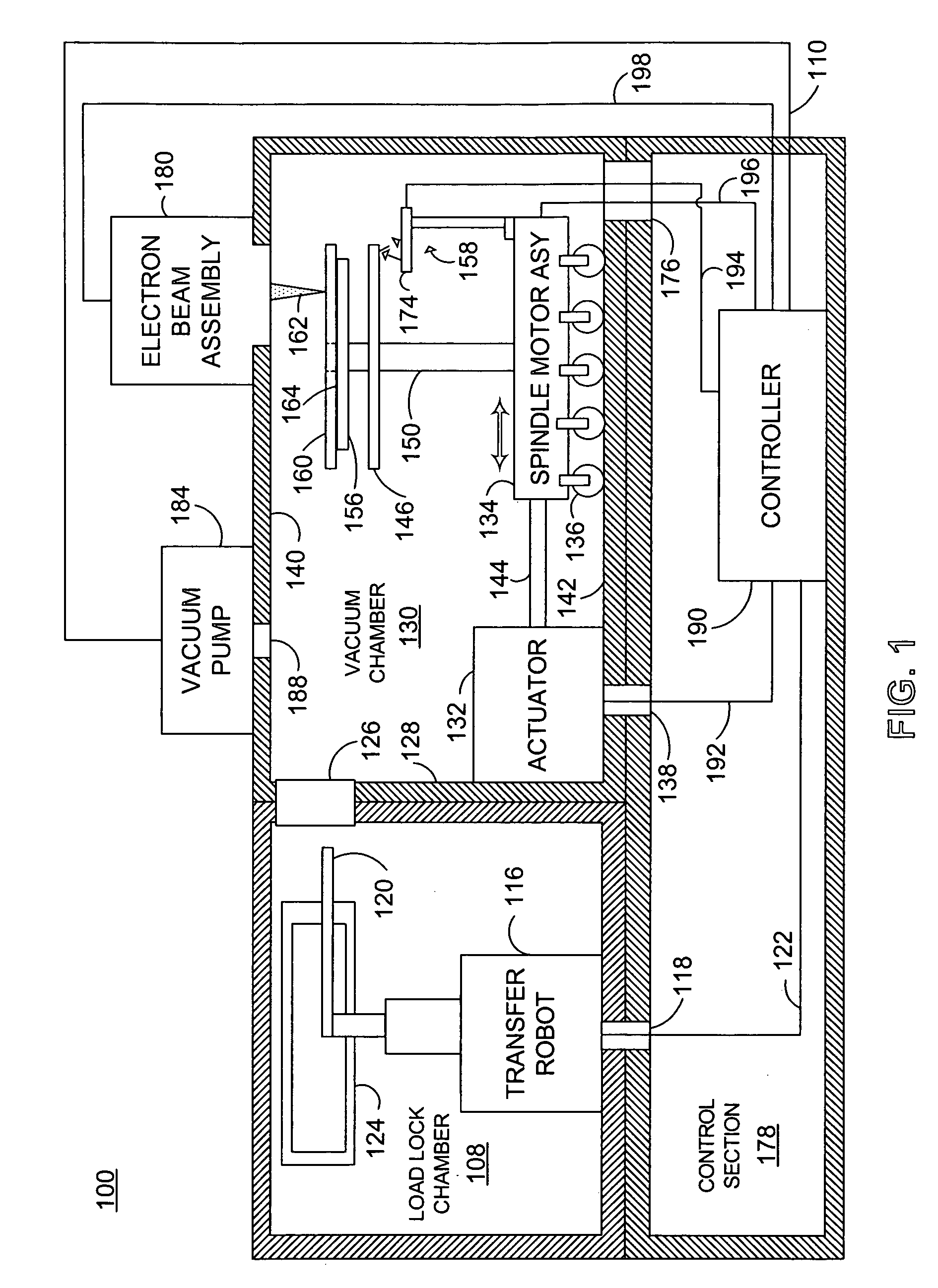

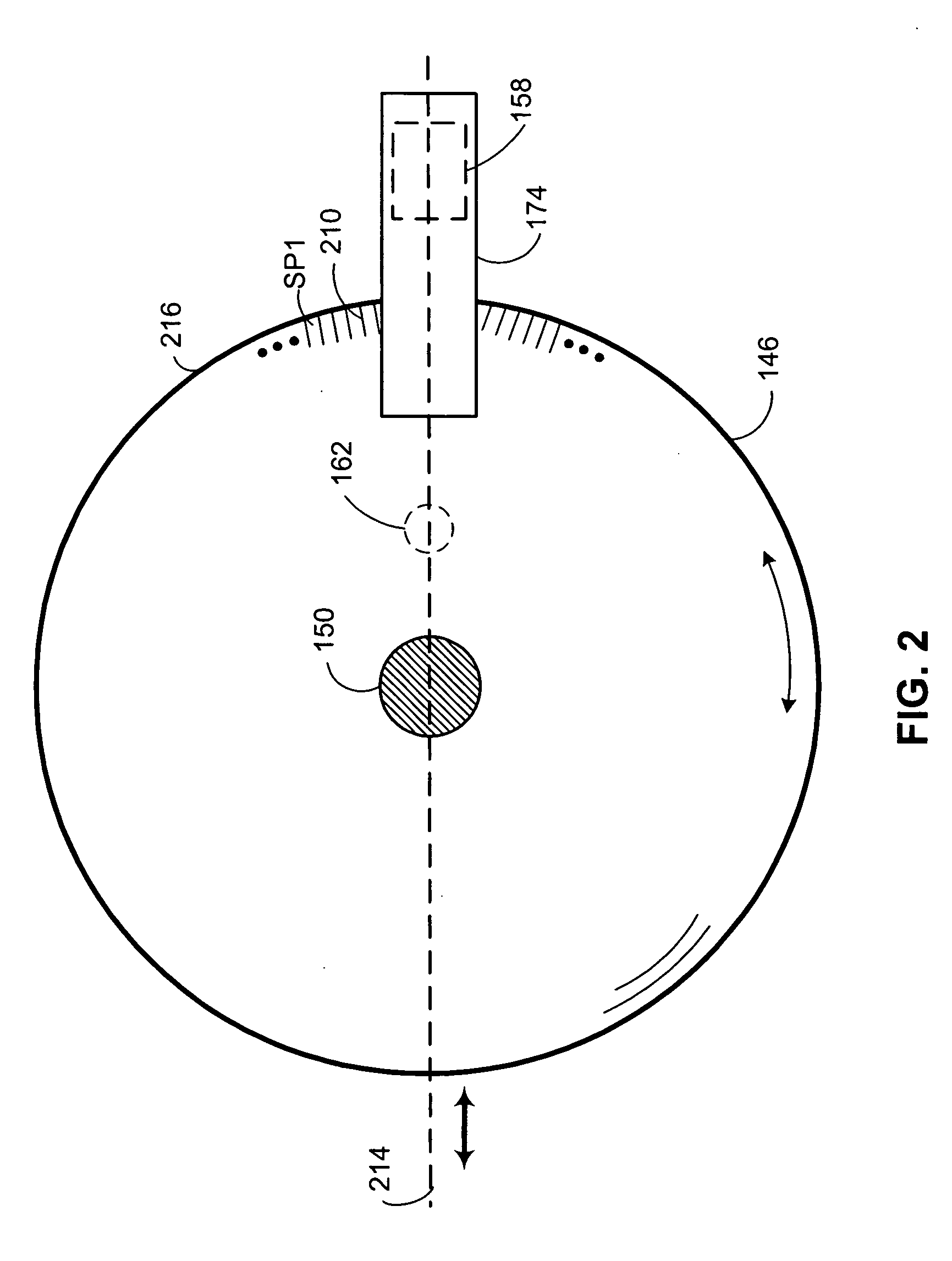

Method and apparatus for constant linear velocity electron beam substrate processing

InactiveUS20050185562A1Electron beam carrier recordingElectric discharge tubesConstant linear velocitySpeed control system

Embodiments of the invention generally provide an electron beam substrate processing system. In one embodiment, the present invention provides an electron beam substrate processing system where a spindle shaft used to rotate substrates during processing includes at least one optical encoder wheel assembly. The optical encoder wheel assembly is configured to provide rotational speed data signal to a rotational speed control system and a pattern generation clock circuit configured to a provide an angular pattern generator clock signal and to a pattern generator circuit. The pattern generation circuit is configured to control modulation of an electron beam used for substrate processing. In one aspect of the present invention, while the spindle shaft is rotated at a constant linear velocity, the pattern generation circuit controls the modulation of an electron beam such that written mark lengths are sized to be about constant in angular dimension.

Owner:SEAGATE TECH LLC

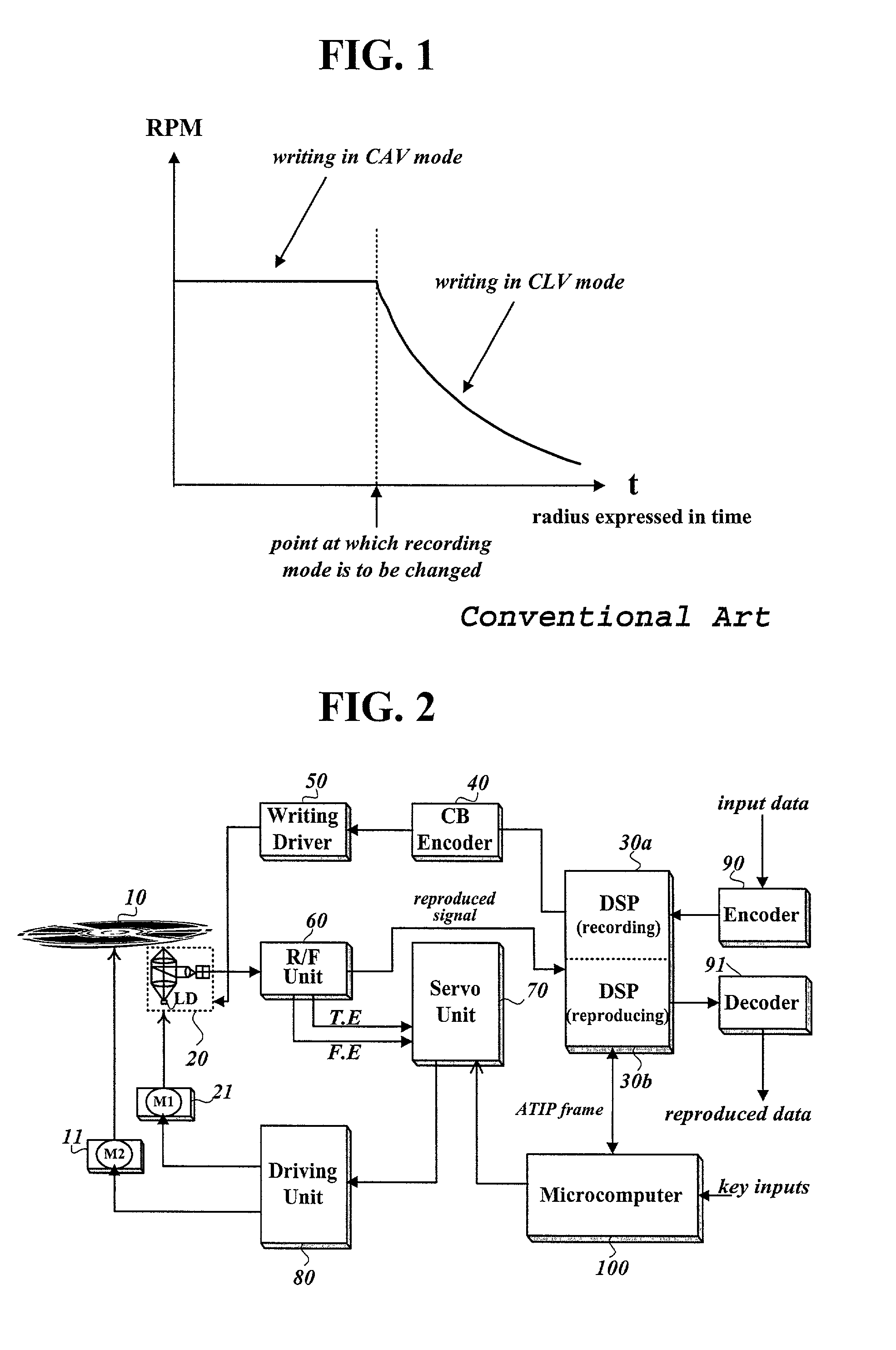

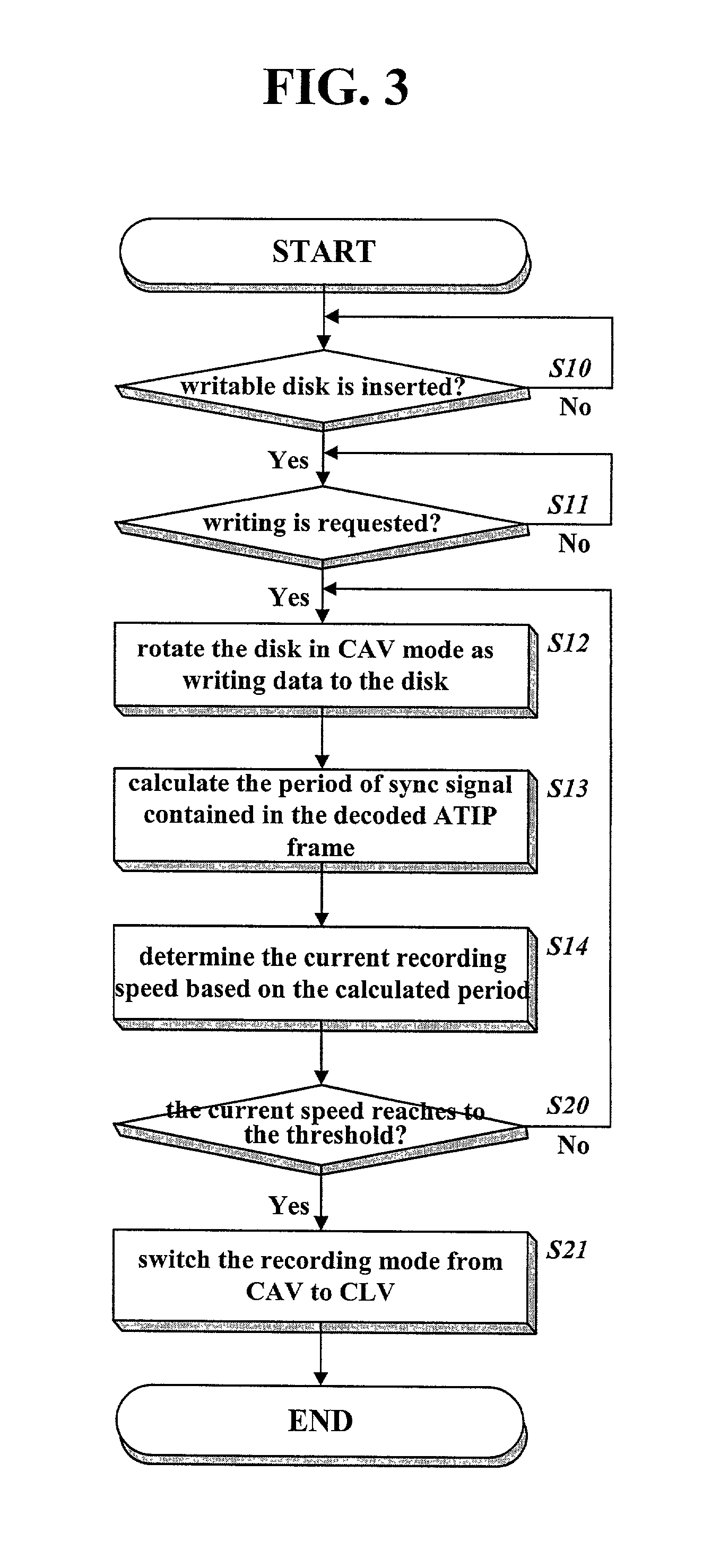

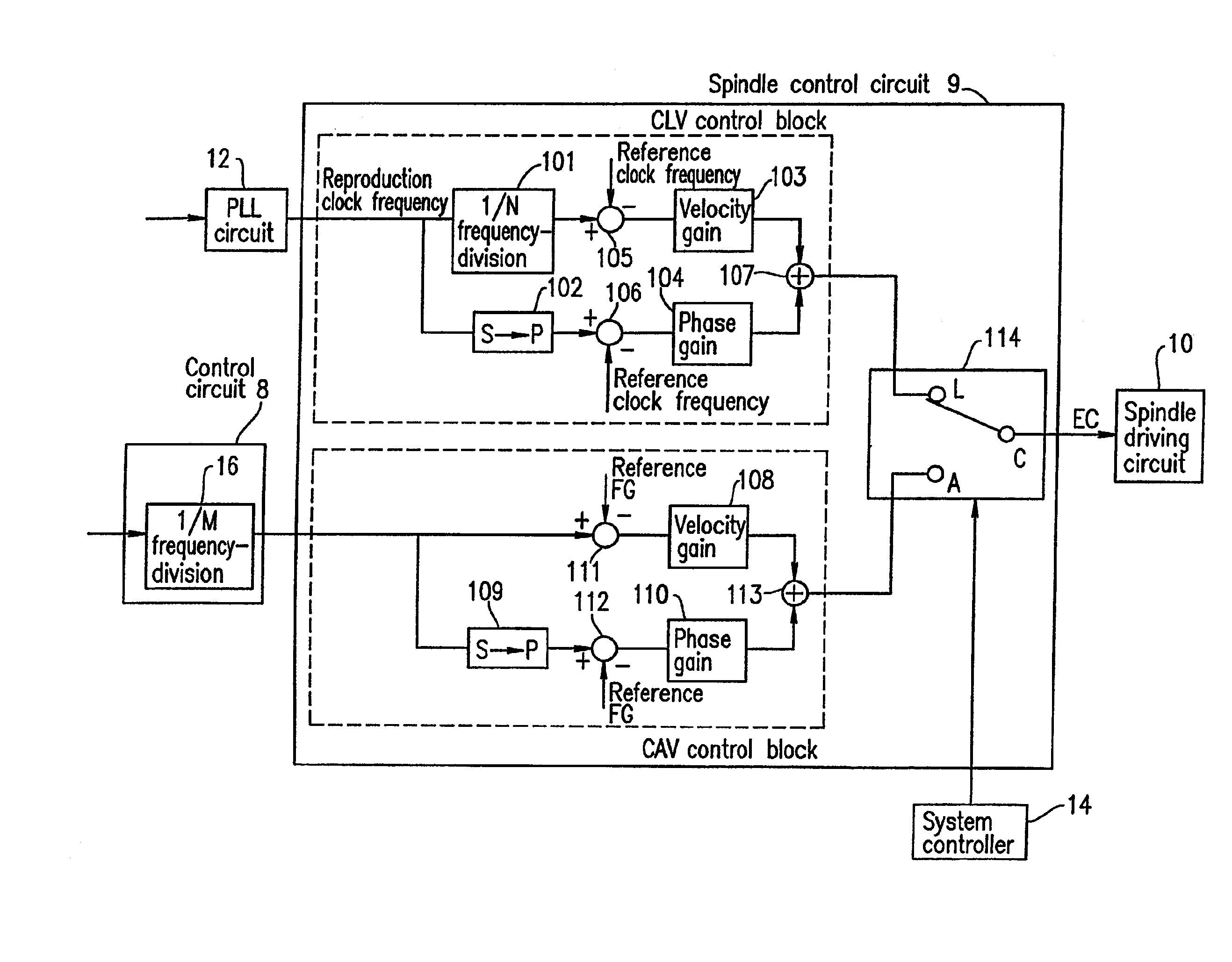

Method of changing a recording mode between constant angular velocity and constant linear velocity

InactiveUS20020003761A1Combination recordingDisposition/mounting of recording headsConstant linear velocityData recording

The present invention relates to a method of changing a recording mode from CAV (Constant Angular Velocity) to CLV (Constant Linear Velocity) mode in the middle of recording data to a disk recording medium. A method according to the present invention reads ATIP-framed data encoded in a wobble signal formed along a spiral physical track while recording input data to a recording medium, detects a sync signal contained in the read ATIP-framed data. Another method measures frequency of a low-frequency component of the wobble signal instead of reading ATIP-framed data. These two methods determines, in common, when to change the recording mode from CAV to CLV based on the period of the detected sync signal or the measured frequency. The present invention makes it possible to record input data to an entire area of a disk more rapidly without fatal errors such as imperfect writing. As a result, total recording time can be reduced with stable recording guaranteed.

Owner:LG ELECTRONICS INC

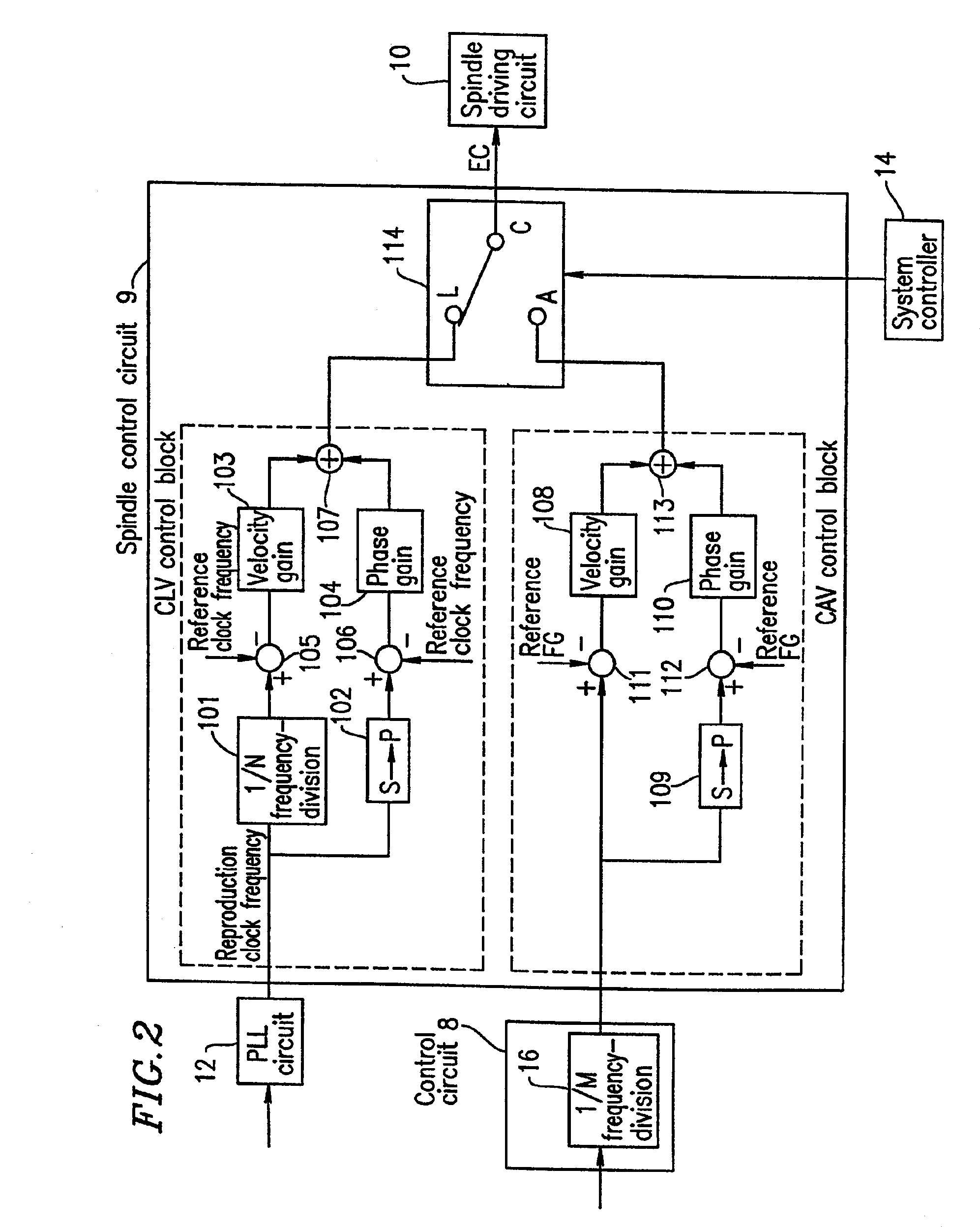

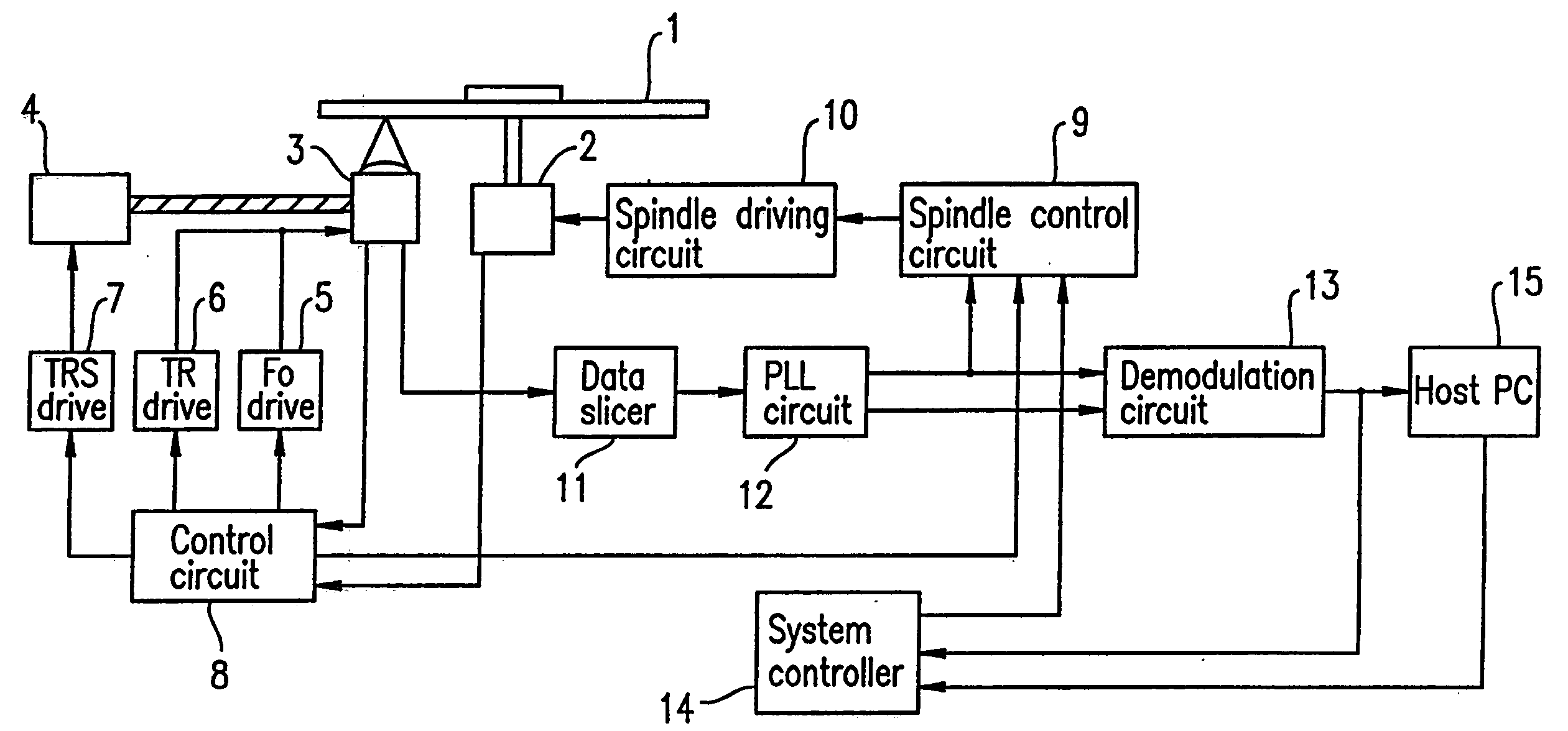

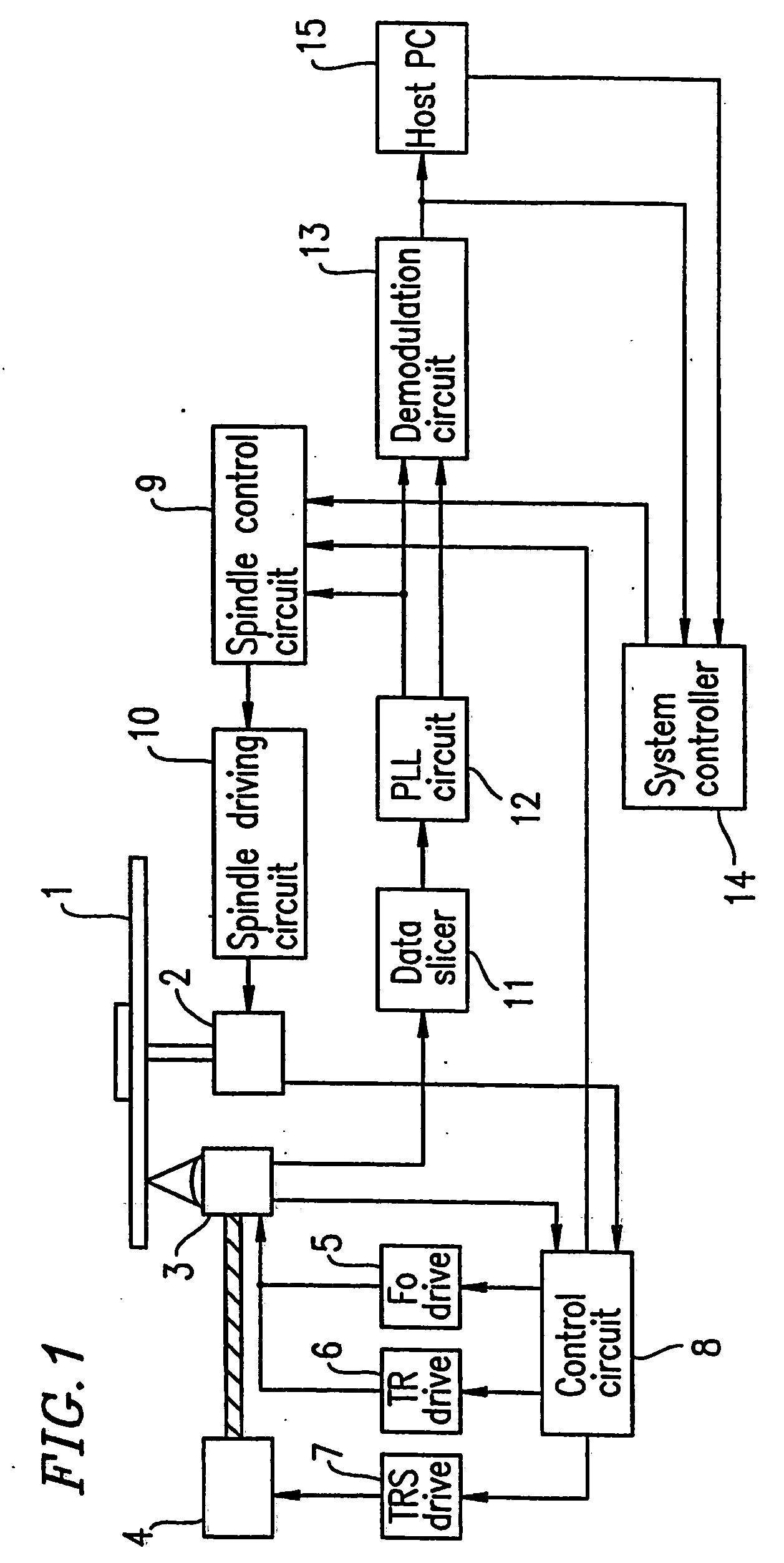

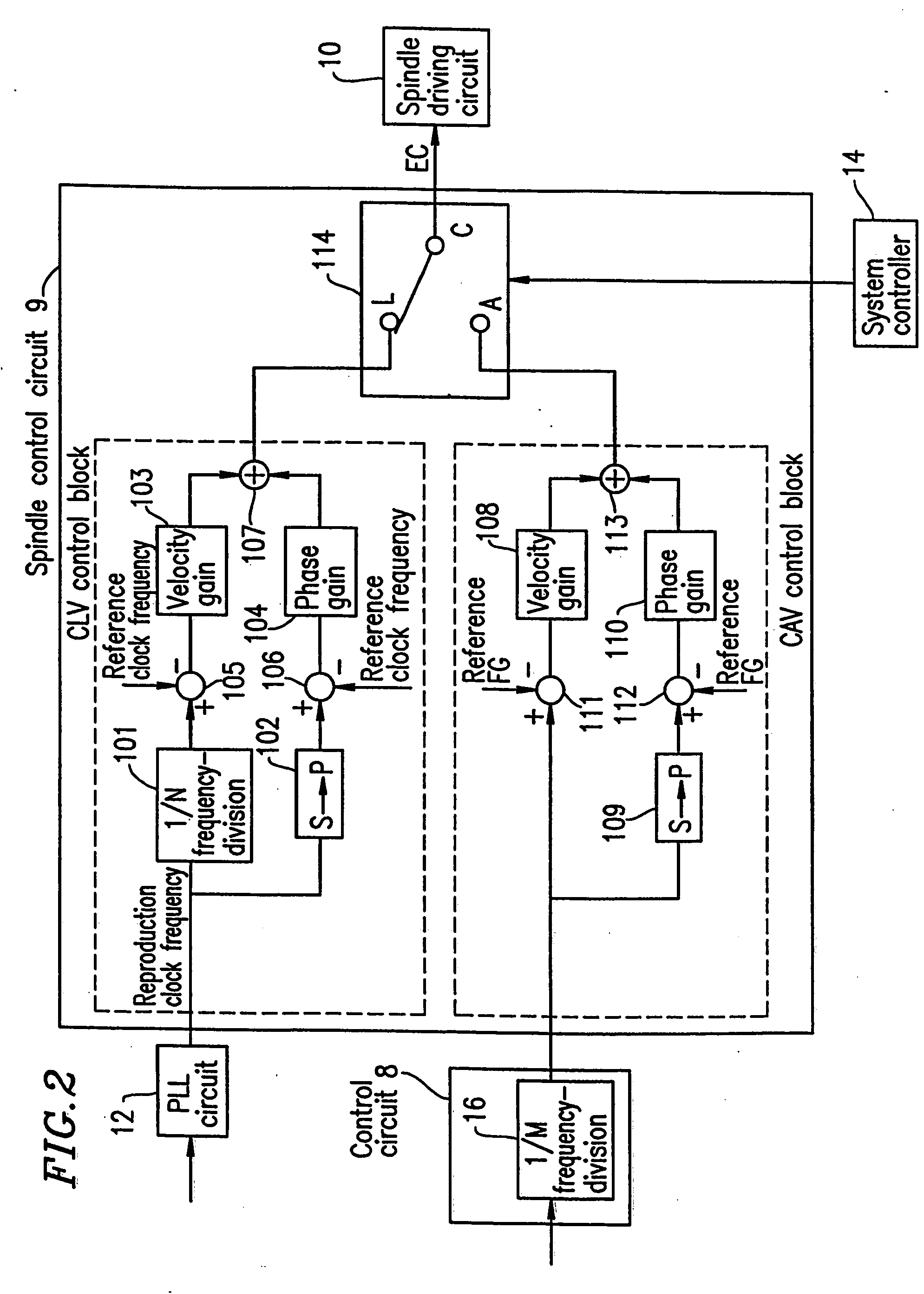

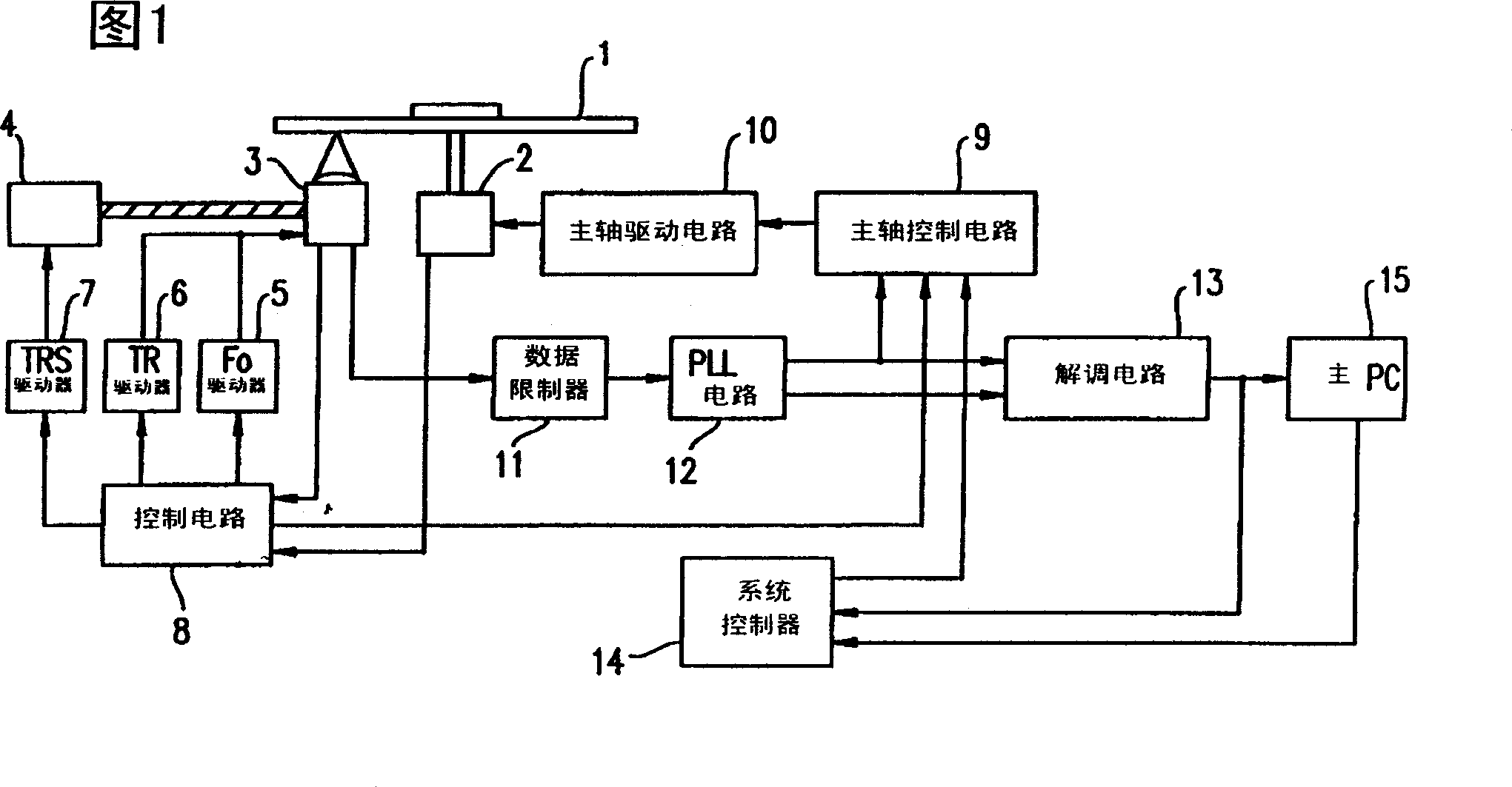

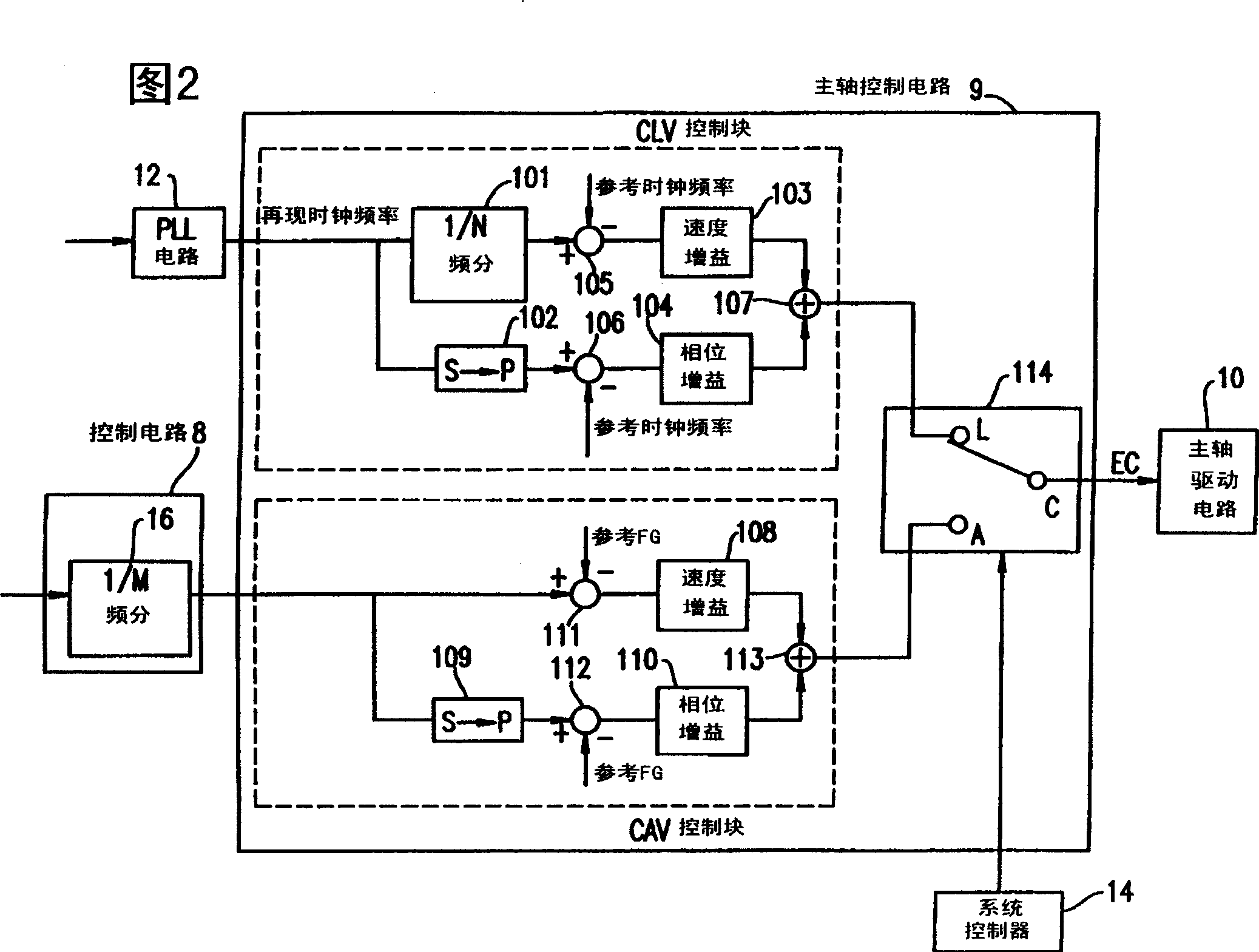

Information reproduction apparatus with selective CLV and CAV control

InactiveUS6870802B1Improve access performanceEasy to controlCombination recordingTelevision system detailsConstant linear velocityEngineering

An information reproduction apparatus of the present invention comprises a rotating section 2 for rotating an information carrier 1 on which a unit of continuous information capable of being continuously read out is recorded, a CLV control section 9 for controlling the rotating section in such a manner that the information carrier is rotated at a constant linear velocity, a CAV control section 9 for controlling the rotating section in such a manner that the information carrier is rotated at a constant angular velocity, a rotation control selection 14 for selectively operating the CLV or CAV control section, and an information determination section 14 for detecting an information length of the continuous information. The rotation control selection section is constructed in such a manner as to selectively operate the CLV or CAV control section based on a result of the detection of the information length of the continuous information.

Owner:PANASONIC CORP

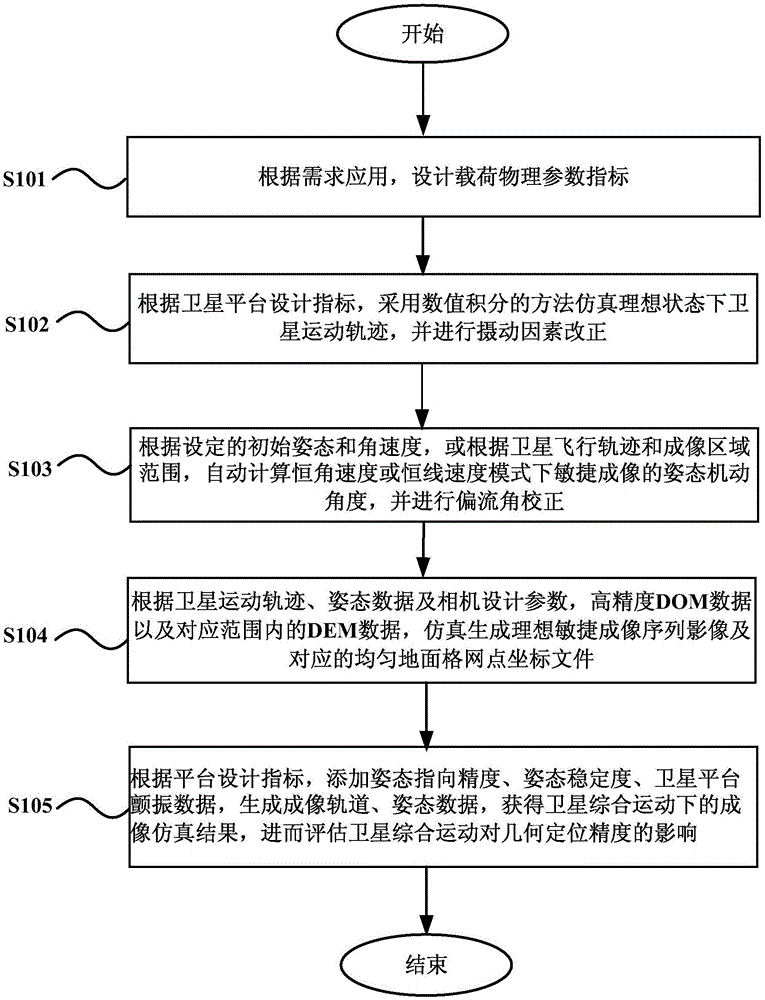

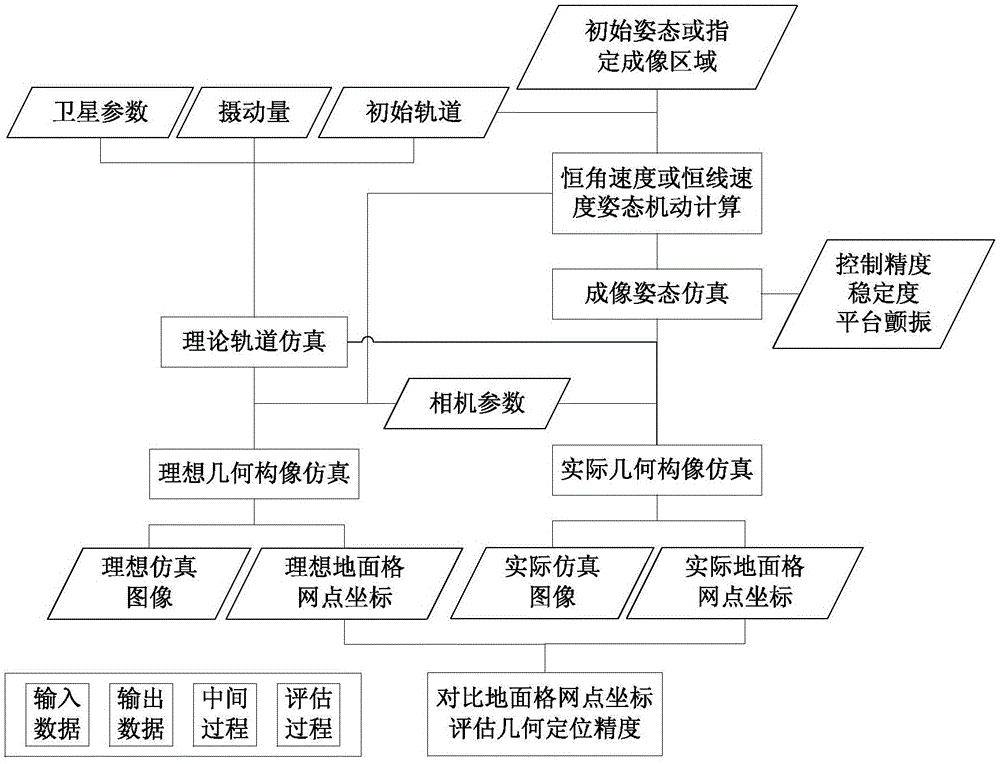

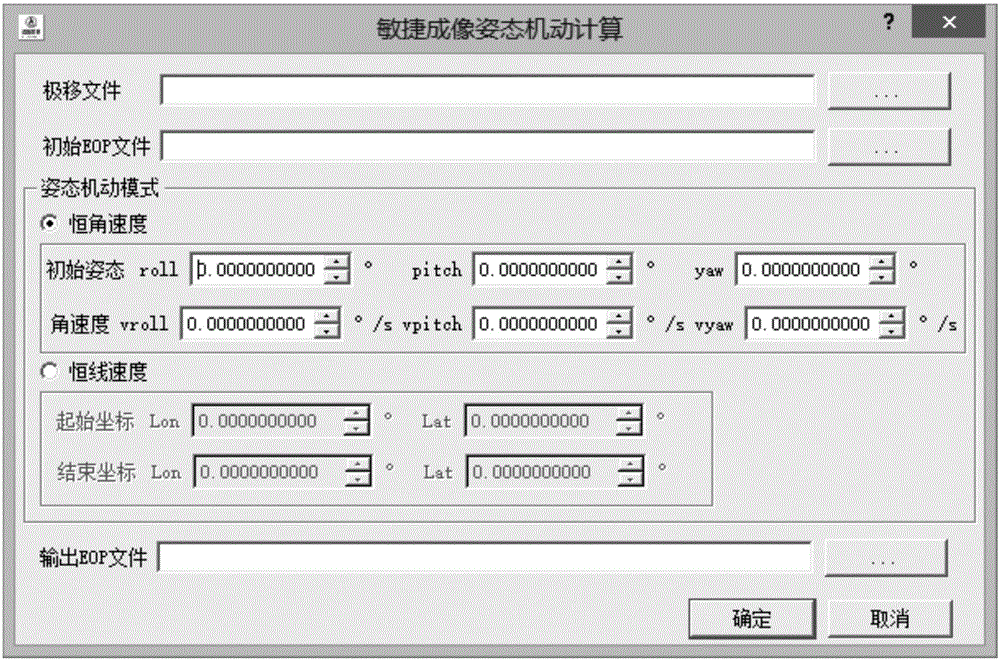

Assessment method of agile imaging simulation and positioning accuracy of satellite

ActiveCN105138756AAchieving Agile Imaging Sequence Image SimulationSpecial data processing applicationsConstant linear velocityGrounding grid

The invention provides an assessment method of agile imaging simulation and positioning accuracy of a satellite. The assessment method comprises following steps: designing a load physical parameter index according to an application demand; adopting a numerical integration method to simulate the movement trajectory of the satellite in the ideal state and correcting perturbing factors according to a platform design index; calculating an attitude maneuver angle for agile imaging in the mode of constant angular velocity or constant linear velocity and performing correction of a drift angle; generating the ideal agile imaging sequence of images by simulation and corresponding coordinate files for uniform ground grid points based on the movement trajectory of the satellite, attitude data of exposure time, design parameters of a camera, DOM data and DEM data in a corresponding data range; and obtaining an imaging simulation result of synthetic movement of the satellite according to the platform design index and movement error terms so that influence of synthetic movement of the satellite upon geometric positioning accuracy is further assessed. The assessment method of agile imaging simulation and positioning accuracy of the satellite has following beneficial effects: by adoption of the method, a real motion state and an imaging process of the satellite on orbit can be simulated; and geometric positioning accuracy for agile imaging of synthetic movement of the satellite is assessed.

Owner:SPACE STAR TECH CO LTD

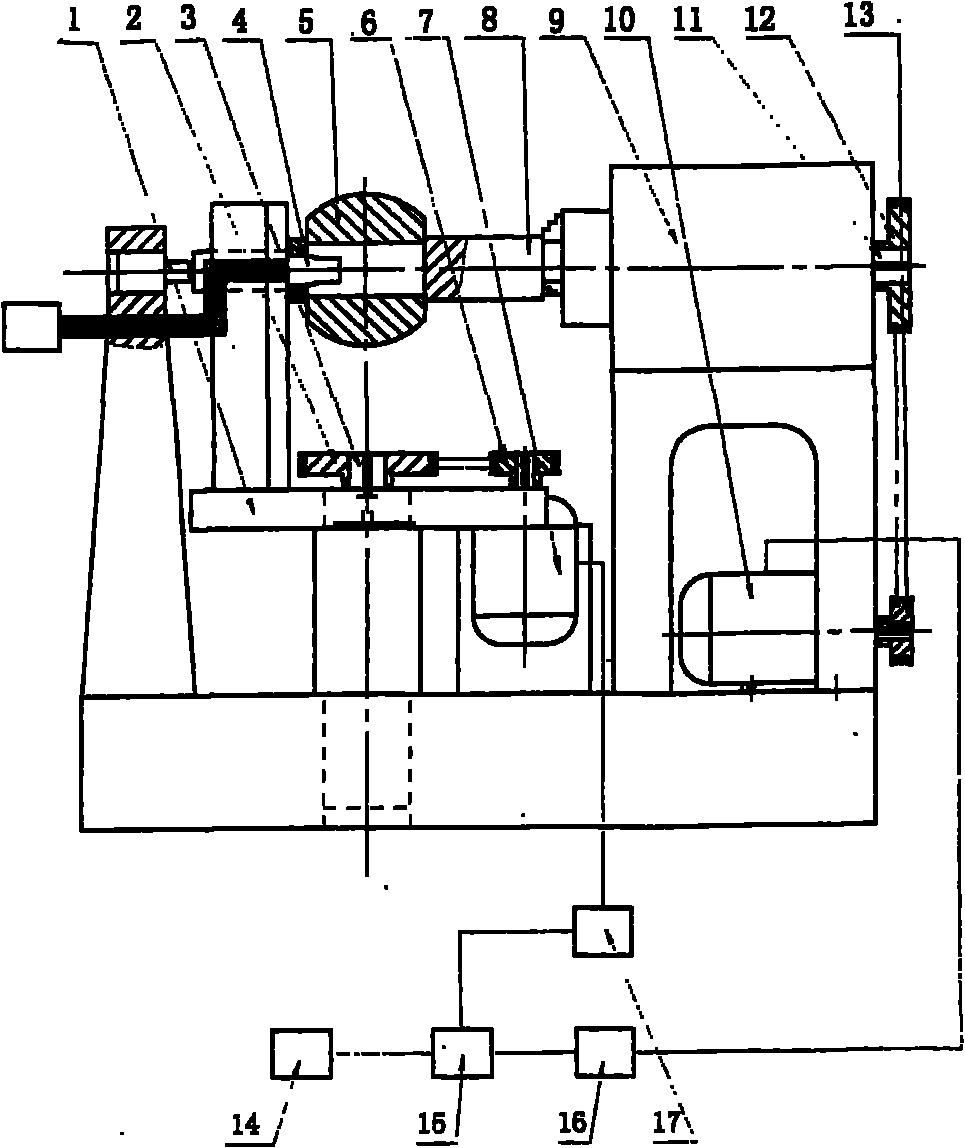

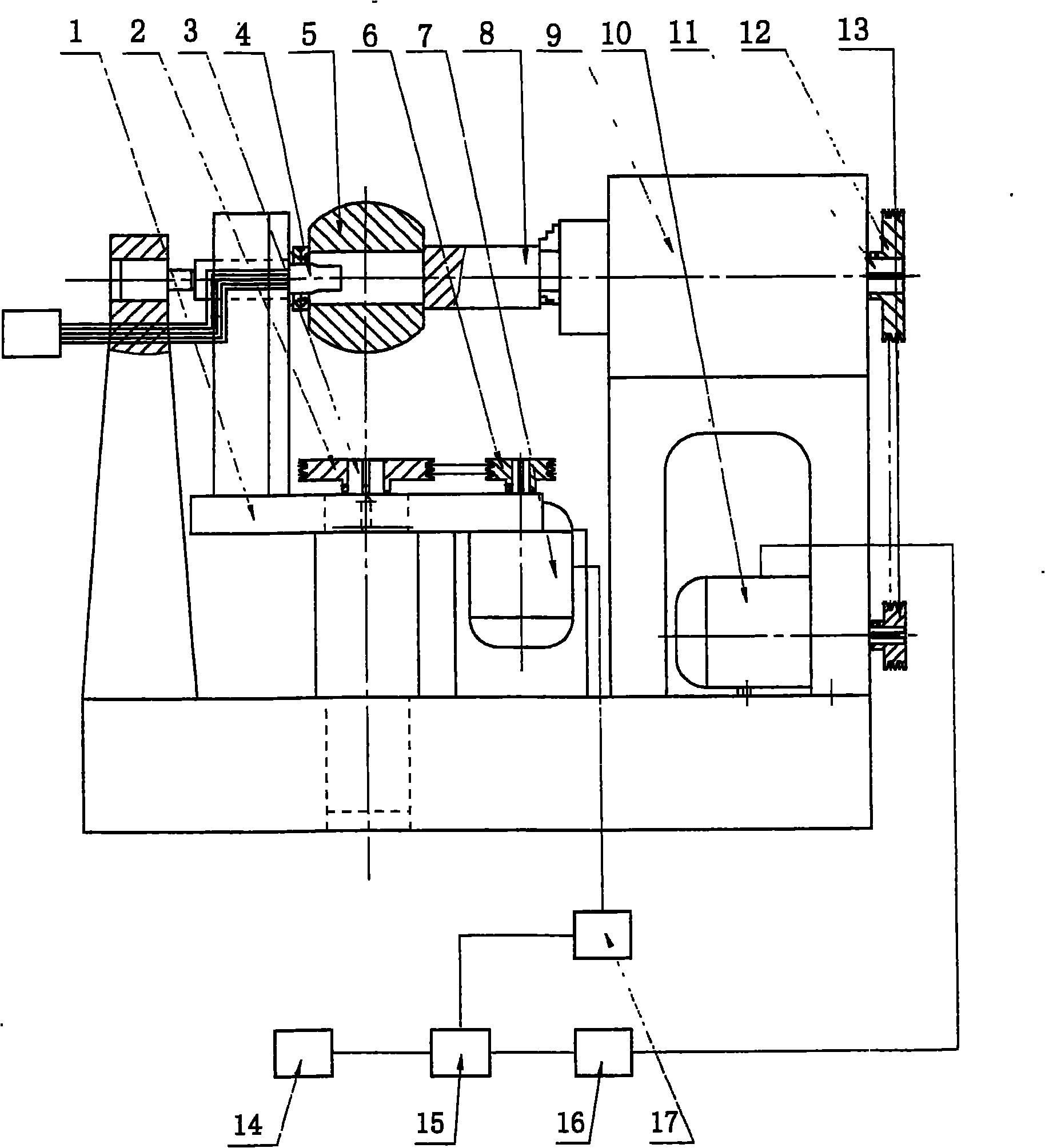

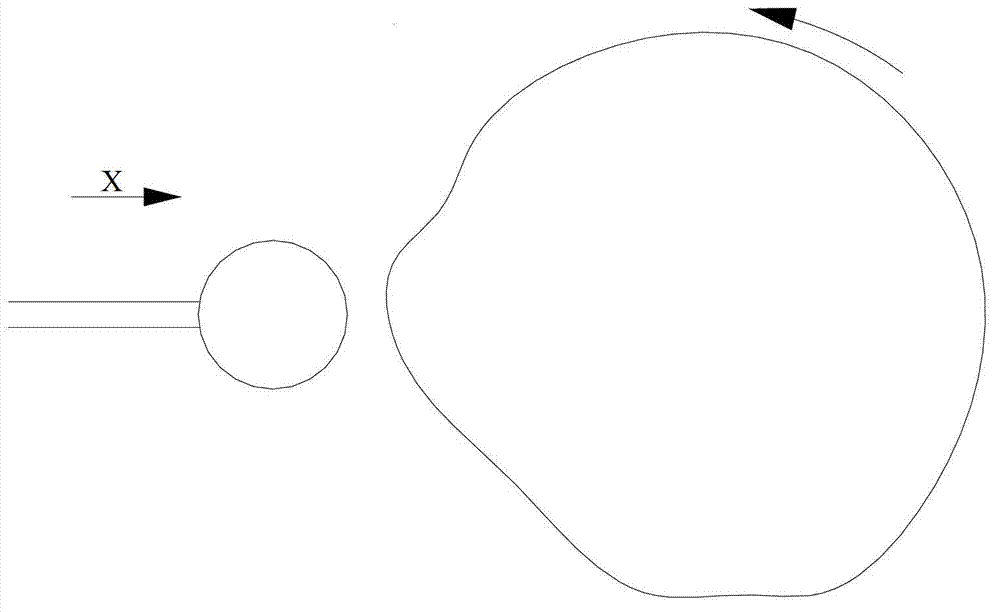

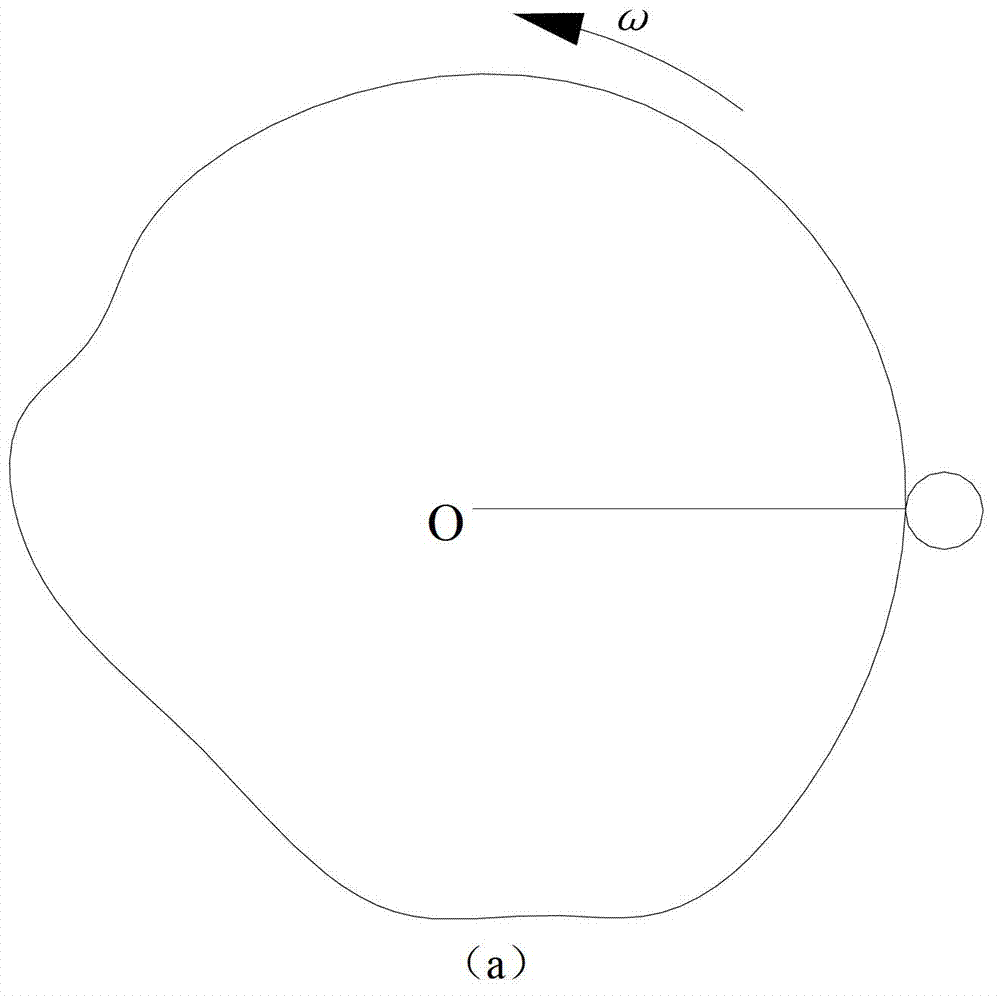

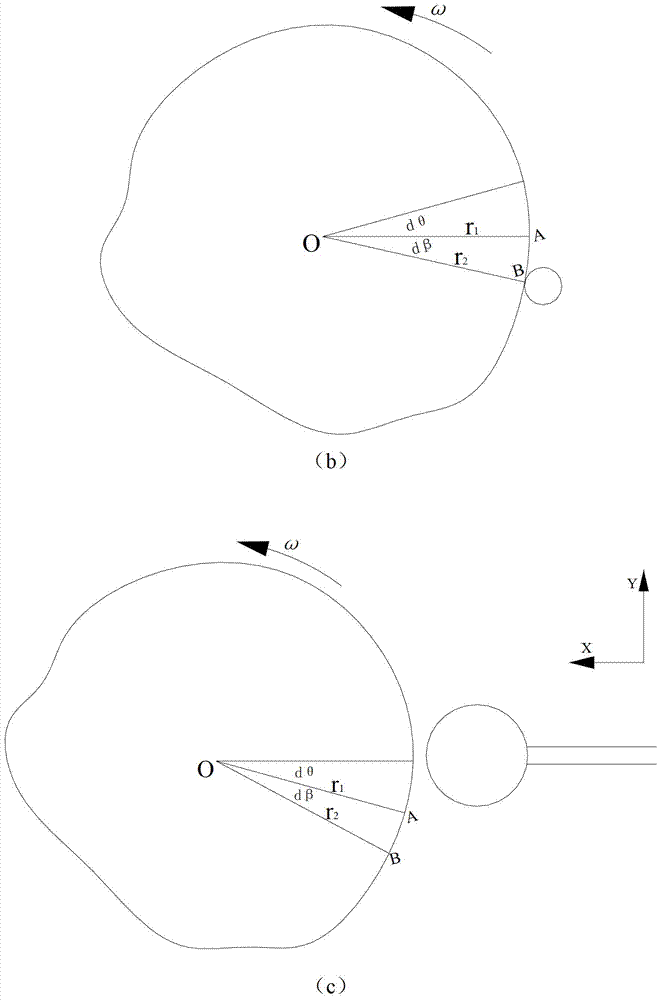

Multi-grinding-unit multi-working-procedure parallel constant linear velocity grinding method and grinding device

InactiveCN102765034AConsistent speedConsistent Grinding QualityGrinding machinesConstant linear velocityConstant angular velocity

The invention discloses a multi-grinding-unit multi-working-procedure parallel constant linear velocity grinding method. The method comprises the following steps that: 1) a rotary working table drives a workpiece to rotate at the constant angular velocity Omega, wherein the curve of the workpiece is r (theta), and the grinding constant linear velocity is set to be V; and 2) tools in grinding units are driven within the time of dt to operate circumferentially along the workpiece for V1*dt, thus the grinding constant linear speed of each grinding unit is V, wherein V1=V-Omega r(Omega dt), and r(Omega dt) is the distance from a tool grinding part on the curve r (theta) of the workpiece to the center of the workpiece, thus the grinding amount of each working procedure is ensured to be constant, and the grinding quality of each part at the periphery of the workpiece can be ensured to be consistent. The invention also discloses a multi-grinding-unit multi-working-procedure parallel grinding device. The rotary workpiece table surface and a plurality of grinding units are combined to be machined at the same time, the parallel machining of multi-working procedure of the curve of the workpiece is realized, thus the losses of efficiency, re-positioning and the like caused by frequency tool replacement are prevented, and the machining efficiency is improved greatly.

Owner:ZHEJIANG UNIV

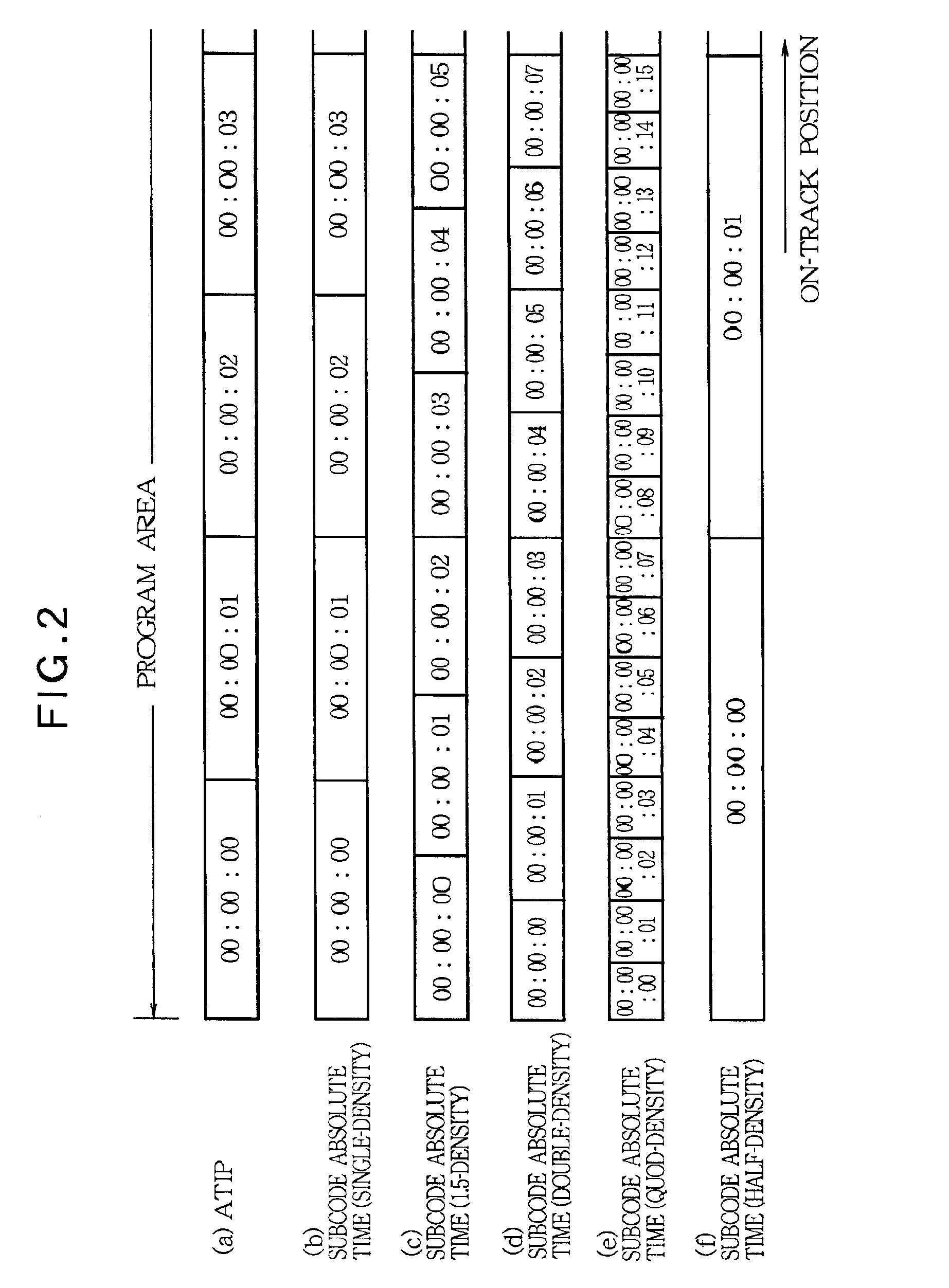

Optical disk recorder for writing data with variable density

InactiveUS6894967B2Reduce recording timeReduce in quantityTelevision system detailsFilamentary/web record carriersConstant linear velocityData recording

An optical disk recording apparatus operates on an optical disk having circular tracks which are provisionally written with an index signal used for securing a constant linear velocity of the optical disk from an innermost circular track to an outermost circular track, and records data along the circular tracks at different linear densities on different annular zones of the optical disk. In the apparatus, a disk drive section rotates the optical disk while synchronizing the index signal successively read from the rotated optical disk with a predetermined reference clock signal to thereby maintain the constant linear velocity of the circular tracks. A clock generating section multiplies or divides the reference clock signal by different rates to generate different writing clock signals in correspondence to the different annular zones of the optical disk. A data recording section operates in synchronization to the different writing clock signals for recording data along the circular tracks at the different linear densities on the different annular zones.

Owner:YAMAHA CORP

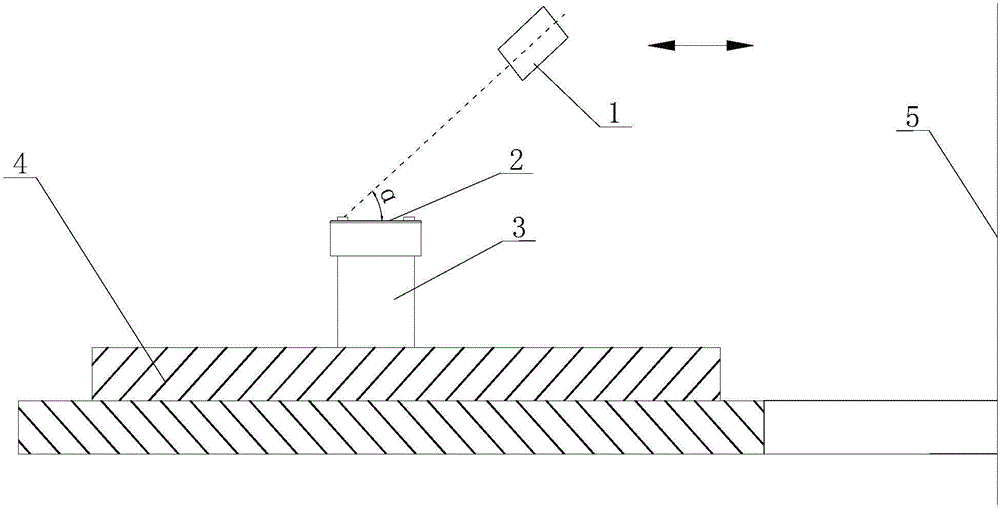

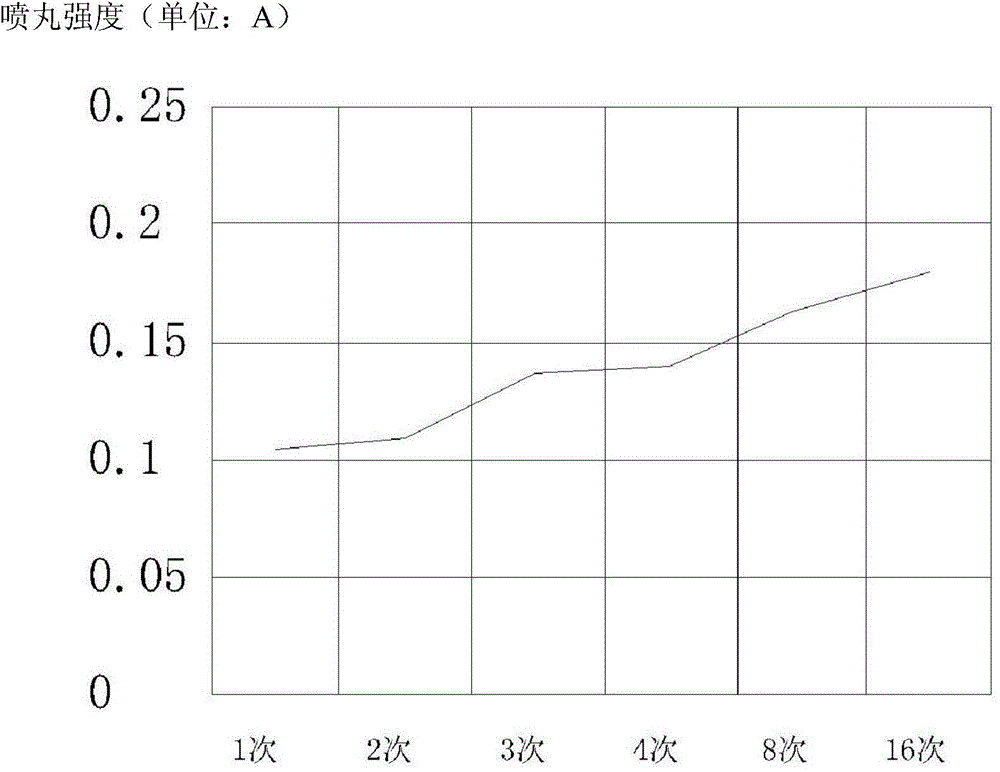

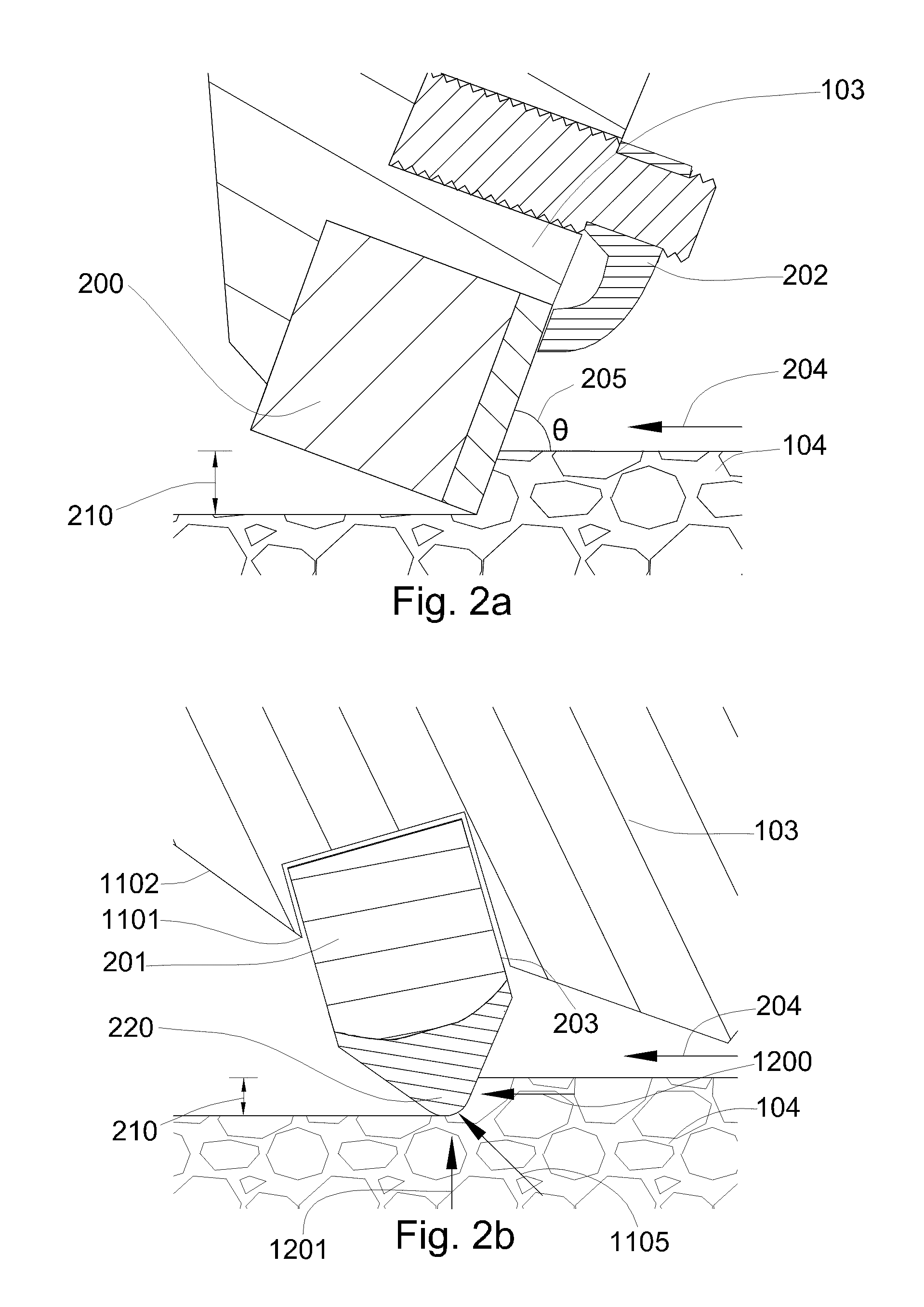

Move mode shot peening specimen testing method

InactiveCN104459035AIncrease success rateHigh strengthNumerical controlMaterial analysisRadial motionConstant linear velocity

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Information reproduction apparatus, information carrier, and information recording apparatus

InactiveUS20050147399A1Improve access performanceReduce noiseTelevision system detailsRecord information storageConstant linear velocityRotation control

An information reproduction apparatus of the present invention comprises a rotating section 2 for rotating an information carrier 1 on which a unit of continuous information capable of being continuously read out is recorded, a CLV control section 9 for controlling the rotating section in such a manner that the information carrier is rotated at a constant linear velocity, a CAV control section 9 for controlling the rotating section in such a manner that the information carrier is rotated at a constant angular velocity, a rotation control selection 14 for selectively operating the CLV or CAV control section, and an information determination section 14 for detecting an information length of the continuous information. The rotation control selection section is constructed in such a manner as to selectively operate the CLV or CAV control section based on a result of the detection of the information length of the continuous information.

Owner:KIMURA NAOHIRO +2

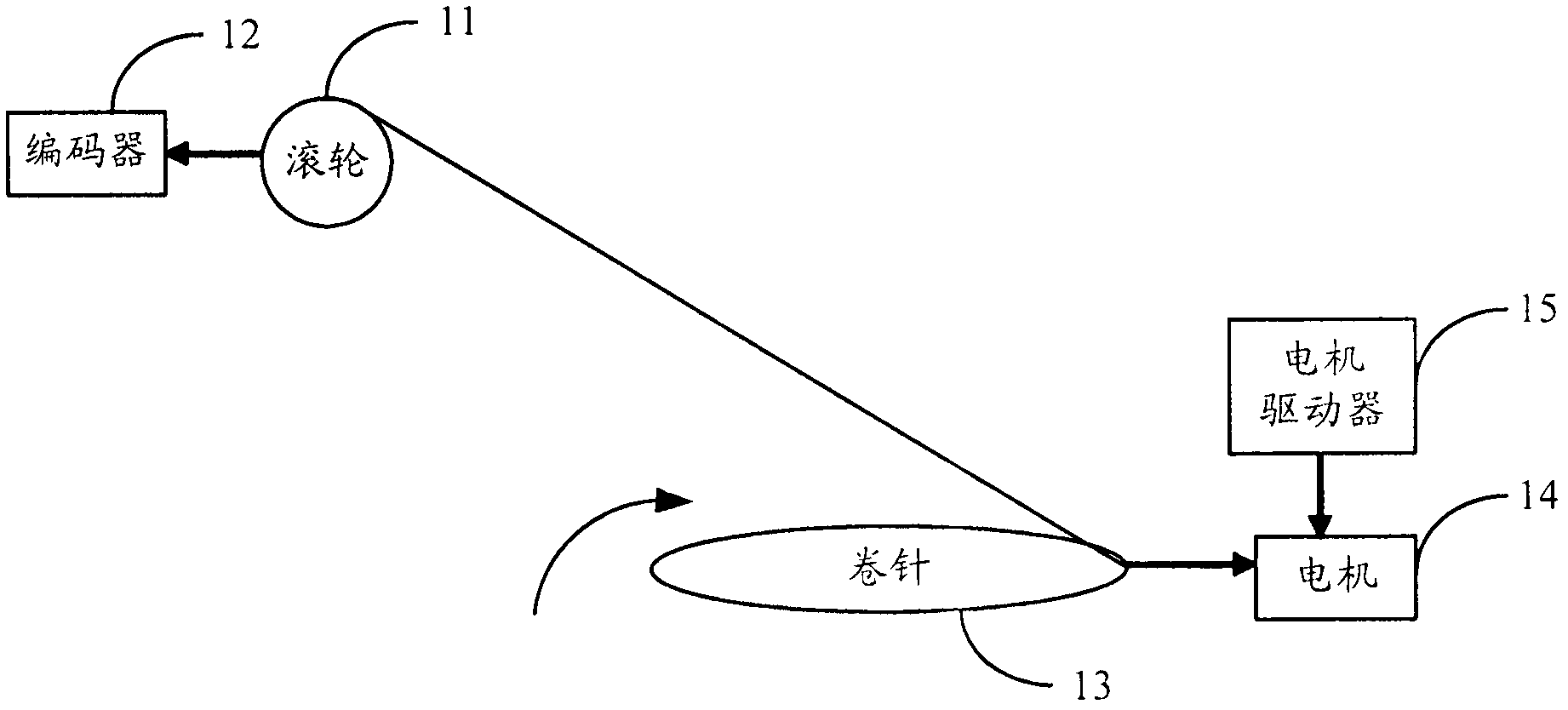

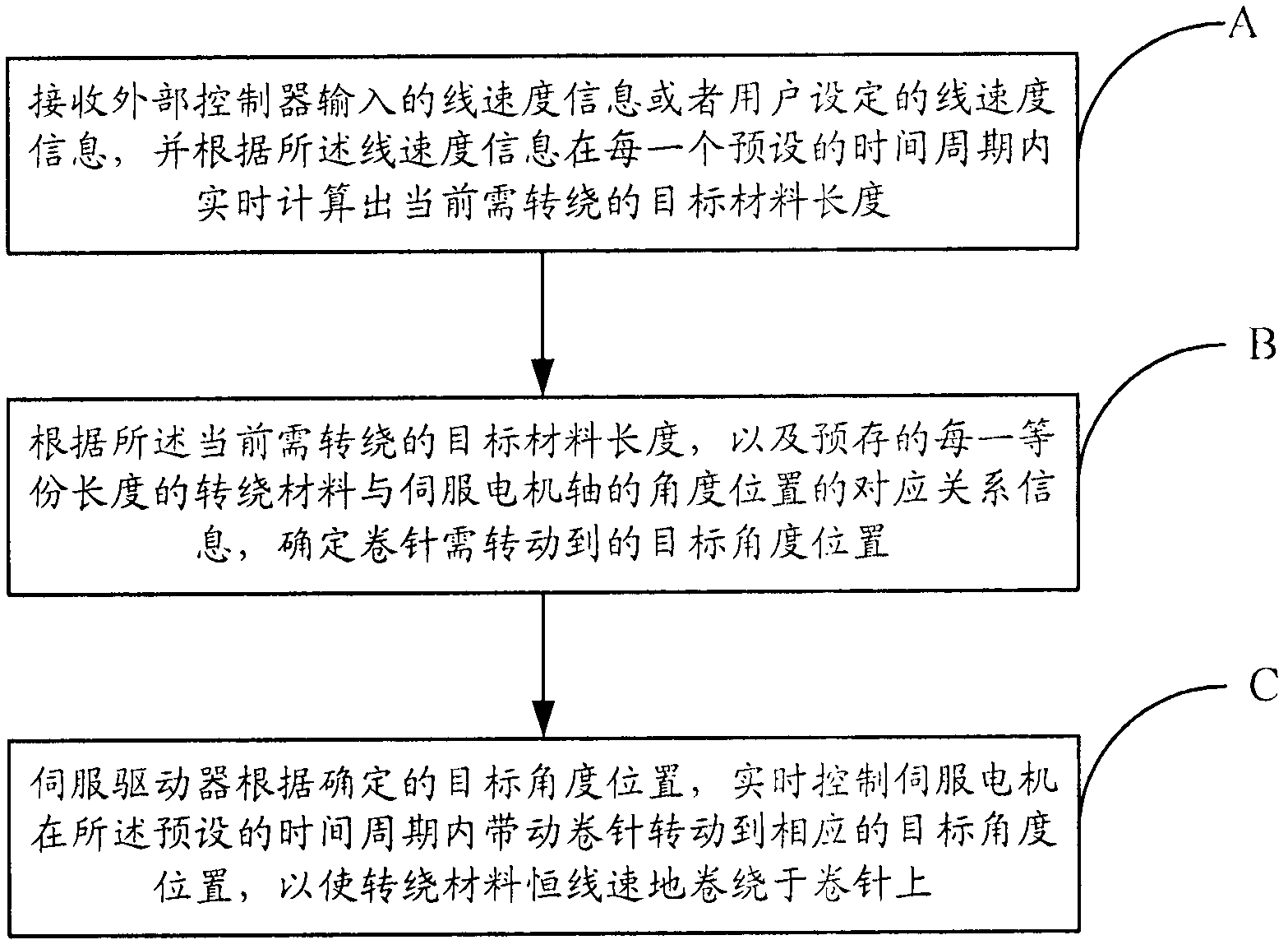

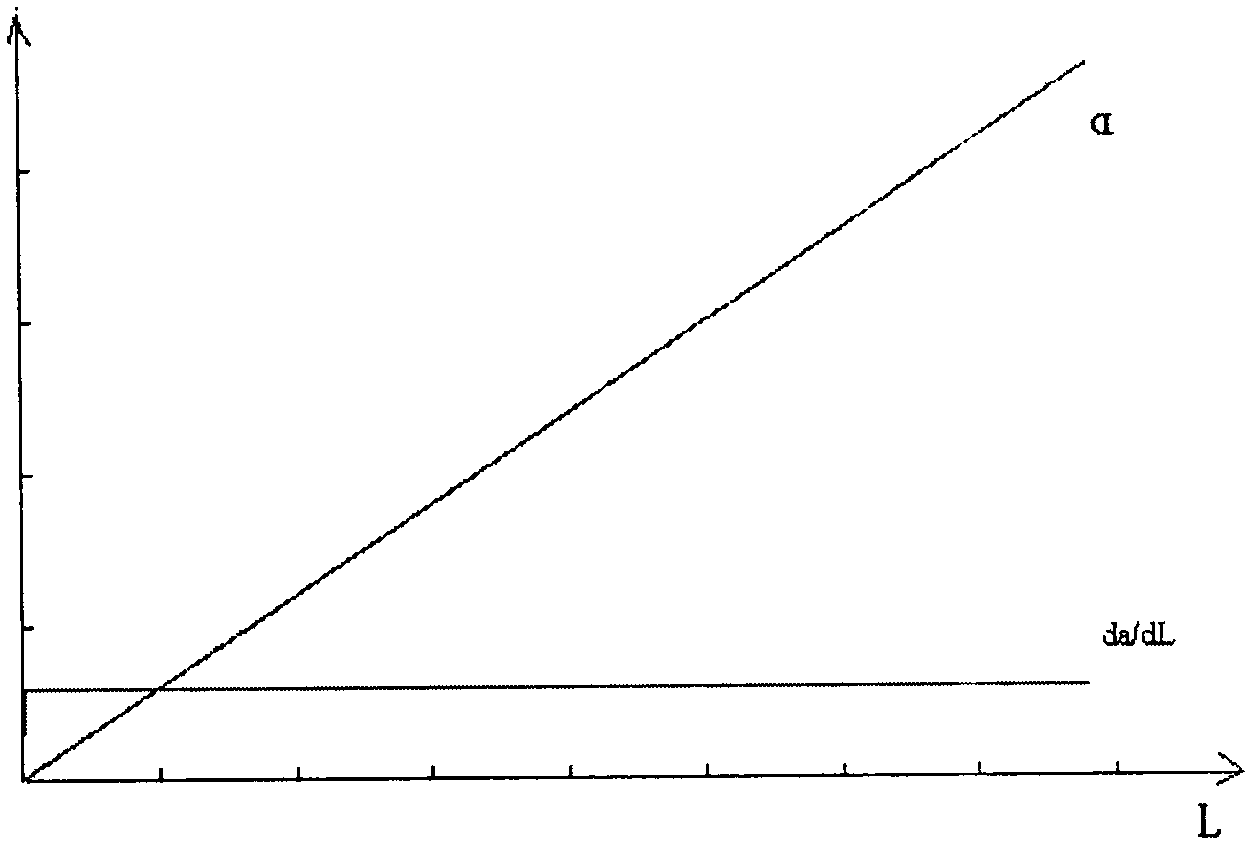

Battery coiling device and coiling control method thereof

ActiveCN102437366AReduce the amount of shape calculationReliable open loop controlFinal product manufactureSecondary cells manufactureConstant linear velocityWire speed

The invention is applied in the technical field of battery manufacture, and provides a battery coiling control method, which comprises the following steps of: A, calculating a current target material coiling length in real time in each preset time period according to received linear velocity information; B, determining a target angular position to which a coiling pin is required to rotate according to the current target material coiling length and pre-stored information about corresponding relationship between each equilong rotating-coiled material and the angular positions of a servo motor shaft; and C, controlling a servo motor in real time to drive the coiling pin to rotate to a corresponding target angular position in the preset time period according to the determined target angular position by using a servo driver, so that the rotating-coiled material is coiled on the coiling pin at constant linear velocity. When the method is used, the rotating angular position information of the coiling pin is sampled and stored in advance in the whole battery coiling process, and angular velocity at which constant linear velocity rotation can be realized is calculated in actual coiling, so that constant linear velocity coiling effects can be improved.

Owner:上海步科自动化股份有限公司

Test fixture that positions a cutting element at a positive rake angle

ActiveUS8453497B2Tool workpiece connectionMeasurement/indication equipmentsRotational axisConstant linear velocity

Owner:SCHLUMBERGER TECH CORP

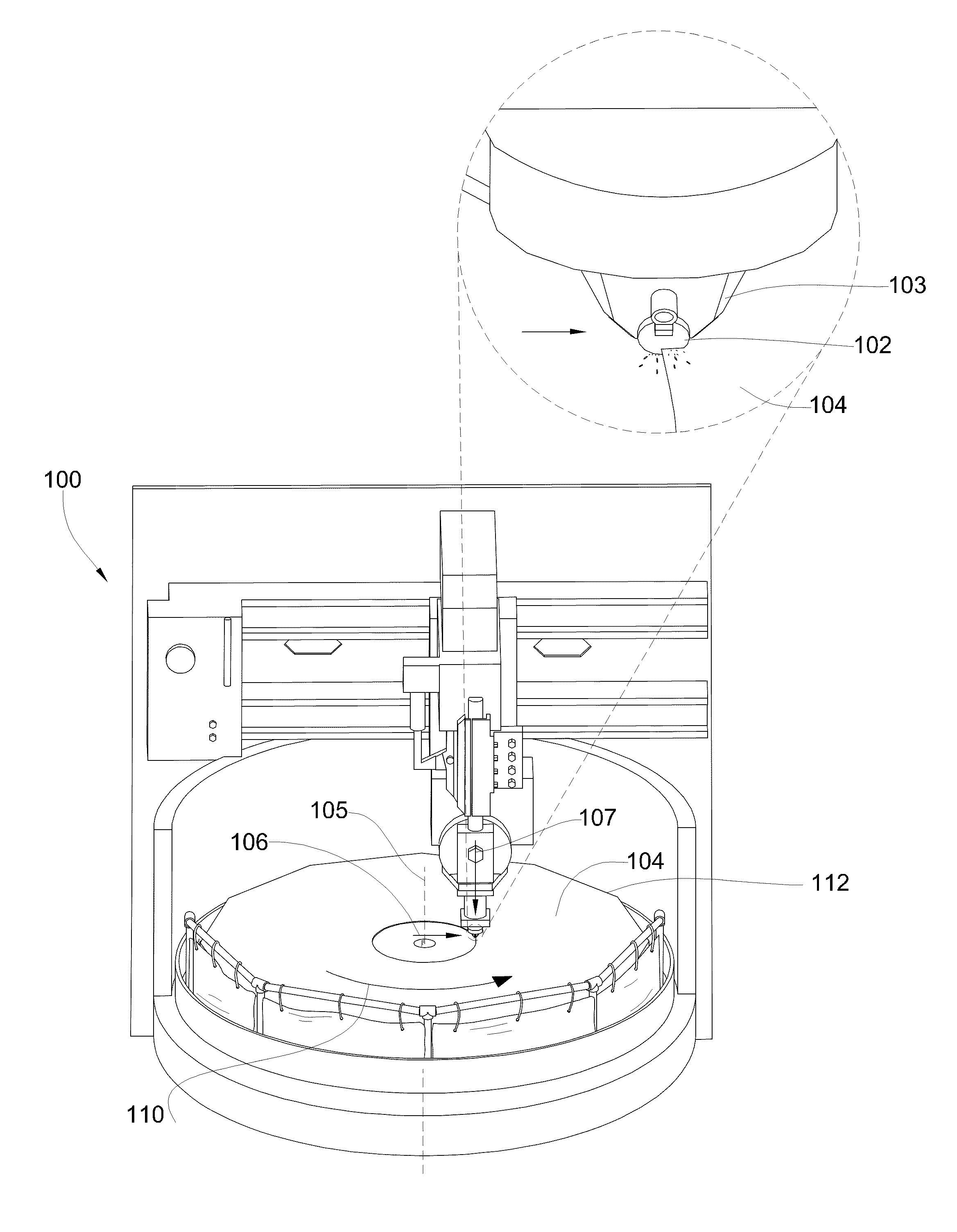

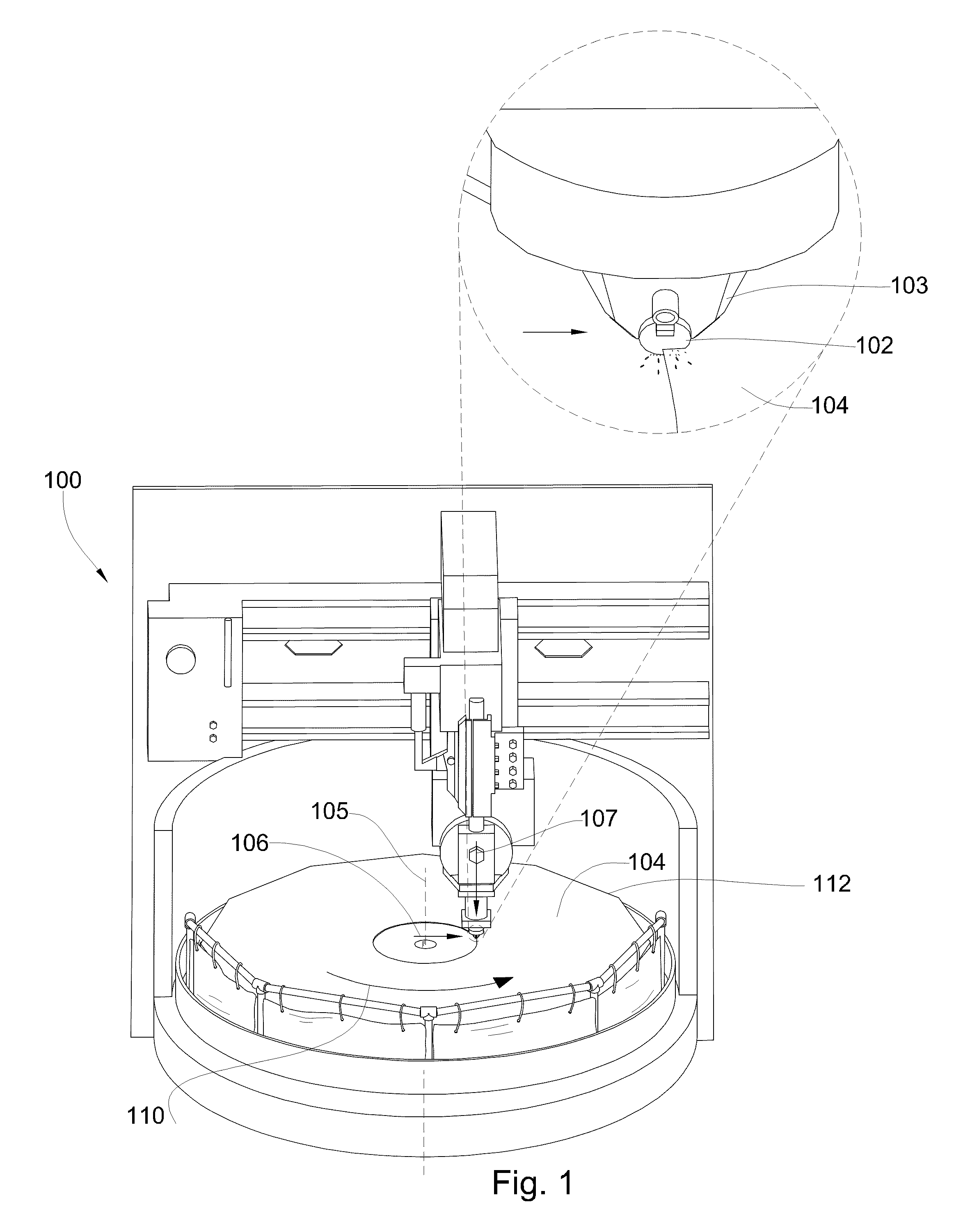

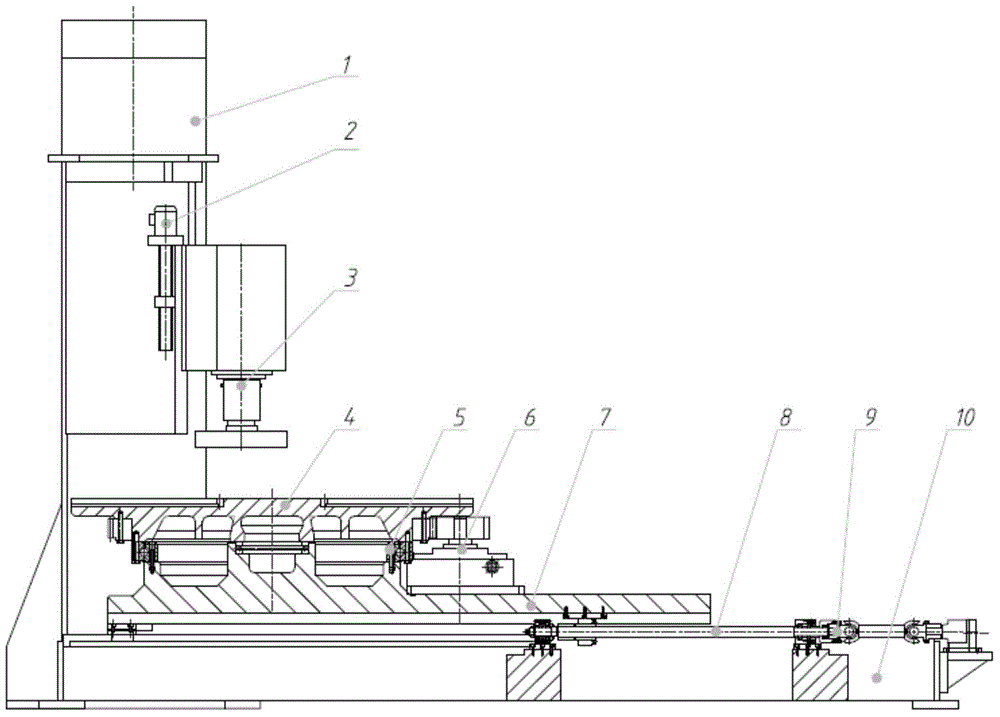

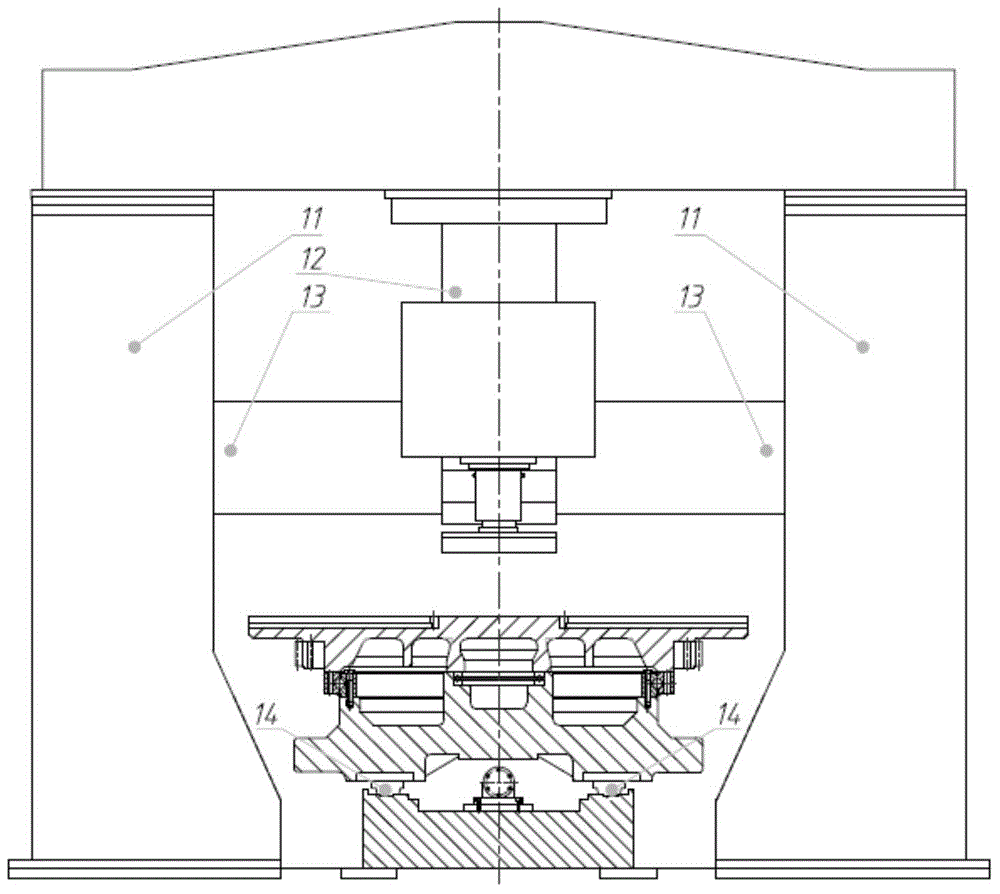

Constant linear velocity gantry vertical-spindle grinding machine with round table

InactiveCN105215814AImprove stabilityExpand the range of grinding operationsGrinding drivesGrinding machinesConstant linear velocityRound table

The invention relates to a constant linear velocity gantry vertical-spindle grinding machine with a round table. The constant linear velocity gantry vertical-spindle grinding machine with the round table comprises a gantry transverse beam (1), a Z-axis servo feed system (2), a grinding head (3), a rotary working table (4), a rotary support (5), a rotary table servo power system (6), a sliding way table (7), ball screws (8), an X-axis servo feed power system (9), a base (10), gantry stand columns (11), an upright sliding way (12), reinforcing ribs (13) and a linear guideway (14). According to the constant linear velocity gantry vertical-spindle grinding machine with the round table, a gantry structure is adopted, the stability of the vertical-spindle grinding machine with the round table is improved, and the abrasive machining range of the grinding machine with the round table is enlarged. Besides, the constant linear velocity gantry vertical-spindle grinding machine with the round table can achieve constant linear velocity grinding, and machining accuracy and ground patterns of the machined surface of a rotary workpiece can maintain consistent.

Owner:YANTAI SHANGWAY MACHINE TOOL MFG CO LTD

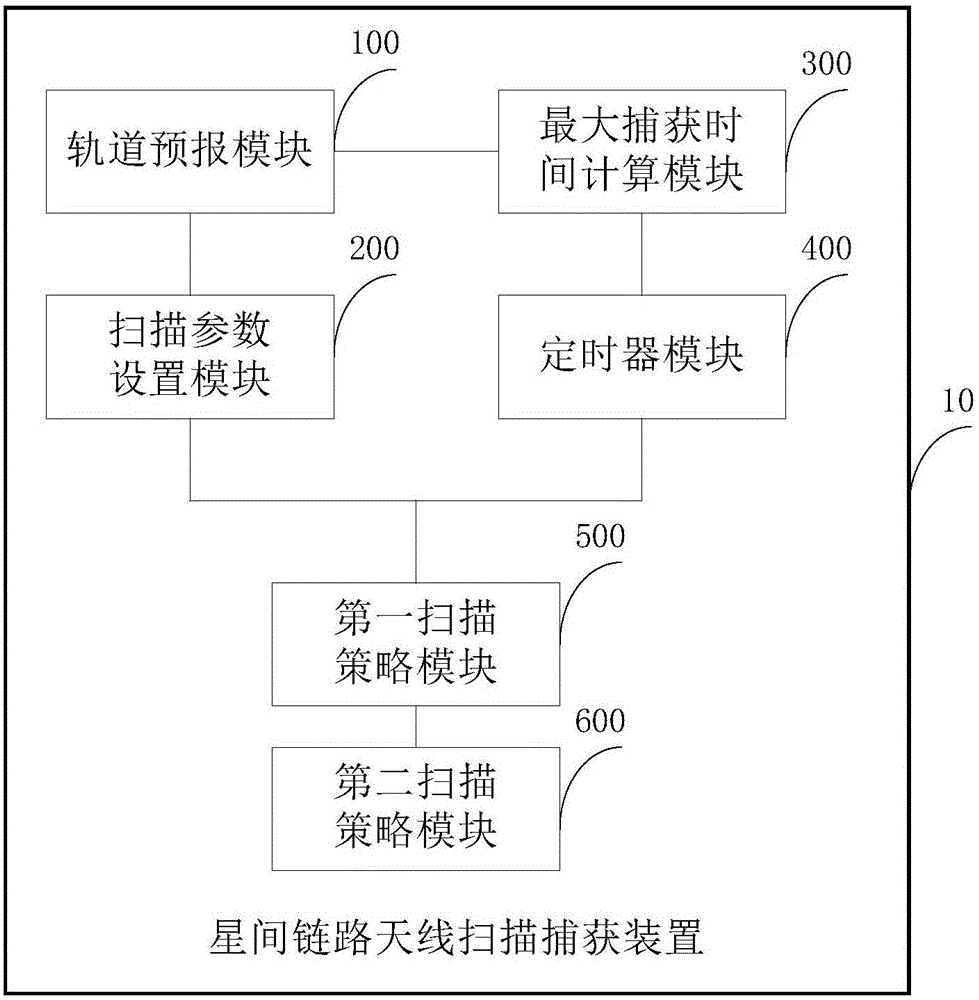

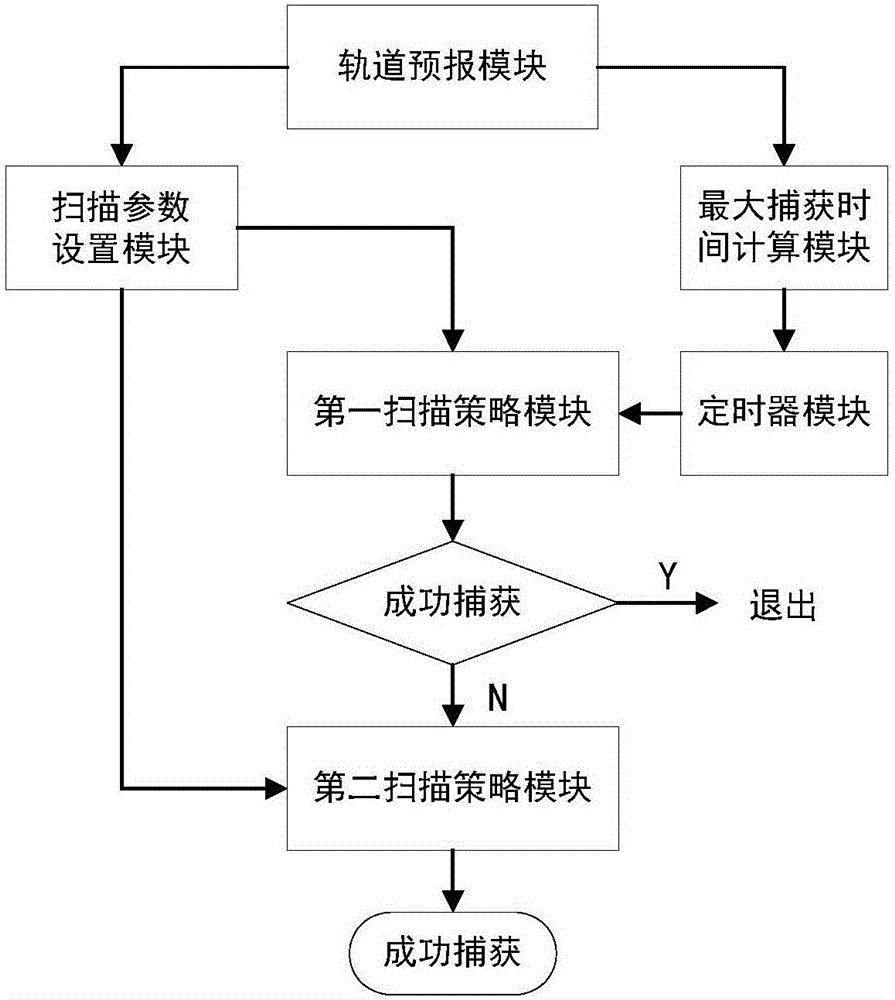

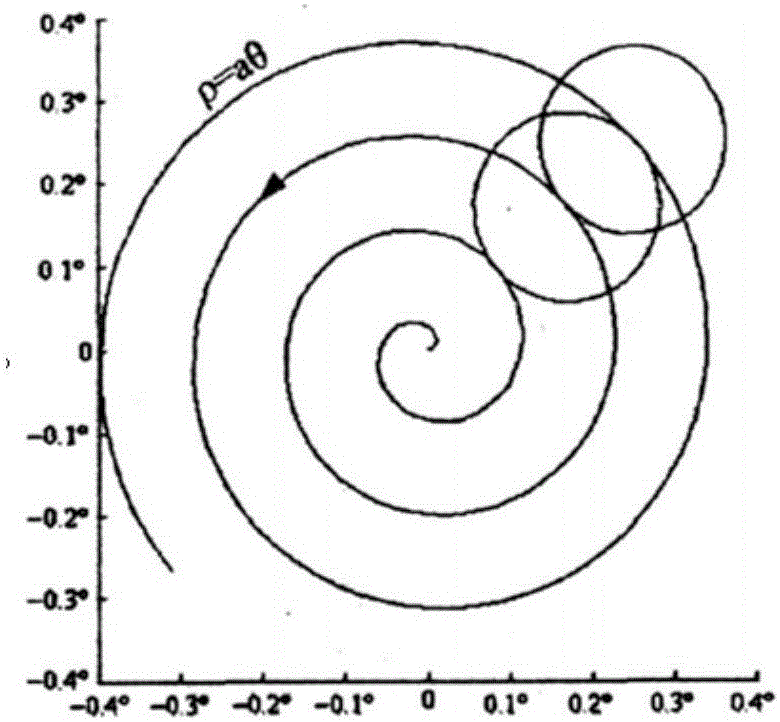

Inter-satellite link antenna scanning acquisition device and method

ActiveCN107181521AShorten capture timeImprove capture success rateRadio transmissionSatellite antennasConstant linear velocity

The present invention discloses an inter-satellite link antenna scanning acquisition device and method. The device comprises: an orbit prediction module configured to predicate antenna parameters; a scanning parameter setting module configured to obtain scanning parameters; a maximum capture time calculation module configured to obtain the required time of scanning the whole determinate region according to the antenna parameters when two satellite antennas are rotated at opposite directions; a timer module configured to limit the scanning time of the two satellite antennas being rotated; a first scanning strategy module configured to perform scanning of the rotation of the two satellite antennas at the opposite directions and determine whether the acquisition is successful or not; and a second scanning strategy module configured to allow the two satellite antennas to return back to the direction of the opposite antenna through orbit prediction at a constant linear velocity and perform scanning in a mode of only one satellite antenna rotation when the two satellite antennas cannot be subjected to successful acquisition in a maximum acquisition time, and determine whether the acquisition can be successful or not. The device can effectively reduce the acquisition time and improve the probability of successful acquisition in a short time.

Owner:TSINGHUA UNIV

Information reproducing apparatus, information carrier, and information recording apparatus

InactiveCN1352793AImprove access performanceReduce noiseTelevision system detailsRecord information storageConstant linear velocityControl manner

An information reproduction apparatus of the present invention comprises a rotating section 2 for rotating an information carrier 1 on which a unit of continuous information capable of being continuously read out is recorded, a CLV control section 9 for controlling the rotating section in such a manner that the information carrier is rotated at a constant linear velocity, a CAV control section 9 for controlling the rotating section in such a manner that the information carrier is rotated at a constant angular velocity, a rotation control selection 14 for selectively operating the CLV or CAV control section, and an information determination section 14 for detecting an information length of the continuous information. The rotation control selection section is constructed in such a manner as to selectively operate the CLV or CAV control section based on a result of the detection of the information length of the continuous information.

Owner:PANASONIC CORP

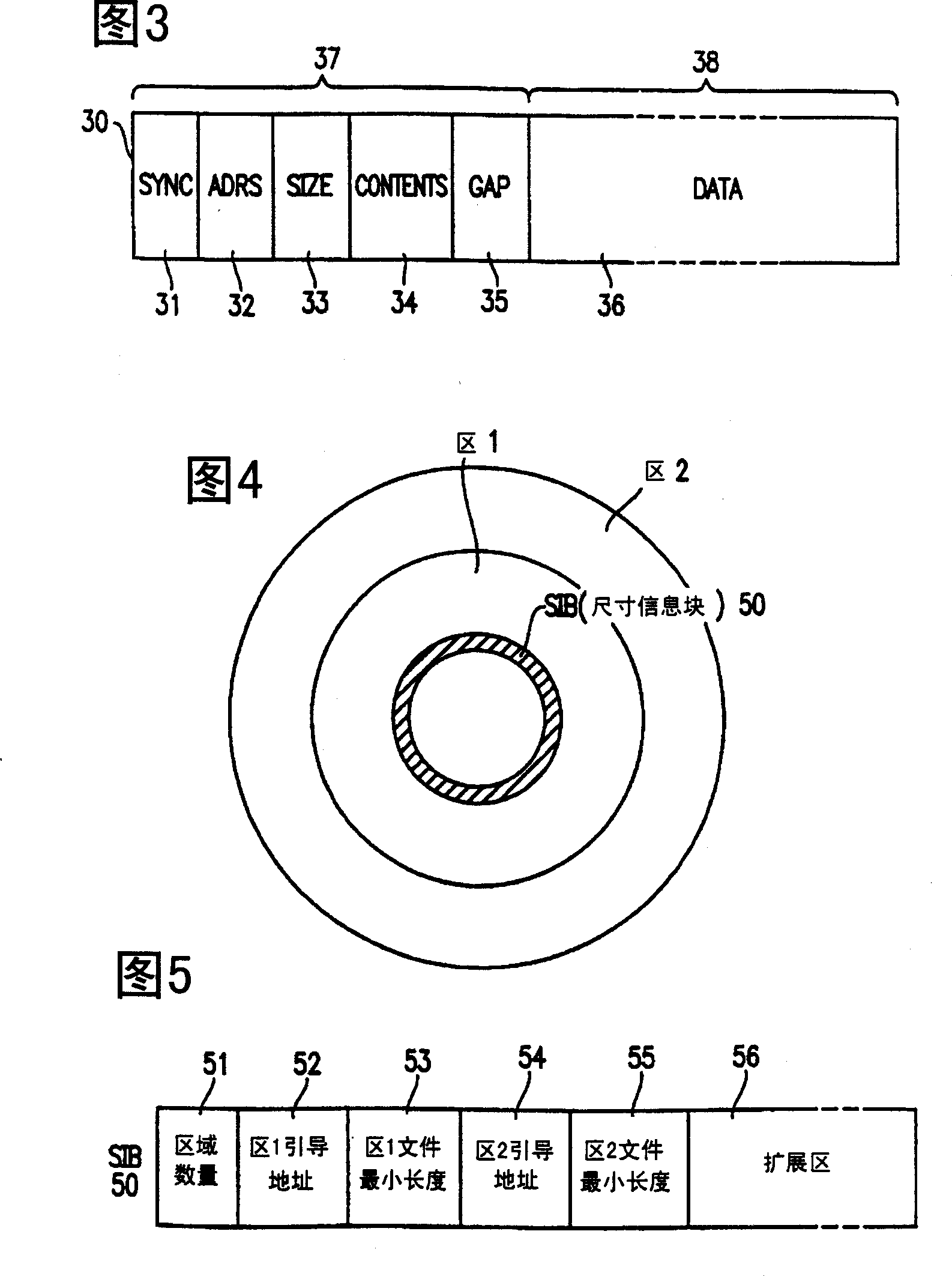

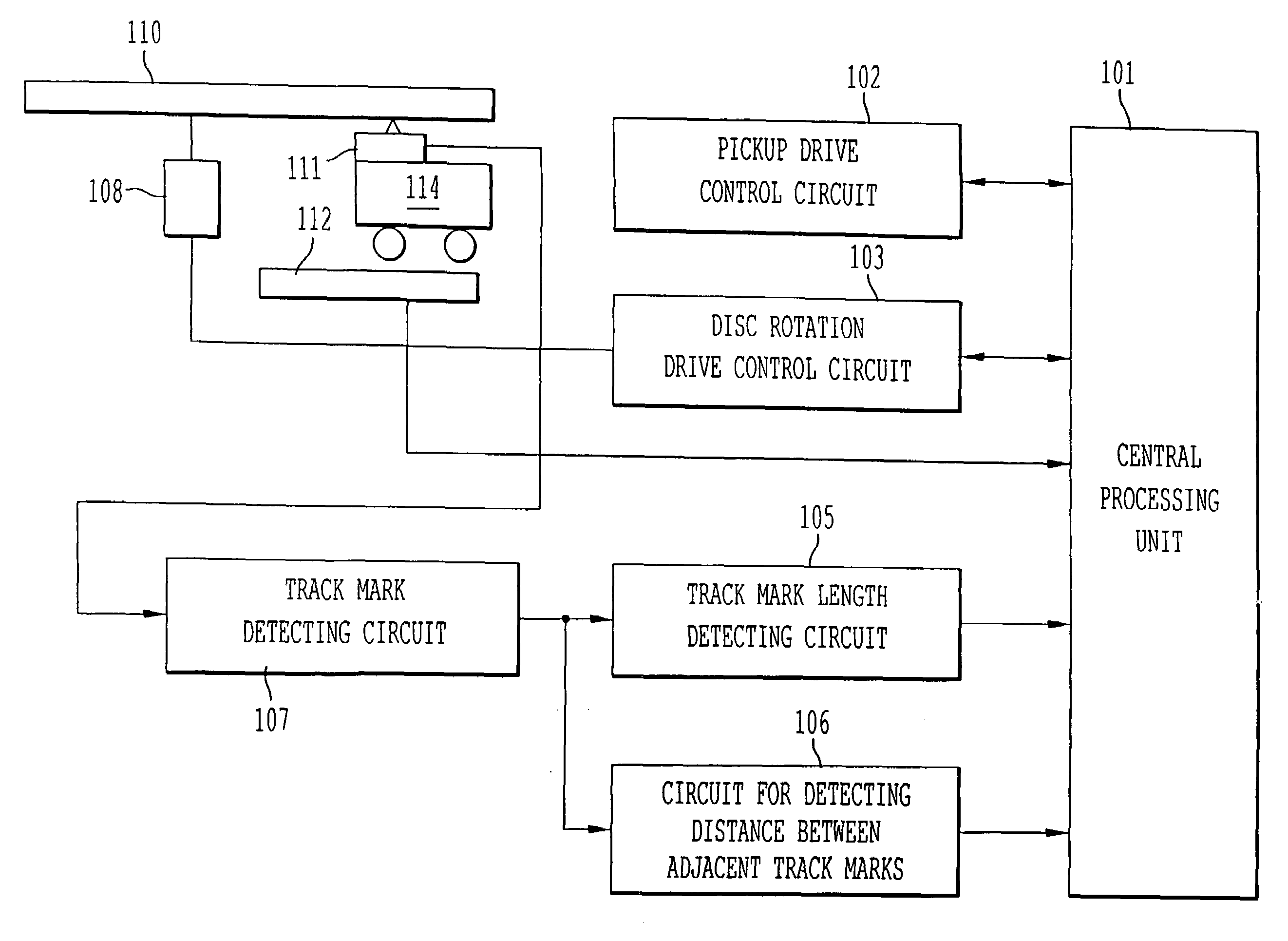

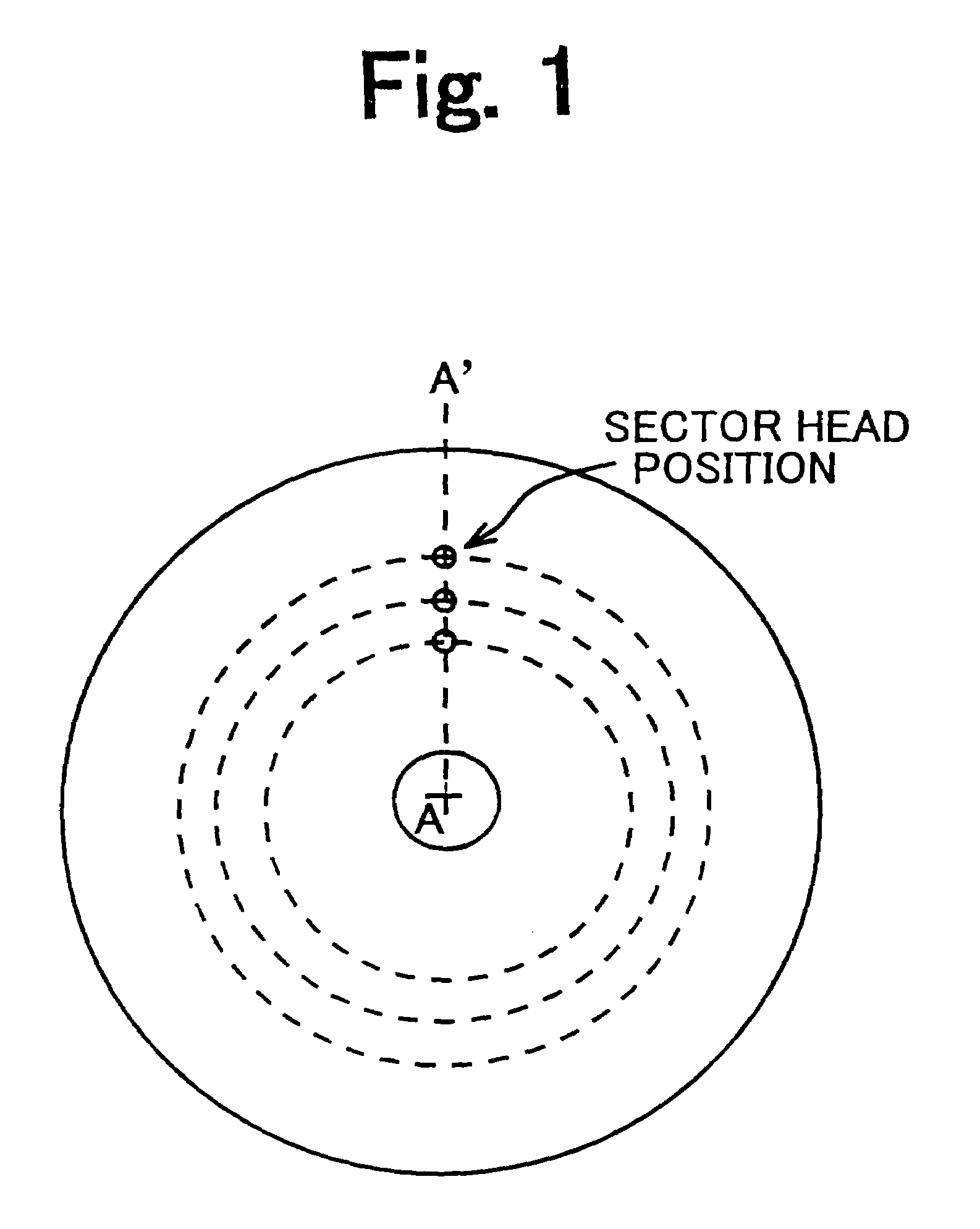

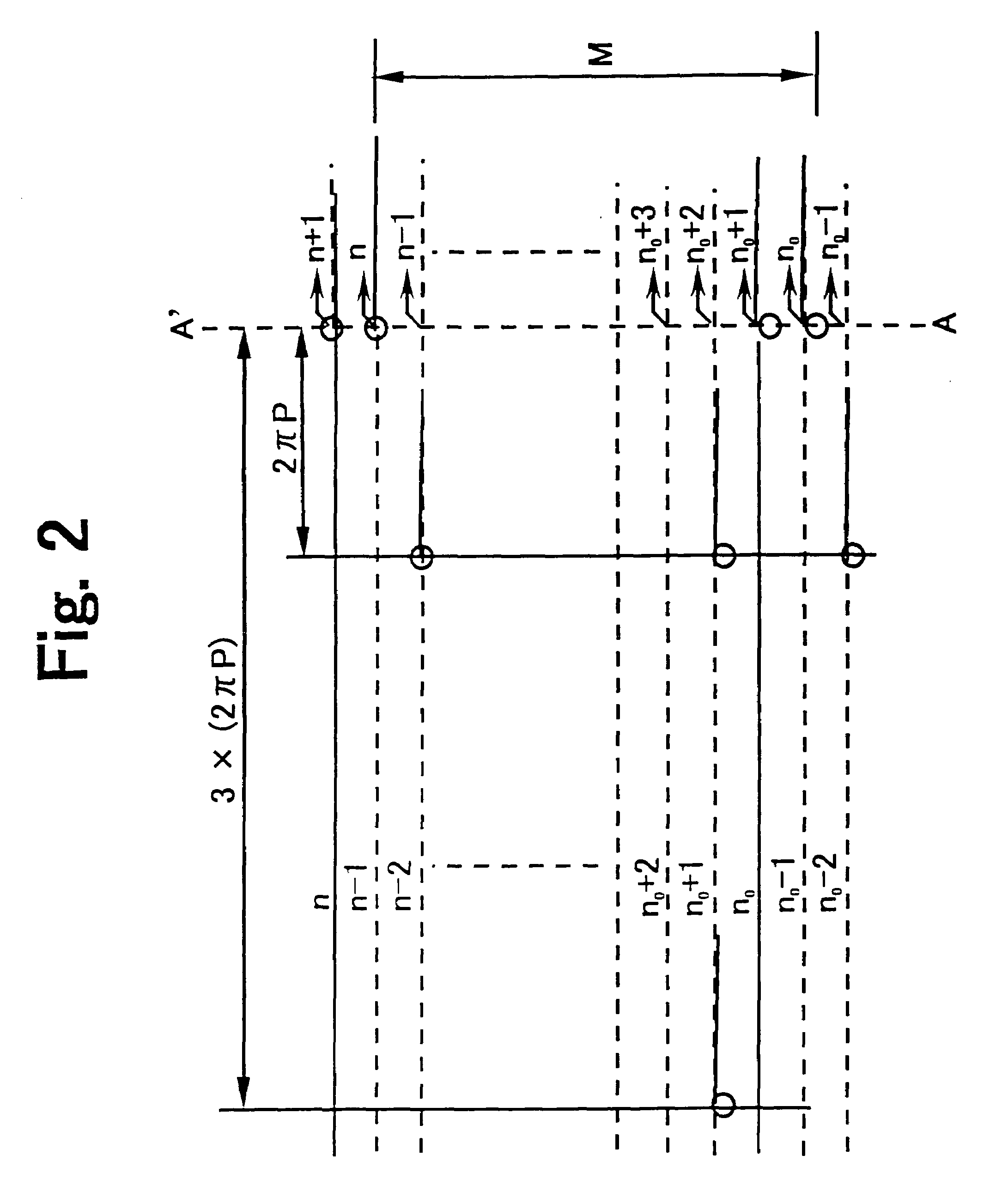

CLV optical disc, CLV optical disc format, and an optical disc medium recording and reproducing apparatus

InactiveUS6940792B1Eliminate unevennessIncrease speedFilamentary/web record carriersOptical discsConstant linear velocityPulse sequence

A CLV optical disc capable of recording the information with a constant linear velocity. In the CLV optical disc, plural lines of specified track exist in the predetermined data area, railroad length of the tracks is integer times of the length of a sector, the length of the sector on the specified tracks is 2×π×N times of a track pitch, the number N is a positive integral number, and head positions of the specified tracks are lined up on a predetermined radius line A—A′ at equal track intervals. Fixed-length track marks are arranged at equal physical length intervals along the information track formed in the state of a spiral. The track position information is obtained by detecting the track marks of the present and adjacent tracks. The CLV optical disc medium recording / reproducing apparatus can perform the seeking operation by use of the CPU and the other relevant units regardless of the operation of controlling the disc revolution number. In the CLV optical disc master board exposure, the CLV drive ordering pulse creating method can be realized by the spindle rotation ordering pulse train and the slider movement ordering pulse train.

Owner:RICOH KK

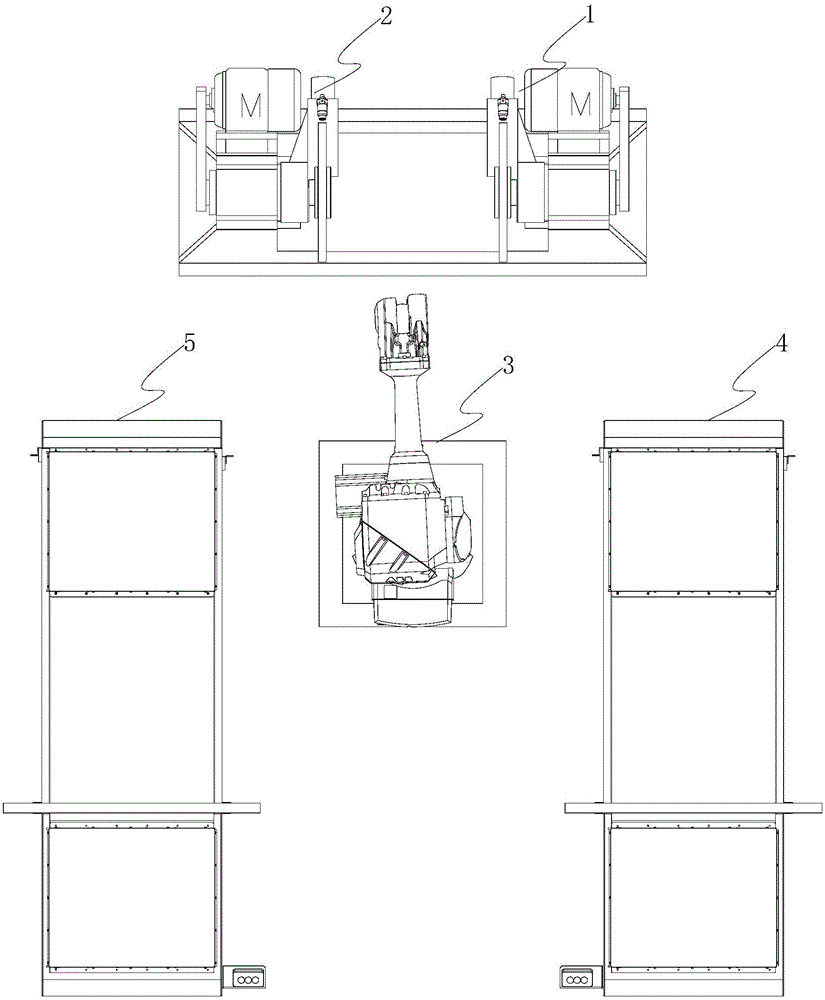

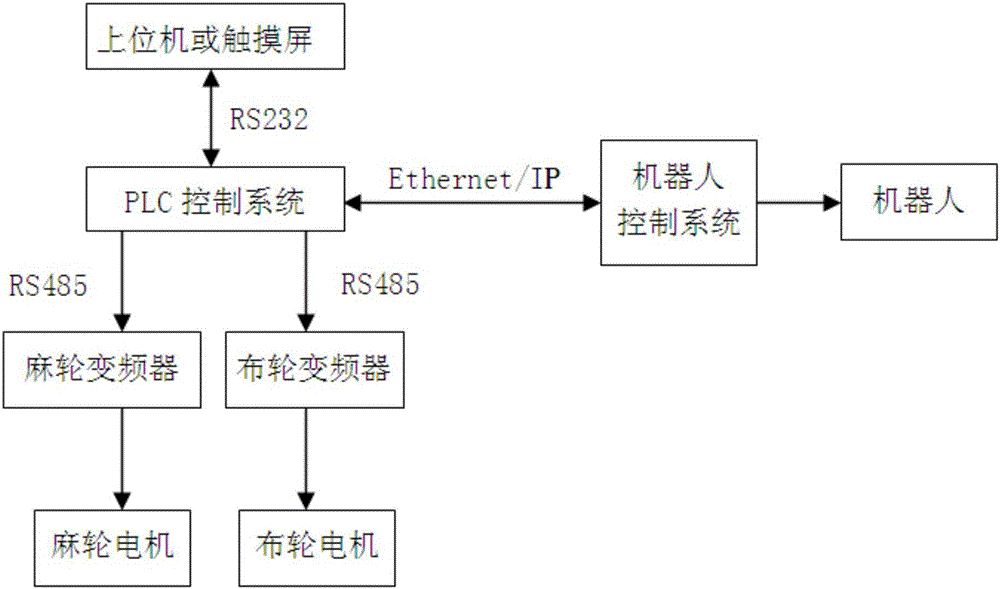

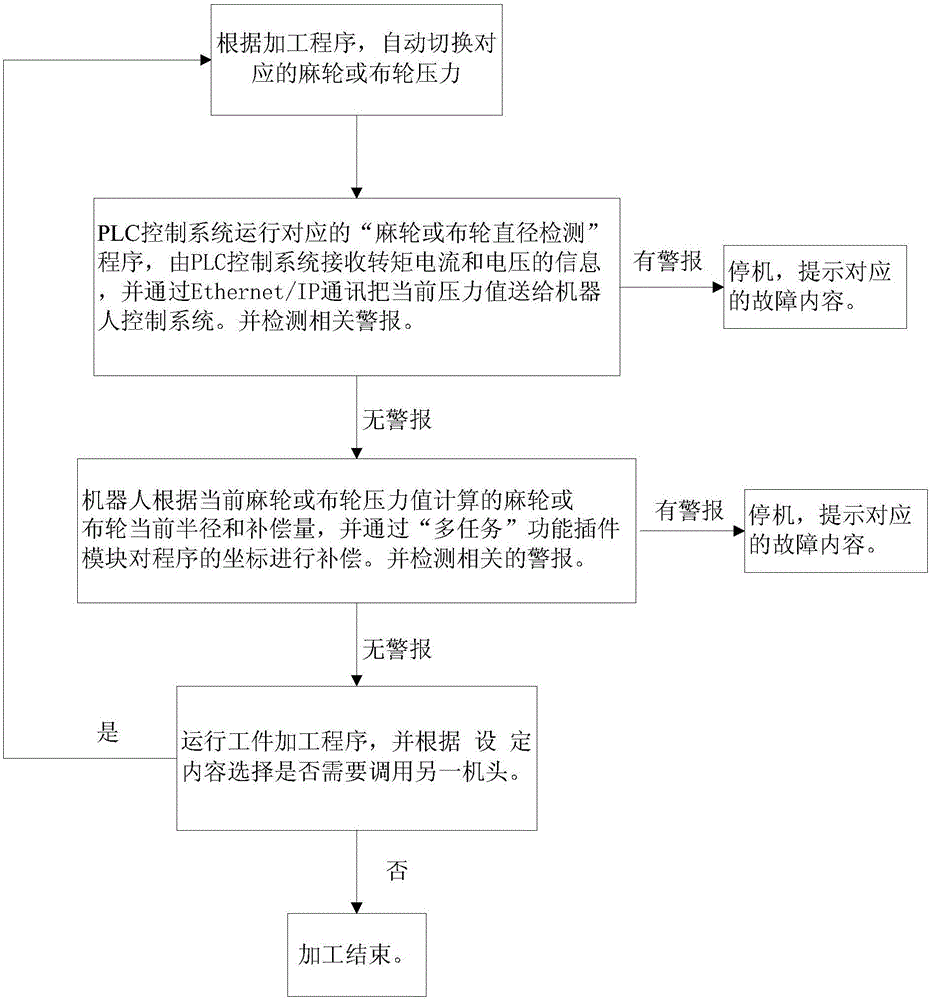

Constant-pressure constant-linear-velocity polishing method for robot polishing machine

ActiveCN106737196AAdapt to processingNovel ideaPolishing machinesAutomatic grinding controlConstant linear velocityControl system

The invention discloses a constant-pressure constant-linear-velocity polishing method for a robot polishing machine. The polishing method comprises a double-station hemp wheel polishing component, a cloth wheel polishing component, a robot, a robot control system and a PLC control system, wherein the hemp wheel polishing component comprises a connected hemp wheel, a hemp wheel motor and a hemp wheel frequency converter, and the cloth wheel polishing component comprises a cloth wheel, a cloth wheel motor and a cloth wheel frequency converter. The polishing method disclosed by the invention has the advantages that real-time interaction communication of the robot control system and the PLC control system is completed by adding an Ethernet communication function module and a multitask function plug-in module in the robot control system, and constant-pressure and constant-linear-velocity grinding polishing and polishing can be automatically realized; a robot end effector continuously changes attitude, so that each surface of a workpiece can be uniformly polished; the actual grinding and polishing arc lengths of a hemp wheel and a cloth wheel are increased, so that the polishing method disclosed by the invention is applicable to larger-size workpiece processing.

Owner:广东博科数控机械有限公司

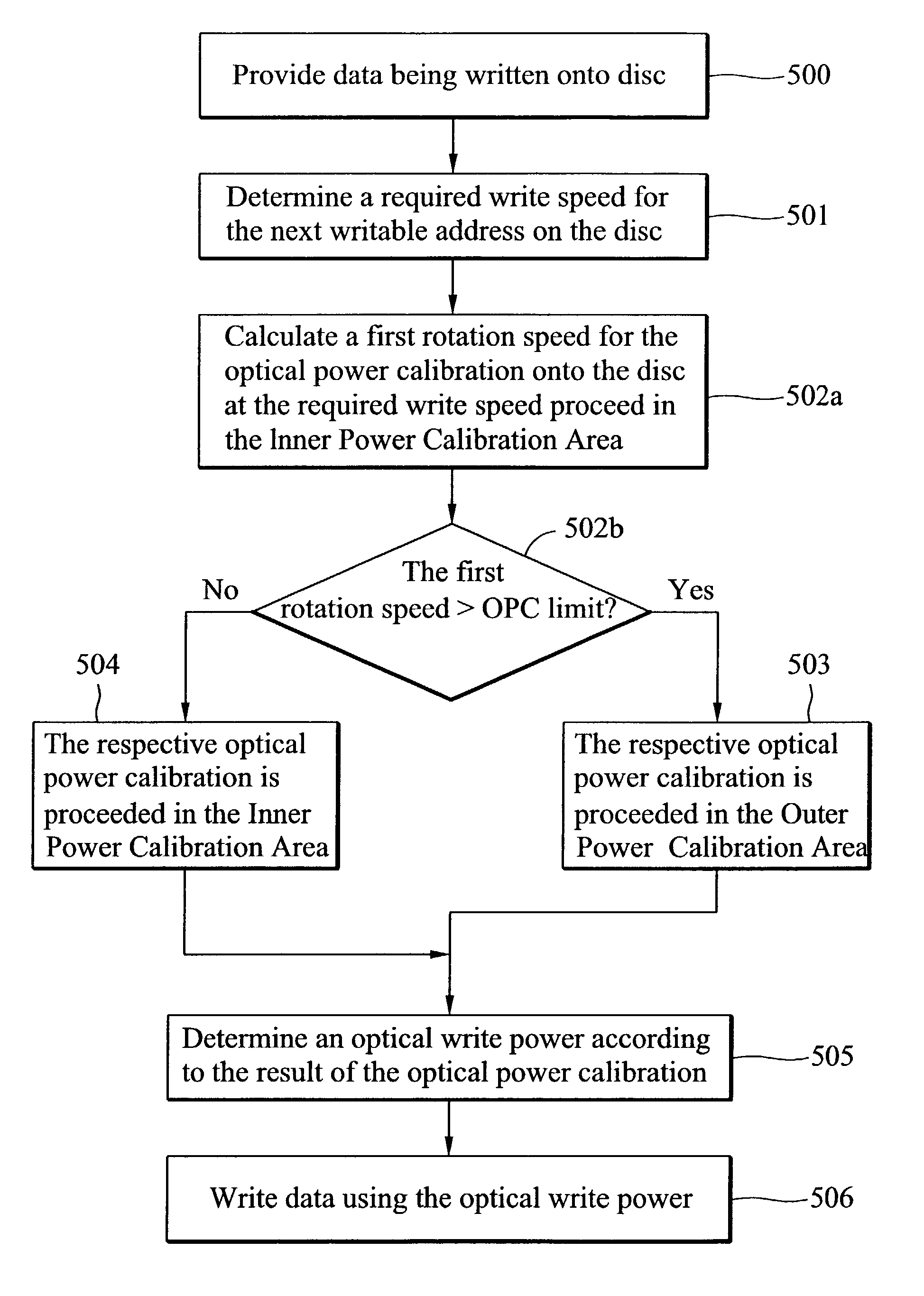

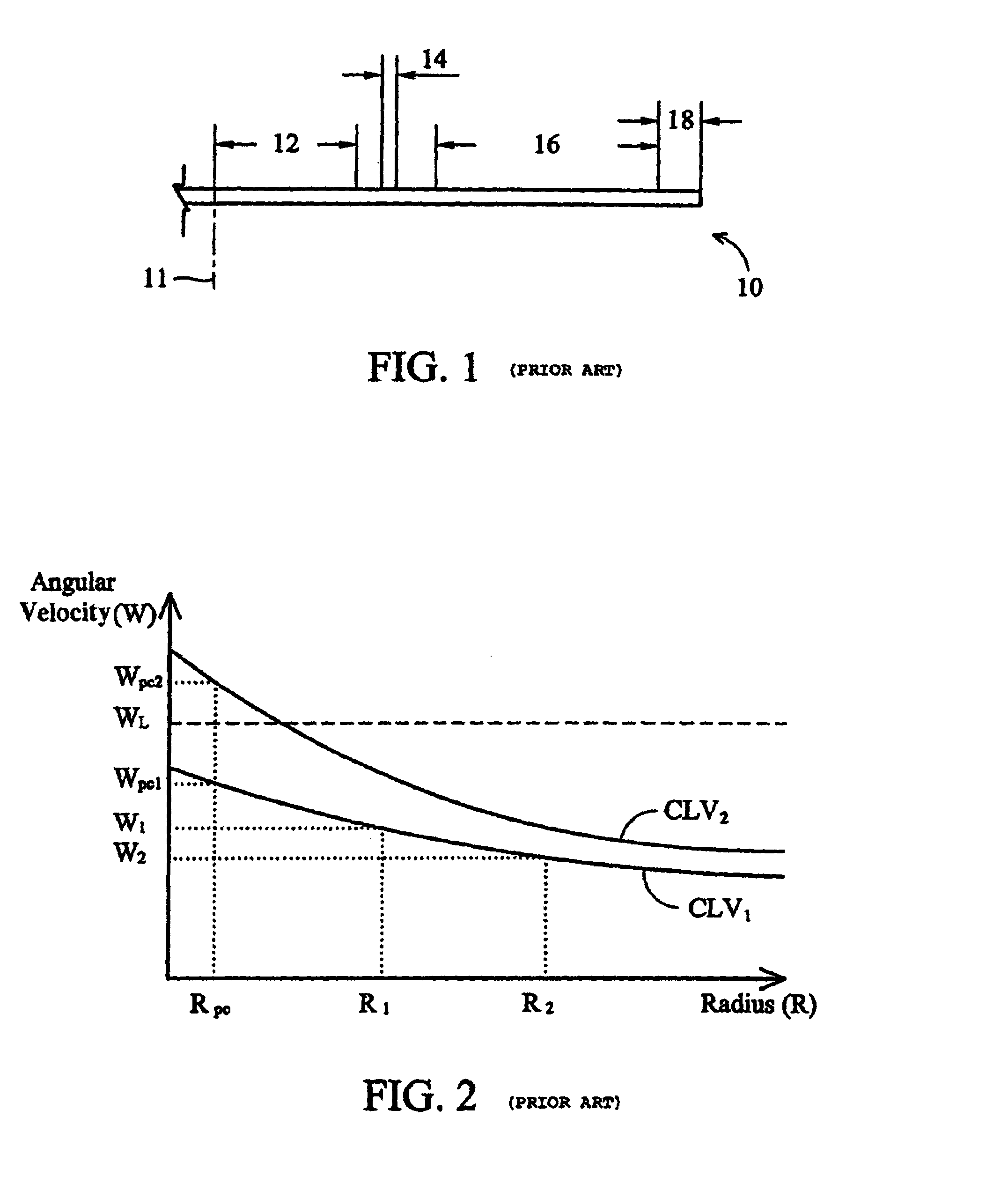

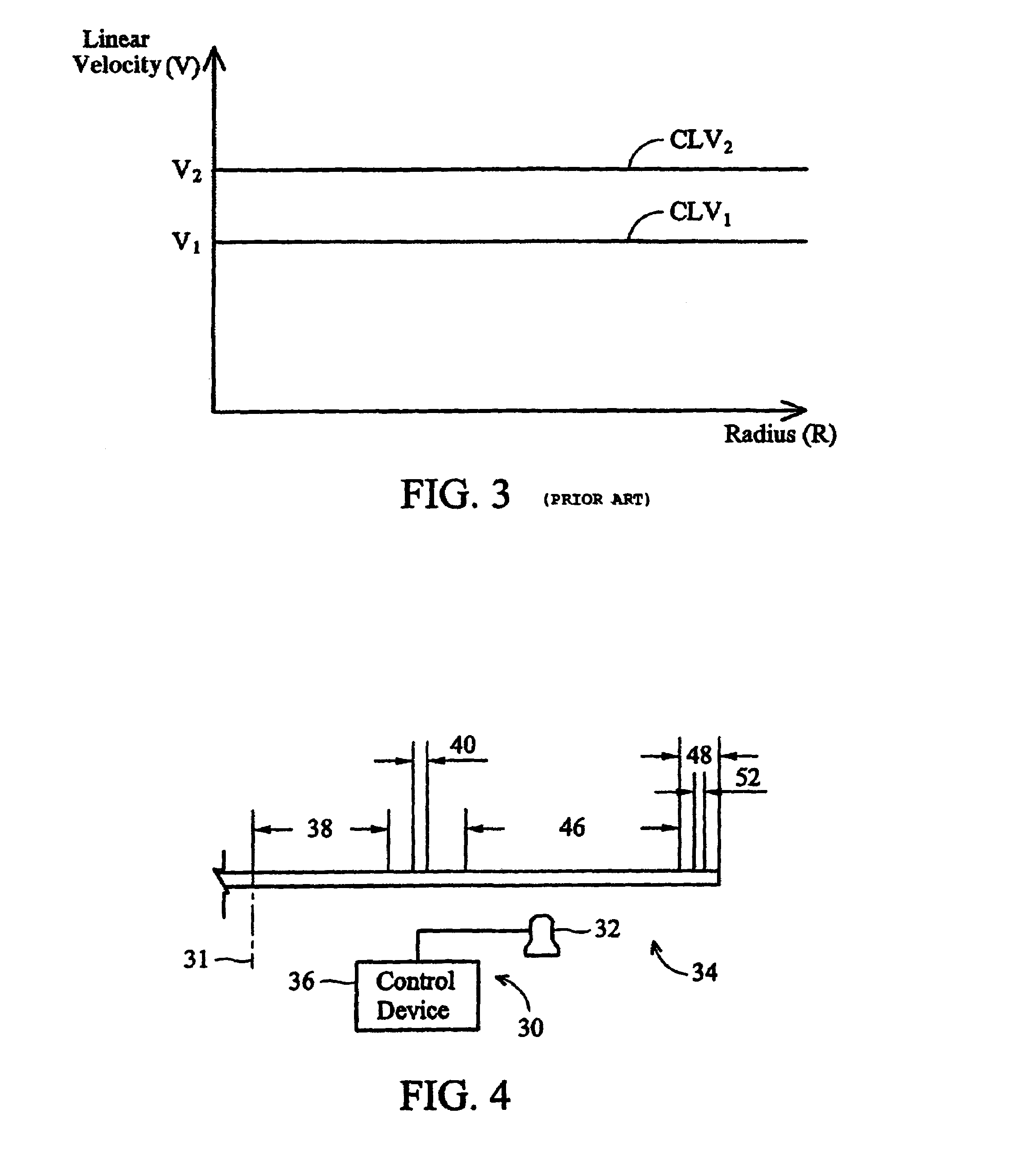

Method for determining an optical write power and an optical disc access system using the same

InactiveUS7002885B2Accurate powerInformation arrangementFilamentary/web record carriersConstant linear velocityOptical power

A method for determining an optical write power and an optical disc access system using the same. In addition to a typical Inner Power Calibration Area, the method includes an Outer (second) Power Calibration Area implementation on the outer area of a Readable / Writable Optical disc with a constant linear velocity (CLV) format; when a data writing speed selected by a user causes a rotation speed required by an optical power calibration on an Inner (first) Power Calibration Area of the disc greater than an Optical Power Calibration (OPC) limit, the optical disc access system uses a lower rotation speed for the optical power calibration on the Outer Power Calibration Area to ensure the accuracy of the power calibration.

Owner:BENQ CORP

Paper winding machine with constant linear speed

InactiveCN104477681AControl speedSimple structureFunction indicatorsWebs handlingMotor speedWinding machine

The invention discloses a paper winding machine with a constant linear speed. The paper winding machine with the constant linear speed comprises a machine frame, a motor, and a winding drum, the bottom of the machine frame is fixedly connected with the motor, the motor is connected with a motor belt pulley through a motor shaft, the motor belt pulley is connected with a winding drum belt pulley through a belt, the winding drum belt pulley is connected with the winding drum through a winding drum shaft, two sides of the machine frame are respectively provided with a guide rail a and a guide rail b, a pressing bar which can be slid along the guide rail a and the guide rail b is installed between the guide rail a and guide rail b, and the bottom of the pressing bar is connected with a roller a and a roller b of the pressing winding drum. The benefic effect of the paper winding machine with the constant linear speed is simple structure, smaller volume, and lower noise generated in the using process, the motor speed is controlled in the working process by the size of the paper roll so as to control the constant linear speed of winding paper, and promote easily.

Owner:保定市富民纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com