Constant-linear-velocity warp pacing device for weaving of crinkled crepe fabric

A technology of constant linear velocity and warp yarn, which is applied in the field of warp yarn constant linear velocity let-off device, which can solve the problems of uneven let-off amount, large unwinding radius, and inability to realize constant linear speed control, etc., and achieve constant let-off amount and easy operation. The effect of simplicity and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

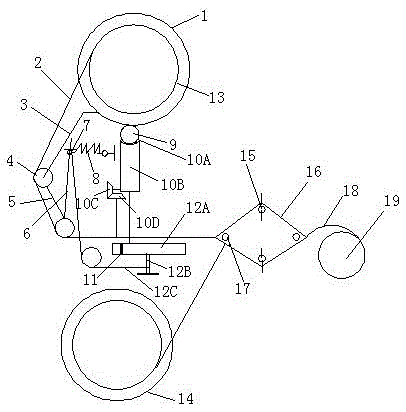

[0016] Such as figure 1 As shown, a warp yarn constant linear velocity warp let-off device for weaving pleated fabrics includes a toothed weaving beam disk 1, bubble warp yarn 2, anti-retraction hook 3, rotary shaft 4, double tension rod 5, tension rod 6, stop Coil 7, spring 8, gear 9, worm 10A, worm wheel 10B, bevel gear 10C, bevel gear 10D, bridge gear 11, winding gear 12A, winding rod 12B, winding rope 12C, weaving shaft 13, ground warp Weaving beam 14, heald frame 15, shed 16, weft yarn 17, fabric 18, take-up roller 19.

[0017] 1. The process of warp yarn sending out of foam beam:

[0018] The bubble warp yarn 2 is drawn out by the unwinding bubble weaving shaft 13, bypasses the double tension bar 5, merges with the ground warp yarn of the ground warp weaving shaft 14, is divided into upper and lower layers by the heald frame 15 to form a shed 16, and is interwoven with the weft yarn 17 to form a fabric After 18, it is drawn out through take-up roller 19.

[0019] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com