Intelligent rewinding machine

A rewinding machine, intelligent technology, applied in thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problem of difficulty in maintaining consistent yarn tension, low tension in the inner layer of the bobbin, and high tension in the outer layer of the bobbin, etc. problems, to achieve the effect of improving the degree of precision control, less mechanical transmission parts, and saving labor costs

Inactive Publication Date: 2011-06-29

平国民

View PDF6 Cites 34 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The previous procedures such as rewinding, winding, and warping of the textile industry all require that the length of the winding yarn is consistent and the winding tension is consistent, but suffer from the lack of relevant control and adjustment devices. In the textile production process, For many years, manual adjustment has been used to solve the problem of yarn tension. The tension can only be controlled within a large fluctuation range. The purpose of dynamic auto-tracking and auto-adjusting

It not only affects the product quality, but also increases the technical requirements for operators

Most of the rewinding machines in the prior art use a large motor to frictionally drive multiple winding bobbins, and set a break-away transmission device for a single bobbin. This design makes all the winding bobbins always have only one speed, which will inevitably cause bobbins inside. The layer tension is small, and the tension of the outer layer of the bobbin is large, especially when the ultra-fine wire is rewound, when it is wound to the outer layer, the ultra-fine wire cannot withstand the pulling of high line speed and high tension, and breakage will occur one after another; even if It is thick silk rewinding, because the tension fluctuation range is large and there are many knots, it will also restrict the improvement of weaving quality, and it is impossible to weave high-grade fabrics

During the rewinding process, if individual bobbins are disconnected or the bobbins are replaced, even if only a few bobbins are still being processed in the whole rewinding machine, the large motor must keep rotating, wasting energy

When the bobbin is broken and spliced several times, it is impossible to calculate the wound length. Even if the bobbin is wound and blanked at the same time, the yarn winding length is also different due to the uncertain slip that often occurs between friction drives. Larger, resulting in the winding length of each bobbin cannot be kept consistent, and the excess yarn has to be cut off during weaving, resulting in a great waste, so that in places where textile enterprises are concentrated, a "waste silk market" will emerge as the times require

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

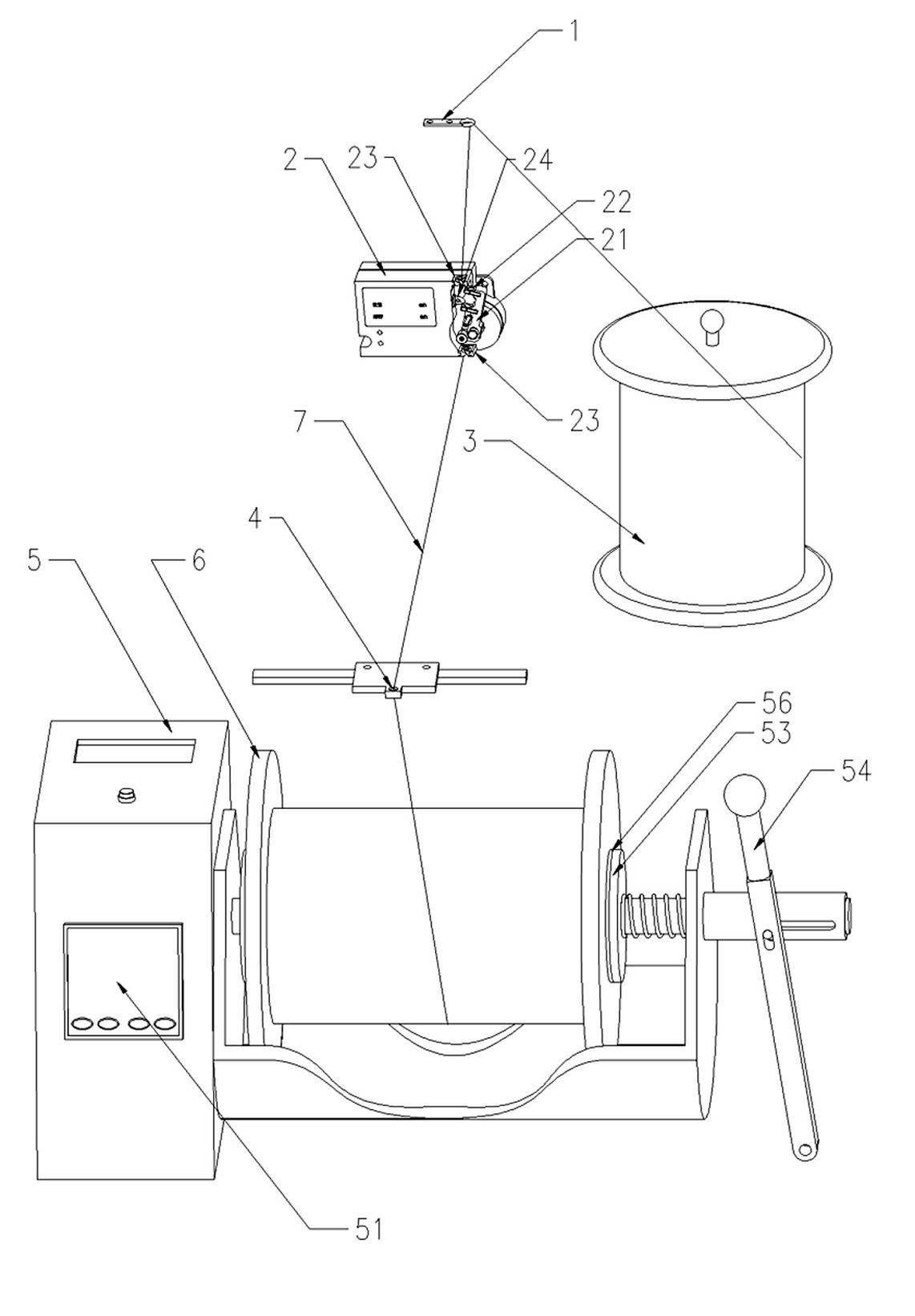

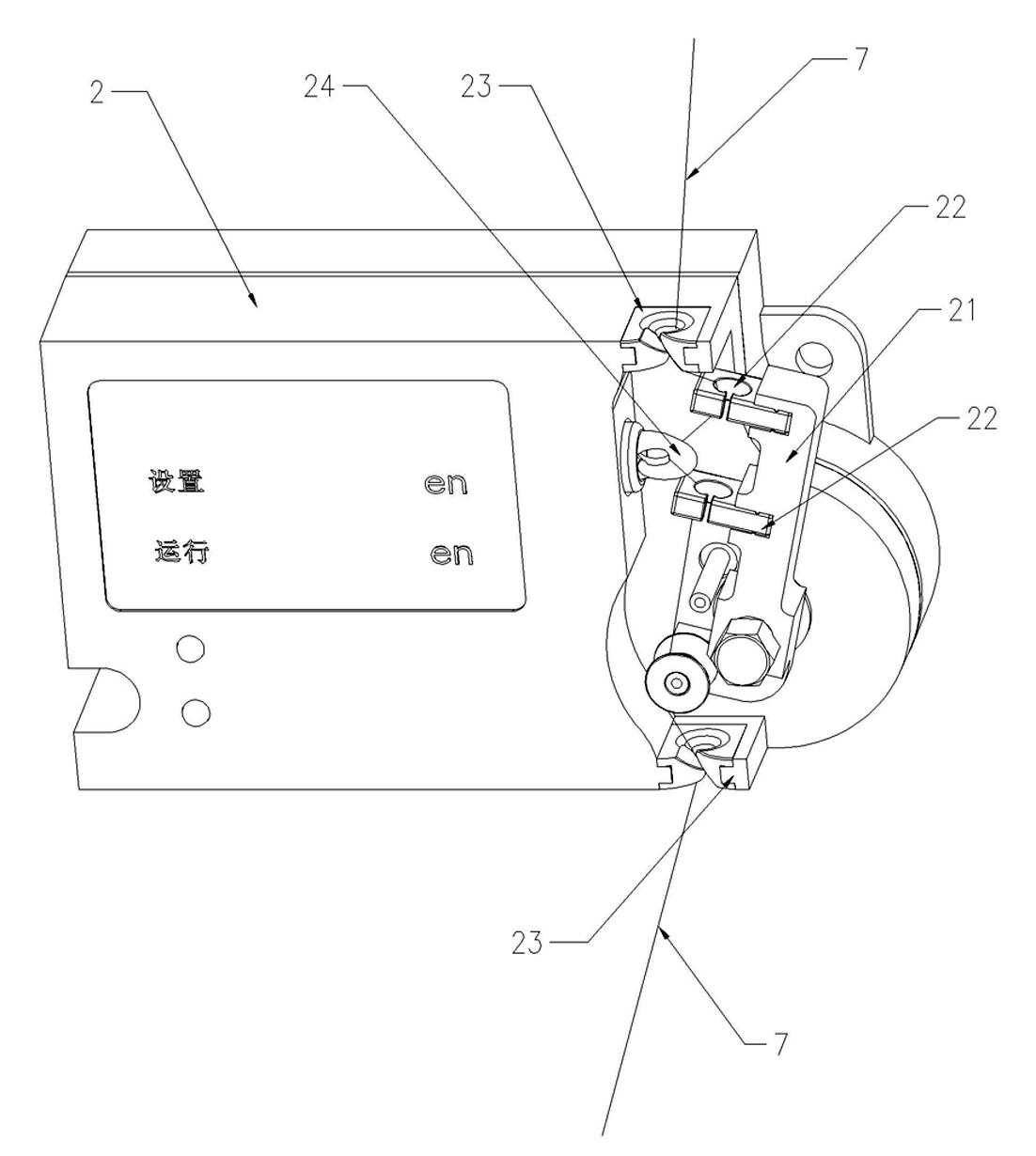

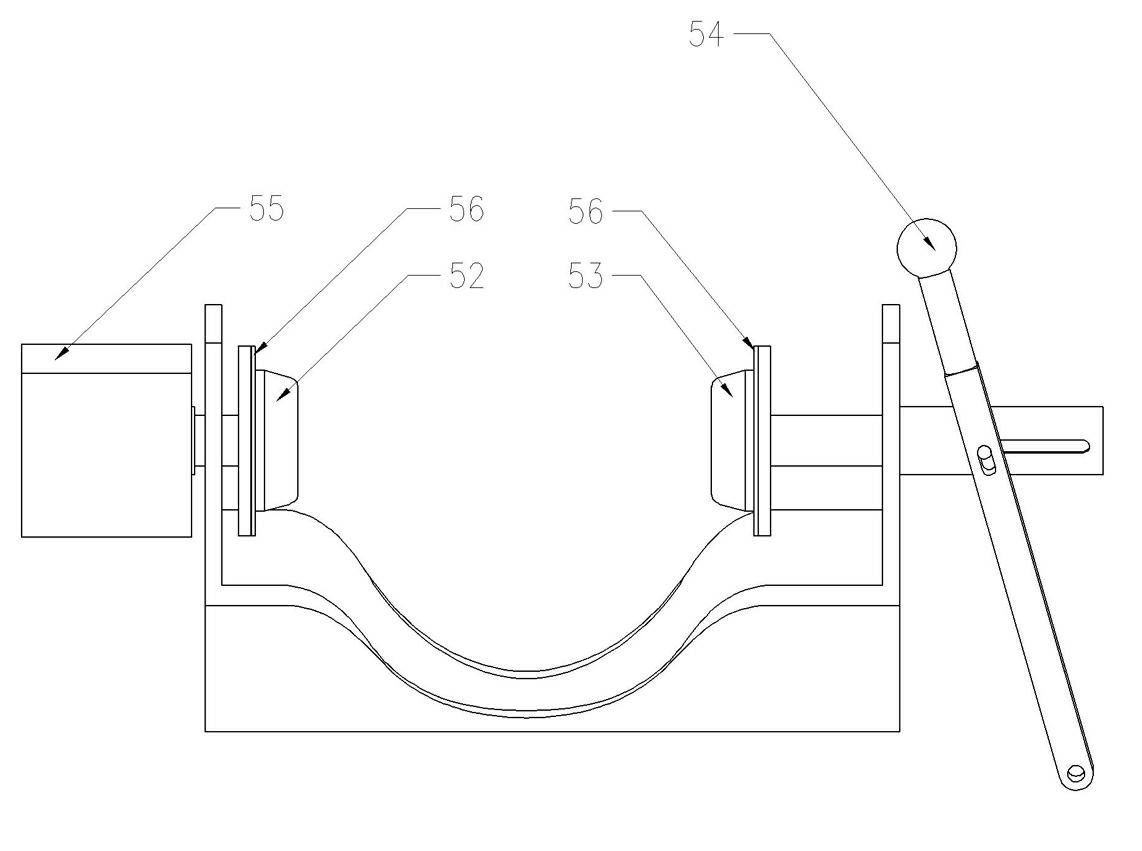

Login to View More Abstract

The invention discloses an intelligent rewinding machine with constant linear velocity, constant tension and fixed wire length, comprising a linear velocity sensor, a tension automatic controller and a single spindle transmission control device, wherein a transmission cone table is directly fixed on an output shaft of a motor; a movable cone table is movably connected with a handle via a pin; the linear velocity sensor has the functions of detecting broken lines, linear velocity and length counting. When a tension detecting hook on the tension automatic controller detects that the tension of yarns is oversize, a swinging arm is controlled to rotate an angle so as to reduce the yarn bending degree of the flowing yarns and reduce the winding tension of the yarns, and vice versa. A computer controller on the single spindle transmission control device receives signals sent by the linear velocity sensor and controls the rotation speed and the broken lines of the motor to warn. As the gradual increasing winding diameter of the tube, the rotation speed of the tube is controlled to gradually slow, so that the winding linear velocity is constant; when the length of the yarns reaches the set value or the broken line signal is received, the power supply of the motor is cut off and the warning light twinkles.

Description

Intelligent rewinding machine technical field The invention relates to textile machinery, in particular to an intelligent rewinding machine. Background technique The previous procedures such as rewinding, winding, and warping of the textile industry all require that the length of the winding yarn is consistent and the winding tension is consistent, but suffer from the lack of relevant control and adjustment devices. In the textile production process, For many years, manual adjustment has been used to solve the problem of yarn tension. The tension can only be controlled within a large fluctuation range. Dynamic auto-tracking and auto-adjusting purposes. It not only affects the product quality, but also increases the technical requirements for operators. Most of the rewinding machines in the prior art use a large motor to frictionally drive multiple winding bobbins, and set a break-away transmission device for a single bobbin. This design makes all the winding bobbins alw...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65H59/10B65H63/08B65H63/028B65H54/74

Inventor 平国民

Owner 平国民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com