Constant linear velocity gantry vertical-spindle grinding machine with round table

A speed gantry vertical and gantry technology, used in grinding machines, grinding machine parts, grinding drive devices, etc., can solve the problems of limited processing scale, unsatisfactory stability, and inability to achieve ideal surface processing quality. Stability and the effect of expanding the grinding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

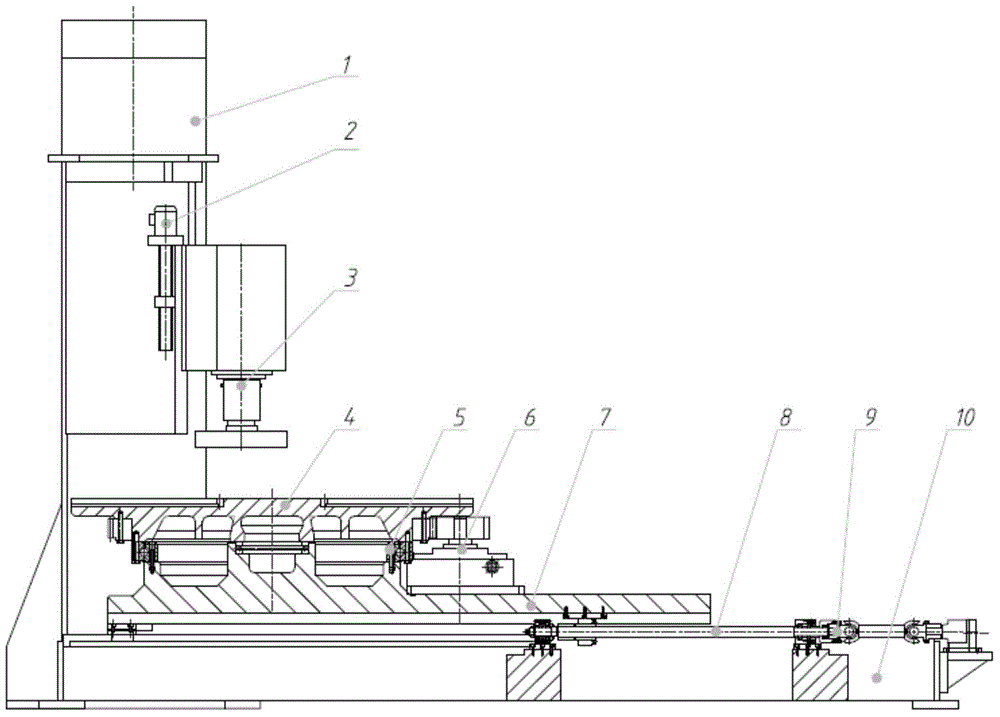

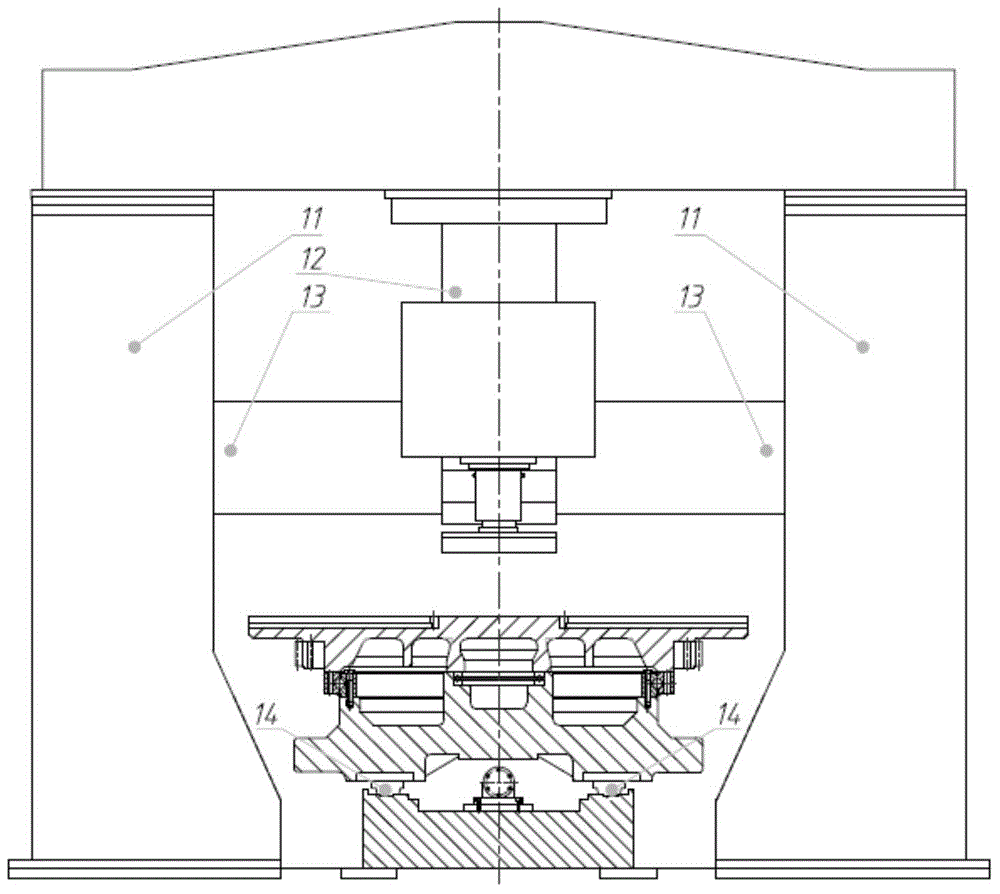

[0016] Such as figure 1 As shown, a constant linear velocity gantry vertical axis round table grinding machine according to the present invention includes: gantry beam 1, Z-axis servo feed system 2, grinding head 3, rotary table 4, rotary support 5, rotary table servo power system 6 , slide rail table 7, ball screw 8, X-axis servo feed power system 9, base 10, gantry column 11, vertical slide rail 12, rib 13, linear guide rail 14, of which:

[0017] The gantry beam 1 is connected with the gantry column 2; the grinding head 3 and the gantry beam are connected together through a vertical slide rail 12, and a Z-axis servo feed system 2 is installed between the vertical slide rail and the grinding head; the vertical slide Reinforcing ribs 13 are installed between the rail and the two-sided gantry columns; the rotary table 4 and the slide rail table 7 are assembled together through the rotary support 5, and the rotary table servo power system 6 is installed between the rotary table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com