Move mode shot peening specimen testing method

A technology of shot peening and test method, which can be used in measuring devices, instruments, scientific instruments, etc., and can solve the problems of simulation error, uneven stress change, long processing time, etc.

Inactive Publication Date: 2015-03-25

SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The technical indicators of the parts after shot peening are not easy to be directly measured by the instrument without destroying the body. Usually, the shot peening parameters need to be determined through the test piece test. The existing shot peening test method is relatively simple and rough. For some specific parts There is a certain error in the simulation, which cannot accurately reflect the real shot peening effect. From the perspective of the gun movement mode, the feed per minute mode is mostly used at present, but in actual processing, it will be affected by the moving speed of the nozzle and the parts. The mismatch of the rotation speed causes the shot peening traces to rise in a spiral shape. It is necessary to spray the parts multiple times to obtain a more uniform shot peening surface.

This method not only requires a longer processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

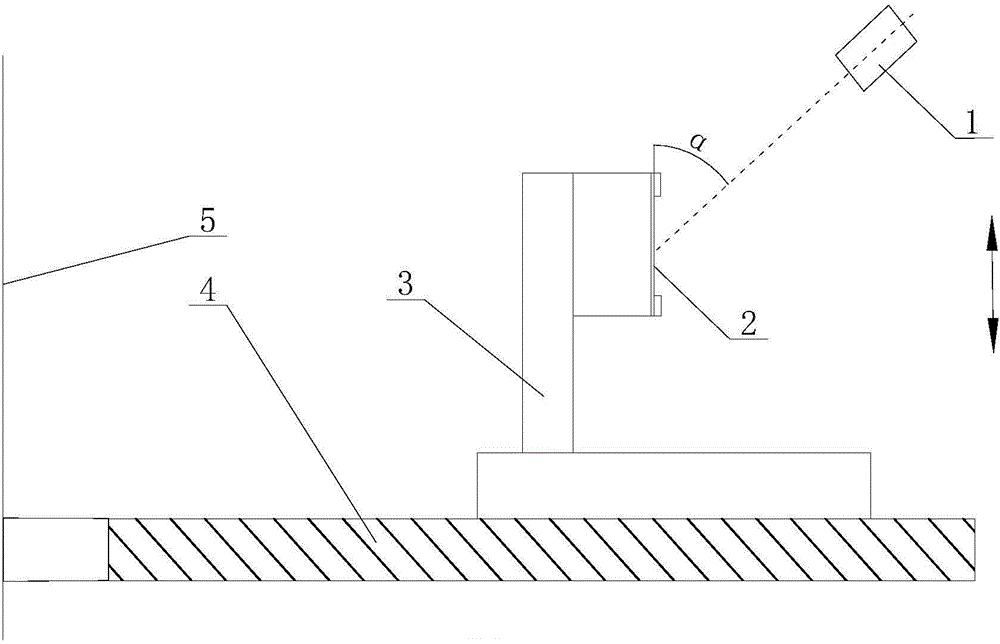

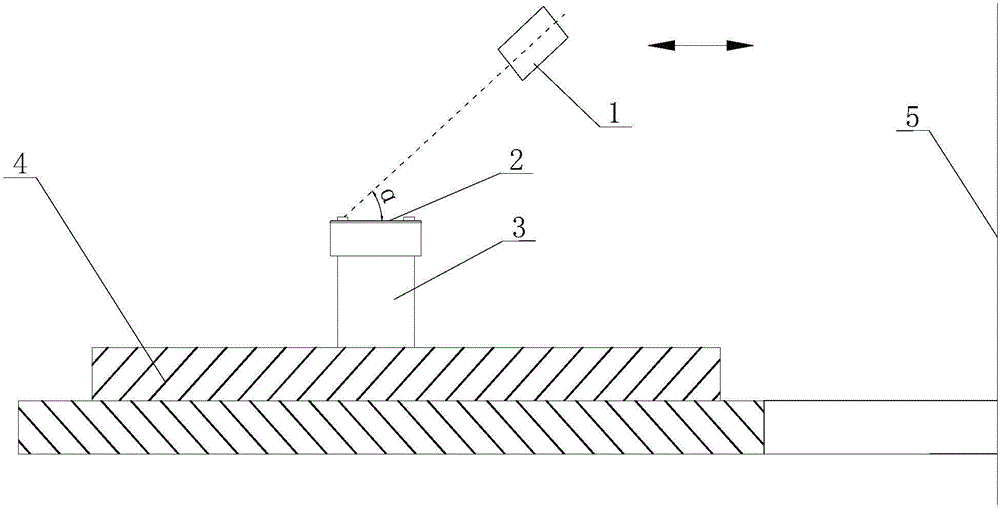

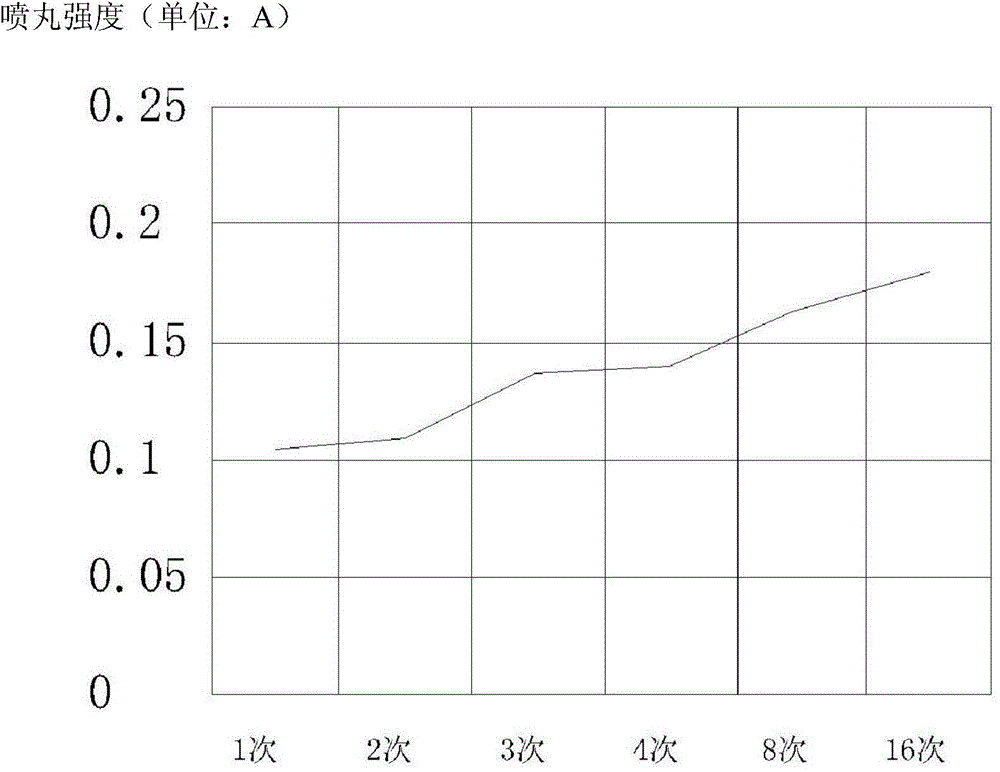

The invention discloses a move mode shot peening specimen testing method, belongs to the technical field of shot peening processing. According to the method, principles of the feeding mode for each turn, constant linear velocity and the like are introduced, so that a stable shot intensity value linear progressively increasing curve can be obtained; very important significance is provided for determining the shot parameters by technology personnel; the parameter selection success ratio is improved; also because the same linear velocity is used in the part blasting process, the quality of shots is improved greatly. The method comprises the following steps: step one, determining the motion track of a spray gun to be axial motion or radial motion according to the structure of a part, executing the step two if the motion trail is axial motion, and executing the step three if the motion track is radial motion; step two, carrying out the shot peening specimen testing method if the motion track of the spray gun is axial motion; and step three, carrying out the shot peening specimen testing method if the motion track of the spray gun is radial motion.

Description

technical field [0001] The invention belongs to the technical field of shot peening processing, and in particular relates to a test method for a moving mode shot peening test piece. Background technique [0002] The technical indicators of the parts after shot peening are not easy to be directly measured by the instrument without destroying the body. Usually, the shot peening parameters need to be determined through the test piece test. The existing shot peening test method is relatively simple and rough. For some specific parts There is a certain error in the simulation, which cannot accurately reflect the real shot peening effect. From the perspective of the gun movement mode, the feed per minute mode is mostly used at present, but in actual processing, it will be affected by the moving speed of the nozzle and the parts. The mismatch of the rotation speed causes the shot peening traces to rise in a spiral shape. It is necessary to spray the parts multiple times to obtain a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/00G05B19/19

Inventor 孟震威时旭李萌萌杨清刘中华

Owner SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com