Speed-variable supersonic flame spraying spherical device

A supersonic flame and variable technology, applied in the direction of spraying device, device for coating liquid on the surface, spraying device with movable outlet, etc., can solve the problem of uneven spraying on the spherical surface, and achieve the effect of avoiding the spraying device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

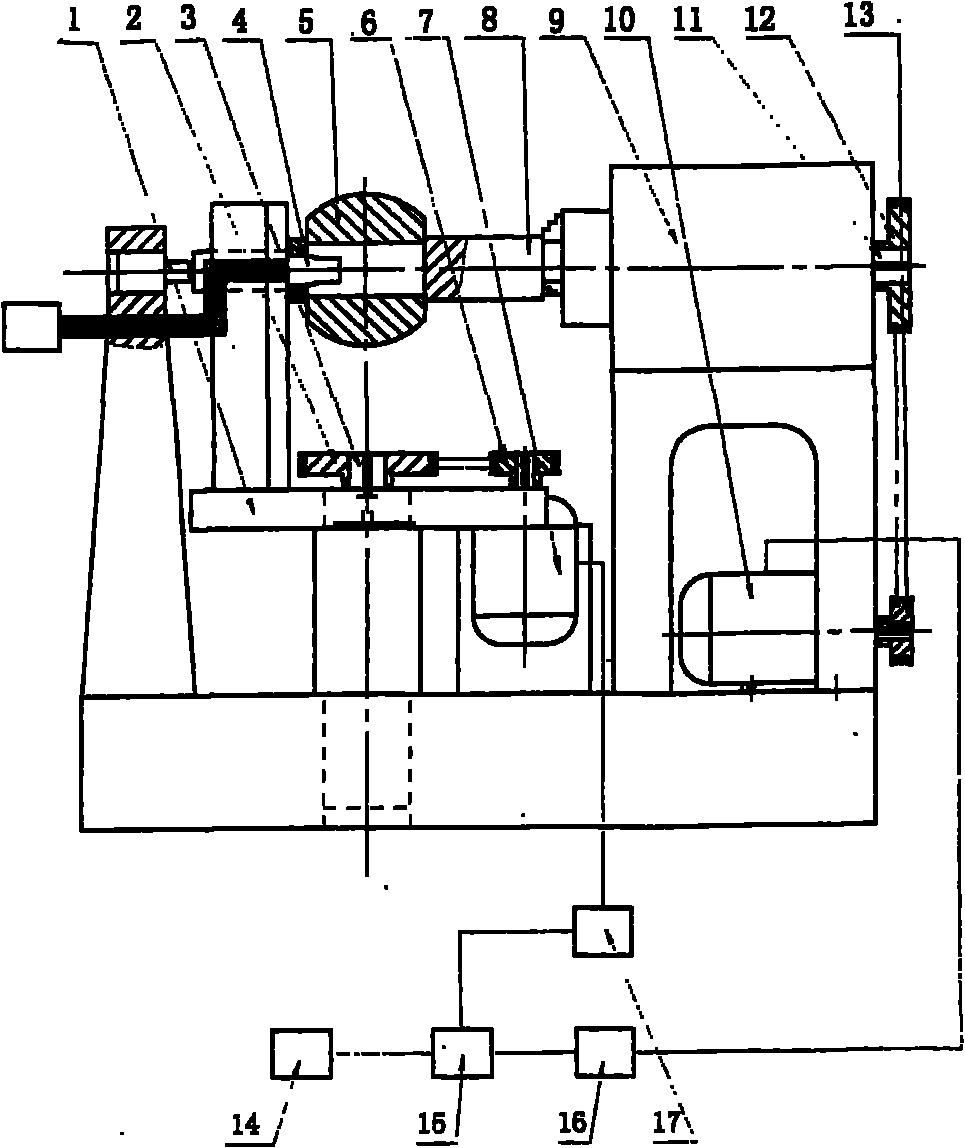

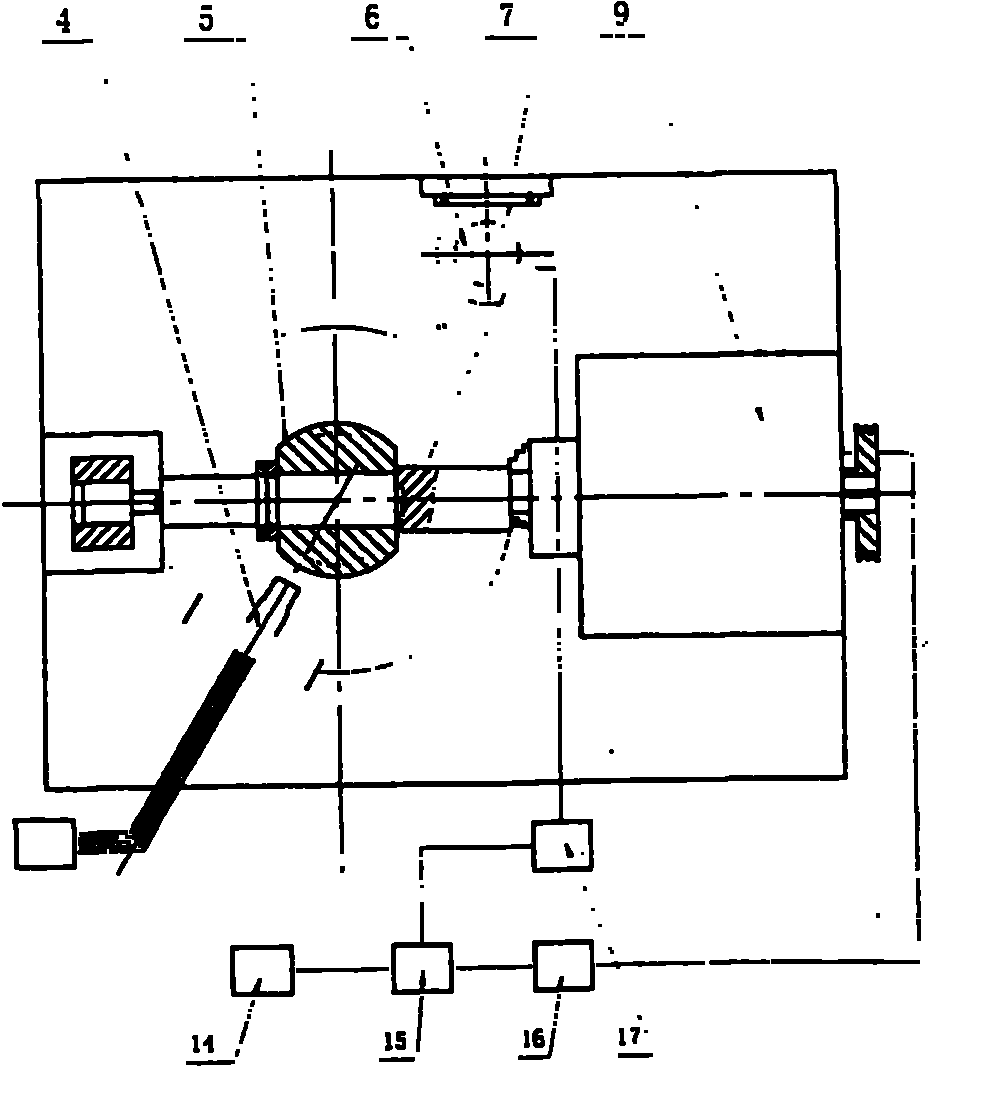

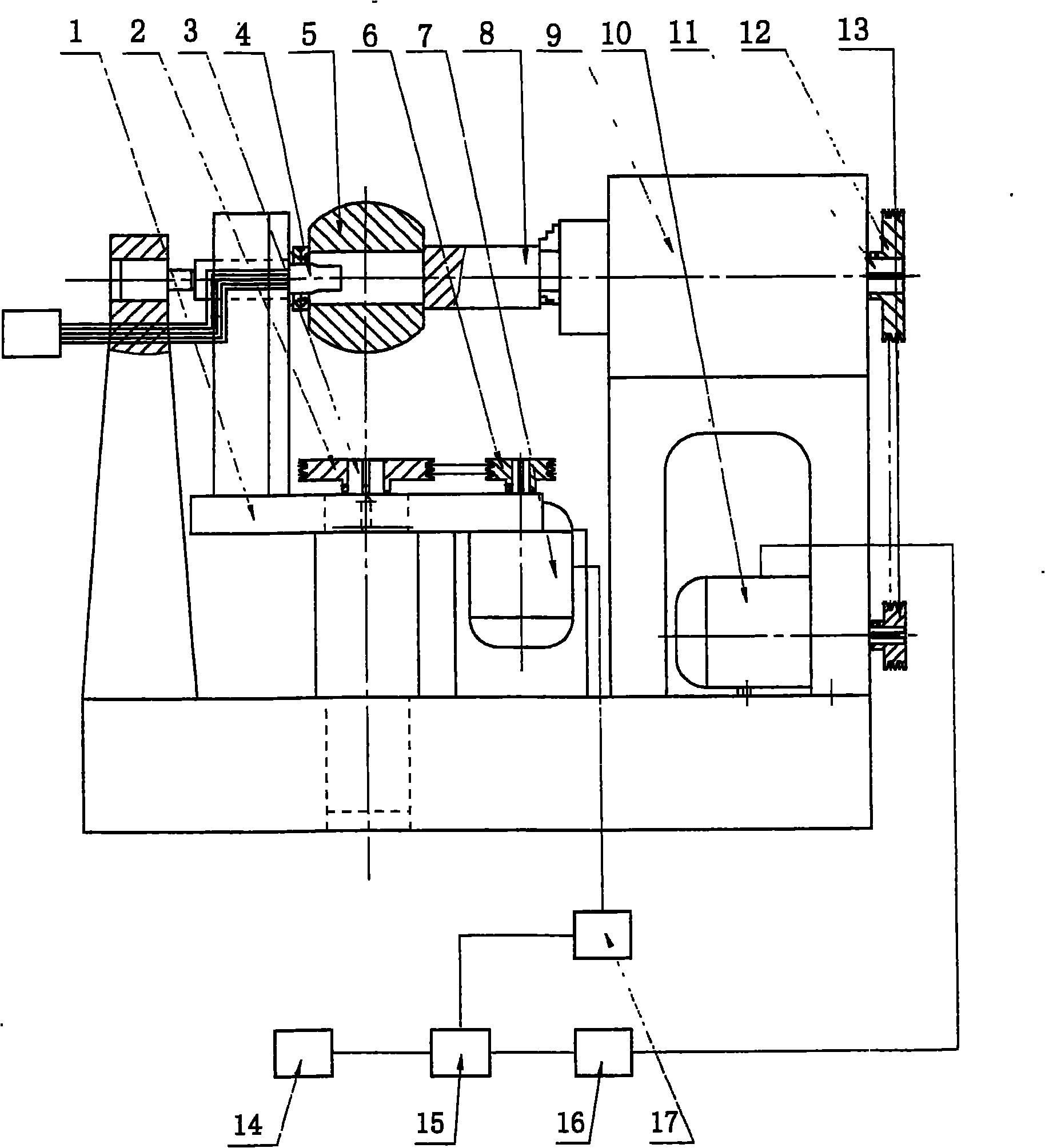

[0010] As shown in the figure, the nozzle 4 is fixed on the turntable 1, the turntable 1, the auxiliary pulley 2, and the shaft 3 are connected, the auxiliary motor pulley 6 is connected with the auxiliary motor 7, the main shaft 11 passes through the head box 9, and the ball table 5. Fixture 8, main shaft 11, main pulley 12 are connected, main motor pulley 13 is connected with main motor 10, touch screen 14, PLC 15 are connected with main inverter 16, main motor 10, auxiliary inverter 17, and auxiliary motor 7 The wires are electrically connected. PLC 15 has a program that produces a continuously changing angular velocity but maintains a constant linear velocity according to the change of the radius of rotation of each point on the spherical surface. There is also a program for constant speed of the nozzle, and the angular velocity of the spherical surface has a functional relationship with the rotation angle of the nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com