Paper winding machine with constant linear speed

A paper reel and line speed technology, which is applied in the field of constant line speed reel, can solve the problems of unstable performance, large volume, paper rupture, etc., and achieve the effect of simple structure, small volume and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

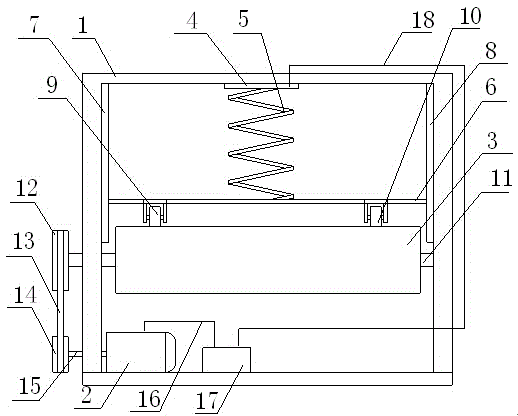

[0015] Such as figure 1 The shown constant linear speed winding machine includes a frame 1, a motor 2, and a reel 3, the bottom of the frame 1 is fixedly connected to the motor 2, the motor 2 is connected to the motor pulley 14 through the motor shaft 15, and the motor pulley 14 passes through the belt 13 is connected to the reel pulley 12, and the reel pulley 12 is connected to the reel 3 through the reel shaft 11. The two sides of the frame 1 are respectively provided with a guide rail a7 and a guide rail b8. b8 Sliding bezel 6, the bottom of bead 6 is connected to roller a9 and roller b10 of compression reel 3, the top of bead 6 is connected to spring 5, the top of spring 5 is connected to sensor 4, sensor 4 is fixedly connected to the top of frame 1, and sensor 4 passes through the signal line 18 is connected to the controller 17, the controller 17 is connected to the motor 2 through the control line 16, the sensor 4 is a high-sensitivity pressure sensor, the roller a9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com