Multi-grinding-unit multi-working-procedure parallel constant linear velocity grinding method and grinding device

A constant linear speed, multi-process technology, applied in the field of glass deep processing methods and automation equipment, can solve the problems of inability to realize multi-process parallel grinding, unable to ensure consistent linear speed of grinding points, etc., and achieve low processing efficiency, grinding Consistent quality and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

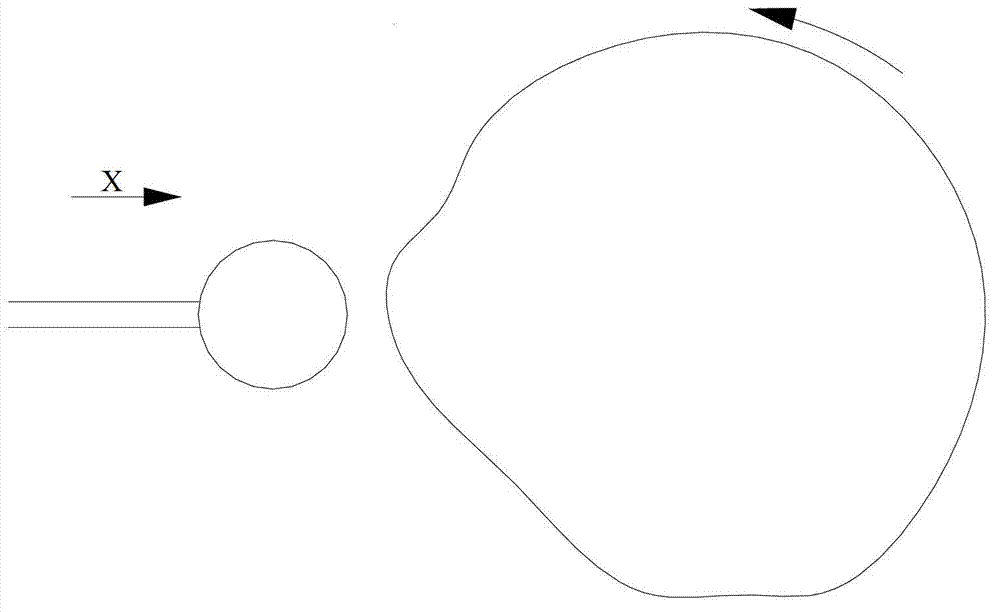

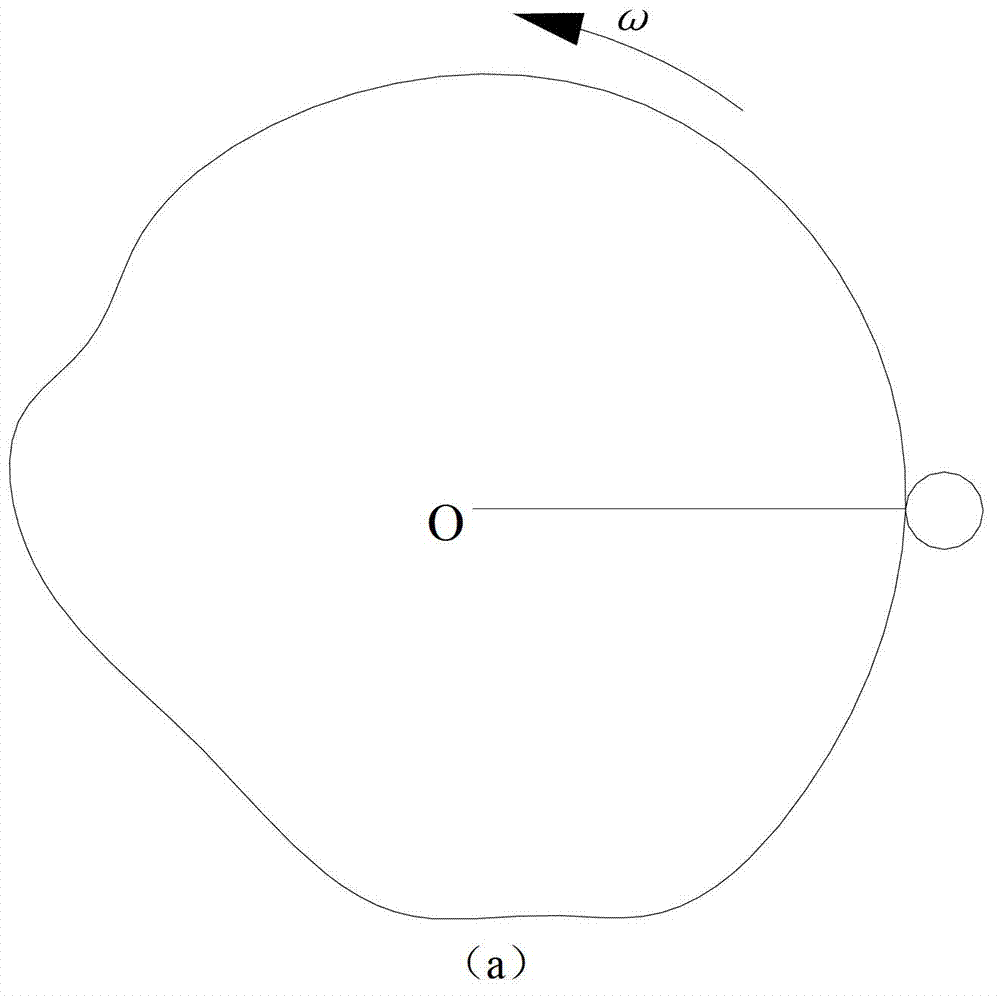

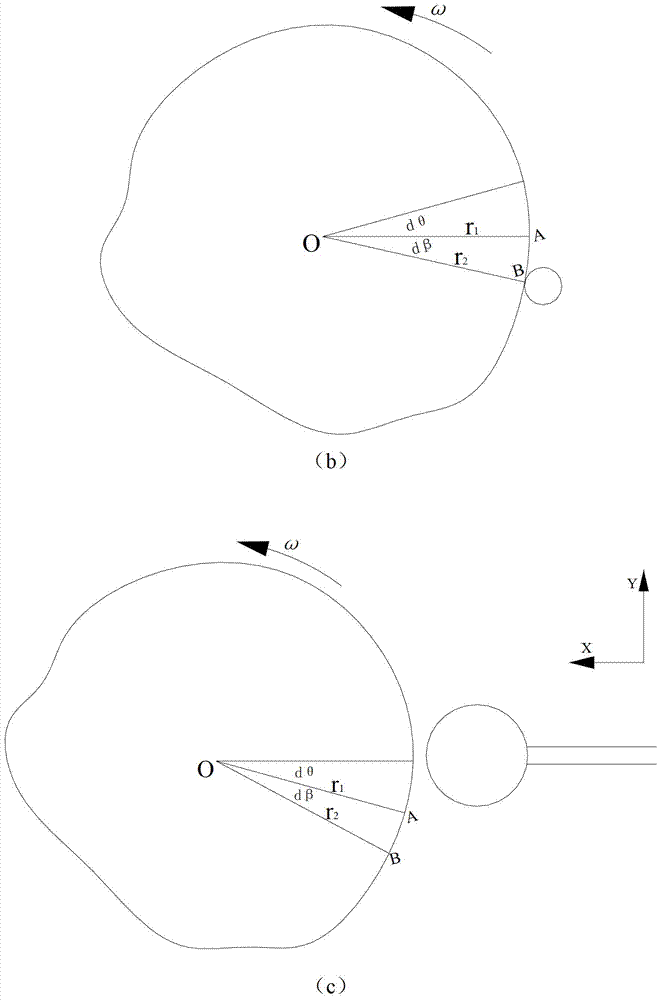

[0040] Such as figure 1 As shown in Fig. 1, it is a method to achieve constant linear speed grinding in the conventional rotating workpiece grinding method, which is mainly realized by controlling the rotation speed of the workpiece and the axial (X direction) feed speed of the tool in the grinding unit. Due to this constant linear speed grinding control method, it is necessary to change the position of the workpiece curve according to the position of the workpiece curve, that is, the workpiece radius of the workpiece curve r(θ) is different at different positions. In order to obtain a constant linear speed, it is necessary to change it according to the change of the radius The rotational speed of the workpiece. Therefore, to achieve constant linear velocity grinding, it is only suitable for grinding workpieces with a single grinding unit. If the number of grinding units exceeds one, that is, two or more, it is impossible to achieve the same grinding line speed for all grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com