Polishing device for side surface of mobile phone glass

A technology of polishing device and glass, applied in the direction of grinding drive device, grinding/polishing equipment, grinding machine parts, etc., can solve the problem of small contact area between fixture and glass, prevent back-and-forth movement, save power, volume, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

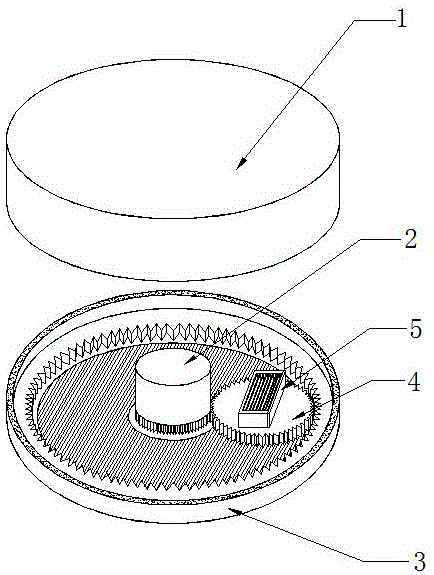

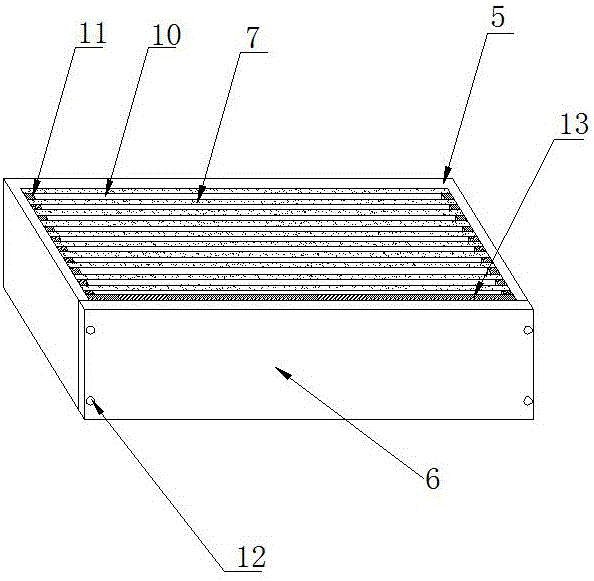

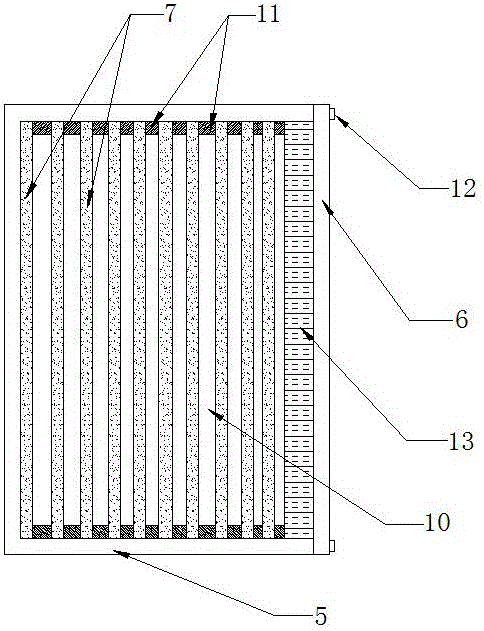

[0021] as attached Figure 1-4 As shown, a mobile phone glass side polishing device includes a grinding head 1, a rotating shaft 2, a rotating disk 3, a planetary gear 4, and a loading box 5. The rotating shaft 2 is installed at the center of the rotating disk 3, and the rotating disk The inner edge of 3 and the outer side of the rotating shaft 2 are provided with a sawtooth structure meshing with the planetary gear 4, and the grinding head 1 that can move up and down freely is provided above the turntable 3, and the planetary gear 4 is provided with a loading material Box 5, the described material carrying box 5 is a cuboid structure with an open top, the three sides and the bottom surface of the described material carrying box 5 are fixed connection structures, and the other side is a movable fastening panel 6, the described The bottom of the loading box 5 is provided with evenly spaced tooth sockets 8, and the top of the tooth sockets 8 is provided with a rubber pad 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com