Special fixture for radial porous parts

A technology for special fixtures and parts, which is applied in the field of special fixtures for radially porous parts, which can solve problems such as low efficiency, unstable part size tolerances, and low efficacy, so as to avoid the time spent on clamping and multiple times of pulling large holes. The effect of stable product quality and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

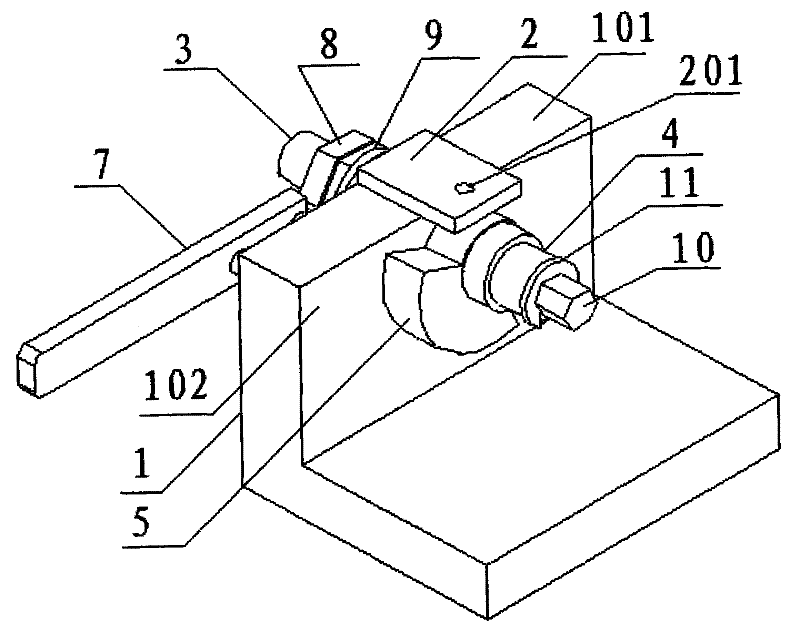

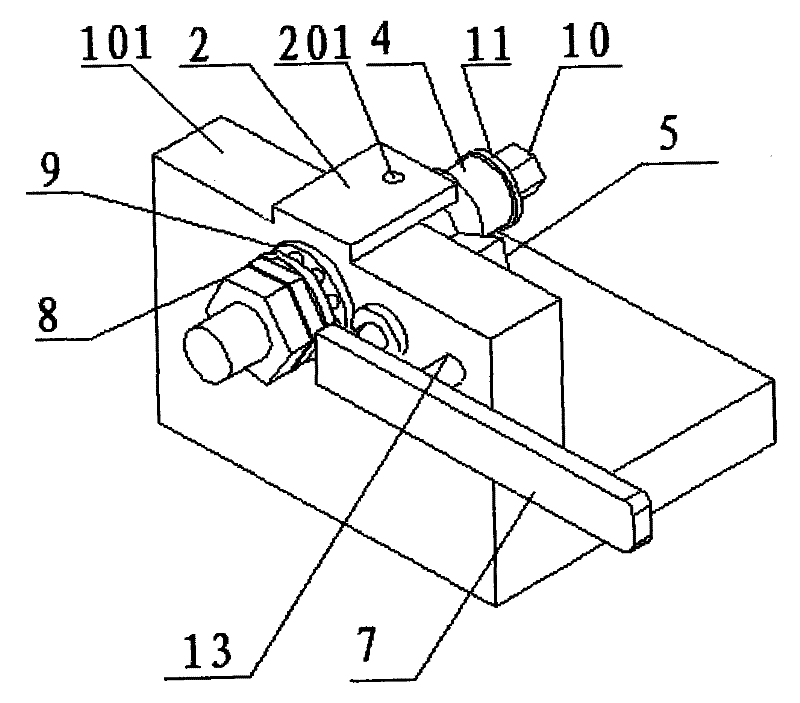

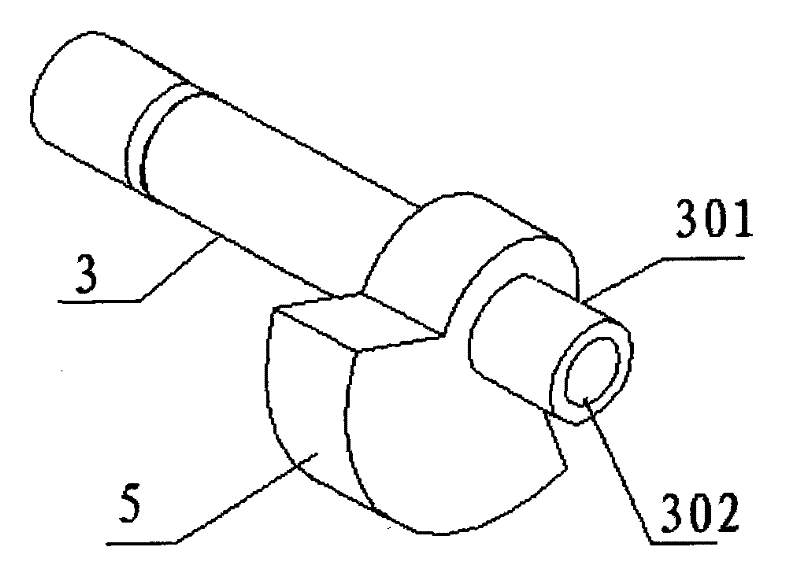

[0024] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a special fixture for radially porous parts includes a base 1, the base 1 includes a first plane 101 and a second plane 102 perpendicular to each other, and the first plane 101 is installed with Drilling template 2, the drilling template 2 is provided with a hole position 201, and the second plane 102 is provided with a screw hole and a tie rod hole; a screw 3 is rotatably arranged in the screw hole, and the screw 3 One end below the drilling template 2 is a positioning shaft 301 for installing the part 4 to be processed, and a positioning block 5 is also fixed on the screw 3, and the positioning block 5 is arranged on the positioning shaft 301 and the base 1 Between, a plurality of positioning pits 501 are arranged on the panel of the positioning block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com