A kind of branch beveling equipment for drawing manifold

A collection tube and equipment technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of few manufacturers and difficult research and development, and achieve the effect of reducing life cycle cost, increasing value, and shortening research and development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

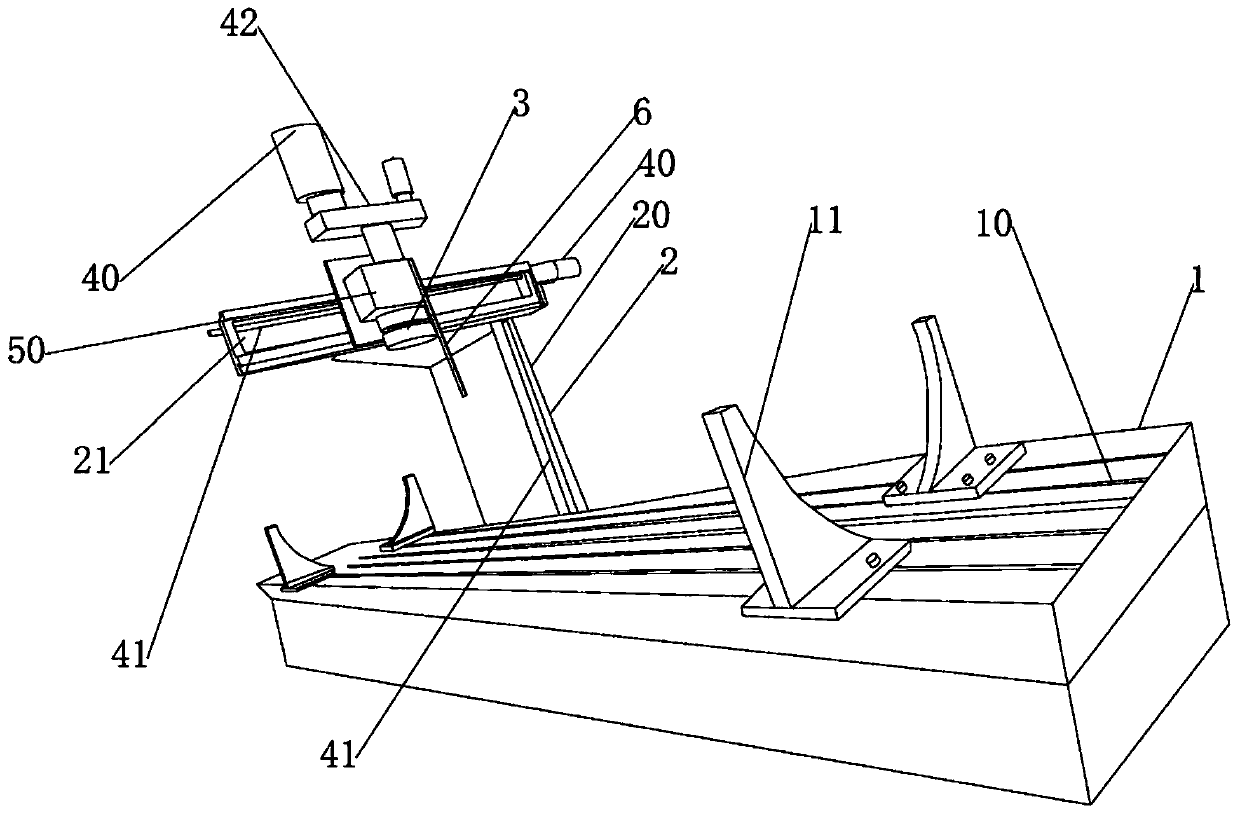

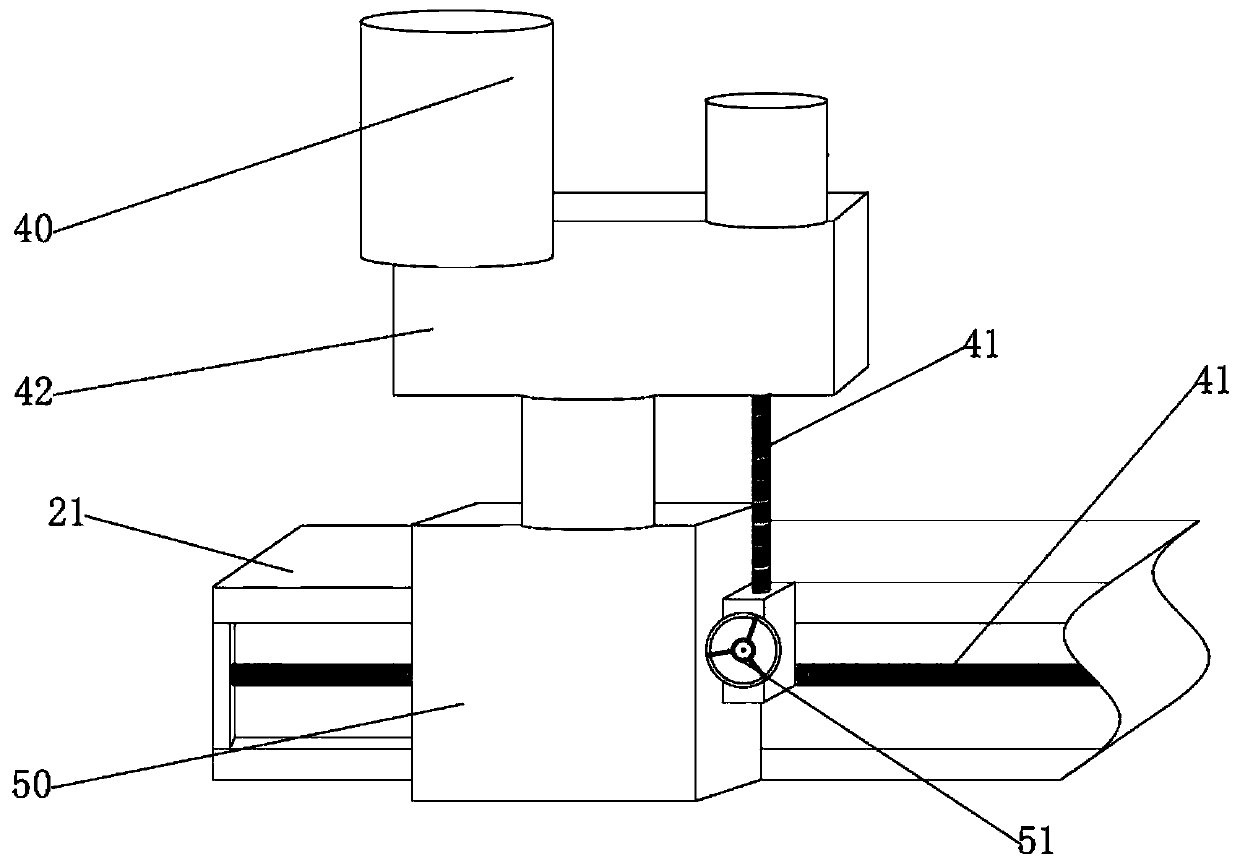

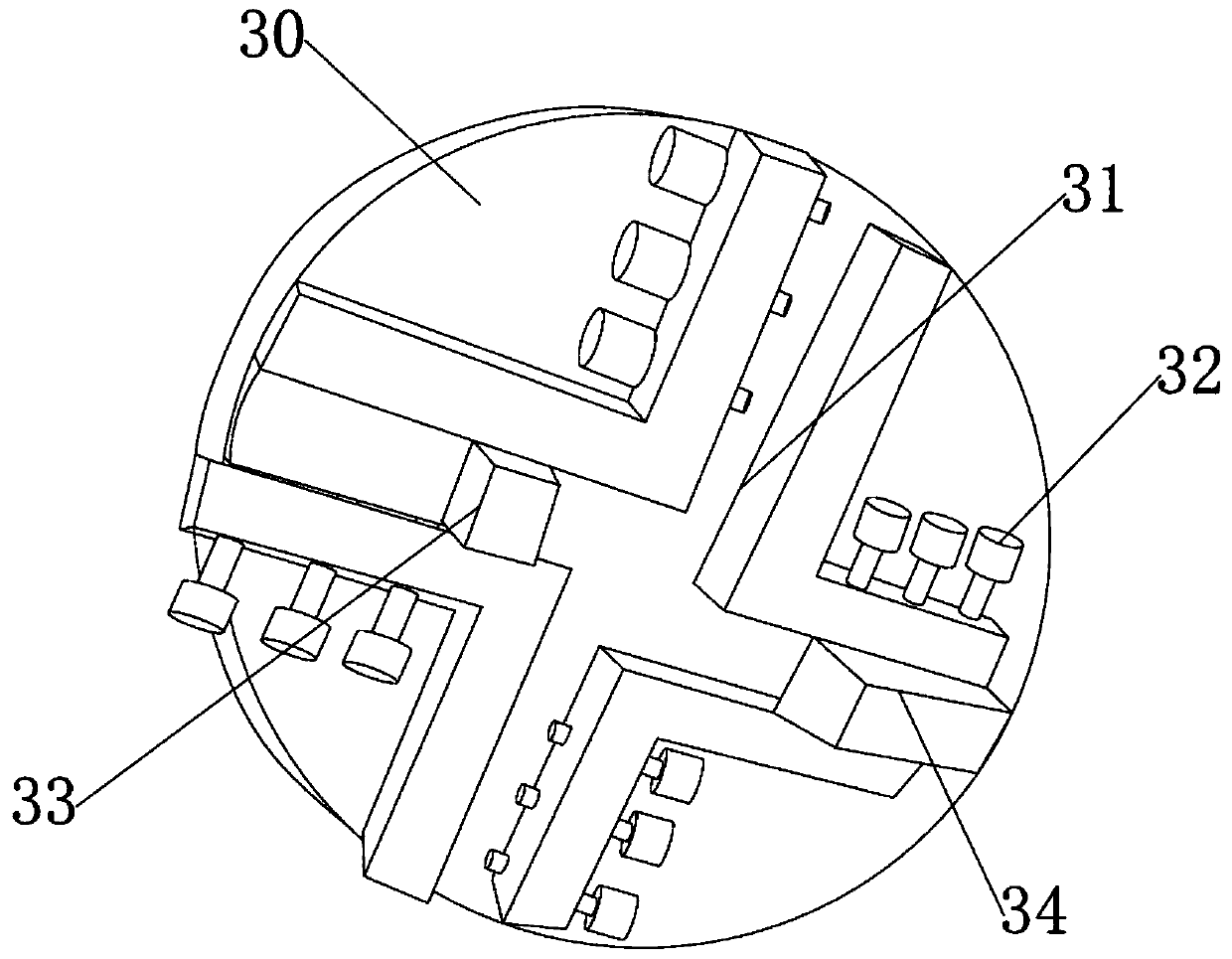

[0020] As shown in the accompanying drawings, a branch beveling equipment for pulling manifold manifolds includes a workbench 1, a column 2, a power unit, a fine-tuning device, and a cutter head 3. The equipment is transformed from a discarded bull planer. There are several parallel installation rails 10, the moving stroke of the installation rails 10 is greater than or equal to 5.5m, a set of support bases 11 are installed at both ends of the workbench 1, and the inner sides of the support bases 11 are provided to match the curvature of the side of the manifold. The arc surface, the column 2 is fixed on one side of the workbench 1, the column 2 includes a backer 20 and a walking beam 21, the side of the backing 20 is provided with a track, the walki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com