Patents

Literature

34results about How to "Eliminate impact on product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

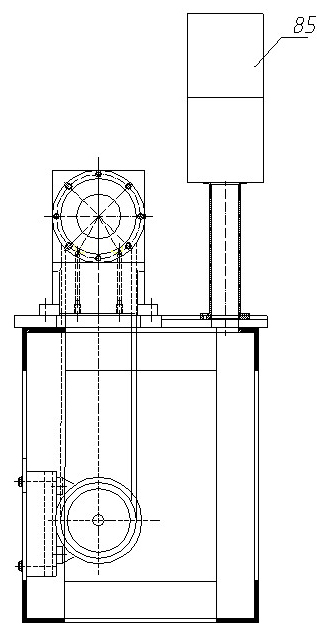

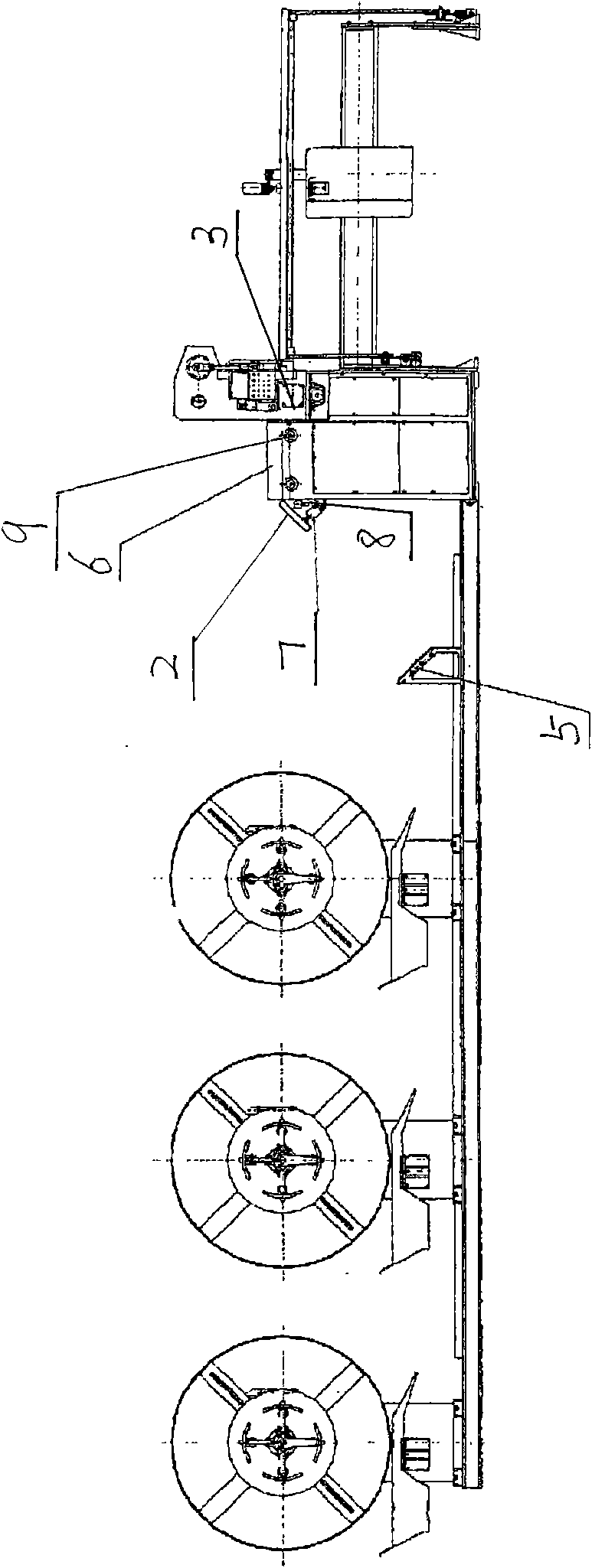

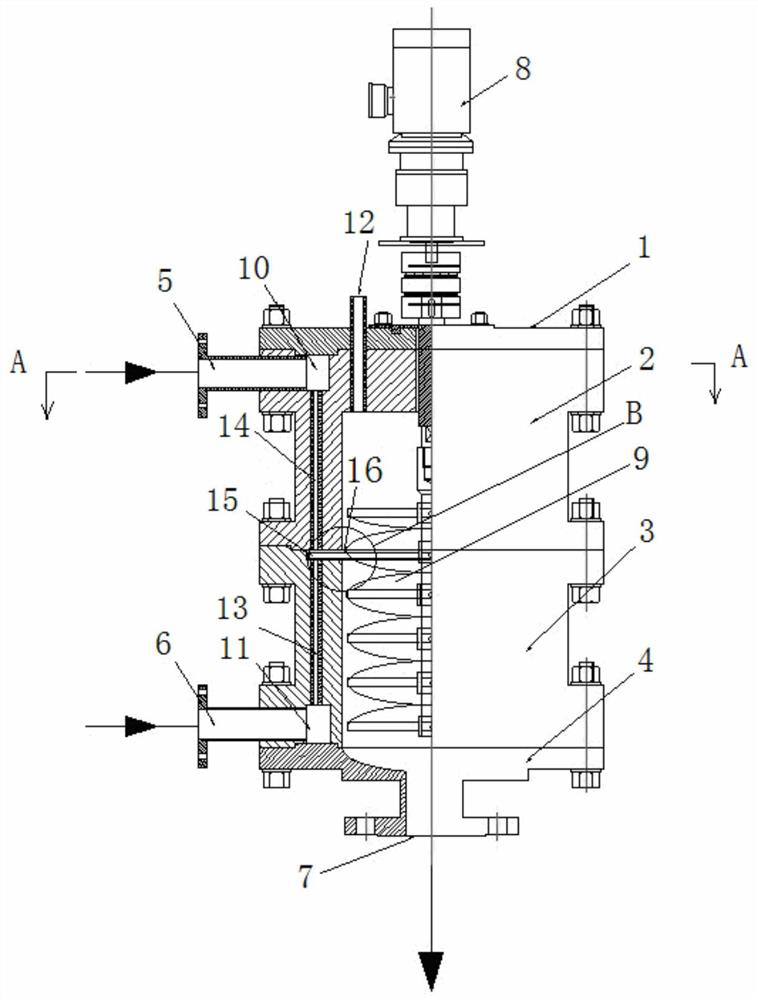

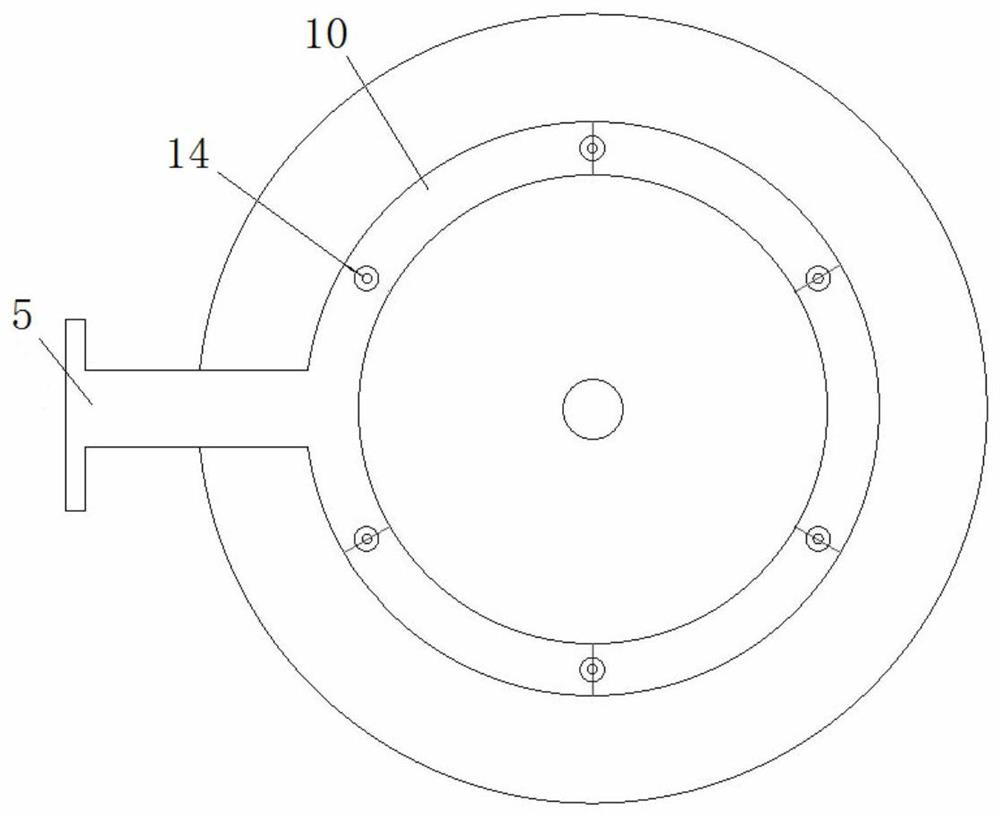

Full-automatic cutting machine of numerical controlled valve

InactiveCN101927355ARealize automatic feeding processEliminate impact on product qualityTurning machinesNumerical controlMachine tool

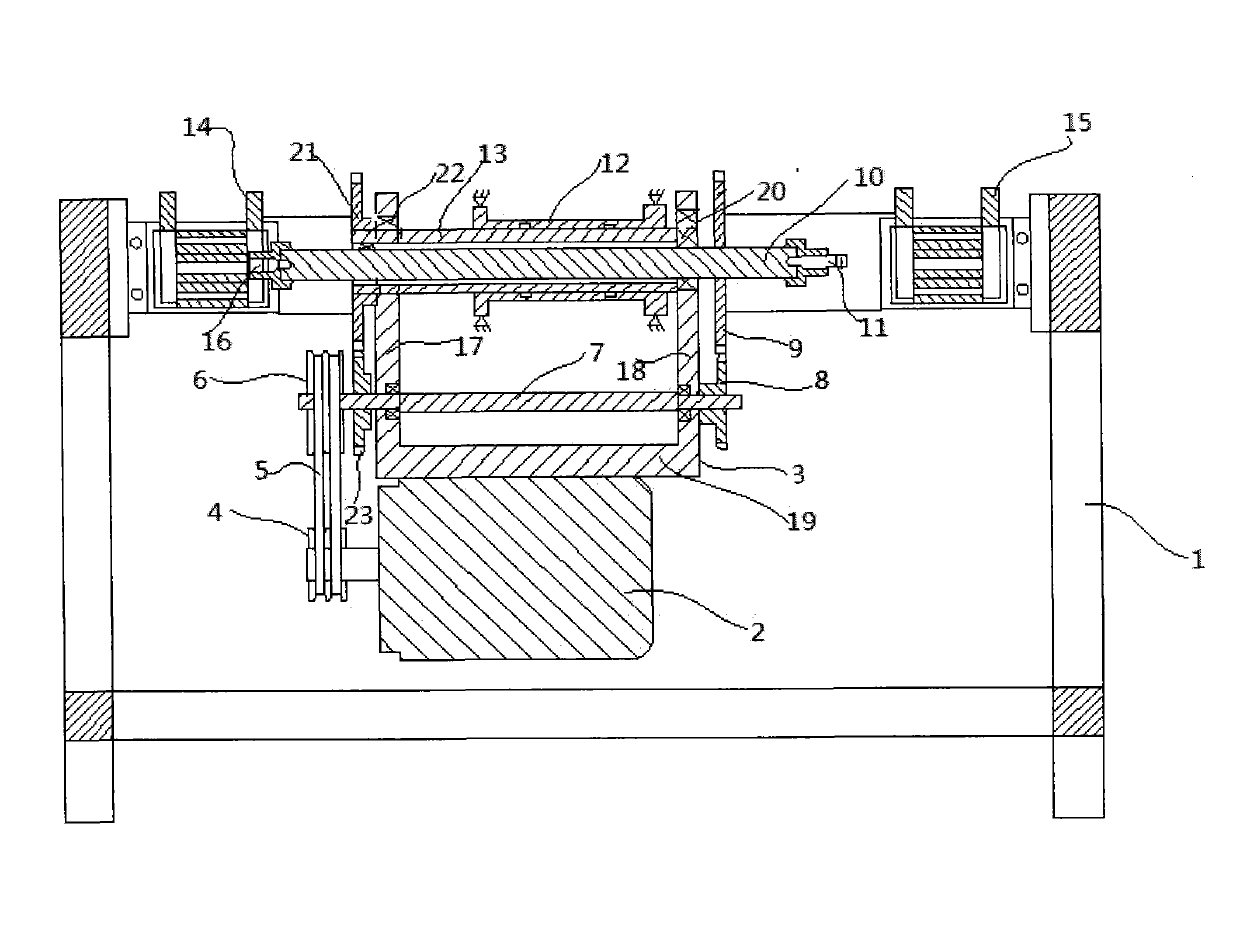

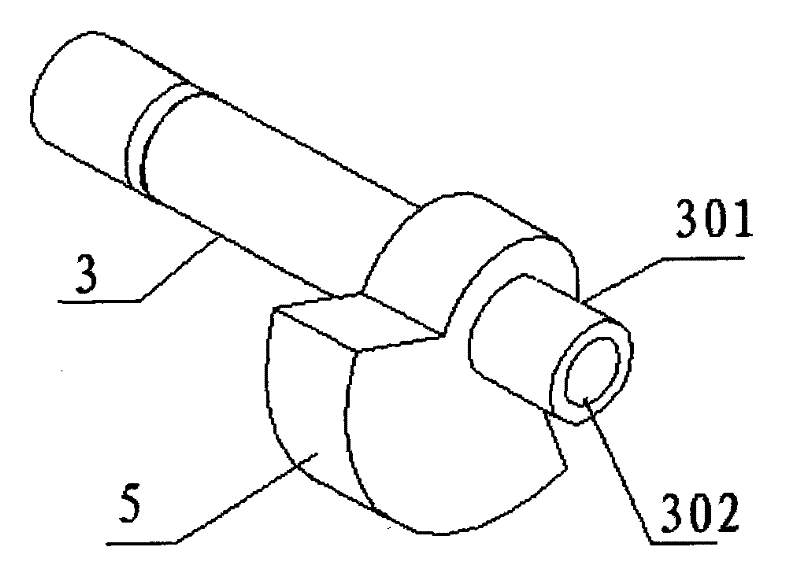

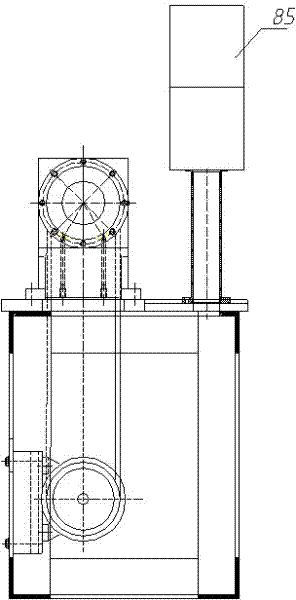

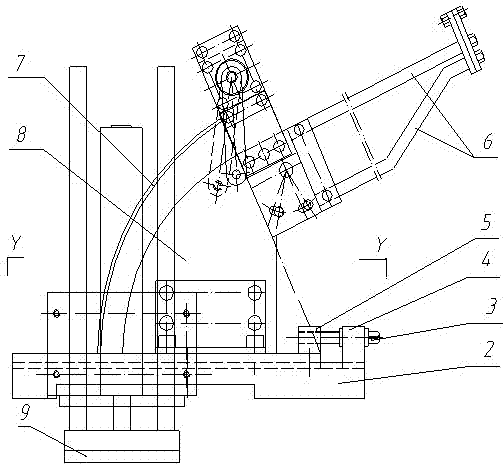

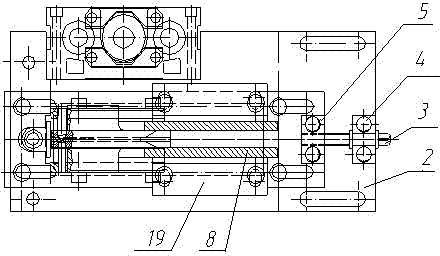

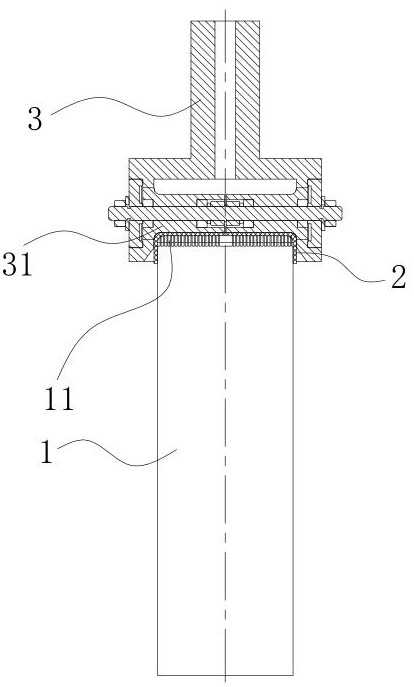

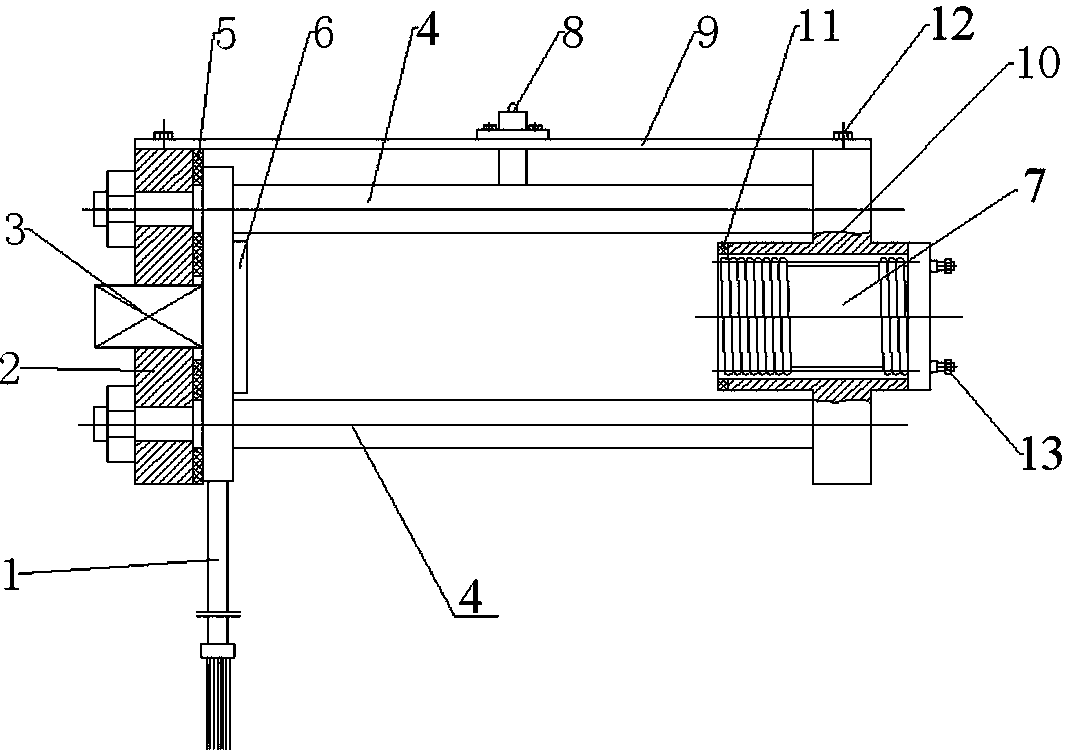

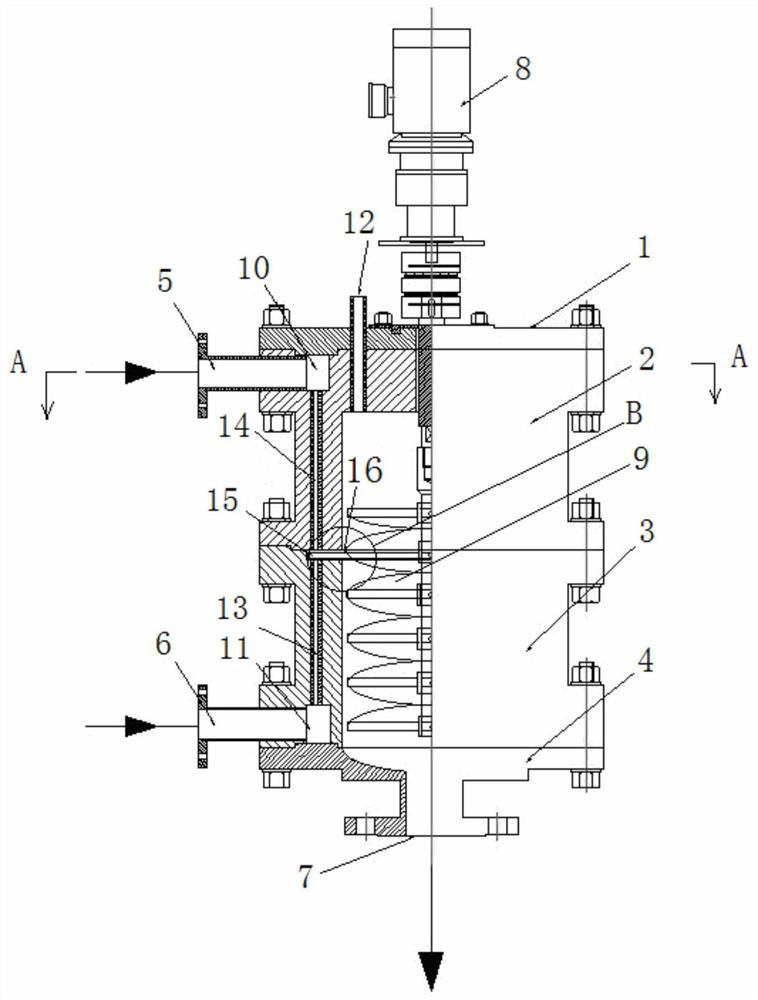

The invention relates to a full-automatic cutting machine of numerical controlled valve, which comprises a machine body, a feeding mechanism, a positioning mechanism, a geared head, a knife rest mechanism, a pushing mechanism and a numerical controlled electric box. The positioning mechanism utilizes a rigid ball base rotary positioning head and a positioning fixture at the end face of a valve disk part in the geared head to realize the full length cutting processing of the valve, and utilizes a flexible ball base rotary positioning head and a positioning fixture at the conical surface of the valve disk part in the geared head to realize the L-check size grooving processing of the valve. The rigid and flexible ball base rotary positioning heads overcome friction between workpieces and a positioner, eliminate the influences of the flat beat of the valve on positioning precision and the length precision of the processed valve reaches + / - 0.025mm. The cutting machine has simple structure, convenient operation and high full-automatic processing efficiency, is applicable to the full length cutting and grooving of the valve, and can be expanded to use the conical surface of the valve to position and process a sandwich groove of a lock and chamfer the end face of a valve rod; therefore, the full-automatic cutting machine has a wide application prospect.

Owner:马勒三环气门驱动(湖北)有限公司

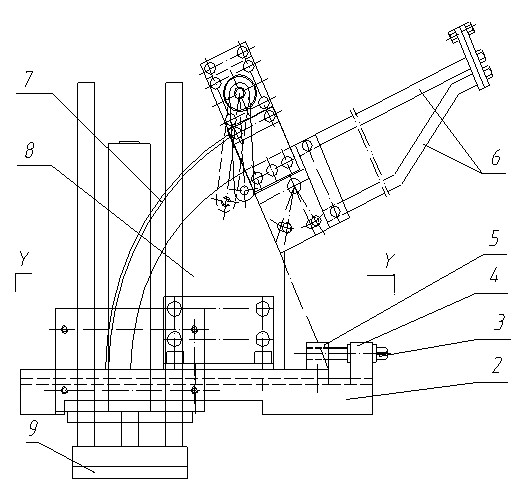

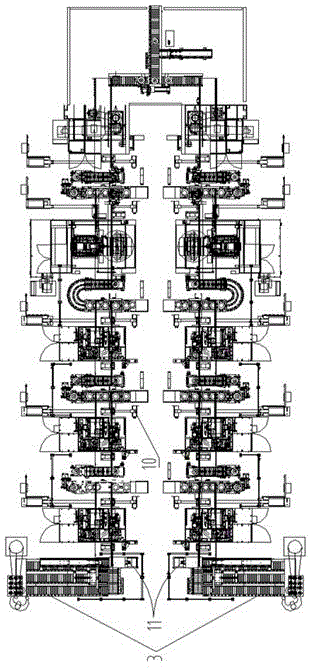

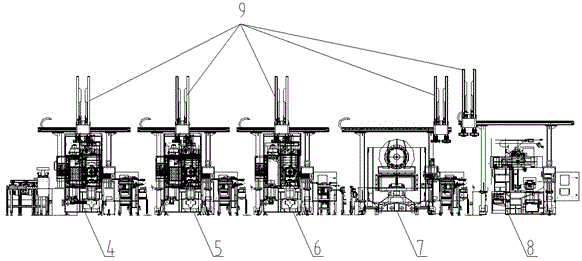

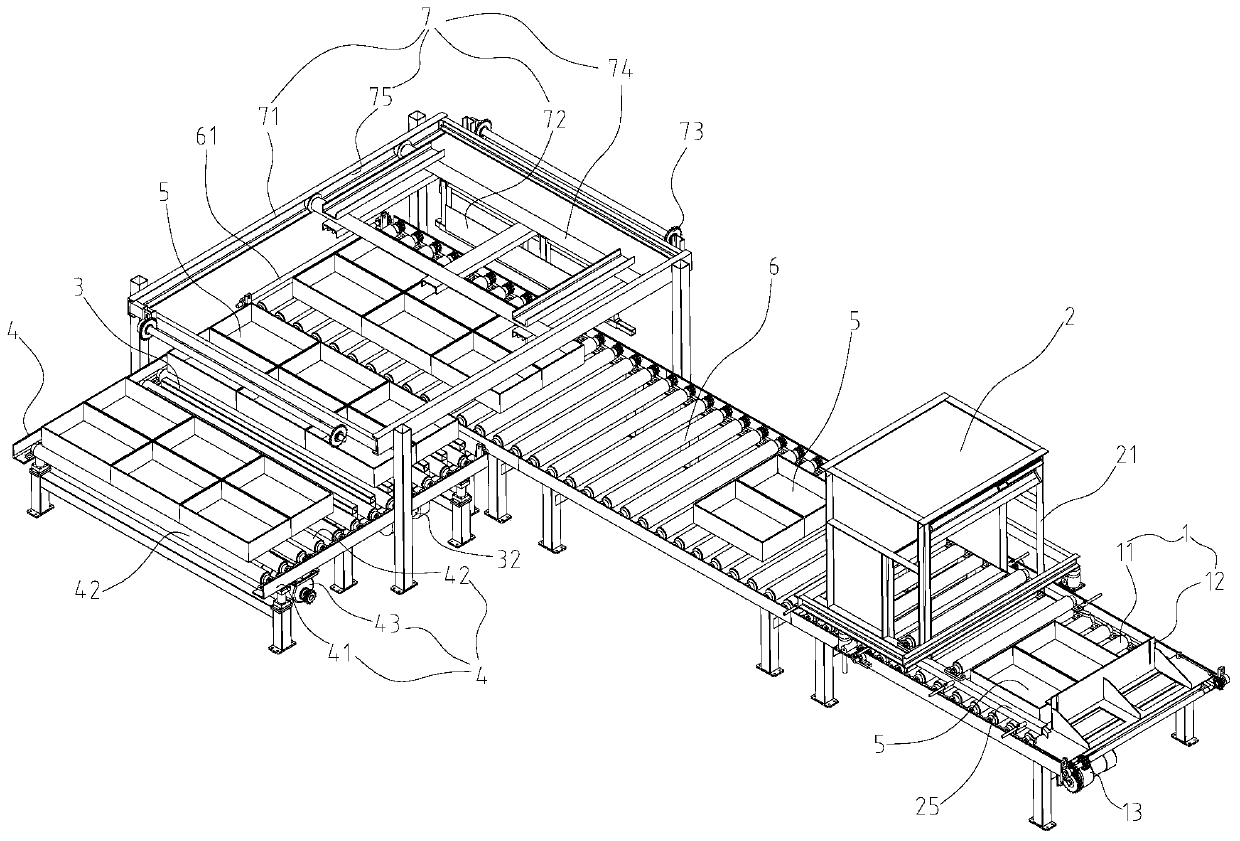

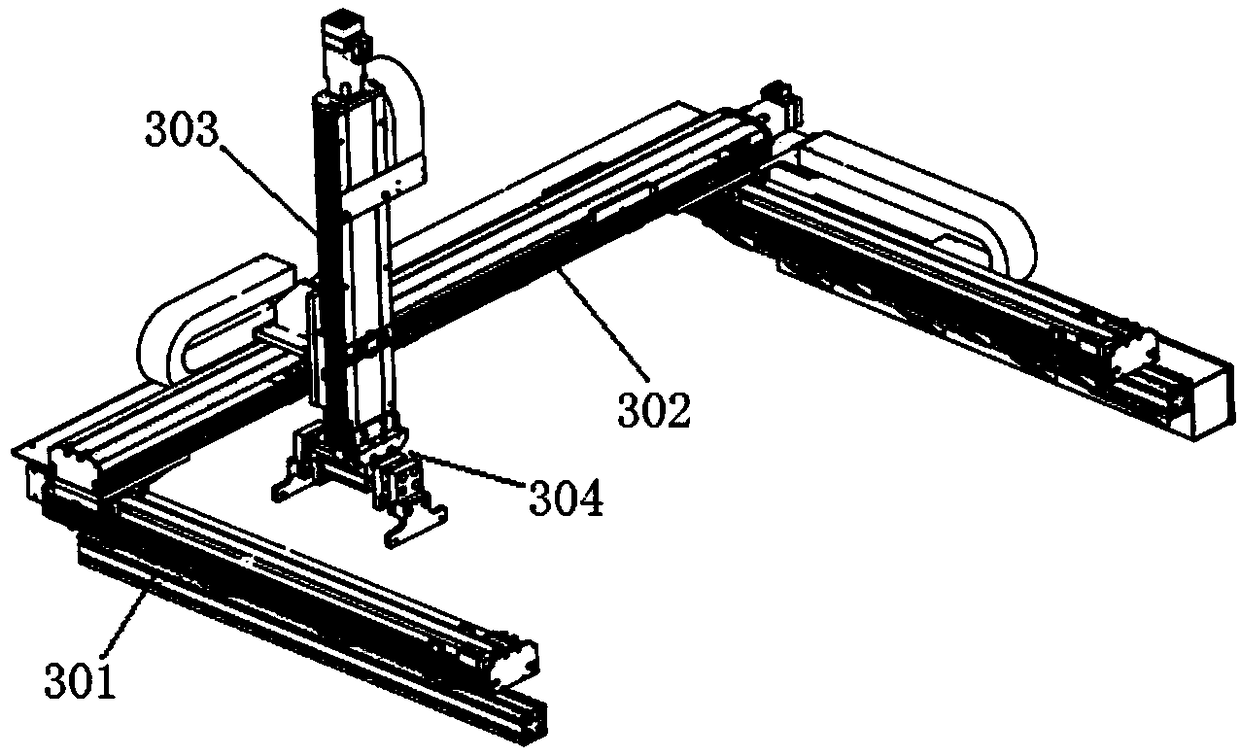

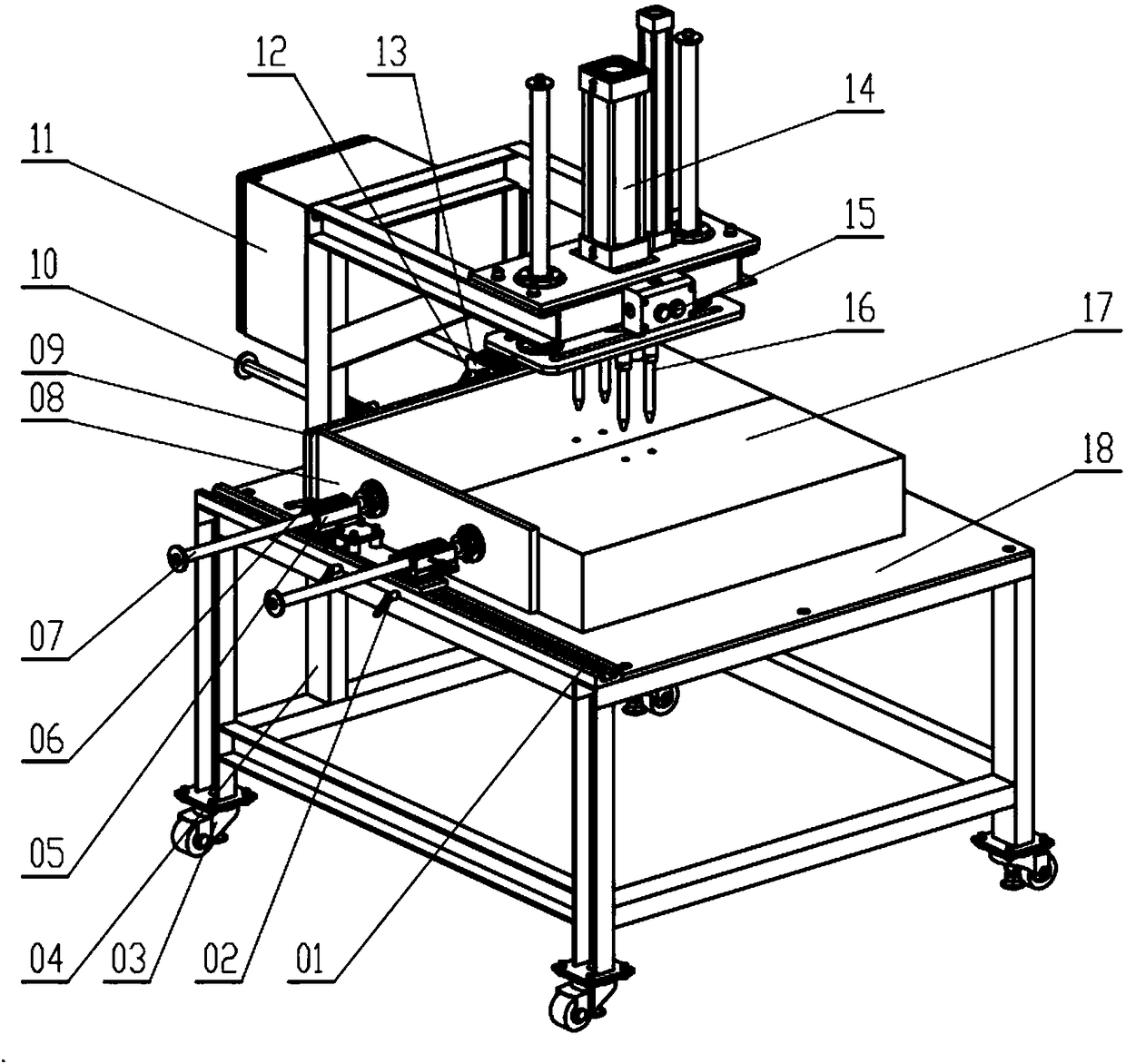

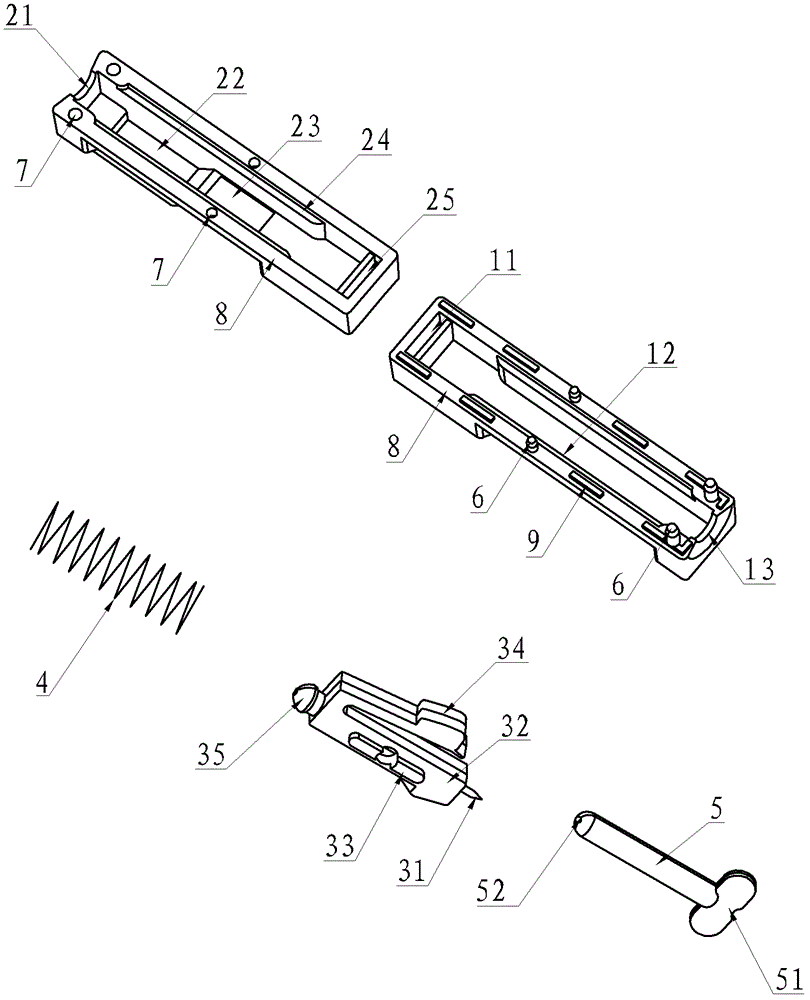

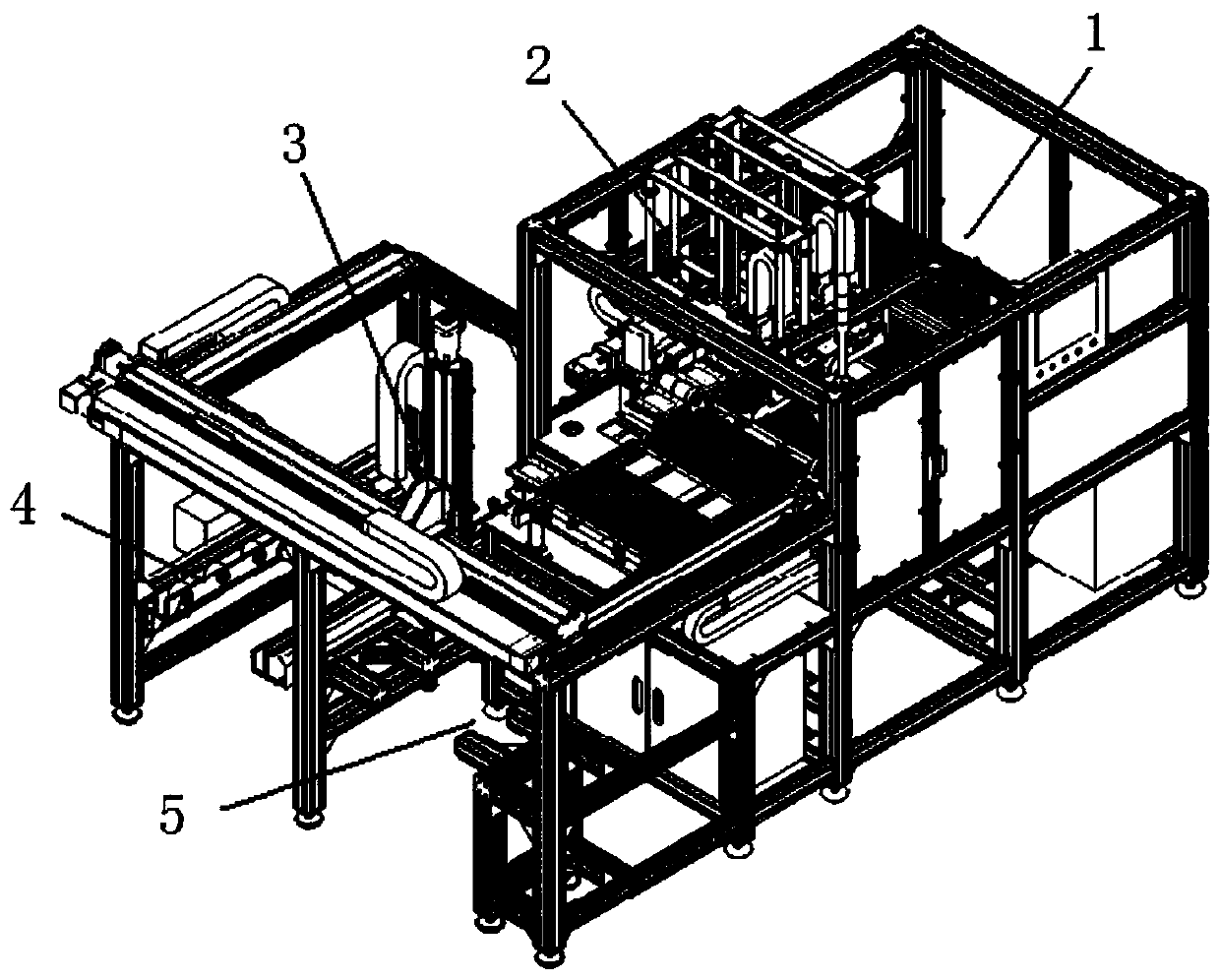

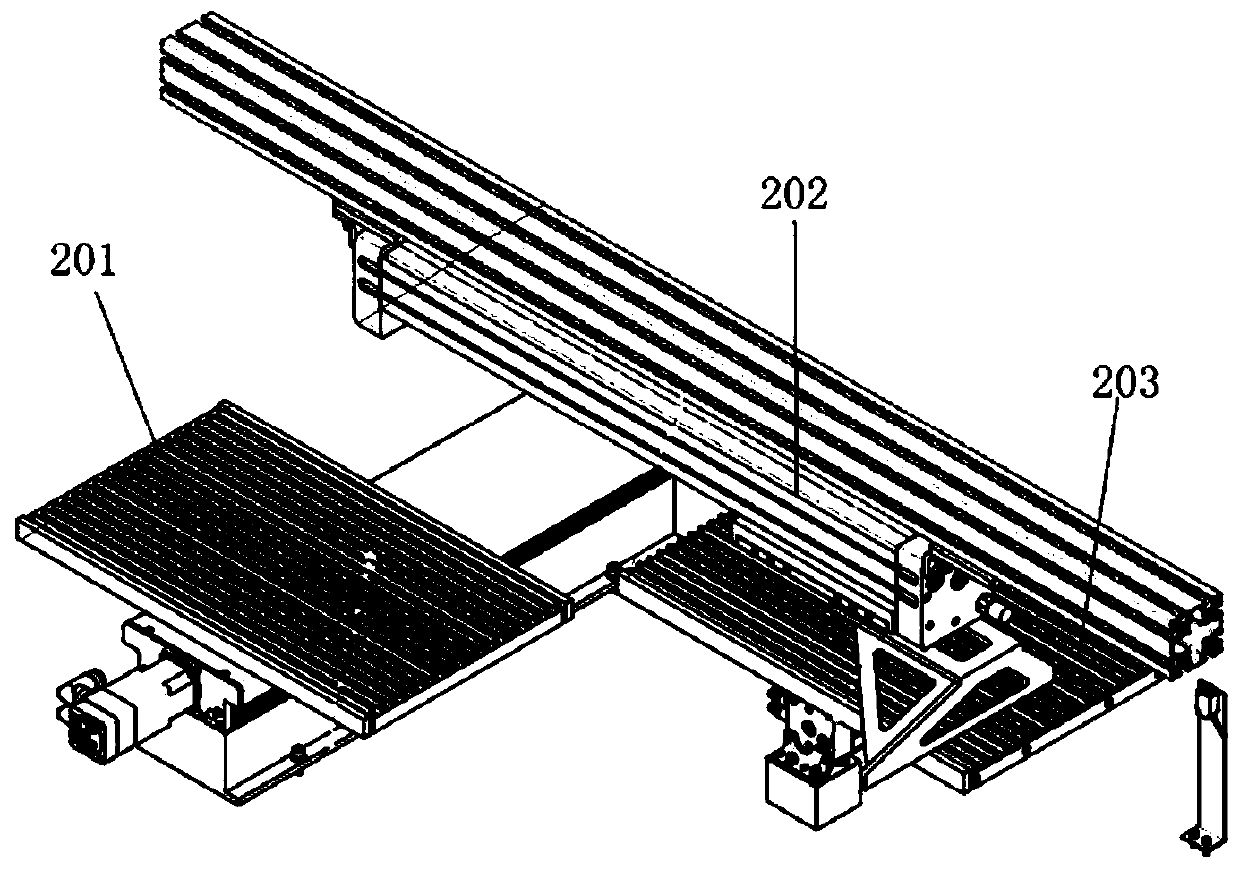

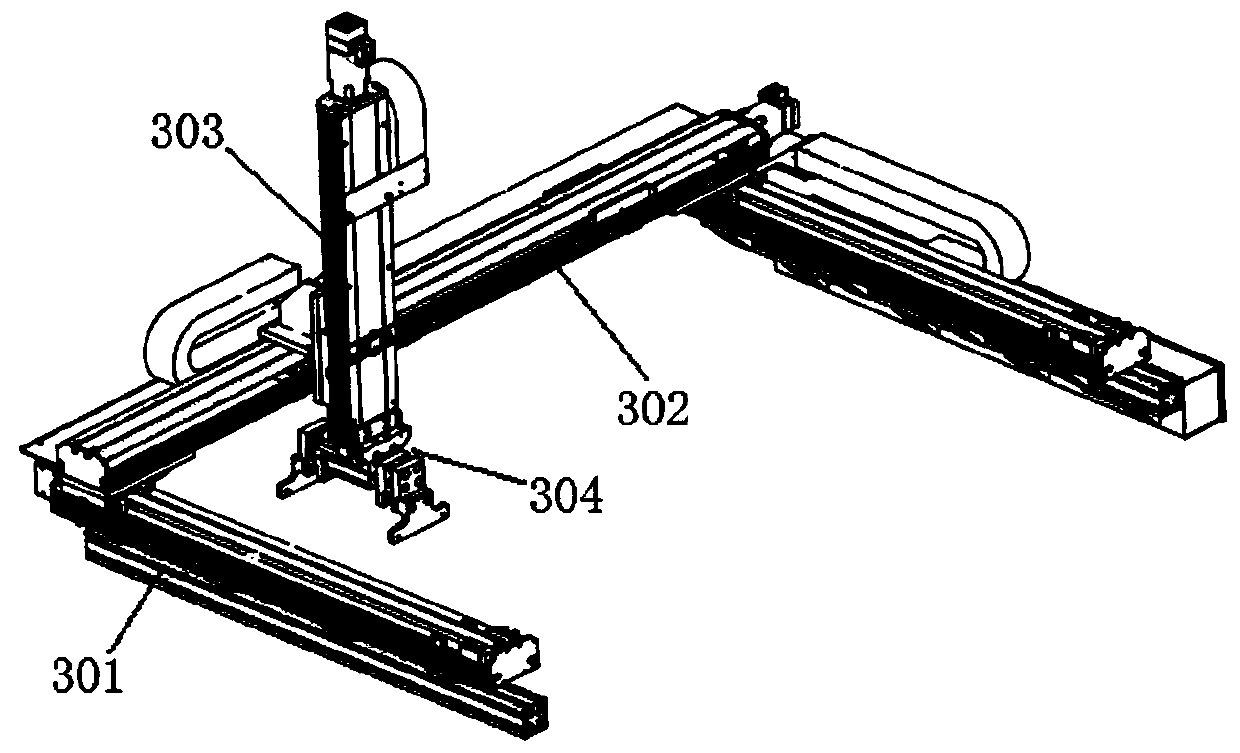

Automated multi-station production line for disc parts

InactiveCN105269000AAchieve zero inventoryEliminate impact on product qualityTurning machinesNumerical controlProduction line

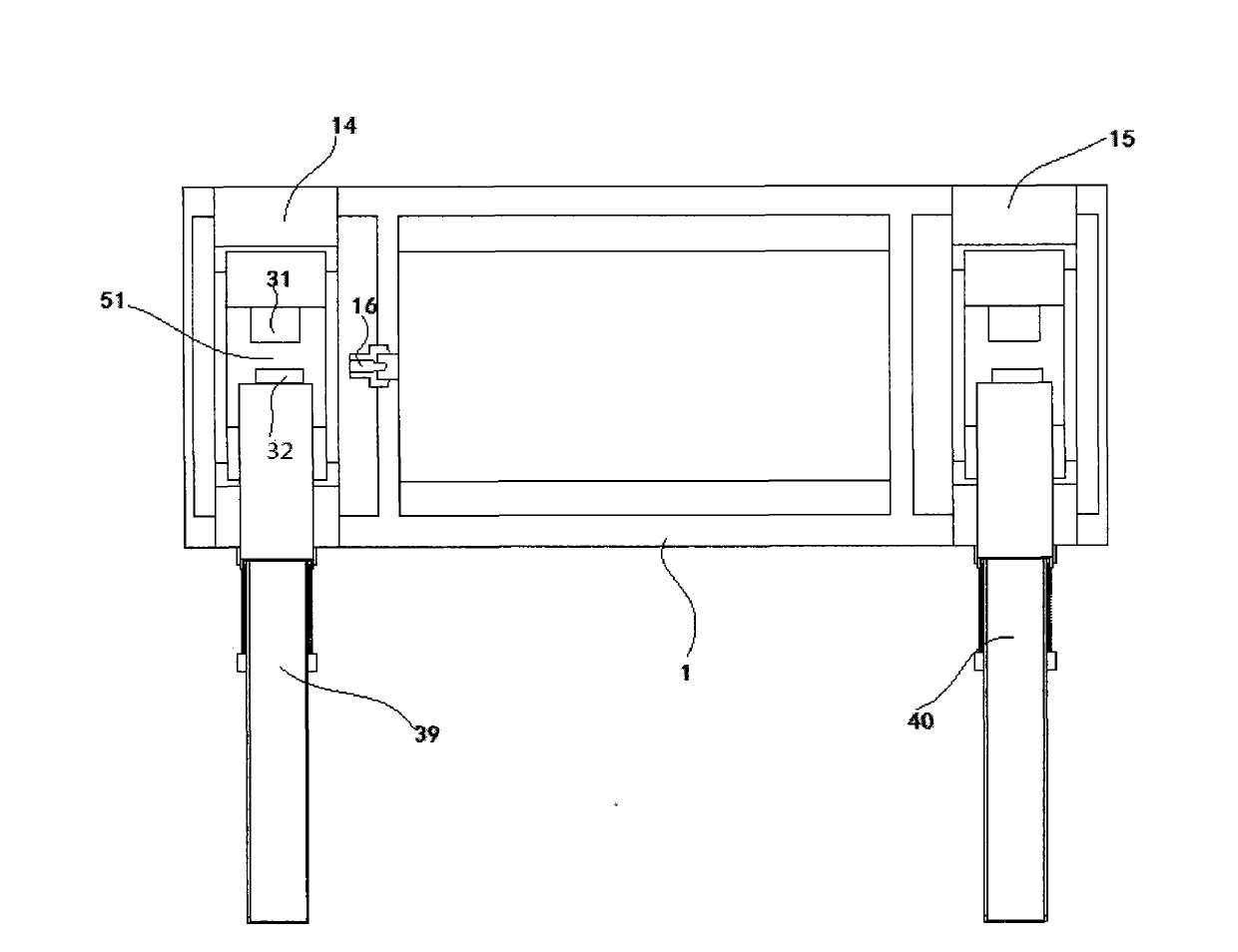

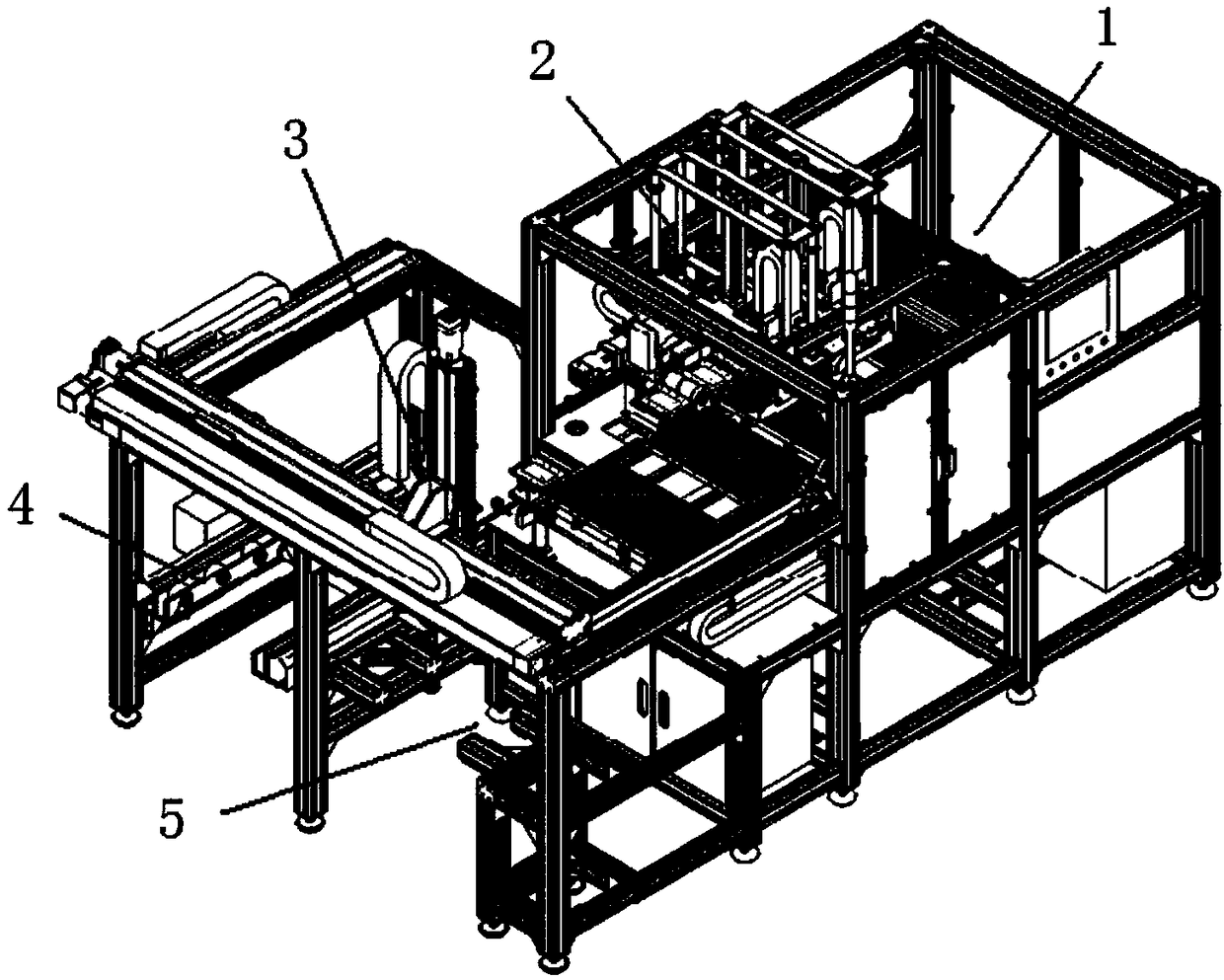

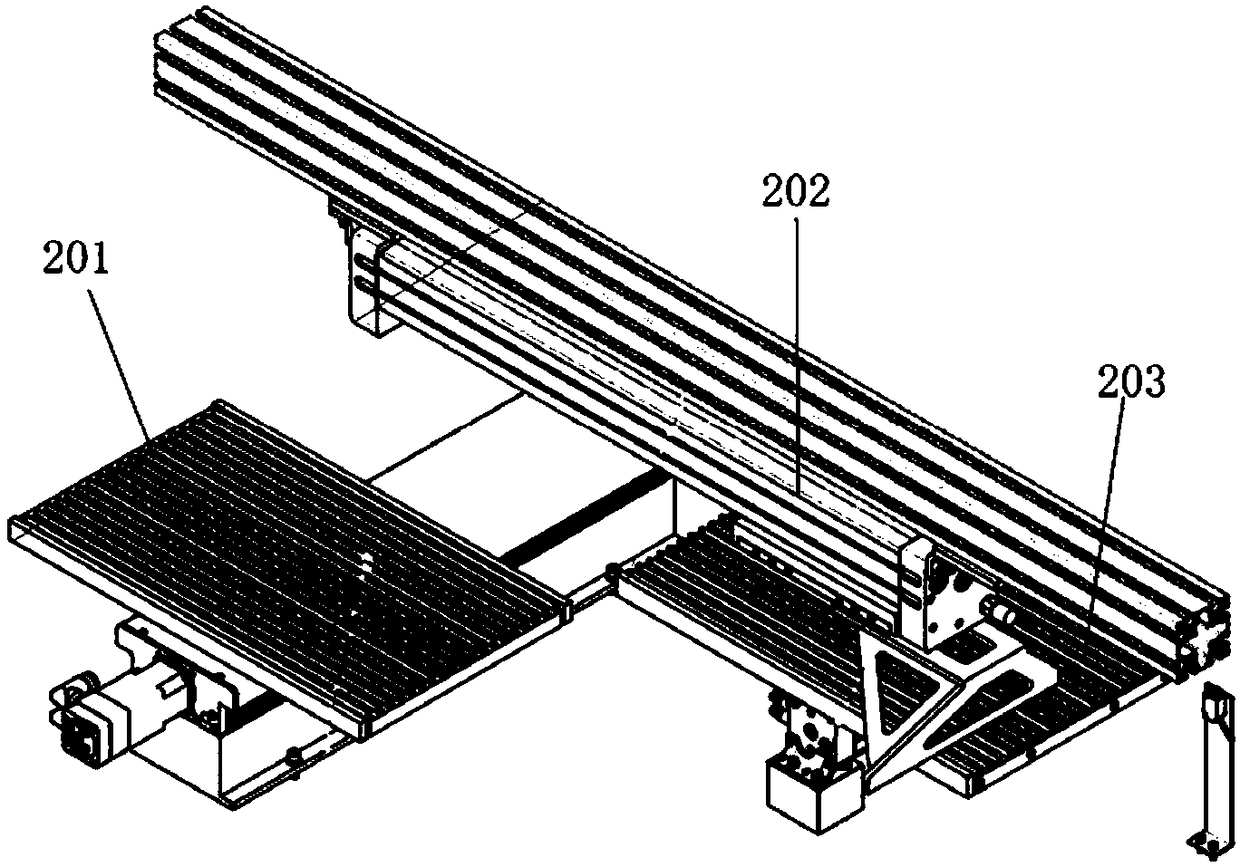

An automated multi-station production line for disc parts comprises a logistics roller table system for connecting all machining units of the production line. The logistics roller table system comprises workpiece overturning devices, a NG material way and a discharging way. The production line further comprises a first numerical control lathe, a second numerical control lathe and a third numerical control lathe which are connected in series. The discharging way and a visual identification system are arranged on the feeding position of the first numerical control lathe. The three numerical control lathes are sequentially connected through the logistics roller table system. A machining center and a two-sided lathe are arranged behind and connected with the three numerical control lathes in series and connected with other parts through a logistics roller table in sequence. The production line further comprises a truss mechanical hand system. The truss mechanical hand system comprises multiple truss mechanical hands arranged above all machine tools on the production line. The workpiece overturning devices are arranged between the first numerical control lathe and the second numerical control lathe and between the second numerical control lathe and the third numerical control lathe respectively. Random sampling detection devices are arranged between every two machine tools.

Owner:YOUJI MACHINE IND CHINA COMPANY

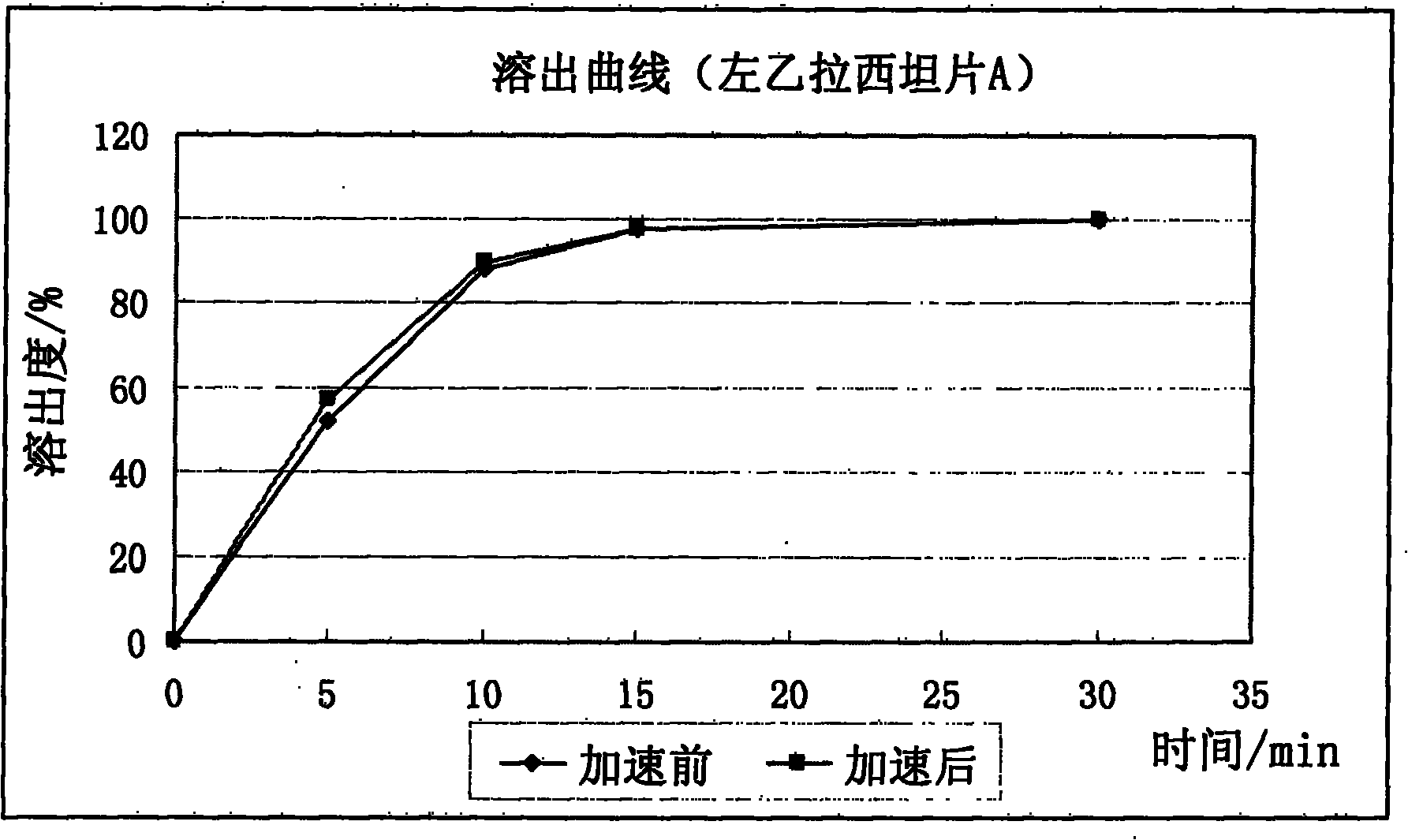

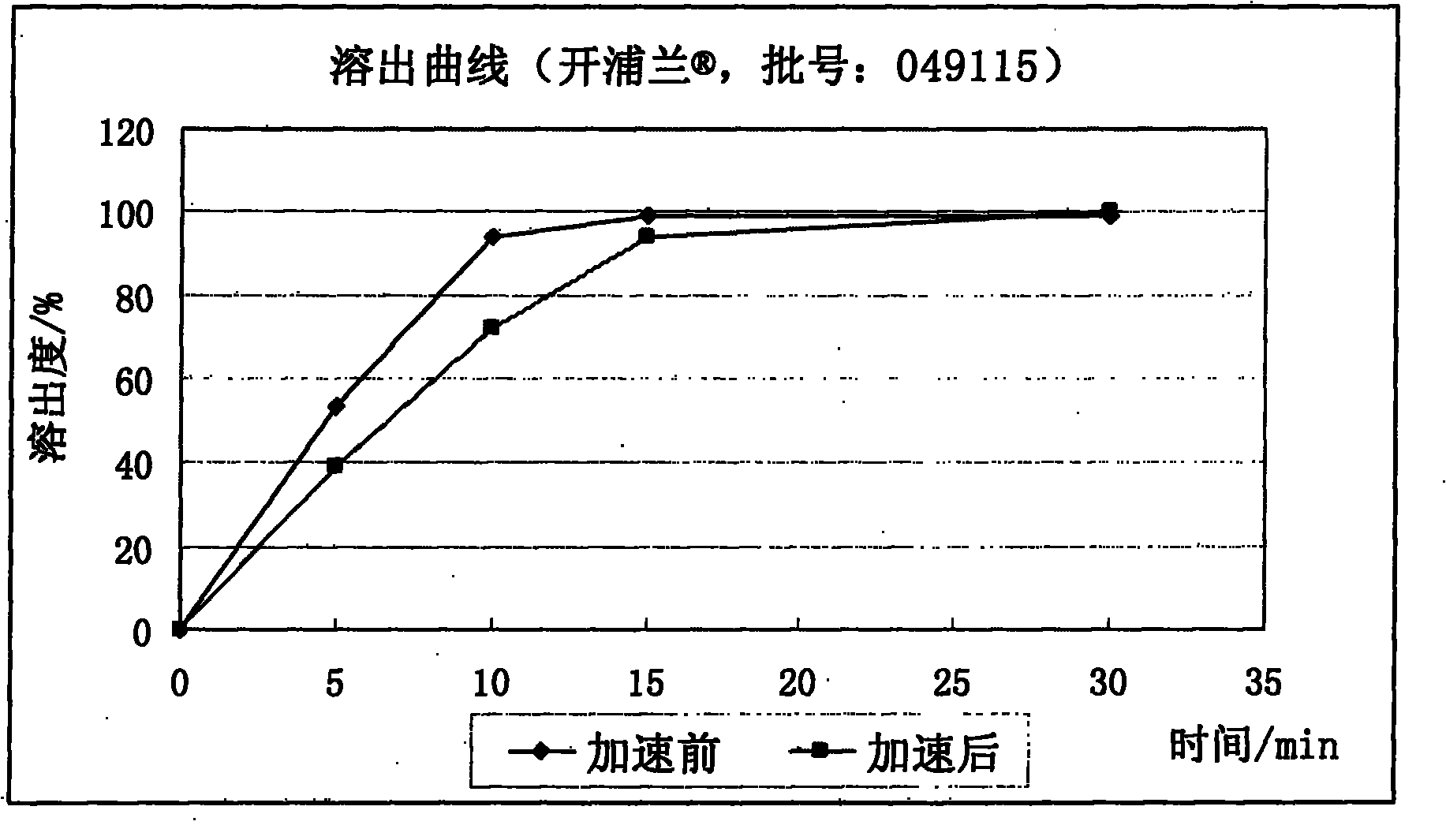

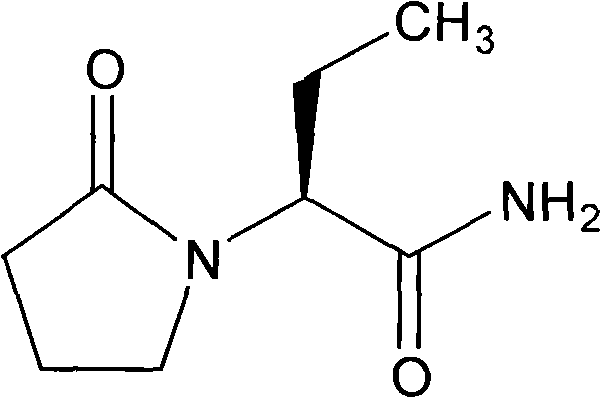

Levetiracetam tablet and preparation method thereof

ActiveCN102038657AEliminate impact on product qualitySimple process controlOrganic active ingredientsNervous disorderActive componentPharmacology

The invention relates to a levetiracetam tablet. The levetiracetam tablet at least comprises levetiracetam used as an active component and a binder accounting for more than 6% of the total weight of the tablet. The invention further relates to a preparation method of the levetiracetam tablet. The improved levetiracetam tablet is simple in production technology and low in cost, and is suitable for commercial production.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD

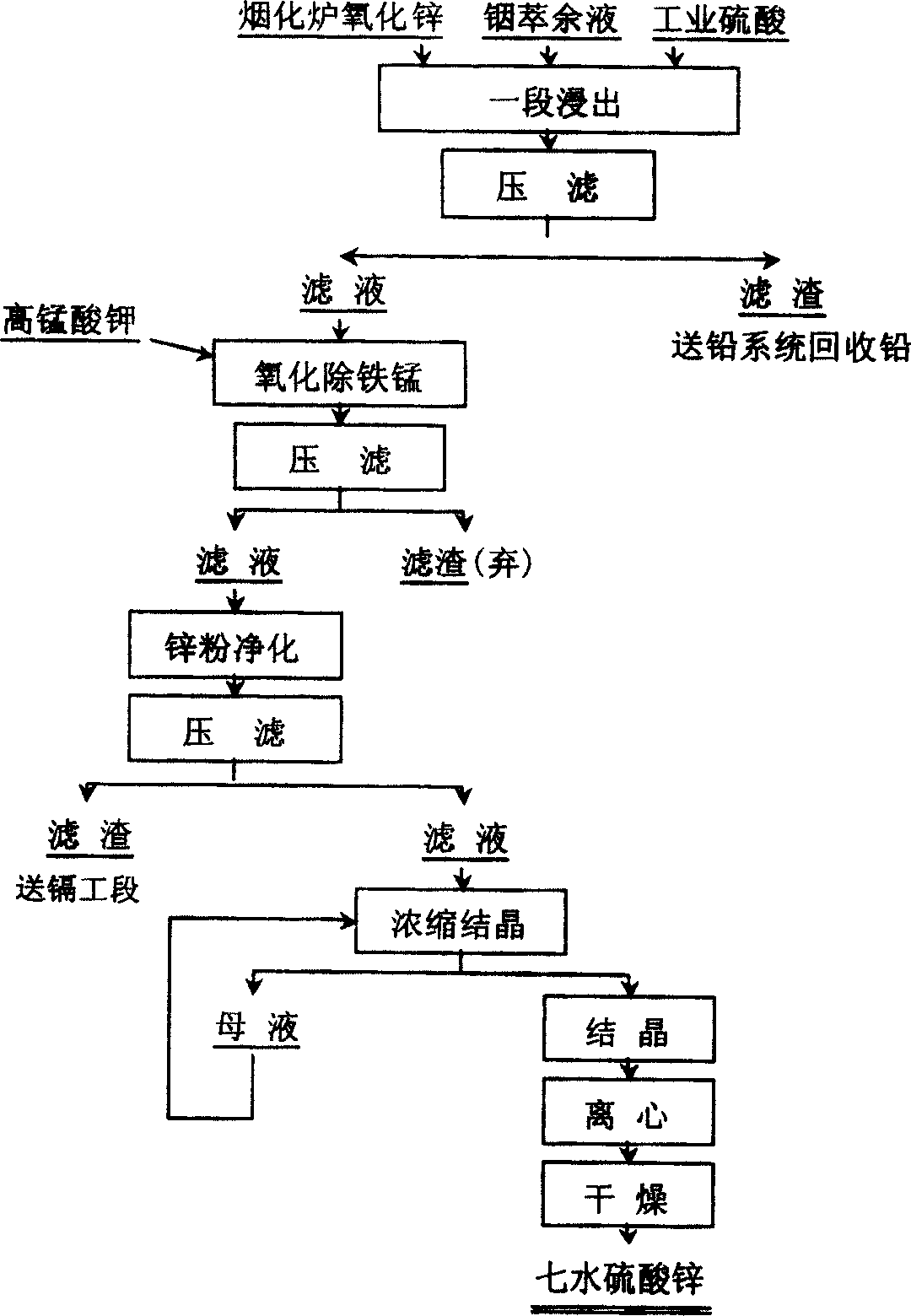

Method of producing zinc vitriol using indium extraction raffinate and zinc oxide

A process for preparing heptahydrated zinc sulfate from the residual liquid after extracting indium and zinc oxide includes such steps as preparing the extracting liquid from said residual liquid and sulfuric acid, heating, extracting zinc oxide while stirring, laying aside, filtering, oxidizing the filtrate by potassium permangnate for removing Fe and Mn, cleaning by using zn powder for displacement, concentrating, crystallizing, separating and drying.

Owner:株洲冶炼集团有限责任公司

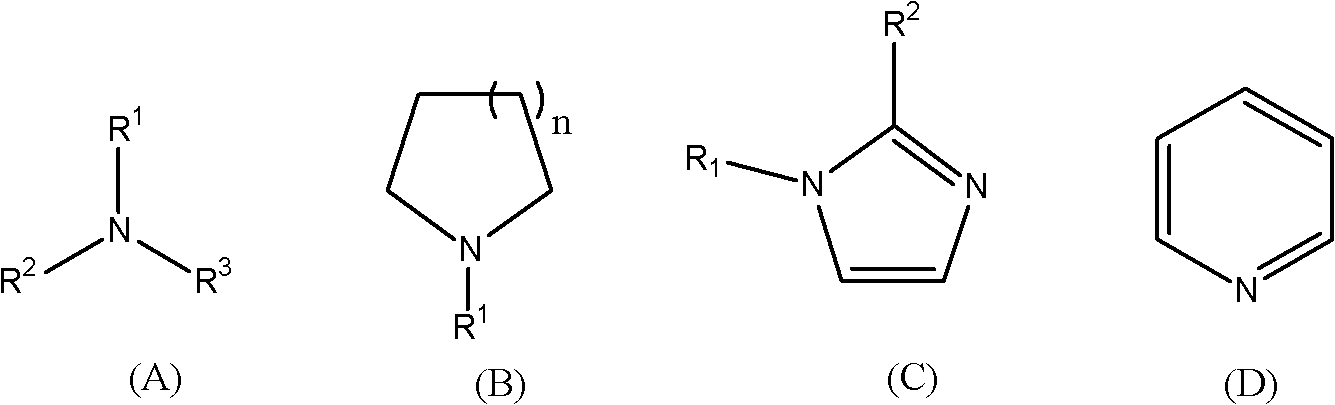

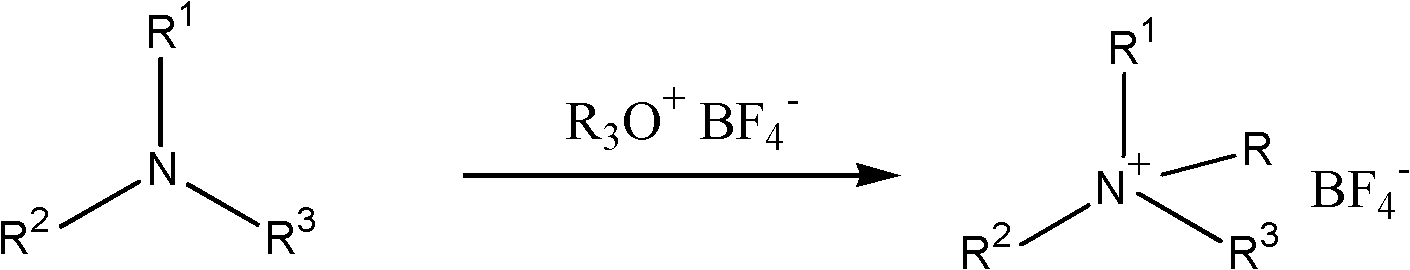

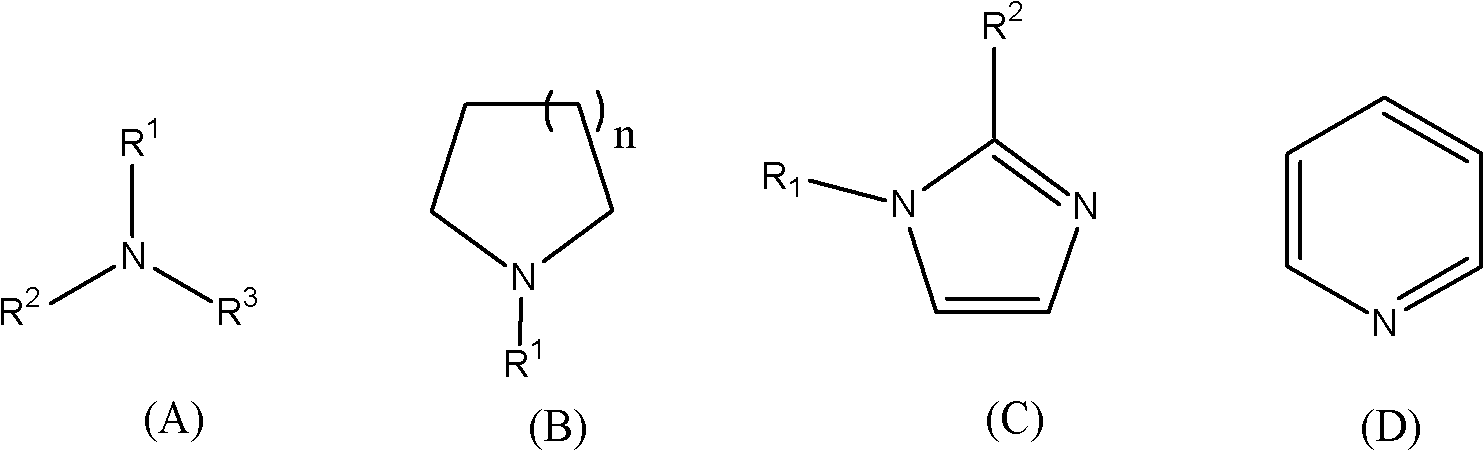

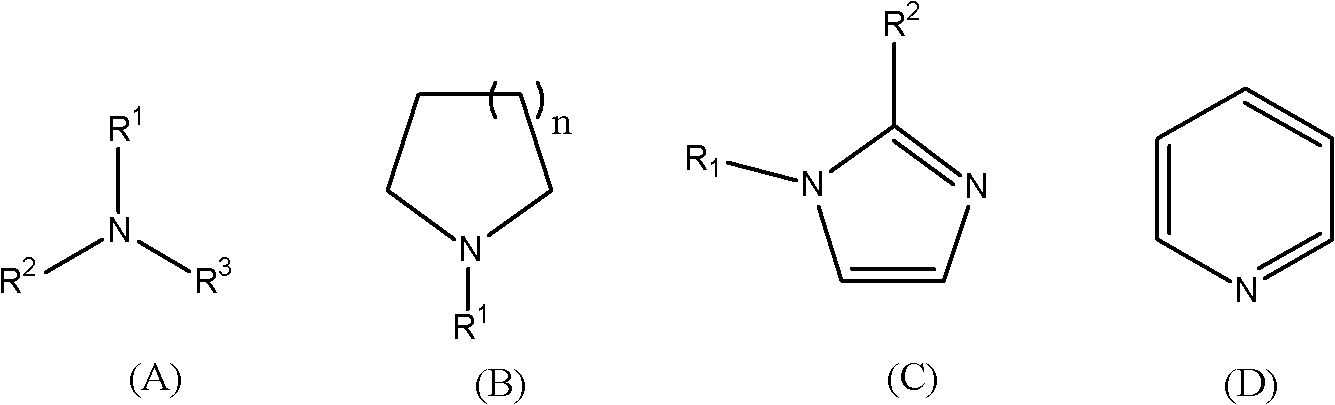

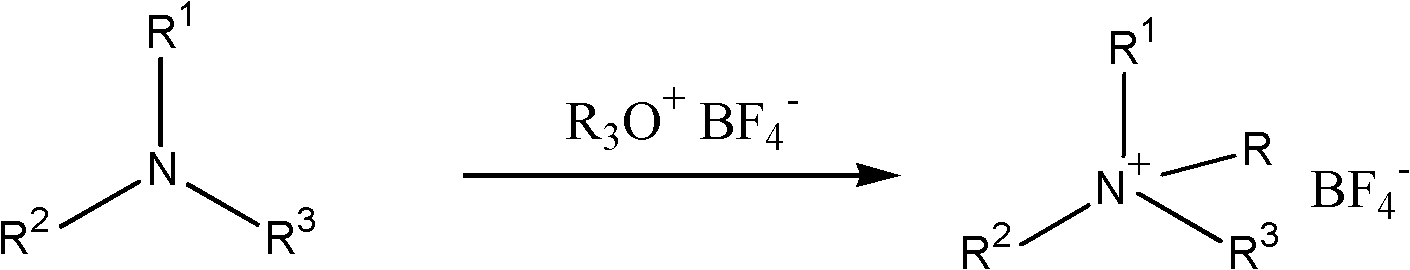

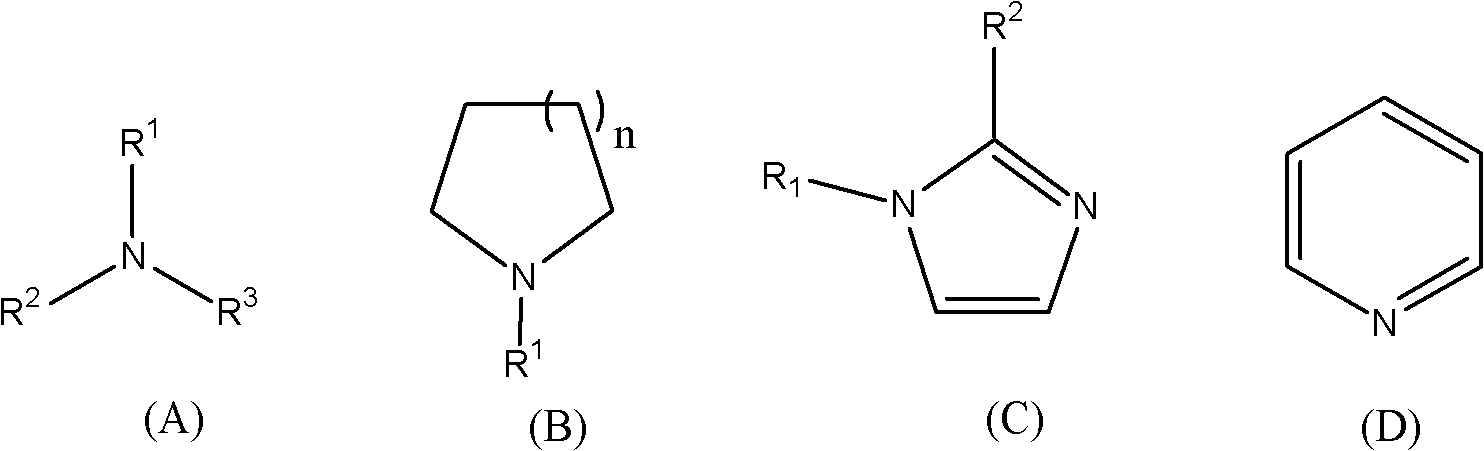

Preparation method of high-purity alkylammonium tetrafluoroborate for super capacitor

ActiveCN102432474AHigh purityHigh yieldOrganic compound preparationElectrolytic capacitorsHalogenTetrafluoroborate

The invention discloses a preparation method of high-purity alkylammonium tetrafluoroborate for a super capacitor, characterized by reacting tertiary amine with tetrafluoroborate alcoxylonium salt at a certain temperature to obtain corresponding alkylammonium tetrafluoroborate, and purifying to obtain the high-purity alkylammonium tetrafluoroborate. The method has the advantages of simple operation steps, good selectivity, high conversion rate, high product purity, and no halogen ions, and can satisfy the requirements of a high performance super capacitor. The use of the prepared alkylammonium tetrafluoroborate as an electrolyte in the super capacitor can achieve the advantages of high product capacity, low internal resistance, and reduced capacity fade at a high temperature.

Owner:锦州凯美能源有限公司

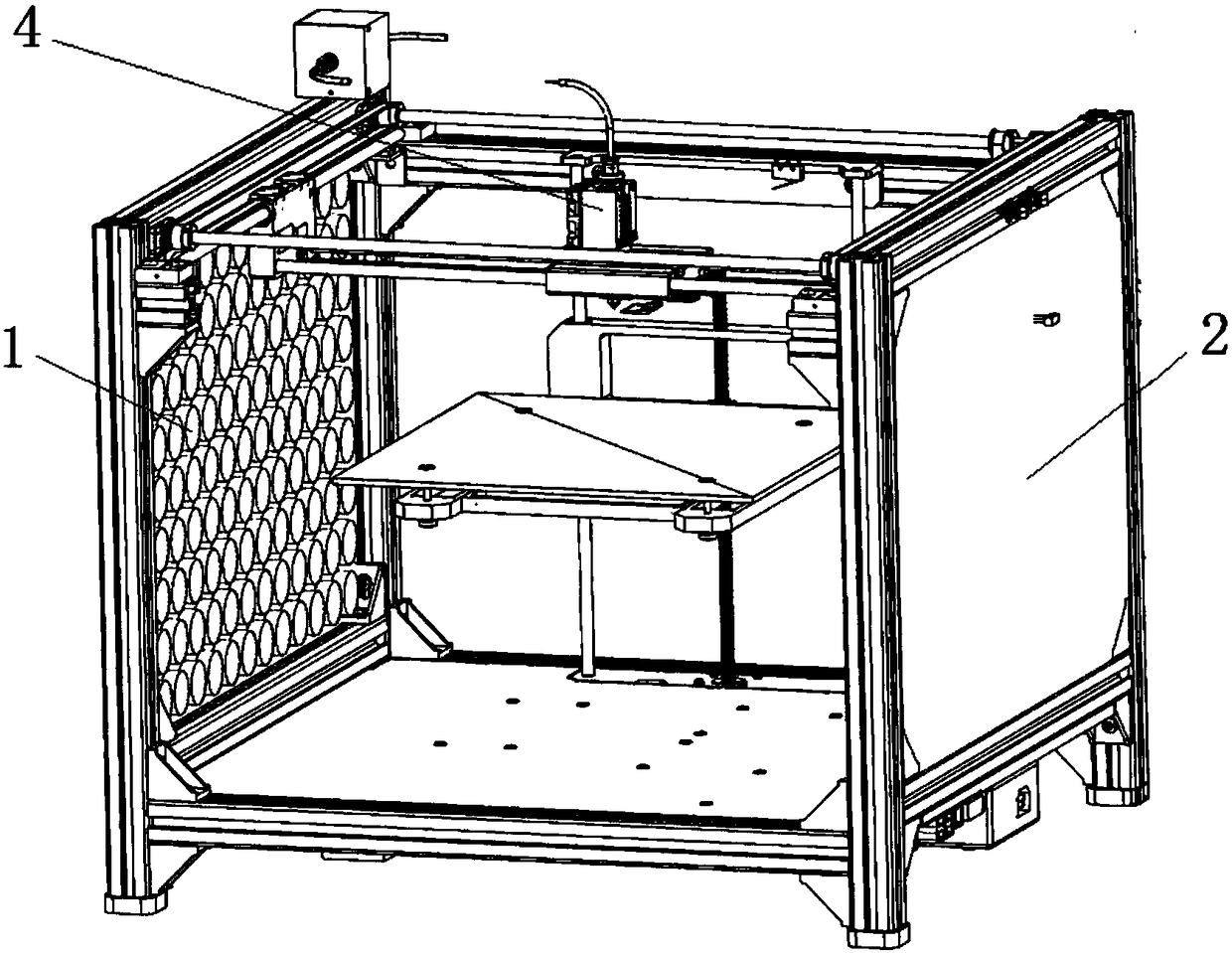

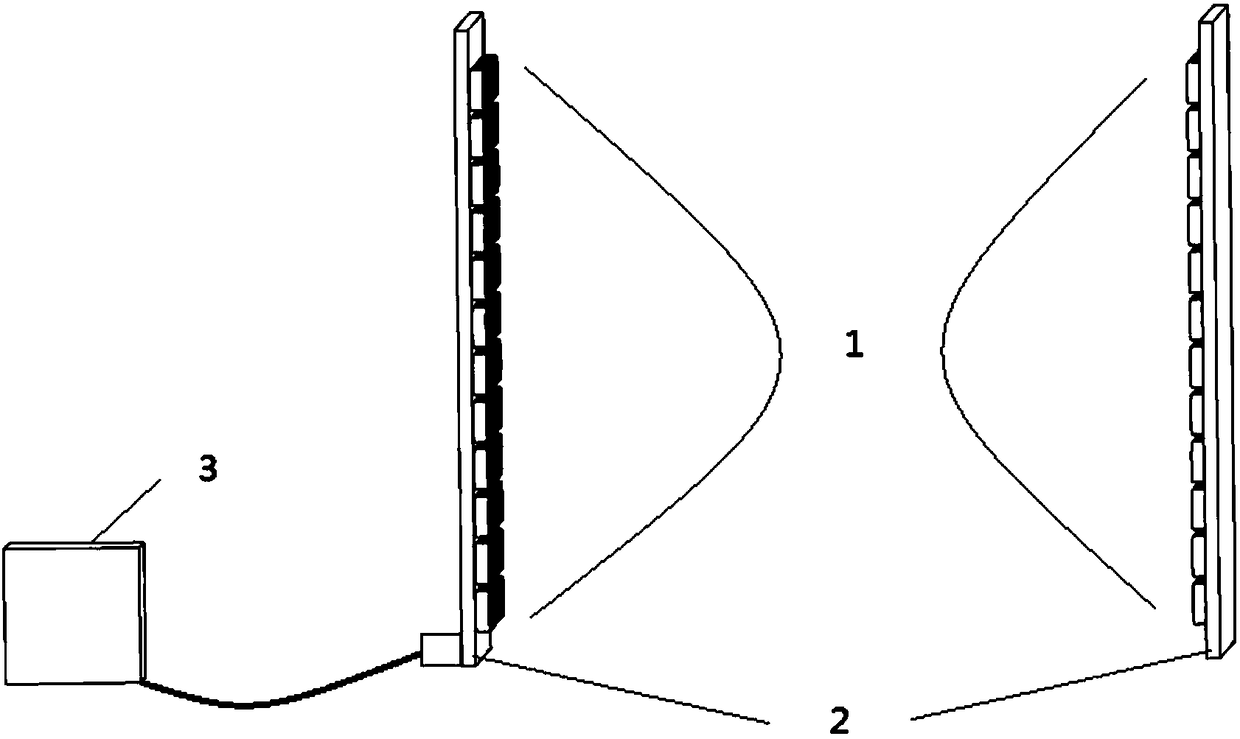

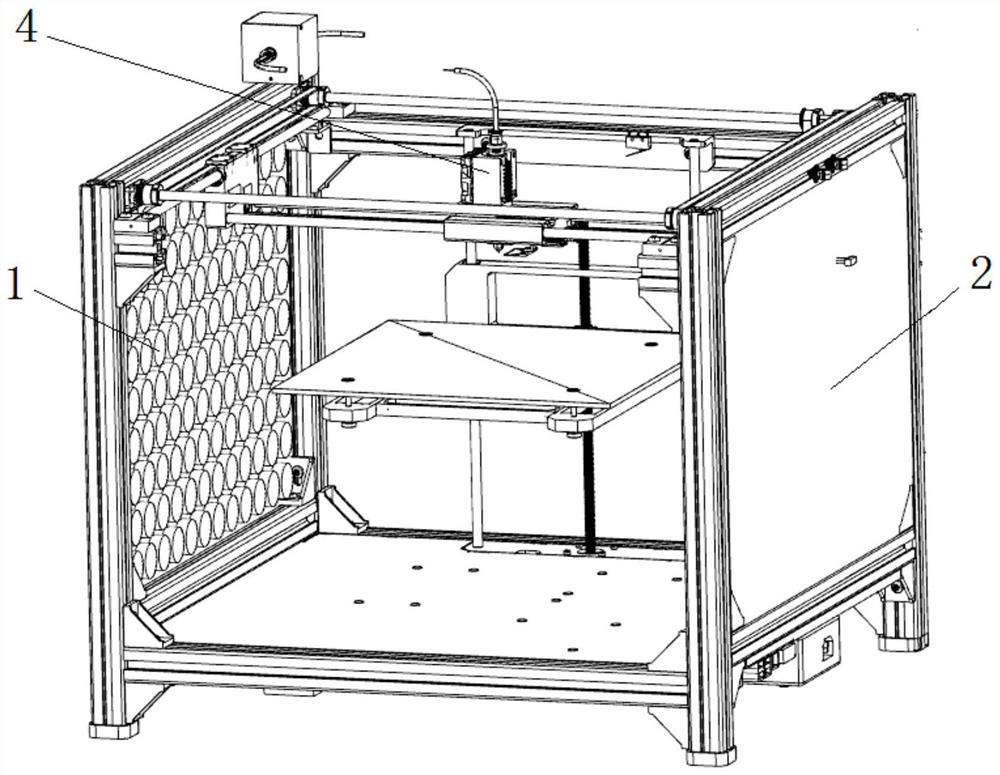

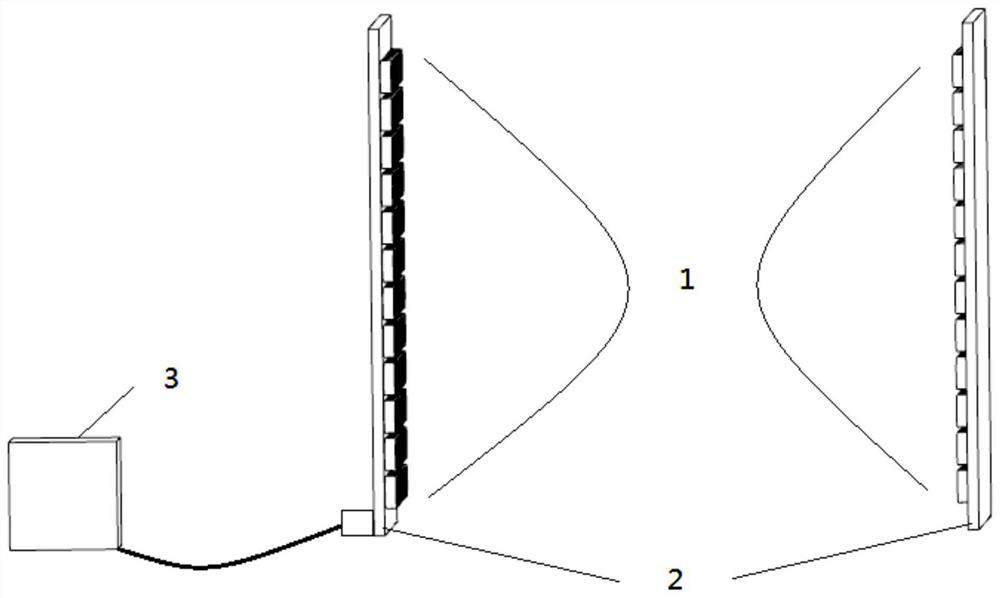

Support-free 3D (Three Dimensional) suspended printing structure and support-free 3D suspended printing method

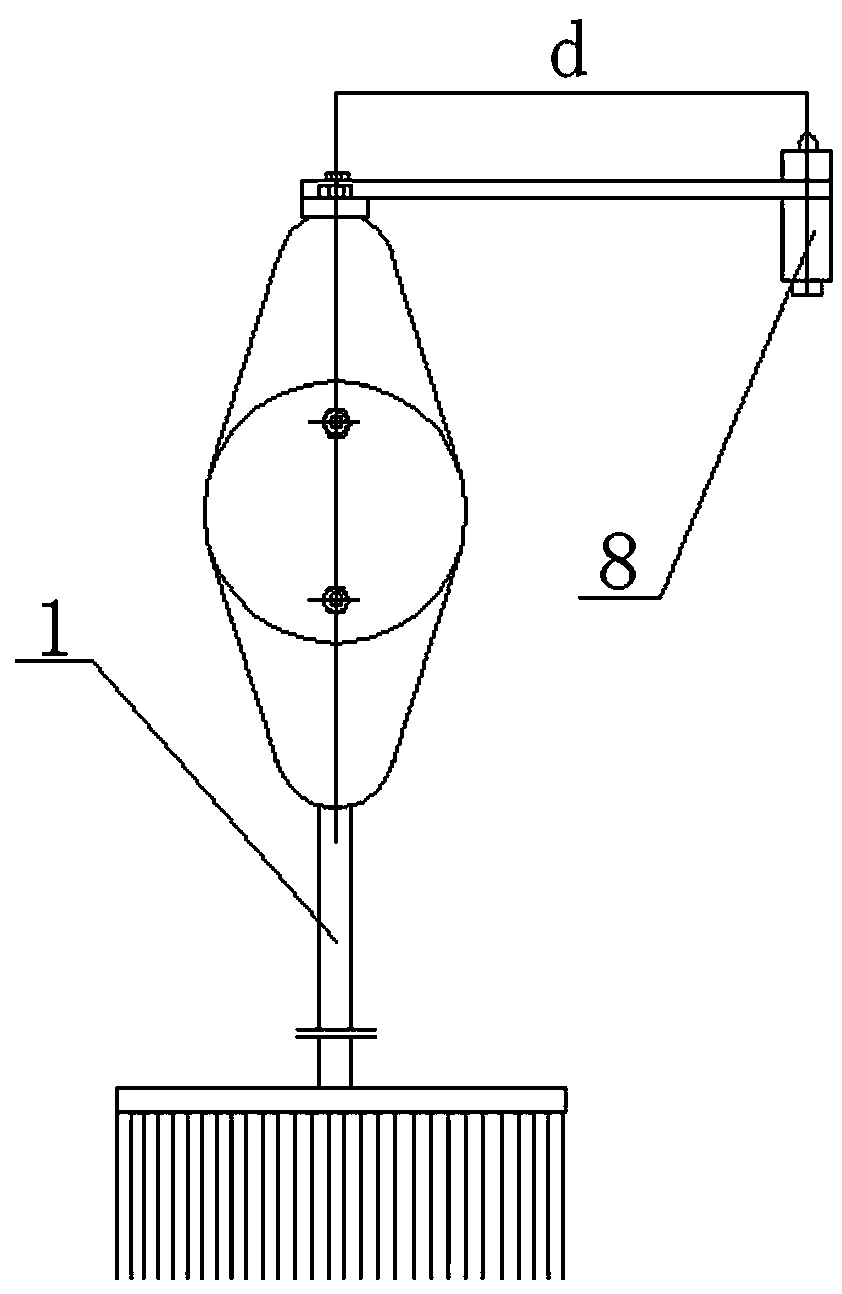

ActiveCN108312497AEnables supportless printingReduce consumptionAdditive manufacturing apparatus3D object support structuresThin shellsUltrasonic radiation

The invention discloses a support-free 3D (Three Dimensional) suspended printing structure and a support-free 3D suspended printing method. The support-free 3D suspended printing method is characterized in that an ultrasonic suspension method is adopted; parts are putted into a sound field in the 3D printing process of the parts; a suspended or floating part is supported under the action of ultrasonic radiation force; the printing of materials of initial several layers is enabled to be finished so as to support subsequent printing, and further 3D printing of the parts is finished under the support-free condition. According to the support-free 3D suspended printing structure and the support-free 3D suspended printing method disclosed by the invention, on the one hand, the cost of supportingmaterials is greatly reduced and the manufacturing efficiency is greatly improved; on the other hand, the influence on product quality, which is possibly caused by unfavorable support, is eliminated.In particular to thin shell parts, certain supporting materials even account for 60 percent or above of the use amount of the integral material; if the parts are printed under the support-free condition, the cost is predicted to be reduced by 50 percent or above, and the manufacturing cycle is shortened by 40 percent or above; in addition, the worry about quality problem caused by support removalis avoided.

Owner:XI AN JIAOTONG UNIV +1

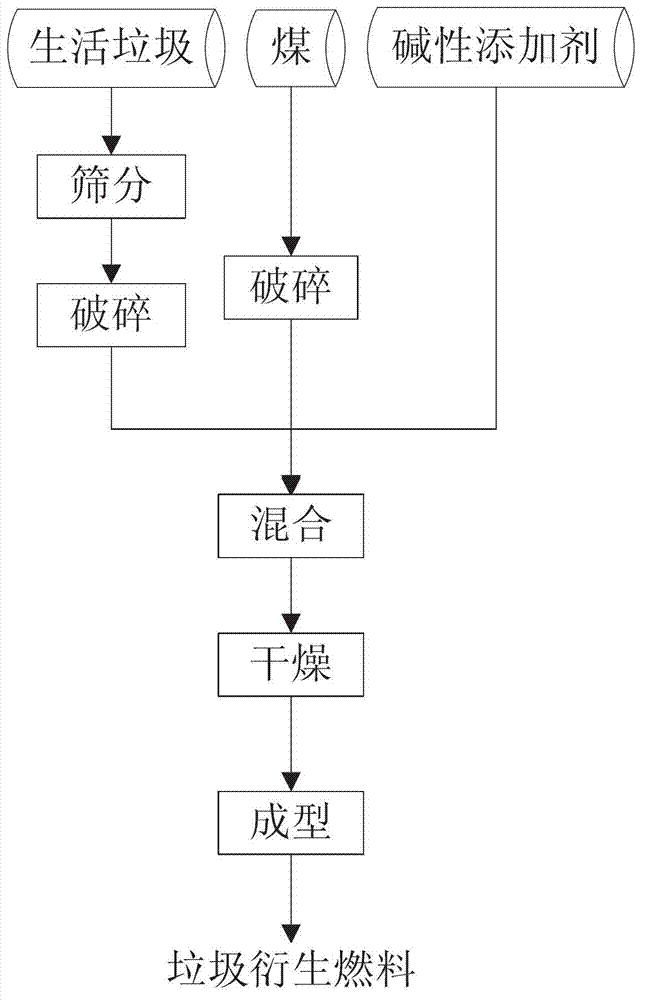

Preparation method applicable to treating garbage derivate by being jointed with cement kiln

InactiveCN102827662ASolve land occupationEliminate pollutionBiofuelsSolid fuelsRefuse-derived fuelLand resources

The invention discloses a preparation method applicable to treating garbage derivate by being jointed with a cement kiln, belonging to the technical field of garbage treatment. The method provided by the invention comprises the following steps: sieving the domestic garbage to remove inorganic incombustible matters; crushing the domestic garbage through a crushing machine; adding 10 to 20% of crushed coal and 5 to 10% of alkaline additive by weight; fully agitating and uniformly mixing the mixtures; and then drying the mixture by forcibly ventilating; and finally extruding to form through forming equipment so as to obtain the garbage derivate fuel. With the adoption of the preparation method provided by the invention, the land resource can be saved, the pollution of the garbage to the environment is removed, the cost of preparing the garbage derivate fuel through the method is low, the quality of the product is high, and a product can be remotely conveyed and stored for a long time, so that the reduction, the recycling and the innocent treatment of the domestic garbage can be achieved.

Owner:TSINGHUA UNIV

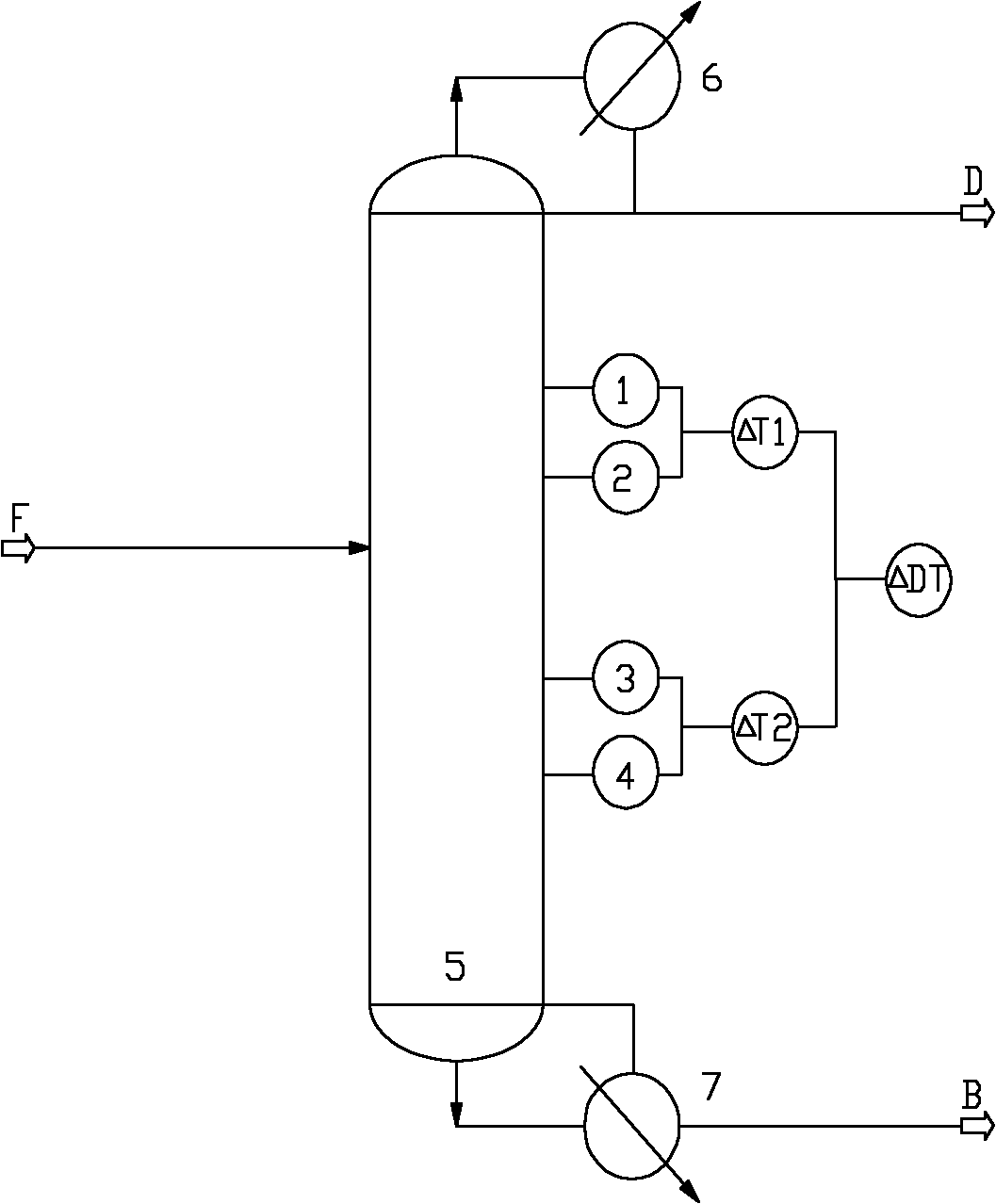

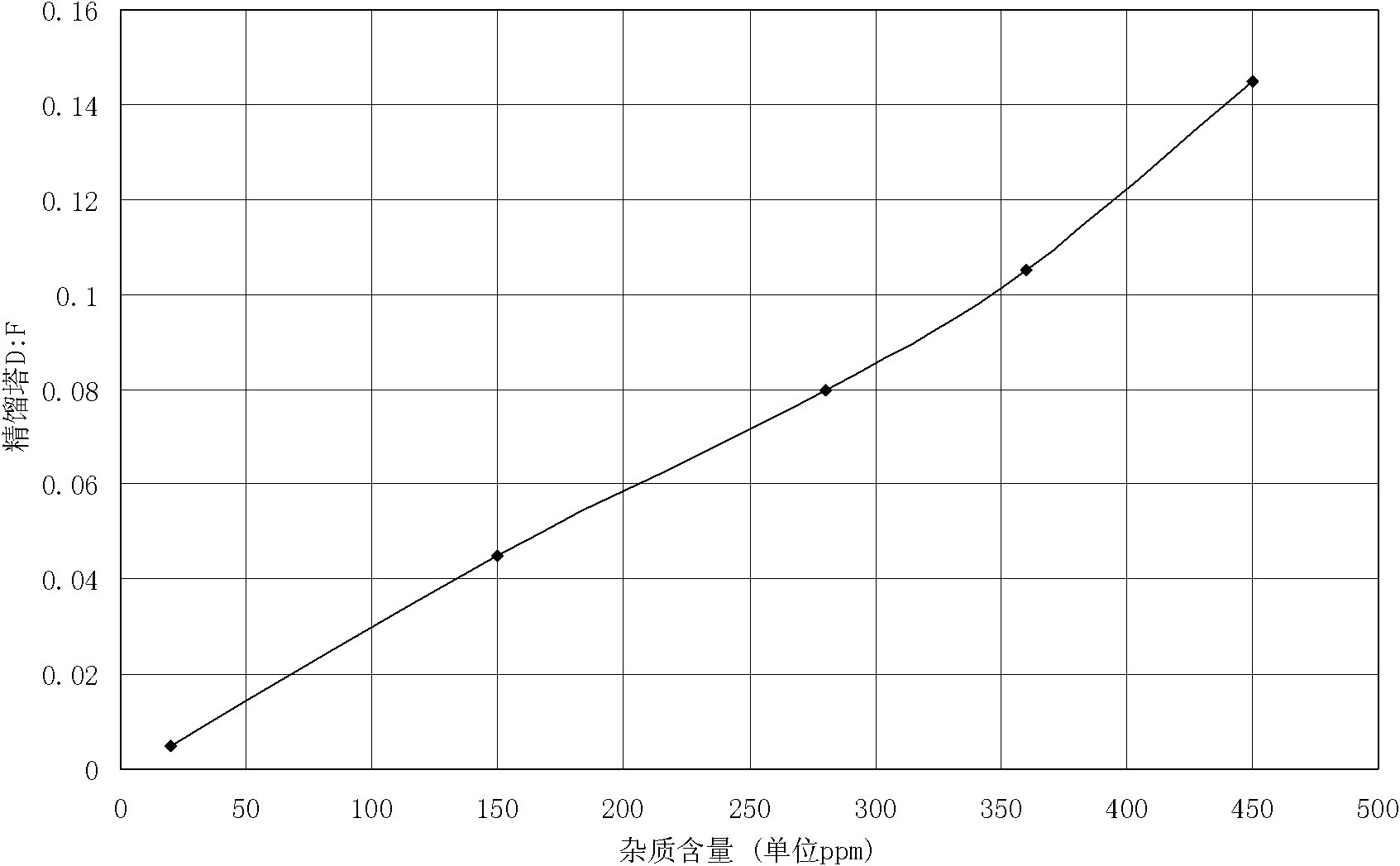

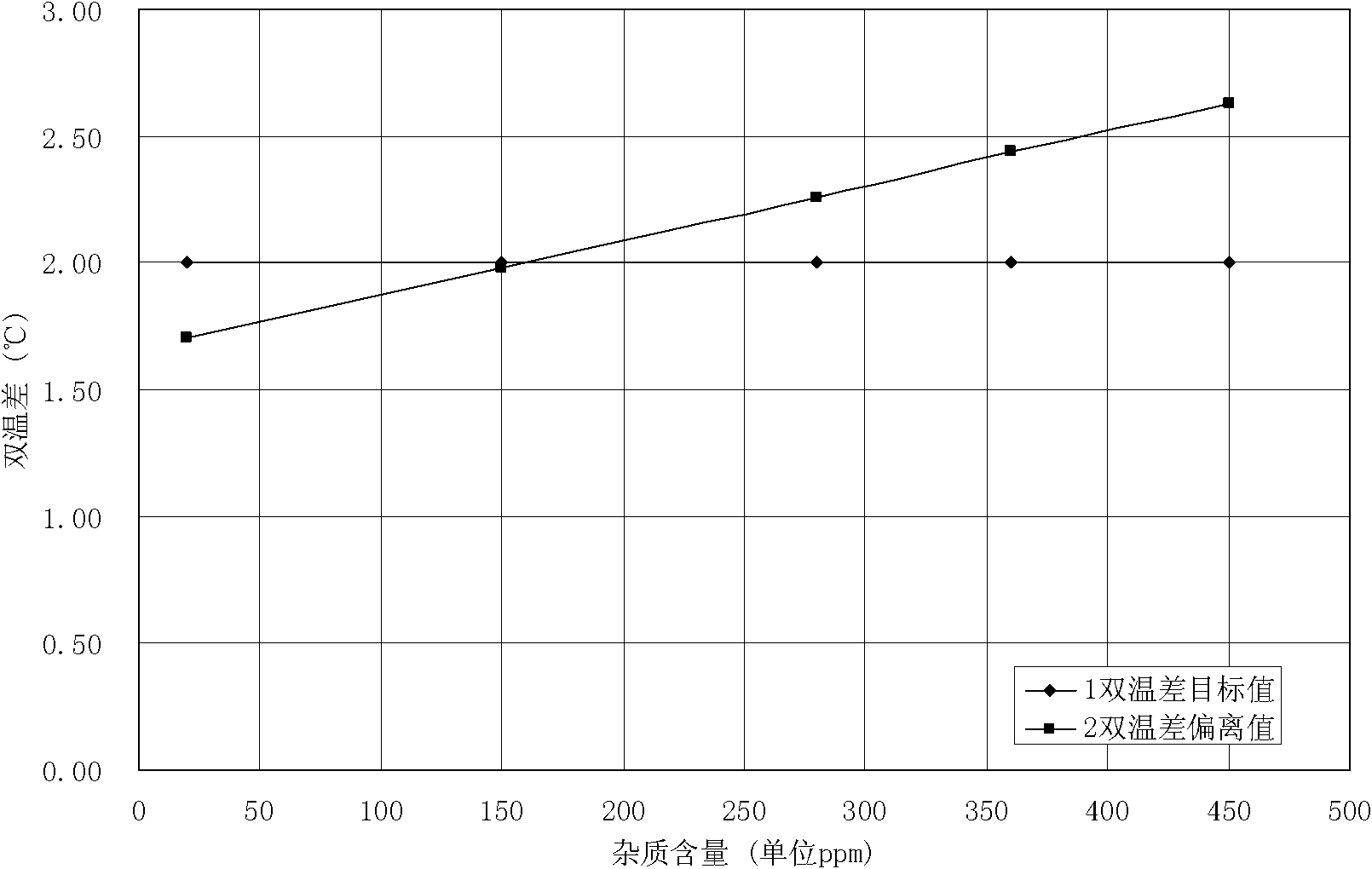

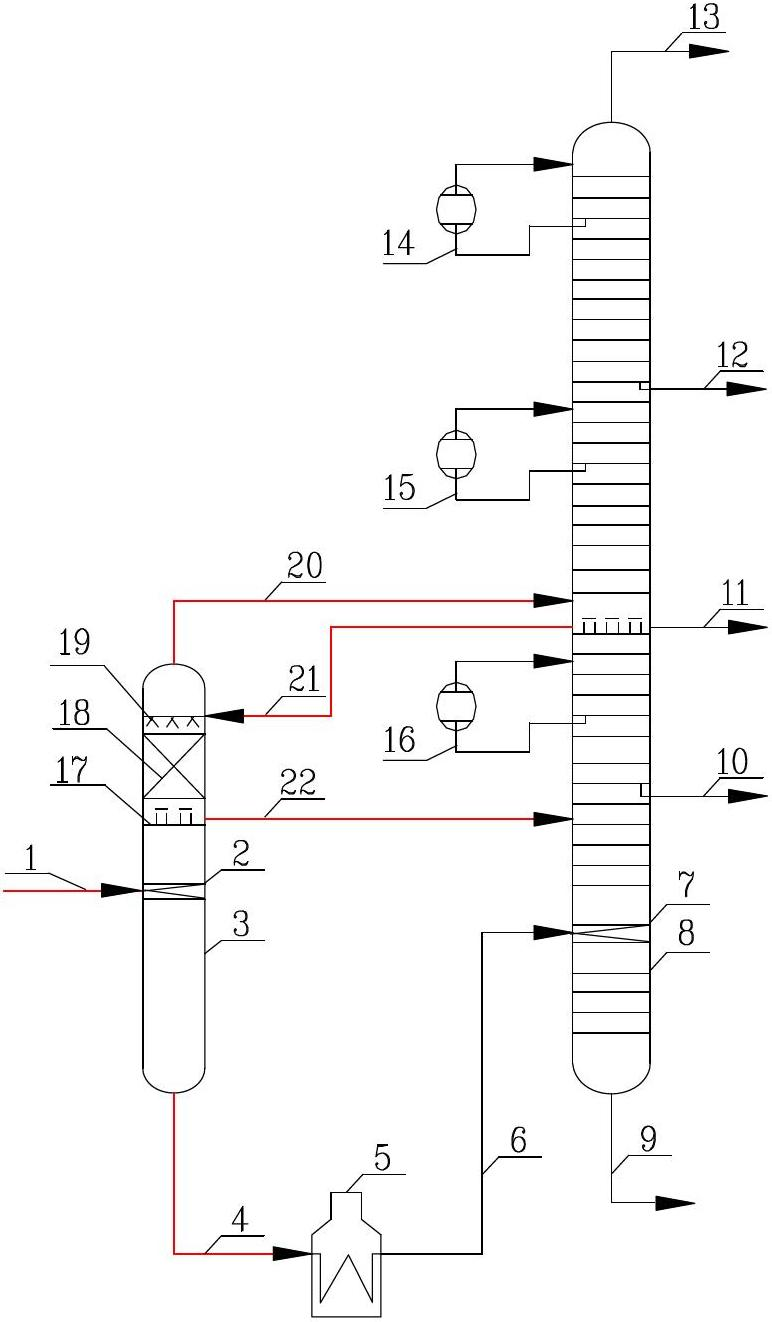

Control method for stably adjusting purity of trichlorosilane

InactiveCN102101672AEliminate impact on product qualityQuality improvementHalogenated silanesTwo temperatureEngineering

The invention provides a control method for stably adjusting the purity of trichlorosilane. Polycrystalline silicon is prepared according to vapor deposition of Siemens, crude chlorosilane is continuously introduced into a rectifying tower, and tower operating characteristics and reflux quantity are not changed. The control method is characterized in that: four temperature measuring points are respectively arranged in a rectifying section and a stripping section, two temperature difference values are calculated, and a double temperature difference value is obtained by subtracting one temperature difference value by the other temperature difference value; the aim of controlling the impurity element content of produced liquid at the bottom of the tower is fulfilled by stabilizing the double temperature difference value and adjusting a ratio of distillate quantity D to feed quantity F on the top of the tower, and the high-purity trichlorosilane is obtained; moreover, products with different purities can be obtained by adjusting different temperature difference points. By the control method, the quality of the trichlorosilane is ensured, and unnecessary loss of the trichlorosilane is reduced.

Owner:HUALU ENG & TECH

Method for conducting mixed preparation of tracer composition through boiling granulator

InactiveCN106565386AImprove working environmentAvoid harmExplosive working-up apparatusGeneral screeningChemistry

The invention provides a method for conducting mixed preparation of tracer composition through a boiling granulator. The method mainly includes the steps of raw material preparation, weighing and general screening, solution weighing, preparing and filtering, equipment parameter setting, no-load check of equipment, adding of raw materials, granulator starting and drug mixing, material discharging and the like. The tracer composition prepared through the method can meet performance and use requirements of products, medicament mixed preparation uniformity and product quality stability are greatly improved, and the method has the advantages that manufacturing is safe, and damage of dust to human bodies and environmental pollution are eliminated.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

Two-way and double-station threading machine

InactiveCN104174939AGood for up and down movementIncrease profitThread cutting machinesDriving apparatusReducerIndustrial engineering

The invention discloses a two-way and double-station threading machine which comprises a stand; the stand is provided with a movable bracket; a thread tapping main shaft is driven to work left and right by the movable bracket so as to carry out alternate processing on two workpieces, so that the idle waiting time is shortened, and the production efficiency is increased; furthermore, the workpieces are matched with the movement of a screw tap, and the loss of the screw tap is less; the influence of human factors to the product quality is completely eliminated in the production, the problems of thread tapping concentric reducer and slanting buckling of the traditional device can be solved, and the thread tapping products are high in yield.

Owner:李洪明

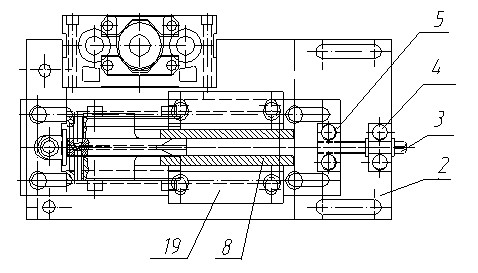

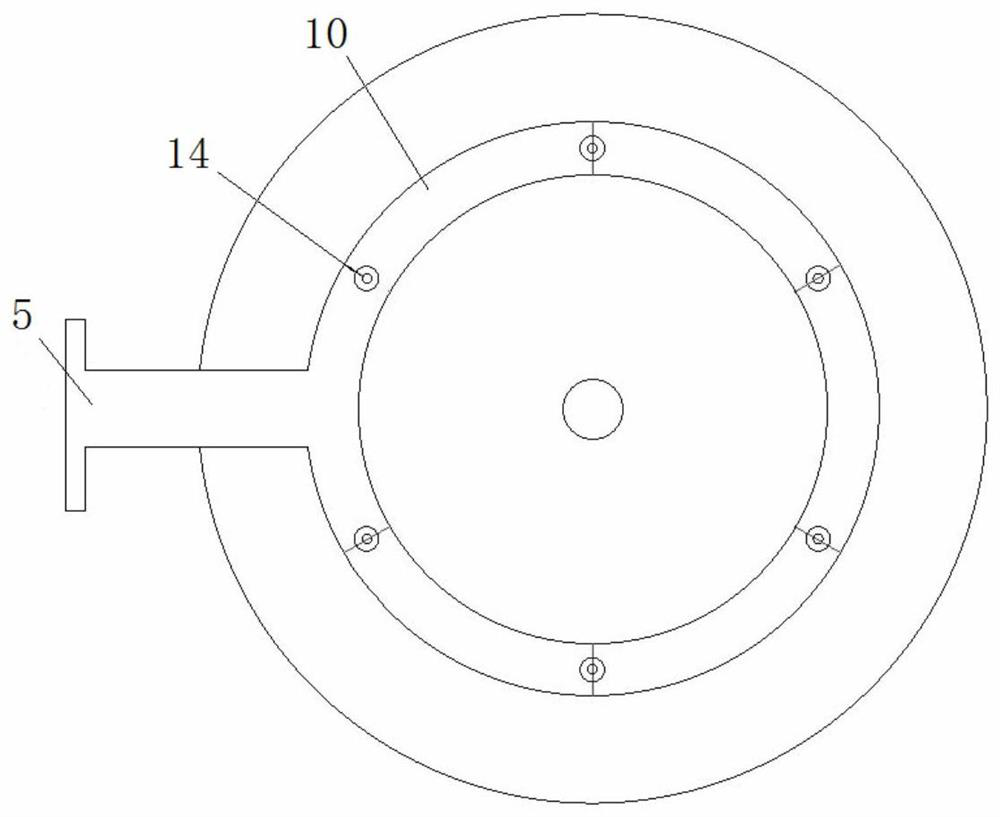

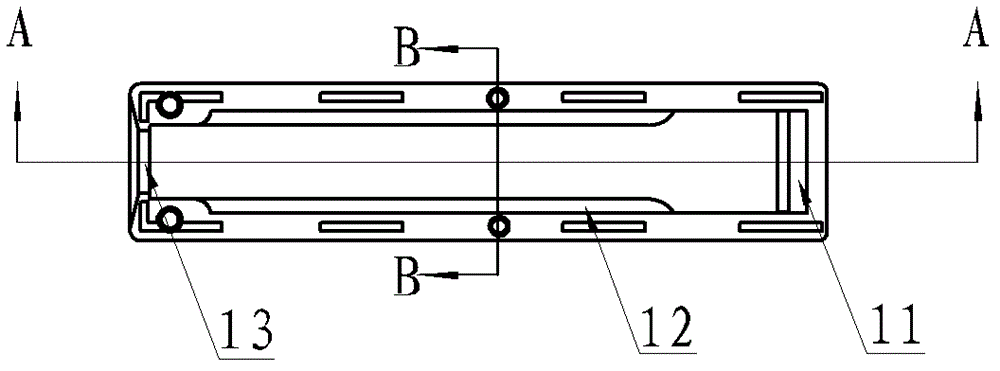

Special fixture for radial porous parts

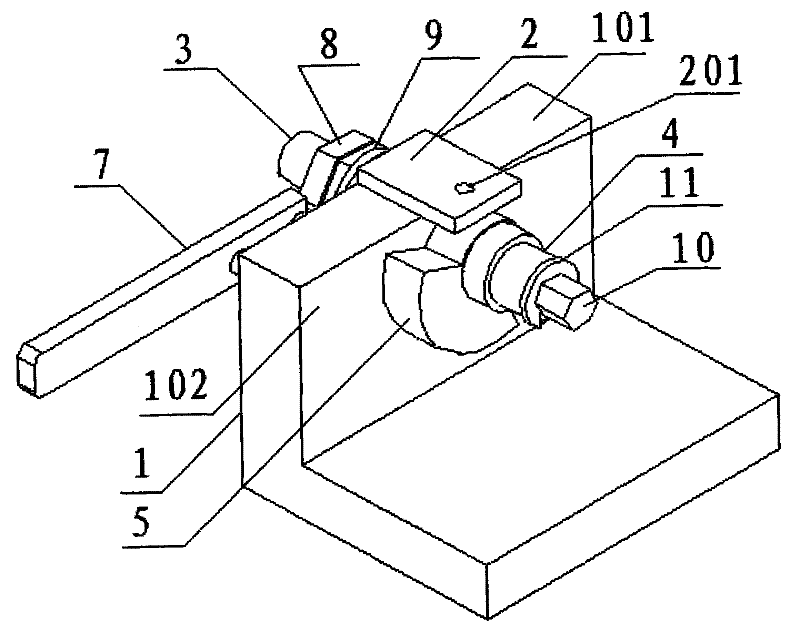

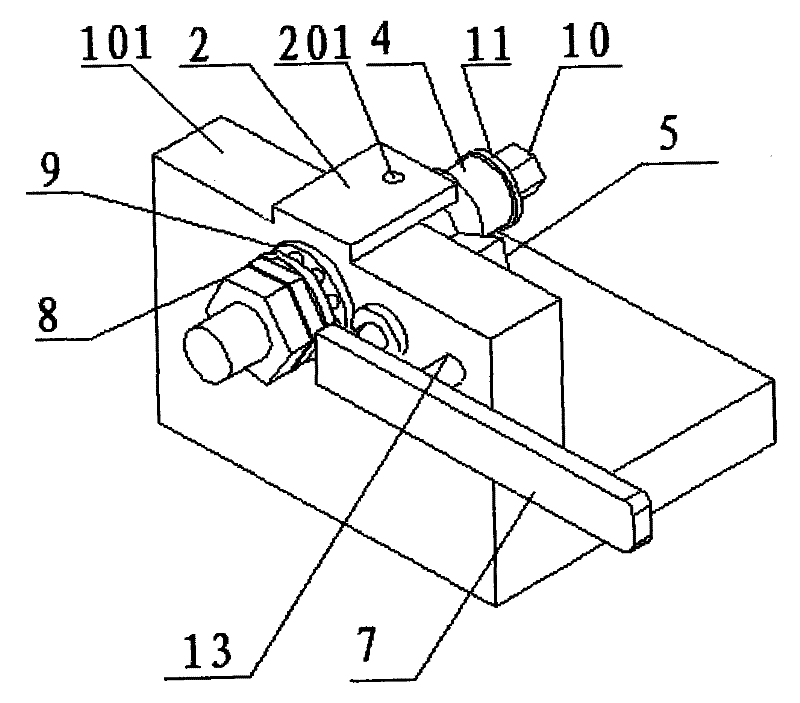

InactiveCN102528492AAvoid multiple clampingAvoid timePositioning apparatusMetal-working holdersFree stateEngineering

The invention relates to a special fixture for radial porous parts, and the special fixture comprises a base, wherein the base comprises a first plane and a second plane which are vertical to each other, a drilling template is arranged on the first plane, a hole site is formed on the drilling template, and a screw hole and a draw bar hole are formed on the second plane, a screw is rotatably arranged in the screw hole, one end, positioned below the drilling template, of the screw is provided with a locating shaft for installing a part to be processed, the screw is also fixedly provided with a locating block, the locating block is arranged between the locating shaft and the base, a panel, opposite to the base, of the locating block is provided with a plurality of locating pits, a draw bar is rotatably arranged in the draw bar hole, one end of the draw bar is connected to a draw bar handle, the other end of the draw bar is provided with a draw bar contact head which can retract under external action and extend in a free state, the draw bar contact head is arranged at one side, which is provided with the locating block, of the base, and the draw bar contact head is positioned in the locating pits when in the free state. After the fixture is used, the processing efficiency is greatly improved and the product quality is stable.

Owner:JIANGSU WANGONG TECH GRP CO LTD

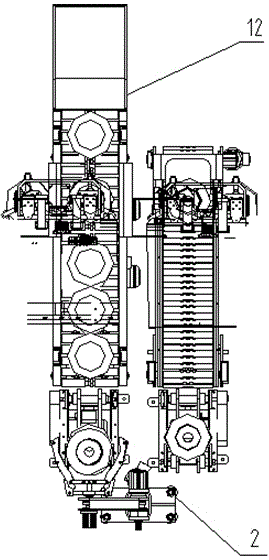

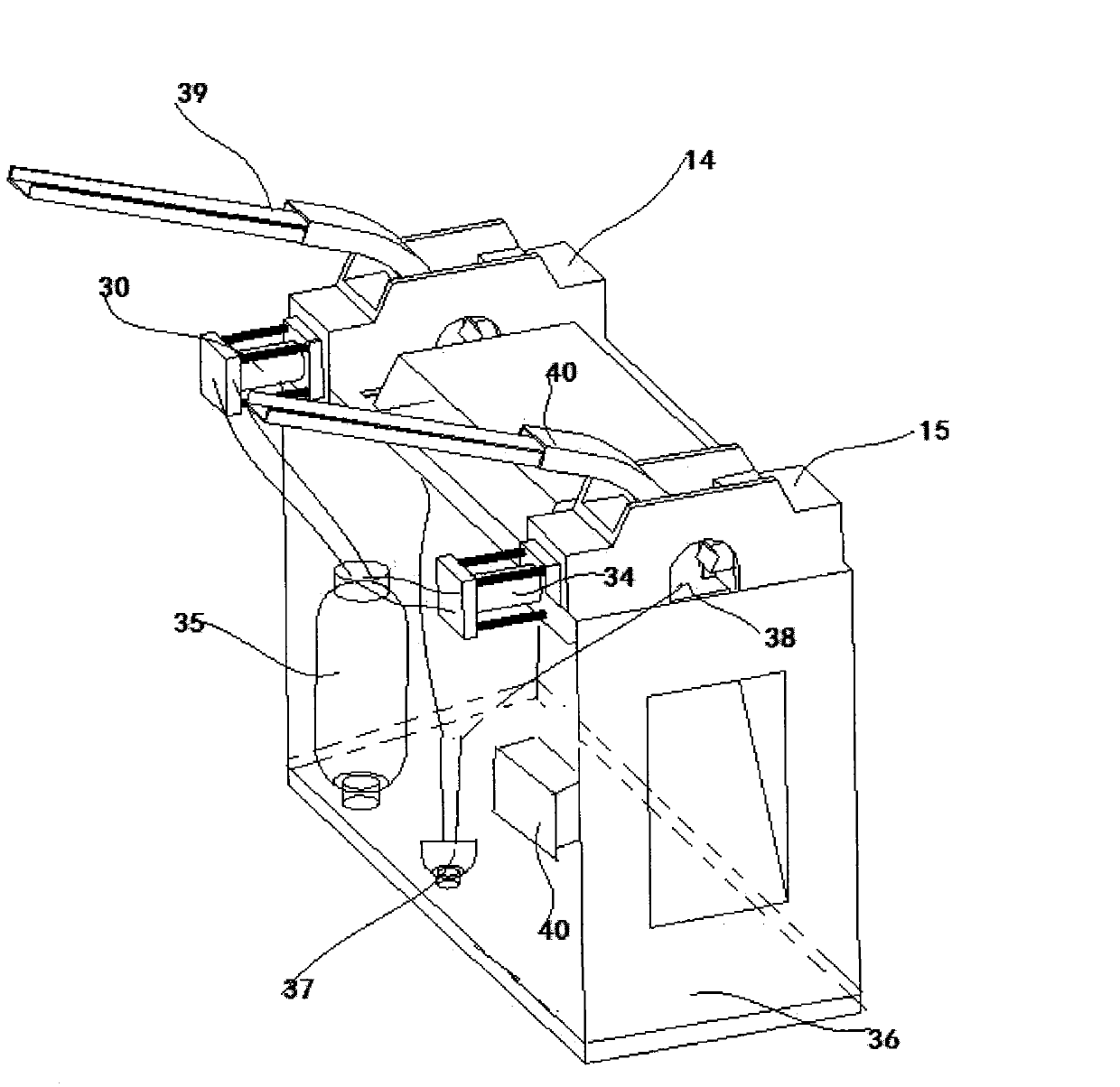

Full-automatic cutting machine of numerical controlled valve

InactiveCN101927355BRealize automatic feeding processEliminate impact on product qualityTurning machinesNumerical controlEngineering

The invention relates to a full-automatic cutting machine of numerical controlled valve, which comprises a machine body, a feeding mechanism, a positioning mechanism, a geared head, a knife rest mechanism, a pushing mechanism and a numerical controlled electric box. The positioning mechanism utilizes a rigid ball base rotary positioning head and a positioning fixture at the end face of a valve disk part in the geared head to realize the full length cutting processing of the valve, and utilizes a flexible ball base rotary positioning head and a positioning fixture at the conical surface of the valve disk part in the geared head to realize the L-check size grooving processing of the valve. The rigid and flexible ball base rotary positioning heads overcome friction between workpieces and a positioner, eliminate the influences of the flat beat of the valve on positioning precision and the length precision of the processed valve reaches 0.025mm. The cutting machine has simple structure, convenient operation and high full-automatic processing efficiency, is applicable to the full length cutting and grooving of the valve, and can be expanded to use the conical surface of the valve to position and process a sandwich groove of a lock and chamfer the end face of a valve rod; therefore, the full-automatic cutting machine has a wide application prospect.

Owner:马勒三环气门驱动(湖北)有限公司

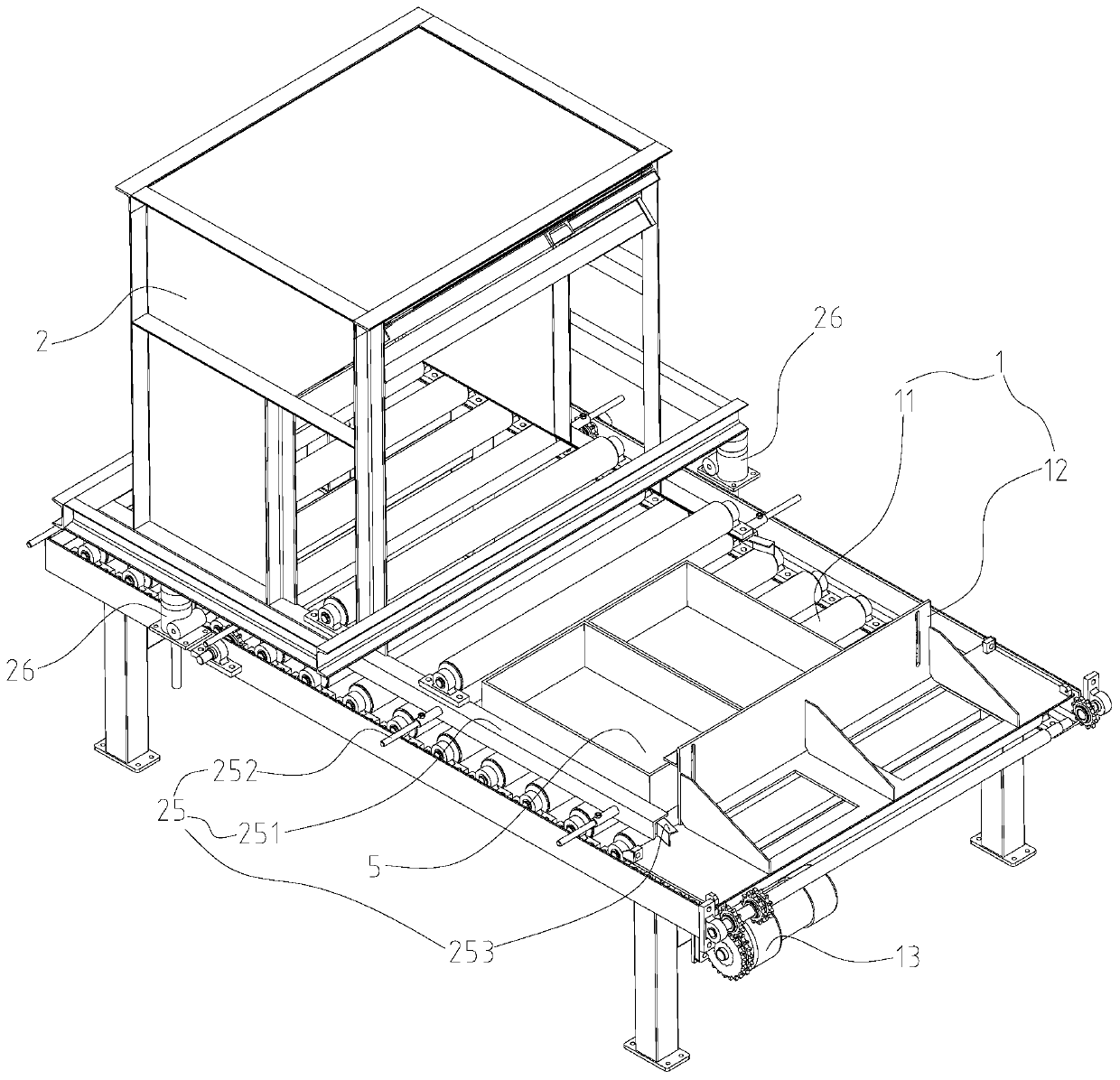

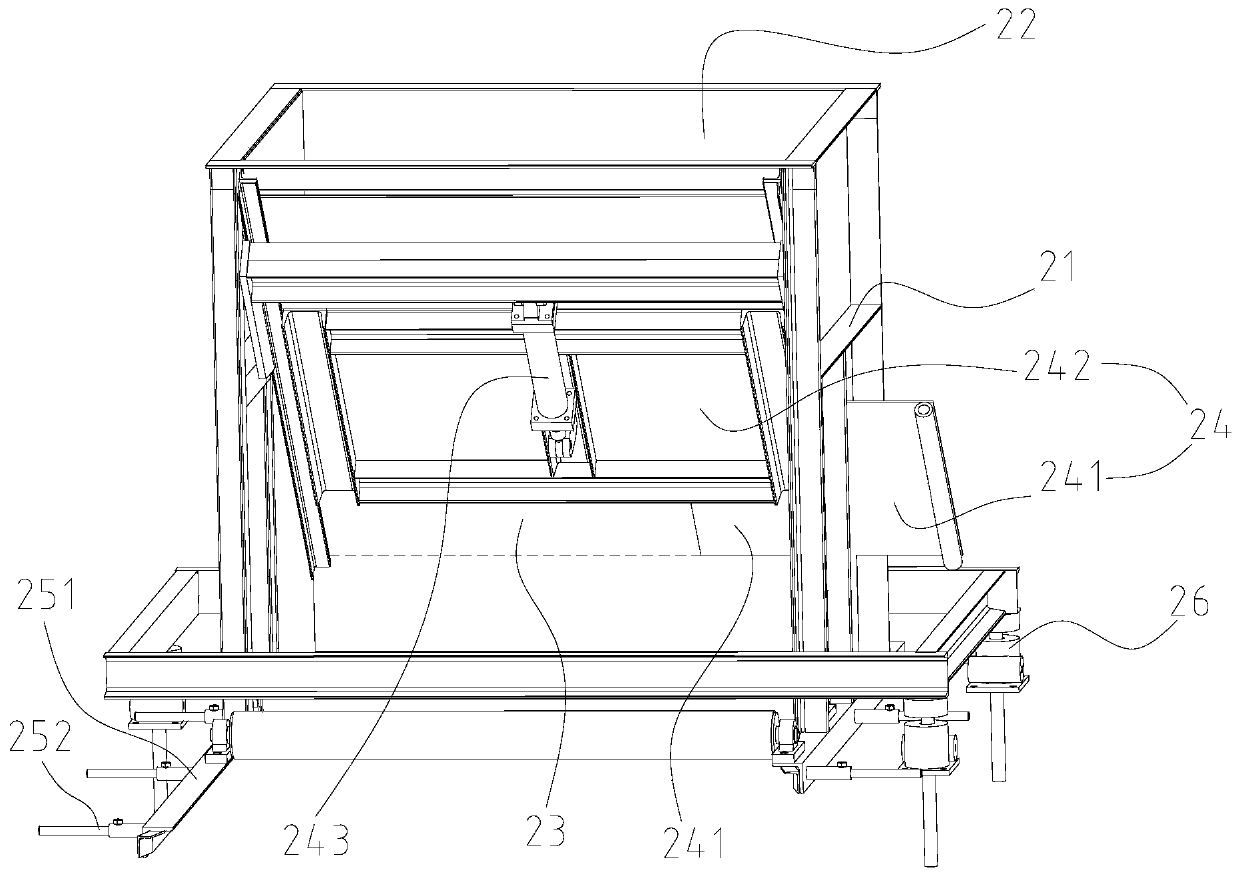

Precast concrete material distributing machine

PendingCN110466047AHigh degree of automationReduce the number of operatorsCeramic shaping plantsFeeding arrangmentsPrecast concreteAutomation

The invention provides a precast concrete material distributing machine and relates to the technical field of concrete pouring equipment. The precast concrete material distributing machine mainly solves the technical problems that in the prior art, the concrete manufacturing process has low automation degree and needs multiple people to work collaboratively. The precast concrete material distributing machine comprises a mold pushing device, a feeding device, vibration devices and a vehicle-loading device. The feeding device is located on the mold pushing device, and the mold pushing device canpush molds under the feeding device. The mold pushing device is connected to the vibration devices so that the molds can be transferred to the vibration devices after being filled. The vibration devices are connected to the vehicle-loading device, and the vehicle-loading device transfers and / or loads the molds on the vibration devices. By the adoption of the precast concrete material distributingmachine, the automation degree of the production process of precast concrete can be effectively increased, and the different product quality caused by the difference in the degree of operation and / orthe operation precision of operators is avoided; and on the other hand, the number of operators can be reduced from 6 to 7 people to 1 to 2 people, and thus the personnel cost is reduced.

Owner:久石(山东)智能设备有限公司

Tab flattening method of all-tab cylindrical lithium batteries

ActiveCN113560369AEliminate impact on product qualityImprove pass rate and safety performanceCell component detailsPhysicsMechanical engineering

The invention discloses a tab flattening method of all-tab cylindrical lithium batteries. The tab flattening method of the all-tab cylindrical lithium batteries mainly comprises the following steps: sleeving each all tab with a flattening sleeve; and therefore, making a flattening head get close to the flattening sleeve while rotating so that the flattening head can directly grind and act on the flattening sleeve after being in contact with the flattening sleeve, and driving the flattening sleeve to elastically deform so that grinding force can be conducted and act on the all tabs to complete flattening. According to the flattening method, the flattening head is not in direct contact with the all tabs, that is to say, the flattening head is not in direct contact friction with the all tabs, and thus the soft all tabs can be effectively prevented from being partially crushed, so that effects on the product quality are eliminated, and the qualification rate and the safety performance of products are better improved; and meanwhile, the flattening sleeve is made of a wear-resistant elastic deformation material so that the elasticity can be recovered after flattening of the all tabs is completed, and thus the working purpose of circular flattening can be achieved.

Owner:宁波久钜智能装备有限公司

Copper bar continuous extrusion short process production method

InactiveCN105107862AImprove conductivityEliminate impact on product qualityExtrusion control devicesDrive wheelFriction effect

The invention provides a copper bar continuous extrusion short process production method. The copper bar continuous extrusion short process production method comprises the following steps of selection of a round copper bar: selecting the round copper bar of which the copper content is 99.95% as a base material; extrusion of the base material: driving the base material into a cavity of a mold under the friction effect of a driving wheel to perform moulding deformation extrusion to obtain a profile; cooling of the profile: cooling down the extruded profile in a cooling kiln in a segmented manner under the protection effect of nitrogen; and rolling: storing the profile which is cooled down to normal temperature in a rolling manner. By the method, the round copper bar is driven to the mold under the friction effect of an extrusion wheel and is extruded continuously, and the copper profile is formed finally. Suitable mold orifices are designed according to different production requirements, and then various special-shaped materials can be produced and machined.

Owner:YUNNAN NEW COPPERSMITH INDAL

Automatic unloading device for UO2 grinding core blocks

ActiveCN108249149AAchieve staff reduction and increase efficiencyReduce labor workloadConveyorsCleaning using toolsEngineeringElectrical and Electronics engineering

The invention discloses an automatic unloading device for UO2 grinding core blocks. The automatic unloading device comprises a mechanism for stacking core blocks on a tray, a core block off-line scrubbing mechanism, a charging tray carrying mechanism, an empty charging tray loading mechanism and a full charging tray unloading mechanism; after core blocks on a grinding line enter the device, the core blocks are firstly stacked orderly row by row through the mechanism for stacking the core blocks on the tray; after the whole tray of the core blocks is stacked, the core blocks are poured out of the tray, and enter the core block off-line scrubbing mechanism to be scrubbed off line; after the core blocks are scrubbed off line, the tray filled up with the core blocks is fed to the charging trayunloading mechanism for being stacked through the charging tray carrying mechanism; and empty charging trays are carried to the tail end of the core block offline scrubbing mechanism from the charging tray charging mechanism through the empty charging tray loading mechanism to wait for loading. The automatic unloading device for the UO2 grinding core blocks belongs to professional equipment, completely depends on independent development and development, and is initiative in China.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

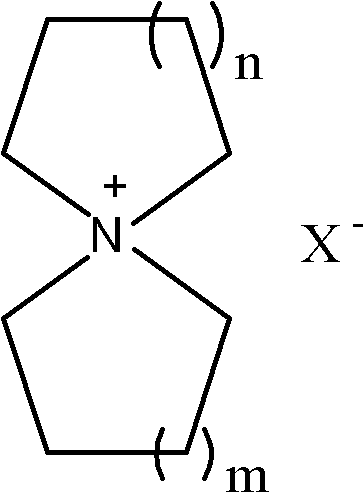

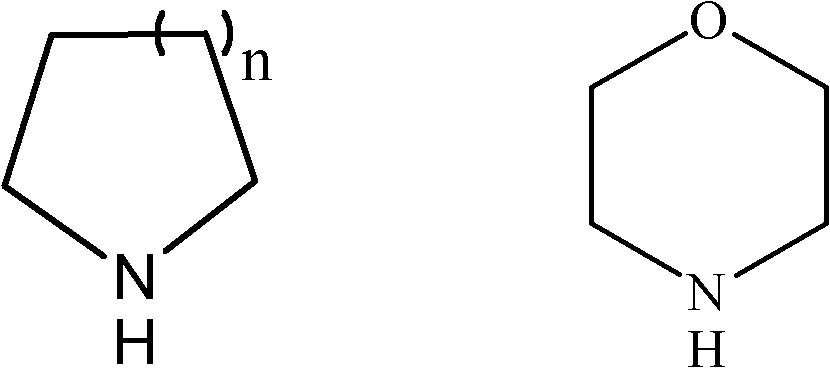

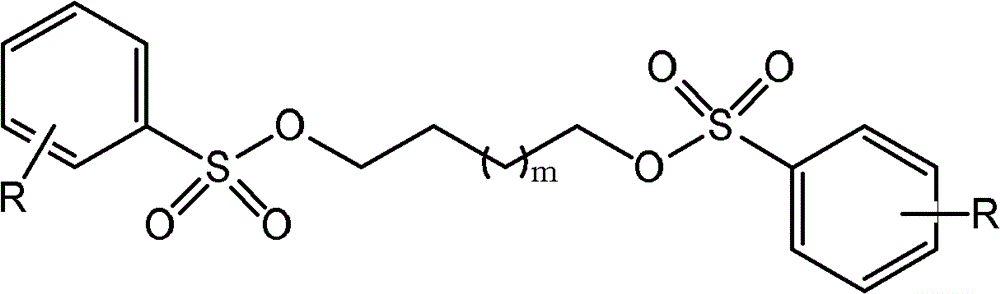

Preparation method of spiro quaternary ammonium salt for organic electrolyte of super capacitor

The invention discloses a preparation method of a spiro quaternary ammonium salt for an organic electrolyte of a super capacitor, which comprises the following steps: by using water as a reaction medium, enabling cyclic diamine and diol disulfonate to be subjected to condensation reaction at a certain temperature to obtain a corresponding spiro quaternary ammonium salt; carrying out ion exchange on the ammonium salt to obtain a corresponding spiro quaternary ammonium salt; and finally, purifying to obtain the target product. The method disclosed by the invention has good selectivity, increases the yield of the target product, improves the quality, and can lower the impurity content in the electrolyte to 5 ppm or below, thereby meeting the requirements of the organic electrolyte of a super capacitor.

Owner:BOHAI UNIV

Method for producing full-water-soluble sugarcane yield-increasing and sugar-increasing fertilizer by utilizing marine wastes

PendingCN113999068AEliminate impact on product qualityThe process is easy to implementBio-organic fraction processingAnimal corpse fertilisersAgricultural scienceHydrolysate

The invention relates to a method for producing a full-water-soluble sugarcane yield-increasing and sugar-increasing fertilizer by utilizing marine wastes, belonging to the technical field of chemical regulation and control of sugarcane, and the method for producing the full-water-soluble sugarcane yield-increasing and sugar-increasing fertilizer comprises the following steps: raw material extraction, raw material enzymolysis and compounding. On one hand, active ingredients in the shell / oyster powder are activated and extracted to obtain an extracting solution, on the other hand, aquatic product processing leftovers are subjected to enzymolysis through compound enzyme to obtain enzymatic hydrolysate, then the extracting solution and the enzymatic hydrolysate are mixed in proportion, a proper amount of auxiliary materials are added, and the full-water-soluble sugarcane yield-increasing and sugar-increasing fertilizer is formed. The preparation method does not need special equipment, the equipment is simple, the process is easy to implement, the influence on surrounding environmental factors is extremely low, additional wastewater is not generated, and the preparation method is more environment-friendly.

Owner:北海宝农农业科技有限公司

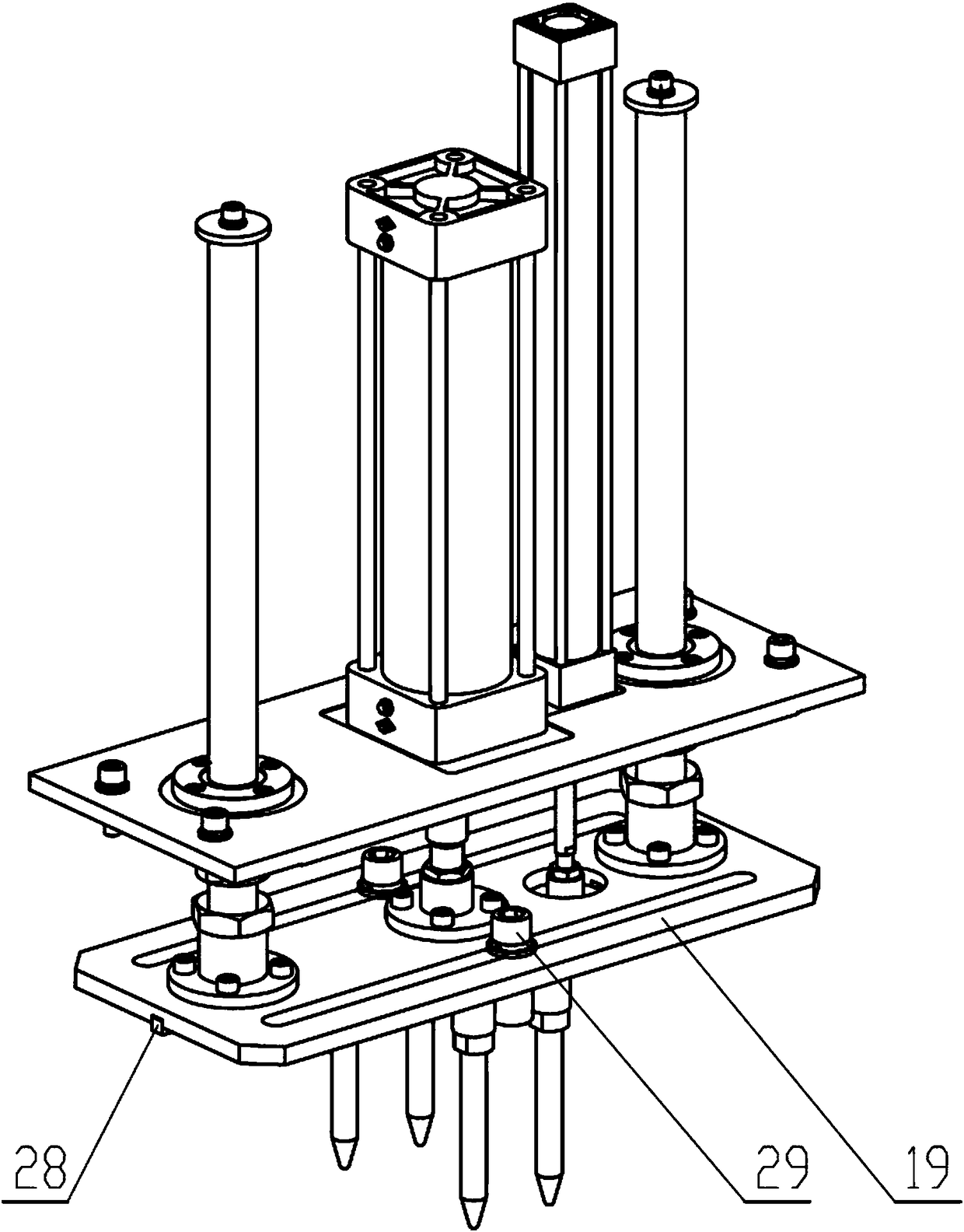

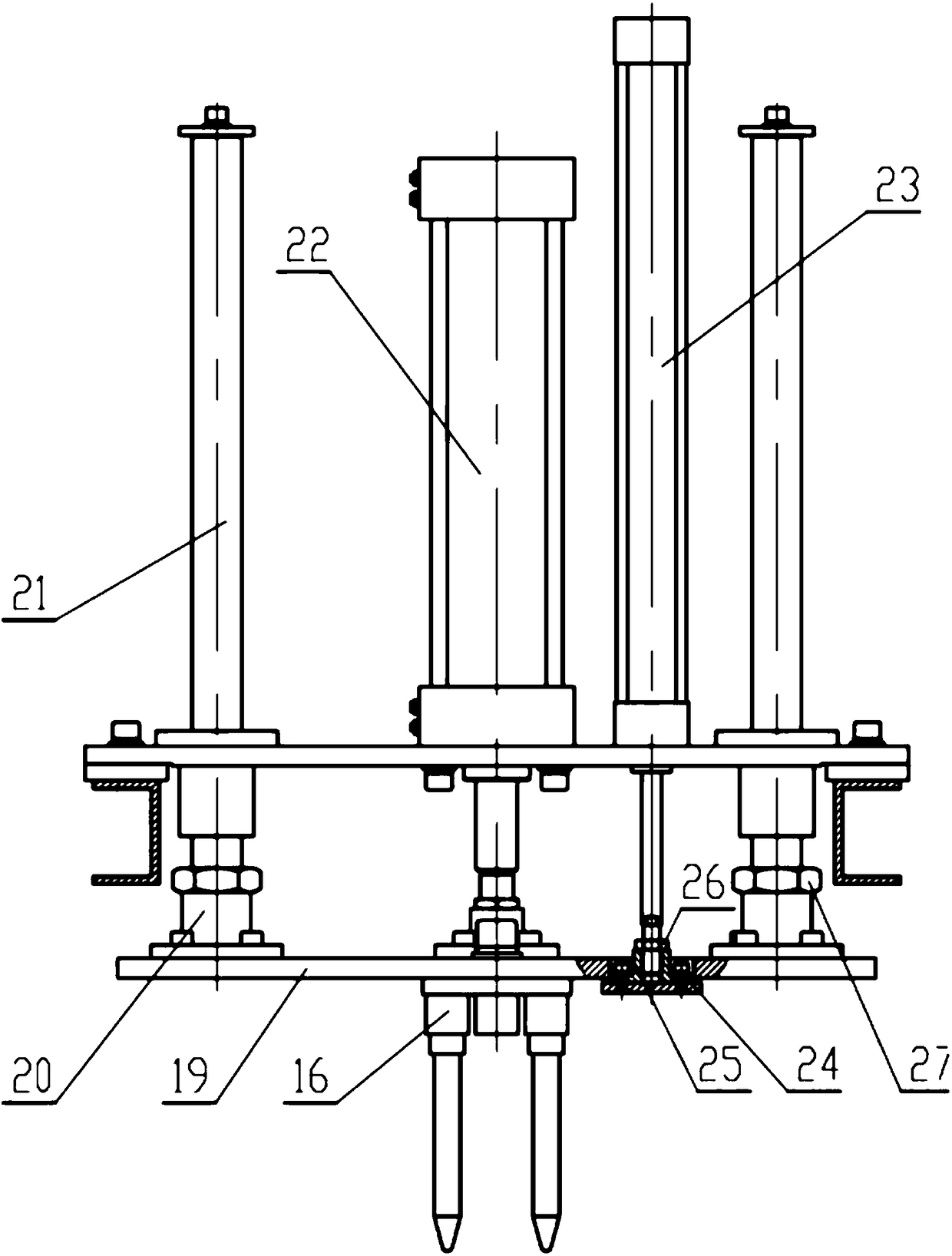

Punching machine for integral ceramic fiber module

InactiveCN108098903AImprove drilling efficiencyEliminate impact on product qualityMetal working apparatusFiberPunching

The invention discloses a punching machine for an integral ceramic fiber module. During use, the to-be-punched integral ceramic fiber module is placed on a workbench, then a second air cylinder pushesan anti-rising plate to move downwards until the anti-rising plate just makes contact with the integral ceramic fiber module, then a first air cylinder pushes pressing heads to move downwards in thevertical direction to perform punching, when the pressing heads return, the anti-rising plate still blocks the integral ceramic fiber module so as to make the integral ceramic fiber module stay on theworkbench, when the pressing heads are completely separated from the integral ceramic fiber module, the anti-rising plate returns to the original position in the vertical direction under the action of the second air cylinder, so that one punching cycle is completed; and the above operation steps of punching are repeatedly executed, and therefore continuous punching can be carried out on the integral ceramic fiber module, the punching efficiency of the integral ceramic fiber module is improved, and the influence of human factors on the product quality is eliminated.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Feeding device for amorphous alloy ribbons

InactiveCN101643160AAvoid harmRemove threatInductances/transformers/magnets manufactureArticle deliveryEngineeringAlloy

The invention relates to a feeding device for amorphous alloy ribbons, which is provided with a feed channel for transporting the amorphous alloy ribbons. The feed channel comprises distributing racks which are arranged in sequence, a vibrator, a cradle and upper and lower feed rollers, which are distributed on a rack in sequence, wherein, the vibrator is provided with a vibrating trough which isconnected with a vibration driving mechanism driving the vibrating trough to vibrate; the vibration driving mechanism can comprise a vibrating cylinder and a pressure-regulating valve of the vibrating cylinder; the front of the bottom surface of the vibrating trough is hinged with the rack and the back thereof is connected with the cylinder. The feeding device features simple structure, convenient use and high production efficiency and can automatically remove the scraps on the amorphous alloy ribbons so as to avoid the operators from being harmed and the product quality from being influenced.

Owner:BEIJING ZJLG AMORPHOUS TECH CO LTD +1

Electromagnetic damping type automatic tobacco sorting manipulator

The invention relates to an electromagnetic damping type automatic tobacco sorting manipulator. The manipulator is arranged above a conveying belt used for conveying tobaccos, and comprises a brush mechanism and two guide rails, wherein the brush mechanism is used for sweeping the tobaccos on the conveying belt into a tobacco collecting box, the two guide rails are arranged in parallel up and down, and form a rail which is across the conveying belt to be used for enabling the brush mechanism to move back and forth on the rail, an electromagnet is arranged on one end of the rail, an elastic damping mechanism is arranged on the other end of the rail, the brush mechanism is connected with the elastic damping mechanism, an armature which can overcome the elastic force of the elastic damping mechanism so as to be attracted to the electromagnet when the electromagnet is electrified is fixed on the brush mechanism, a photoelectric sensor is arranged above the conveying belt, and both the photoelectric sensor and the electromagnet are connected with a control mechanism. The electromagnetic damping type automatic tobacco sorting manipulator has the advantages of simple structure and high degree of automation and is favorable for improving the product quality, releasing the labor force and saving the cost.

Owner:HENAN UNIV OF SCI & TECH

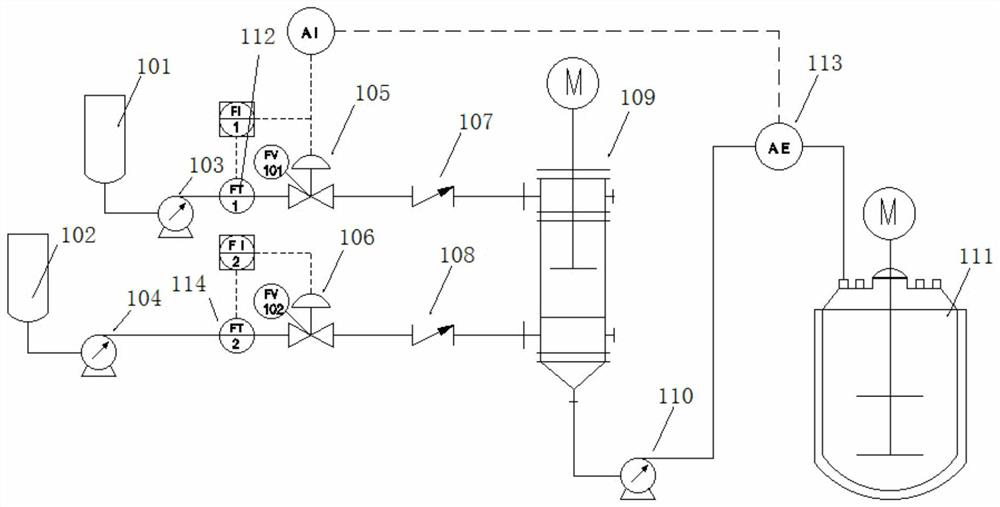

Device and method for continuously preparing azo compound

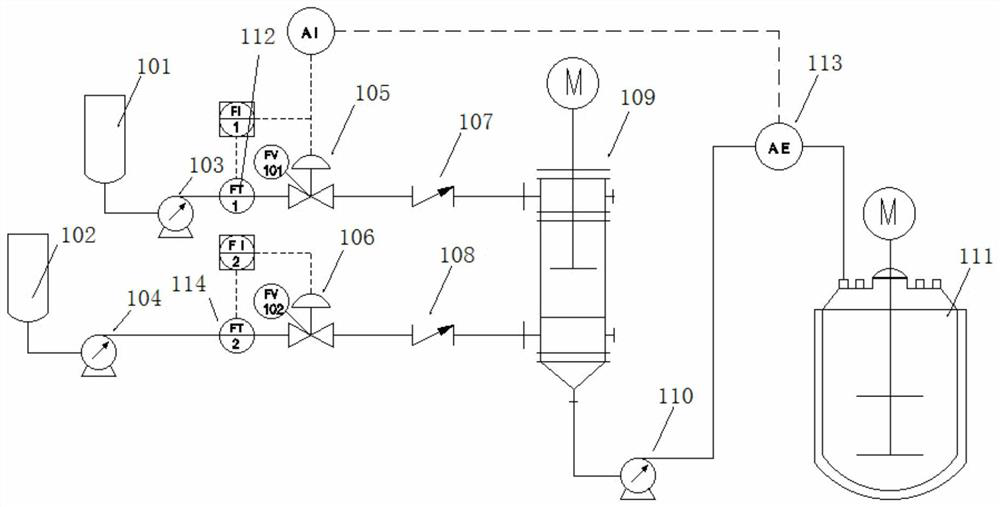

ActiveCN112169746AEnhanced mass transferImprove reaction efficiency and product yieldChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical stationary reactorsChemical industryProcess engineering

The invention relates to the field of mixing devices in the chemical industry, in particular to a device and method for continuously preparing azo compound. After the diazonium salt solution in a first storage tank 101 and the coupling component solution in a second storage tank 102 continuously collide, mix and react in an impinging stream stirring reactor 109, the generated material is conveyedinto a slurry tank 111 under the action of a discharge pump 110, and the azo compound is obtained. The device is compact in overall structure and small in occupied area, can be used for chemical unitoperation of extraction and rapid mixing reaction, is particularly suitable for reaction for producing high-viscosity materials after mixing reaction, and facilitates continuous operation. According to the method disclosed by the invention, a micro impinging stream technology is combined with a stirring reactor so that mass transfer is enhanced, the blockage problem is effectively prevented, automatic control is conveniently realized, the reaction efficiency and the product yield are improved, and continuous synthesis of the azo compound is realized.

Owner:SHENYANG RES INST OF CHEM IND

Preparation process of thermal stabilizer of tin methyl thio hydroacetate tin isooctoate for PVC

Owner:江从宇

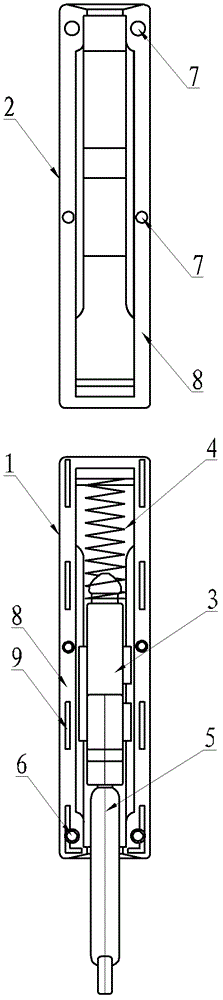

Split welding fixed disposable blood taking needle

ActiveCN102626313BSimple structureEasy to assembleDiagnostic recording/measuringSensorsJoint surfaceBiomedical engineering

The invention discloses a split welding fixed disposable blood taking needle, which comprises a lower shell, an upper shell, a sliding needle block, a return spring and a needle tip cap, wherein the return spring is arranged on one end of the sliding needle block, the needle pin cap is arranged on the other end of the sliding needle block, an integer formed by connecting the sliding needle block and the return spring and the needle pin cap is arranged in an inner cavity of the lower shell, the upper shell and the lower shell are welded into a whole in a joint surface through the same material plastic-plastic ultrasonic wave connecting technology, thus the upper shell and the lower shell are more firmly connected into a whole. The split welding fixed disposable blood taking needle has the advantages of increasing the operating efficiency by 100 times to 150 times in comparison with manual assembly, being good in connecting quality, being smaller in welding deformation and residual stress due to no need of cooling curing time, increasing yield, ensuring quality from the structure, thus the production efficiency can be greatly increased, the labor cost is lowered, and the quality is improved.

Owner:江苏健裕健康医疗器械有限公司

A kind of device and method for continuous preparation of azo compounds

ActiveCN112169746BRealize continuous synthesisEnhanced mass transferChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical stationary reactorsChemical industryUnit operation

The invention relates to the field of mixing devices in the chemical industry, in particular to a device and method for continuously preparing azo compounds. After the diazonium salt solution in the first storage tank 101 and the coupling component solution in the second storage tank 102 continuously collide and mix in the collision flow stirring reactor 109, the generated materials are sent to the In the slurry tank 111, an azo compound is obtained. The device of the invention has a compact overall structure and a small floor space, and can be used for chemical unit operations of extraction and rapid mixing reactions, especially suitable for the reaction of producing high-viscosity materials after mixing reactions, and is convenient for realizing continuous operation. The method of the invention combines the micro-collision flow technology with the stirring reactor, strengthens the mass transfer, effectively prevents the clogging problem, facilitates the realization of automatic control, improves the reaction efficiency and product yield, and realizes the continuous synthesis of azo compounds.

Owner:SHENYANG RES INST OF CHEM IND

Flash distillation washing method for atmospheric and vacuum distillation of crude oil

InactiveCN102676204AEliminate impact on product qualityReduce heat loadHydrocarbon distillation control/regulationVacuum distillationGas phaseFuel tank

The invention belongs to the technical field of petroleum processing, and relates to a flash distillation washing method for the atmospheric and vacuum distillation of crude oil. The method comprises the following steps: carrying out heat exchange on petroleum dehydrated crude oil, so that light components are vaporized, then feeding oil gas into a flash distillation washing tower through a pipeline to carry out flash distillation, so that light and heavy components of the oil gas are separated; taking flash distillated oil gas carrying the heavy components and part of second side cut distillate oil from an atmospheric tower as washing oil, carrying out reverse contact on the washing oil on packing in the flash distillation washing tower to carry out washing and mass transfer separation, so that flash top oil gas escapes from the top of the flash distillation washing tower and then enters an upper gas-phase space of a second side cut oil extraction plate of the atmospheric tower, and heavy-component washing oil is extracted from an oil collecting tank of the flash distillation washing tower and then automatically flows to places above and below a third side cut extraction plate of the atmospheric tower; after un-vaporized flash bottom oil is pumped out by using a pump from the bottom of the flash washing tower, carrying out heat exchange on the un-vaporized flash bottom oil and heating the un-vaporized flash bottom oil by using an atmospheric furnace, and then feeding the un-vaporized flash bottom oil into the atmospheric tower so as to separate out atmospheric overhead oil, atmospheric lateral line distillate oil and atmospheric heavy oil through distillation. The method disclosed by the invention is reasonable in process route, good in adaptability, good in energy conservation, low in investment, convenient to control, and friendly in production environment.

Owner:COOEC ENPAL ENG

a kind of uo 2 Green blank automatic unloading and palletizing device

ActiveCN108249149BAchieve staff reduction and increase efficiencyReduce labor workloadConveyorsCleaning using toolsEngineeringElectrical and Electronics engineering

The invention discloses a UO 2 The automatic unloading device for grinding pellets includes a pellet coding plate mechanism, an offline pellet scrubbing mechanism, a tray transport mechanism, an empty tray loading mechanism, and a full tray unloading mechanism; when the pellets on the grinding line enter After the installation, the pellets are first neatly coded row by row by the pellet coding disc mechanism; after the entire disc of pellets is coded, the pellets are inverted and sent to the pellet offline scrubbing mechanism for offline scrubbing; the offline scrubbing is completed Finally, the tray transport mechanism will send the tray filled with pellets to the full tray unloading mechanism for palletizing; then the tray transport mechanism will move the empty tray from the empty tray loading mechanism to the pellets offline. Scrub the end of the mechanism and wait for loading. UO 2 The automatic unloading device for grinding core blocks is a professional equipment that is completely independently researched and developed and is the first of its kind in China.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Preparation method of high-purity alkylammonium tetrafluoroborate for super capacitor

ActiveCN102432474BHigh purityHigh yieldOrganic compound preparationElectrolytic capacitorsTetrafluoroborateHalogen

The invention discloses a preparation method of high-purity alkylammonium tetrafluoroborate for a super capacitor, characterized by reacting tertiary amine with tetrafluoroborate alcoxylonium salt at a certain temperature to obtain corresponding alkylammonium tetrafluoroborate, and purifying to obtain the high-purity alkylammonium tetrafluoroborate. The method has the advantages of simple operation steps, good selectivity, high conversion rate, high product purity, and no halogen ions, and can satisfy the requirements of a high performance super capacitor. The use of the prepared alkylammonium tetrafluoroborate as an electrolyte in the super capacitor can achieve the advantages of high product capacity, low internal resistance, and reduced capacity fade at a high temperature.

Owner:锦州凯美能源有限公司

An unsupported 3D suspension printing structure and method

ActiveCN108312497BEnables supportless printingReduce consumptionAdditive manufacturing apparatus3D object support structuresUltrasonic radiationUltrasound Radiation

The invention discloses a support-free 3D (Three Dimensional) suspended printing structure and a support-free 3D suspended printing method. The support-free 3D suspended printing method is characterized in that an ultrasonic suspension method is adopted; parts are putted into a sound field in the 3D printing process of the parts; a suspended or floating part is supported under the action of ultrasonic radiation force; the printing of materials of initial several layers is enabled to be finished so as to support subsequent printing, and further 3D printing of the parts is finished under the support-free condition. According to the support-free 3D suspended printing structure and the support-free 3D suspended printing method disclosed by the invention, on the one hand, the cost of supportingmaterials is greatly reduced and the manufacturing efficiency is greatly improved; on the other hand, the influence on product quality, which is possibly caused by unfavorable support, is eliminated.In particular to thin shell parts, certain supporting materials even account for 60 percent or above of the use amount of the integral material; if the parts are printed under the support-free condition, the cost is predicted to be reduced by 50 percent or above, and the manufacturing cycle is shortened by 40 percent or above; in addition, the worry about quality problem caused by support removalis avoided.

Owner:XI AN JIAOTONG UNIV +1

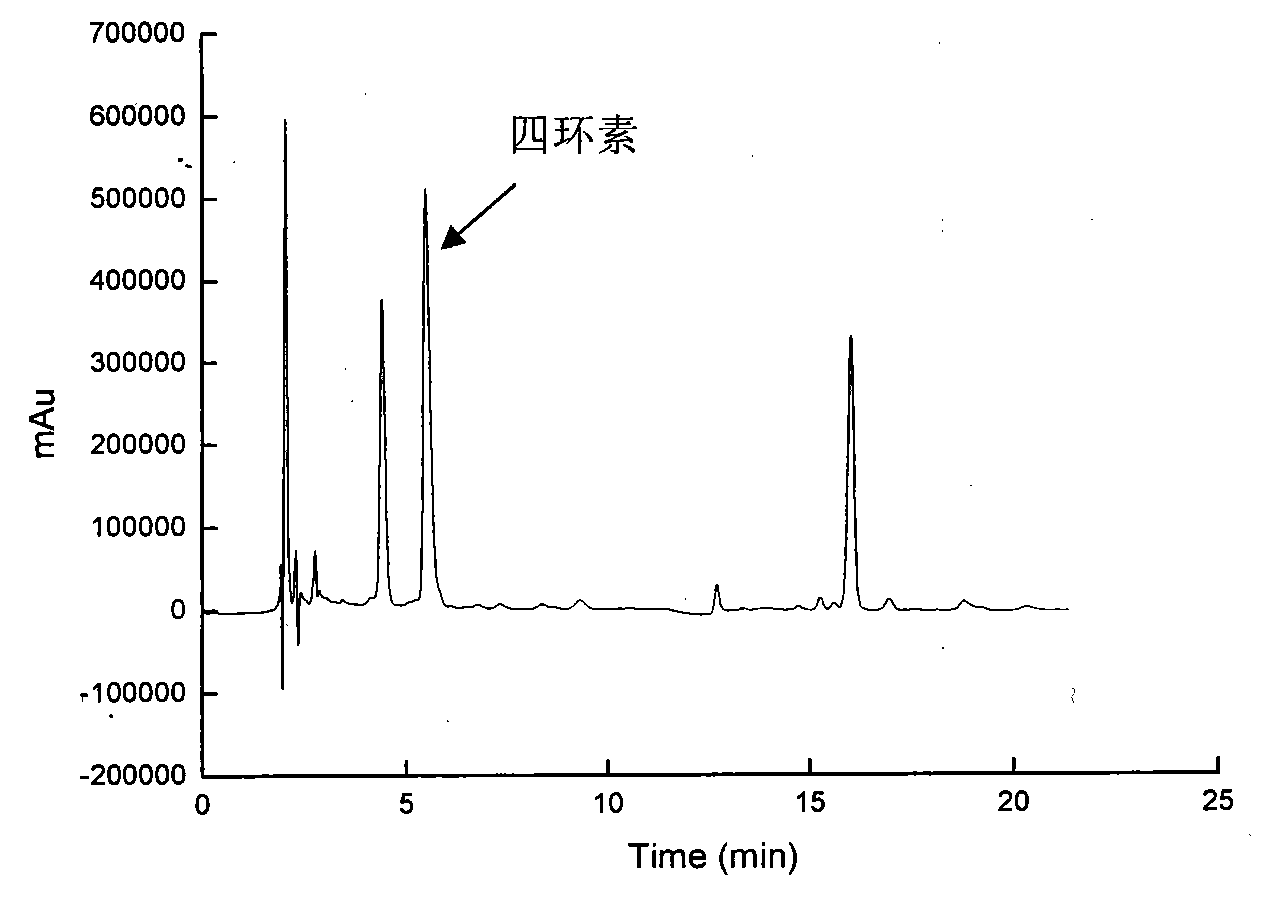

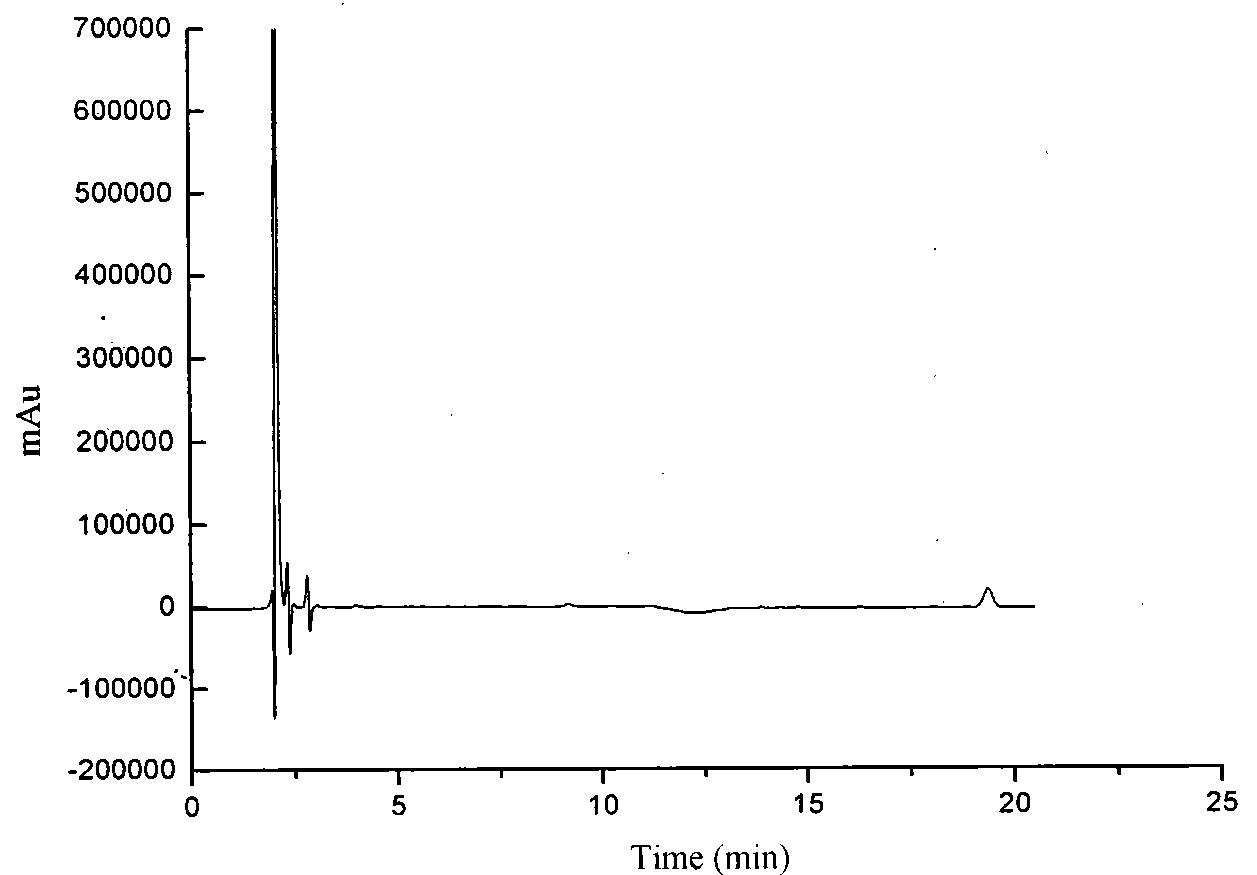

Method for producing yeast extract by use of bacterial residues after tetracycline degradation

InactiveCN103555583AUnique preparation processFull of nutritionMicroorganism lysisMicroorganism based processesEffective microorganismCandida tropicalis

The invention discloses a method for producing a yeast extract by use of bacterial residues after tetracycline degradation, belonging to the technical field of microbial fermentation. The method comprises preparation of saccharomyces cerevisiae, candida tropicalis and EM (effective microorganisms) second-order seed, preparation of aspergillus niger seed, preparation of a bacterial residue culture medium and preparation of the yeast extract, wherein the preparation of the yeast extract comprises the following steps of performing inoculation culture on the prepared several kinds of bacteria; then adding a yeast extraction enzyme according to an amount of 0.03% by mass; hydrolyzing for 16-24 hours; heating to 80 DEG C to inactivate the enzyme; after the product is cooled, centrifuging for 10 minutes at a speed of 4,000r / min; performing reduced-pressure concentration on the filtrate while controlling the moisture to 15-20% to obtain the yeast extract. The method disclosed by the invention has the advantages of low production cost, simple and unique preparation process and short production period, and can realize high-value conversion of tetracycline bacterial residues.

Owner:NINGXIA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com