Electromagnetic damping type automatic tobacco sorting manipulator

An automatic sorting and manipulator technology, applied in sorting and other directions, can solve problems such as low work efficiency, low degree of automation, and product quality impact, and achieve the effects of simple structure, accurate classification of tobacco leaves, and improved automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

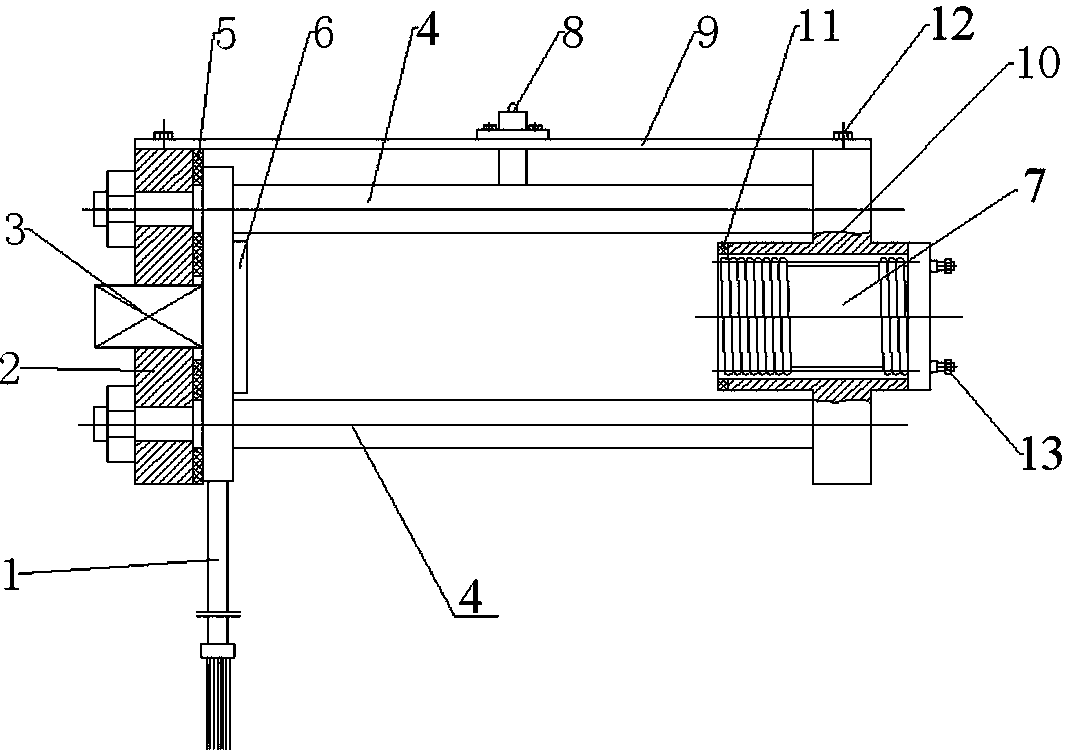

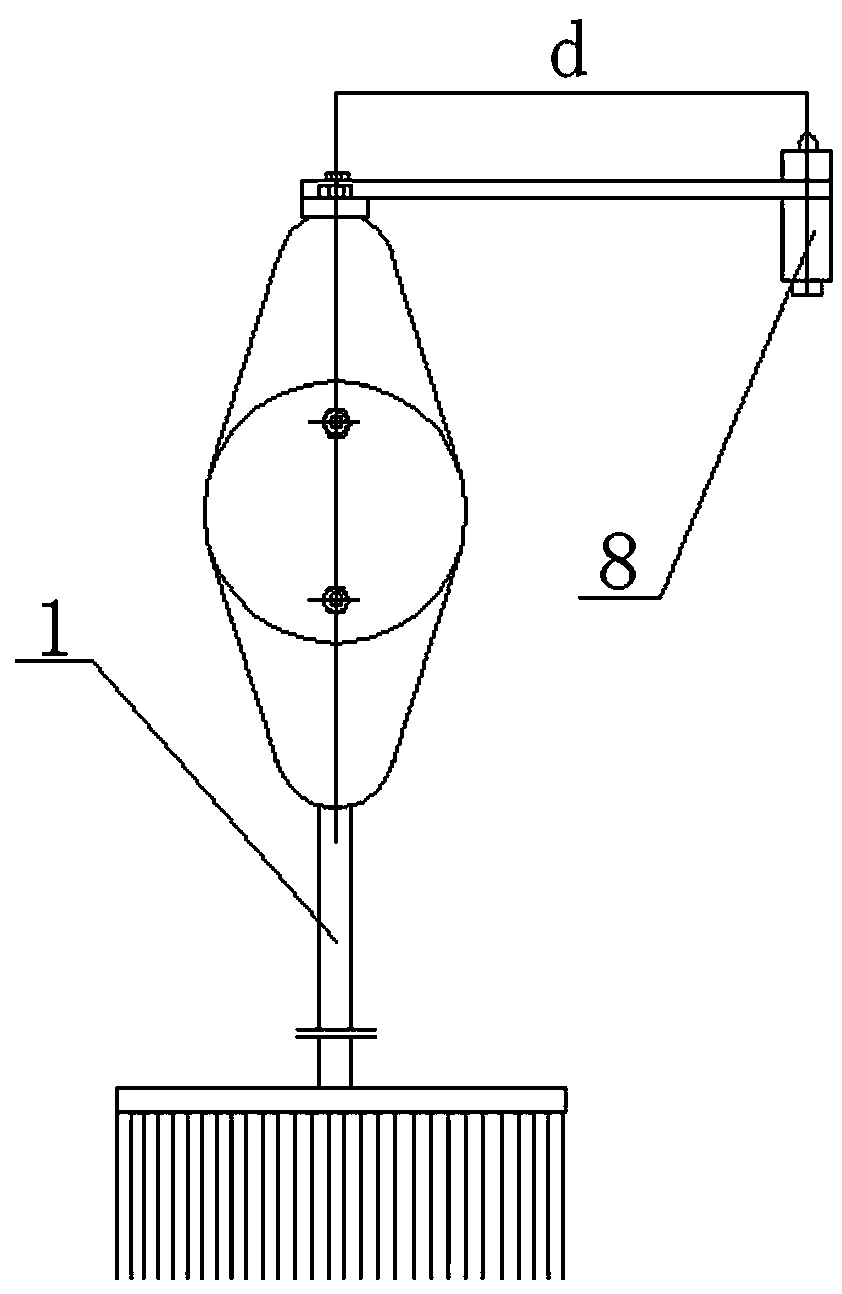

[0021] A damping electromagnetic automatic sorting manipulator for tobacco leaves, the manipulator is arranged above a conveyor belt for transporting tobacco leaves, and the manipulator includes a brush mechanism 1 for transferring tobacco leaves on the conveyor belt to a tobacco leaf storage box and an up and down parallel Two guide rails 4 are set, the moving direction of the brush mechanism 1 is perpendicular to the moving direction of the conveyor belt, the brush mechanism 1 is installed on the two guide rails 4, and the two guide rails 4 pass through a guide rail fixing frame 2 Connect together to form a track across the top of the conveyor belt for the brush mechanism 1 to move back and forth on it. One end of the track is provided with an electromagnet 7, and the other end is provided with a damping mechanism 3. The brush mechanism and elastic The damping mechanism 3 is connected, and the armature that can be attracted to the electromagnet 7 by overcoming the elastic for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com