An unsupported 3D suspension printing structure and method

A 3D printing, unsupported technology, applied in the field of 3D printing, can solve problems affecting product quality, unfavorable support removal, and low manufacturing efficiency, so as to improve printing efficiency, promote overall cost reduction, and shorten the manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

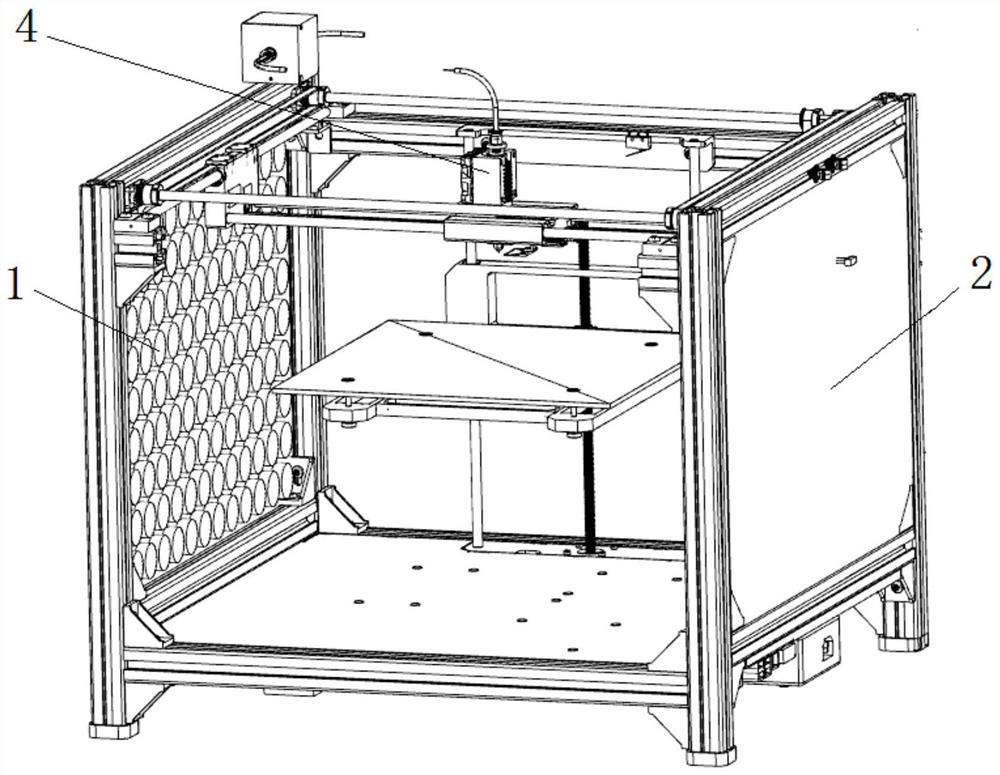

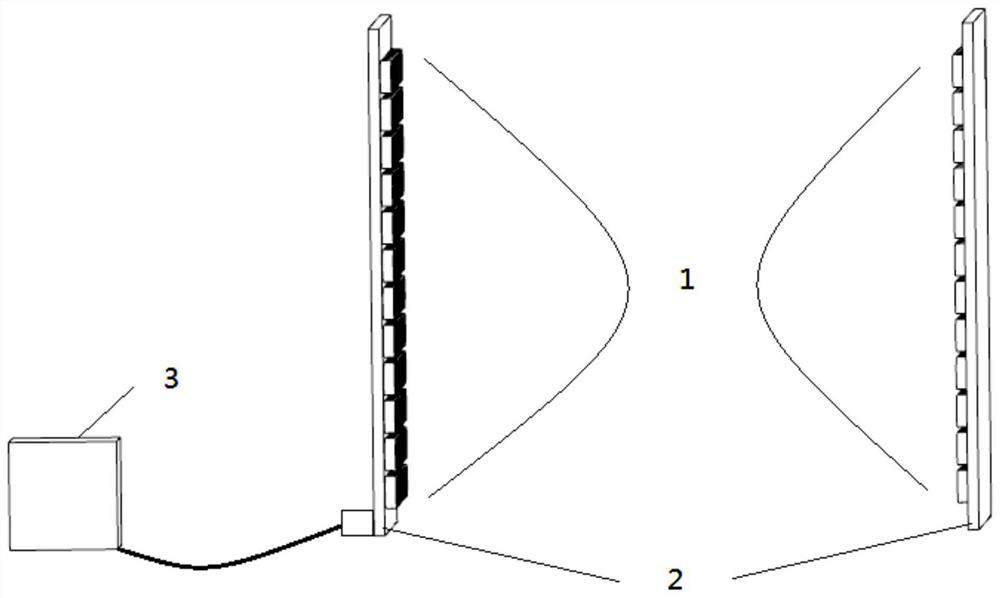

[0032] see Figure 1 to Figure 2 , is the unsupported 3D suspension printing structure diagram, where, figure 1 It is the overall 3D printing equipment diagram, including sound field layout and print head layout; figure 2 The sound field part is taken out separately, and its structure includes the generating power required to build the sound field, the transmitting end and the reflecting end connected to the generating power wire.

[0033] An unsupported 3D suspension printing structure provided by the present invention includes an ultrasonic phase array support 2, a buzzer array 1 arranged on both sides of the ultrasonic phase array support 2, an ultrasonic transmitting power supply and a control mechanism connected to the buzzer array 1 3, and the 3D printing head 4 arranged above the ultrasonic phase array support 2, wherein two groups of buzzer arrays ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com