Thin-wall tubular model slicing method, system and printing method for five-axis 3D printer

A 3D printer and thin-walled technology, applied in the field of 3D printing, can solve problems such as poor versatility and complicated slicing process, and achieve the effect of improving printing effect, high surface precision, and improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] This embodiment provides a thin-walled tubular model slicing method for a five-axis 3D printer. Taking the mainstream five-axis 3D printer for layered slice printing of a thin-walled elbow model as an example, the five-axis 3D printer is a traditional five-axis 3D printer. In the 3D printer gantry-type three-axis motion mechanism, a double-rotation cradle-type structure turntable is introduced; the double-rotation cradle-type structure turntable includes a turntable table, and the turntable table has a rotation degree of freedom in the horizontal direction and a rotation degree of freedom in the normal direction.

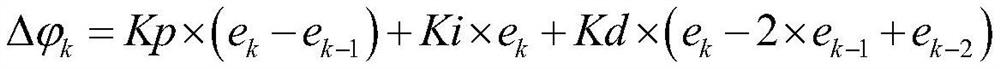

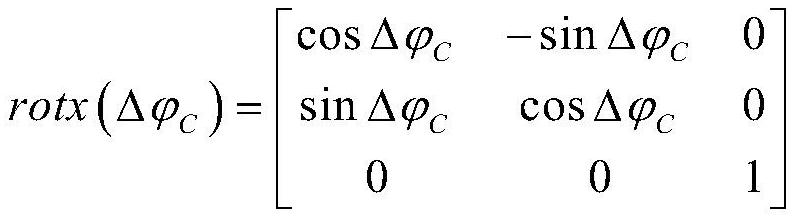

[0075] Specifically include the following steps:

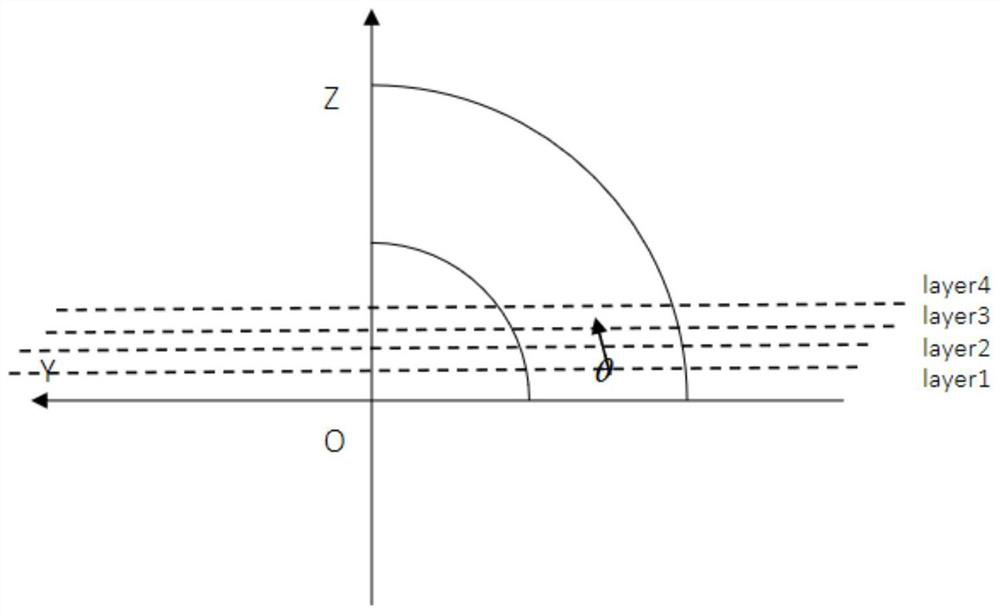

[0076] Step 1. Establish a coordinate system

[0077] First establish the turntable coordinate system xyz, define the center of the turntable table as the coordinate origin o, the rotation axis of the turntable table around the horizontal direction is the x-axis, denoted as the A-axis, and the rotation axis a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com