Six-axle composite non-stop 3D printer

A 3D printer, uninterrupted technology, applied in the field of additive manufacturing, can solve the problems of waste of printing support materials, long cooling time, slow printing speed, etc., to reduce the printing time, shorten the cooling time, and improve the printing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

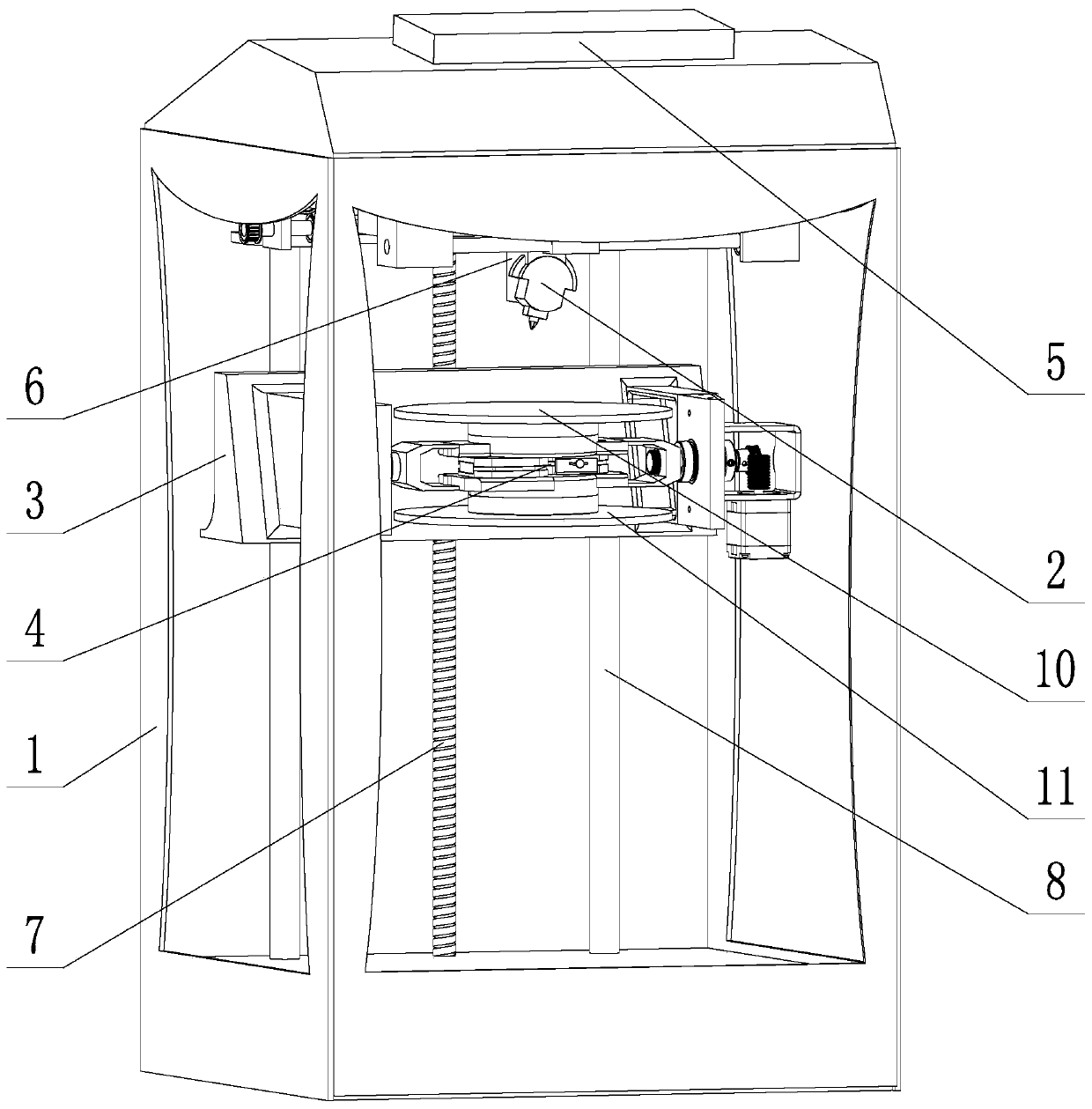

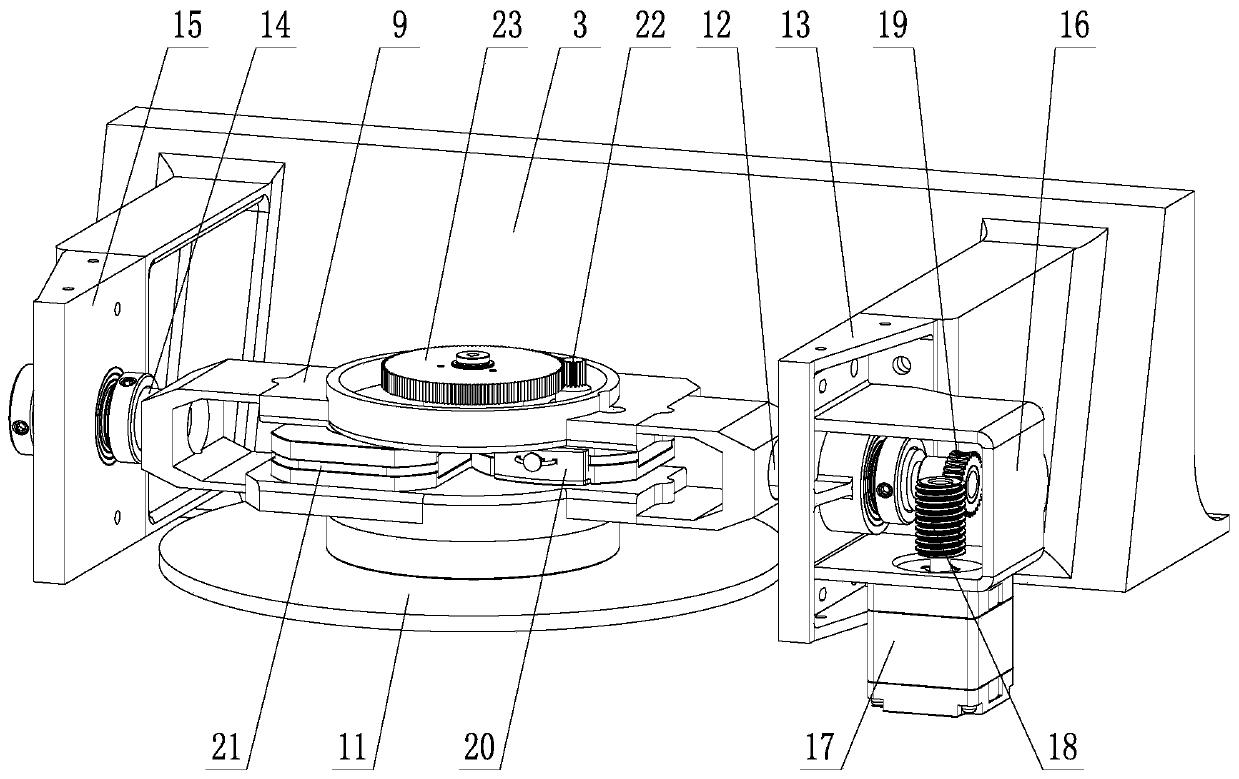

[0019] Such as figure 1 , 2 As shown, a six-axis composite uninterrupted 3D printer includes a frame 1, a print head 2, a suspension beam 3 and a two-degree-of-freedom linkage double-layer working platform 4; a console 5 is arranged on the outer top of the frame 1; The print head 2 is arranged on the top of the frame 1 through the print head mounting frame 6, and the print head mounting frame 6 is connected with the internal top of the frame 1 through a two-degree-of-freedom driving mechanism. Turn the drive motor, the print head 2 is fixedly connected to the motor shaft end of the print head swing drive motor, the print head 2 has a swing degree of freedom; the Z-direction lead screw 7 is vertically fixed inside the frame 1 and Z guide rod 8, on the said cantilever beam 3 is fixedly equipped with a Z-direction nut slide table, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com