Dual-mechanical-arm type 3D printer capable of realizing 360-degree 3D rotation and printing method thereof

A 3D printer and dual robotic arm technology, applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of printing suspended models that require support, low degree of automation, poor product accuracy, etc., and achieve positioning accuracy High, high printing efficiency, the effect of product precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

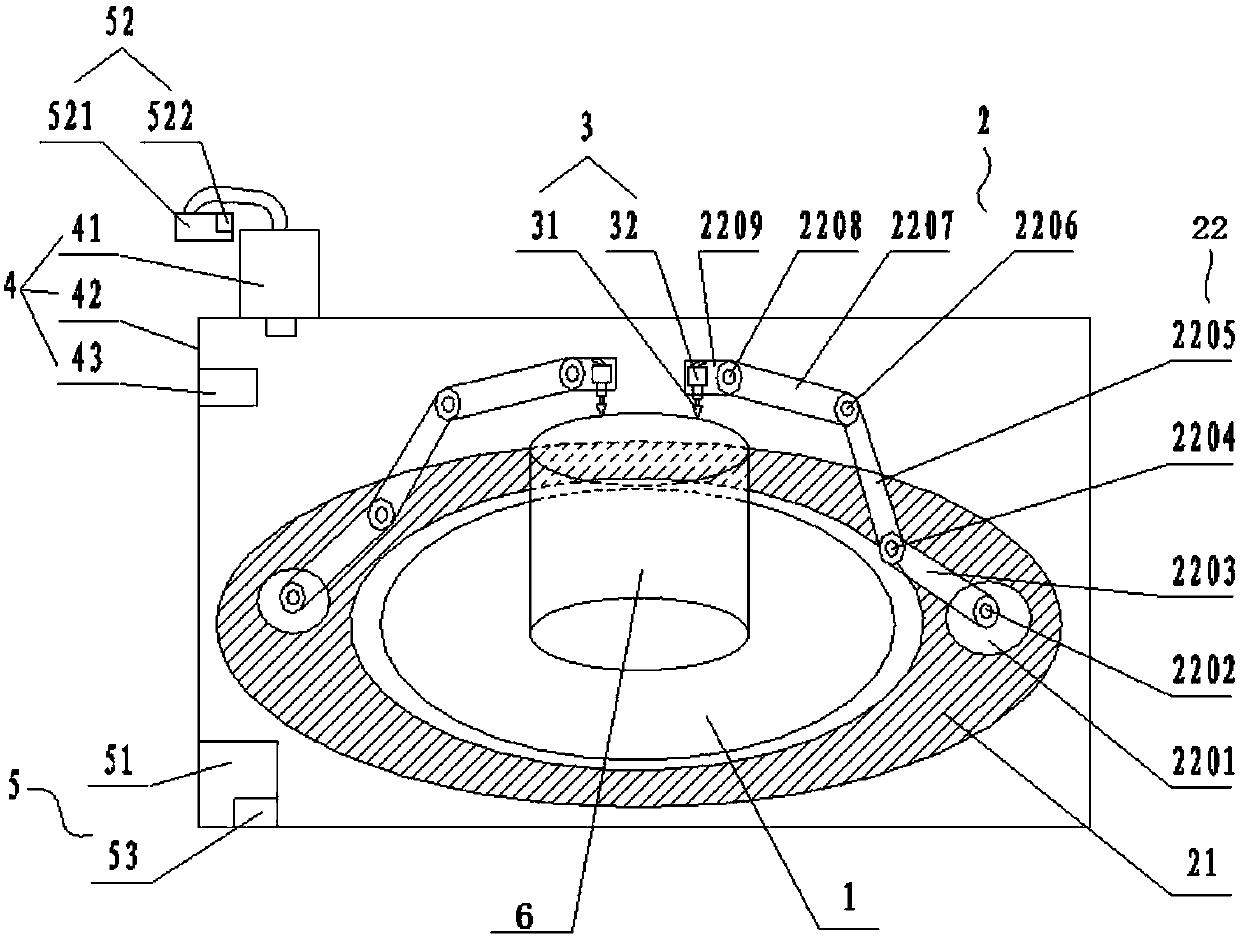

[0082]A 360-degree three-dimensional rotating dual-arm 3D printer, including a printing platform system 1, a robotic arm system 2, a printing nozzle 3, a vacuum body environment system 4, and a control system 5, wherein:

[0083] The printing platform system 1 includes a printing platform, and the printing platform adopts a flat plate with a smooth surface to ensure uniform heating;

[0084] The manipulator system 2 includes a whole chassis 21 of the manipulator and two multi-degree-of-freedom manipulator systems 22. The multi-degree-of-freedom manipulator system 22 is a 6-degree-of-freedom manipulator system, and the print nozzle 3 has two The printing nozzle 3 is a rotary printing nozzle; the overall chassis 21 of the mechanical arm is installed outside the printing platform system 1, and the bottom of the overall chassis 21 of the mechanical arm is connected to the output end of the rotating motor 1 through the shaft of the overall chassis to realize the overall 360-degree ...

Embodiment 2

[0094] In the second embodiment, the printing method of printing a model with no suspended parts by a 360-degree three-dimensional rotating dual-arm 3D printer is described.

[0095] figure 1 It is a structural schematic diagram of a 360-degree three-dimensional rotating dual-arm 3D printer of the present invention, including a printing platform system 1, a robotic arm system 2, a printing nozzle 3, a vacuum body environment system 4, and a control system 5. The printed model is without suspension part model.

[0096] combine figure 1 A printing method for printing a model with no suspended parts by a 360-degree three-dimensional rotating dual-manipulator 3D printer is described. The printing method includes the following steps:

[0097] a). The model is sliced by the slicing software to identify that the printed model has no floating parts;

[0098] b). The robotic arm performs a 360-degree three-dimensional rotation printing process, including the following steps:

[0...

Embodiment 3

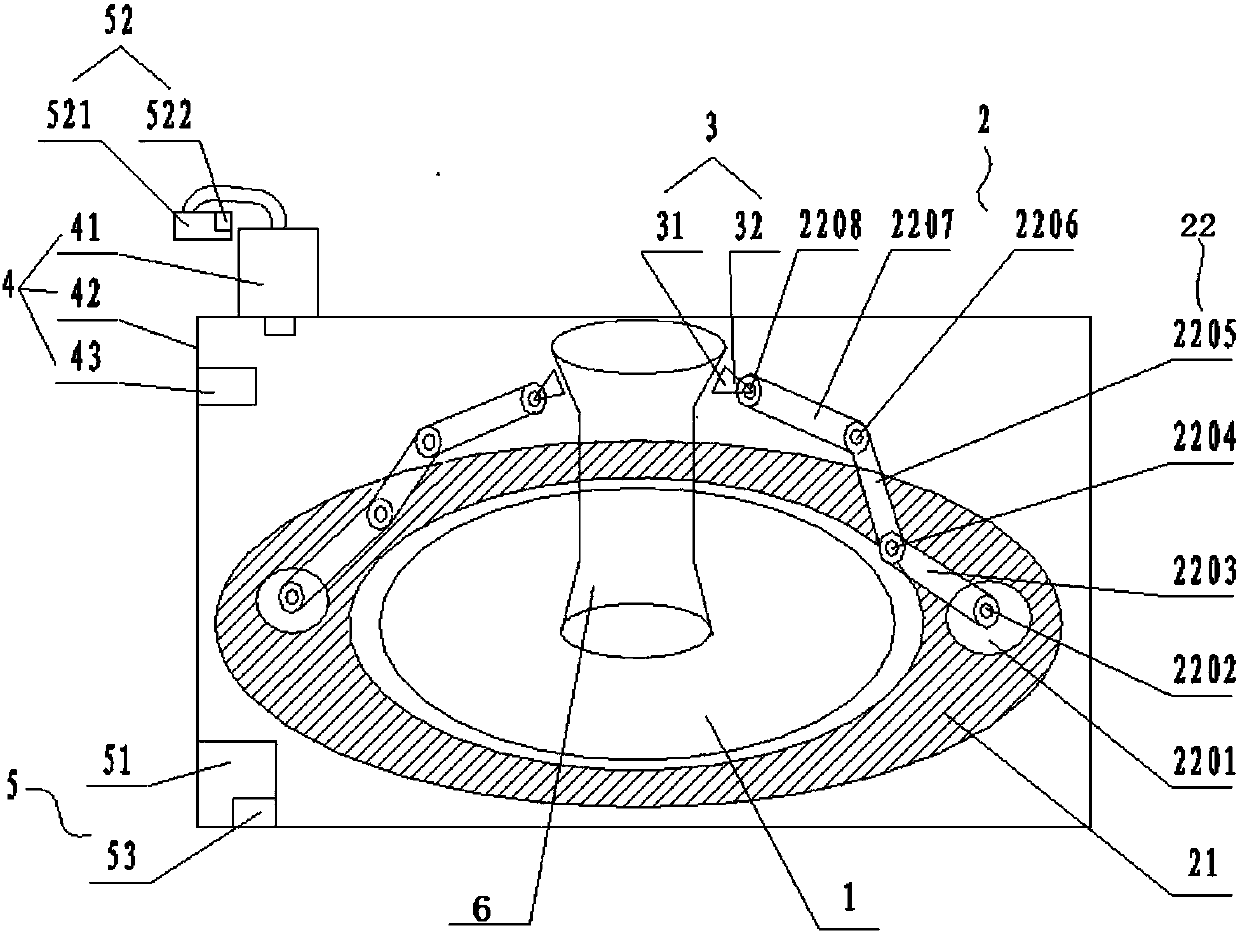

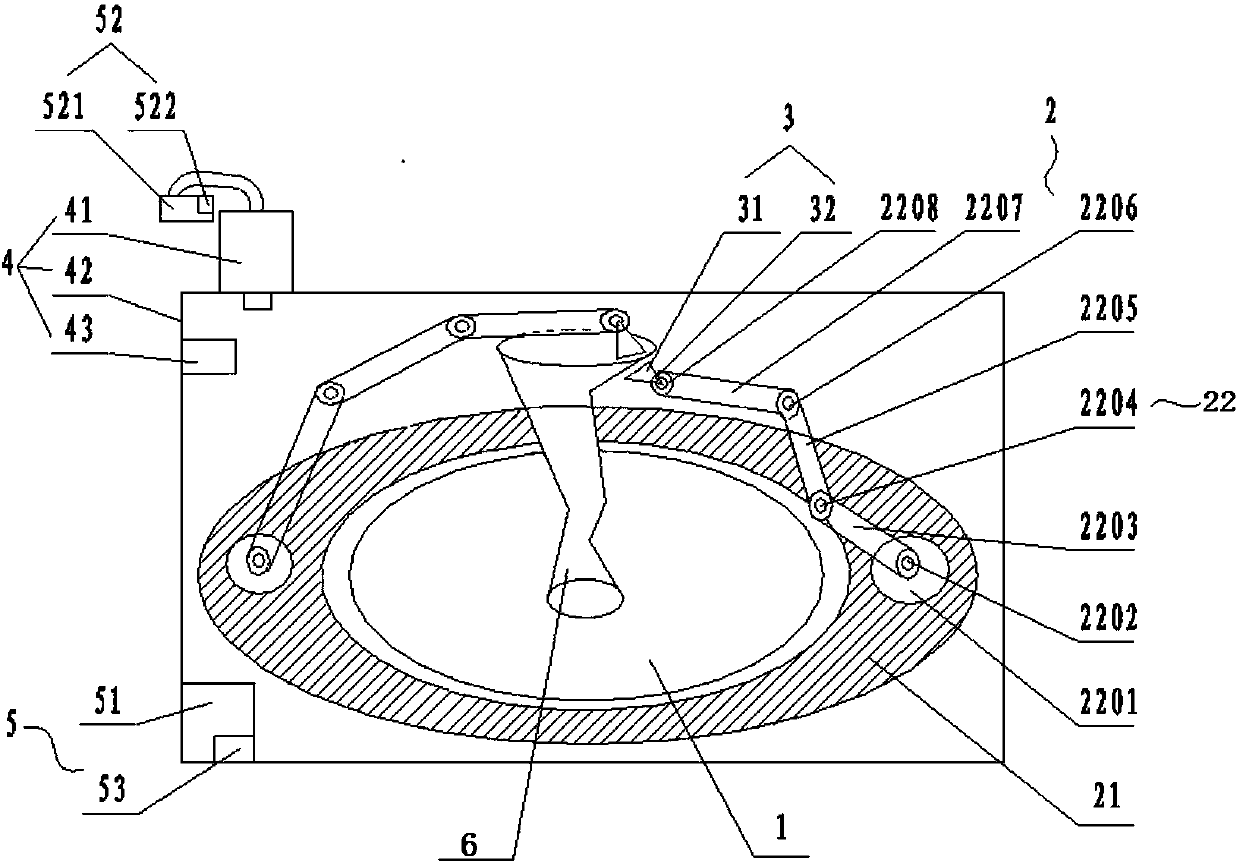

[0112] This implementation case uses a 360-degree three-dimensional rotating dual-arm 3D printer to illustrate the printing method of printing a symmetrical suspended part model.

[0113] figure 2 It is a structural schematic diagram of the 360-degree three-dimensional rotating dual-arm type 3D printer of the present invention printing a symmetrical suspended part model, including a printing platform system 1, a robotic arm system 2, a printing nozzle 3, a vacuum body environment system 4, and a control system 5 .

[0114] combine figure 2 A printing method for printing a symmetrical suspended part model with a 360-degree three-dimensional rotating dual-arm 3D printer is described. The printing method includes the following steps:

[0115] a). The model is sliced by the slicing software to identify whether the printed model has suspended parts, and if there are suspended parts, perform step b), step d), and step e);

[0116] b). The robotic arm performs a 360-degree thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com